ISSUE 194 | NOVEMBER 2022 Beetaloo Basin’s low carbon future PSSS strives to meet any pipeline needs 36 From filling sandbags to COO 22 32 Outstanding contribution PETER COX RECOGNISED FOR PIPELINE CAREER – page 26

Pipeline Replacement Advanced Leak Survey gas.picarro.com Emissions Measurement Emissions Reduction Measure and Reduce Emissions • Picarro provides the only data driven solution to measure, quantify and report methane emissions across your network • Enables effective and scalable emissions reduction programs • Supports OGMP 2.0, NGSI, One Future, Veritas, Marcogaz • Adopted and implemented by multiple leading operators worldwide NEW! Network Assessment Viewer delivers total measured methane emissions for your entire network, tracked by regions and over time. YOU CAN’T FIX WHAT YOU CAN’T MEASURE

MPCKINETIC.COM SAFELY DELIVERED

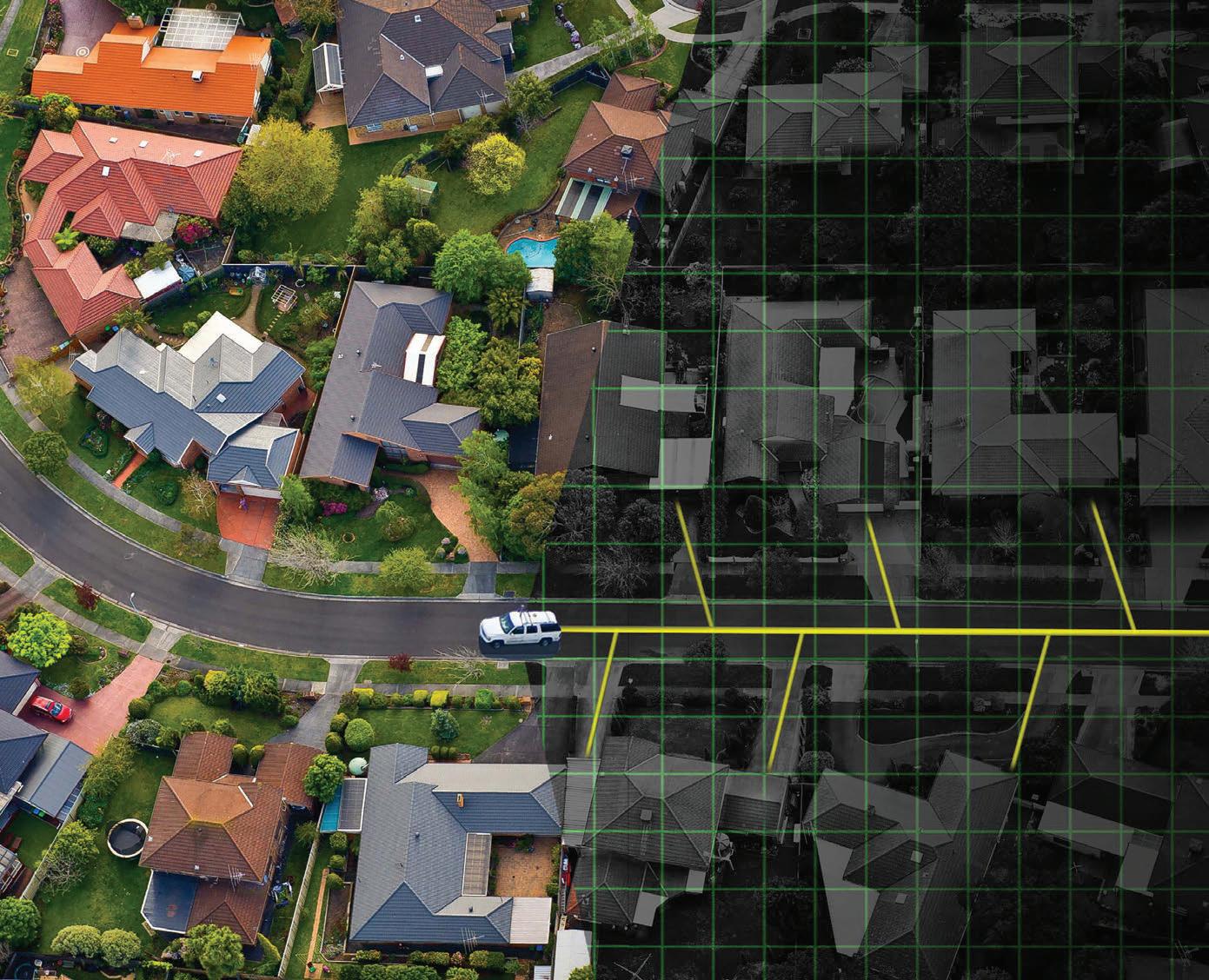

SMARTER SOLUTIONS // Infrastructure

MPK. Right solutions. Right people. Right for the future.

re-energised

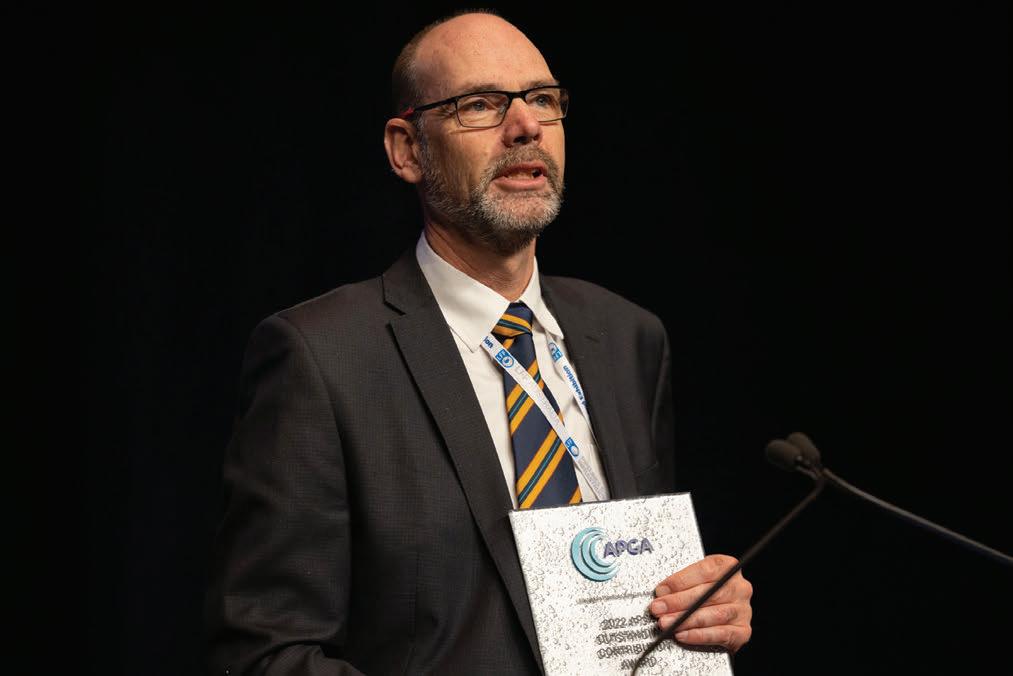

Cover image: Peter Cox receives the Outstanding Contribution to the Australian Pipeline Industry Award from APGA CEO Steve Davies. ImagecourtesyofAPGA.

EXECUTIVE REPORT

CEO’s Message 8 APGA MEMBER NEWS

Speciality pipeline recruiter celebrates 30th anniversary 12 APGA MEMBER Q&A Pipeline Actuation Control's Matt Nash 14 POLICY

Gas and energy policy 16

FUTURE FUELS

Our industry can deliver a global renewable gas industry 18

PIPELINES IN NORTHERN TERRITORY

Northern Territory gives green light for infrastructure progress 20 Beetaloo Basin has promise in a low carbon future 22

PIPELINE PEOPLE

Industry veteran’s contribution recognised with prestigious APGA Award 26

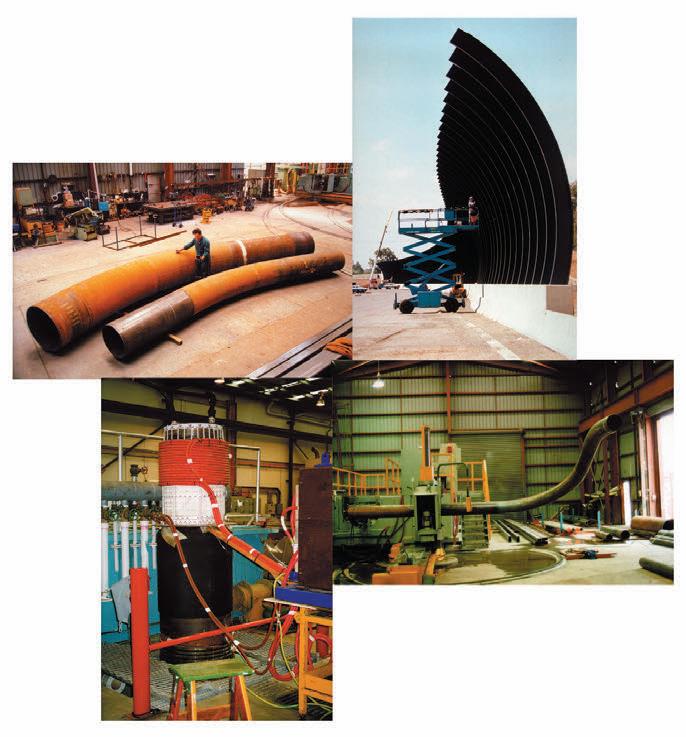

The industry through MPK’s eyes 30

From filling sandbags to COO: Taddam Farrant is no longer a new kid on the block 32 Jonh Kalis’ outstanding contribution 34 PSSS team strives to meet pipeline needs 36

INTEGRITY & MAINTENANCE

Building a reputation for innovation and responsiveness 38 REHAB & REPAIR

Savcor Products help customers avoid costly corrosion failures 41

The ongoing journey of composite repairs for pipelines, process piping, tank and vessels 42

PIPELINE

CONSTRUCTION

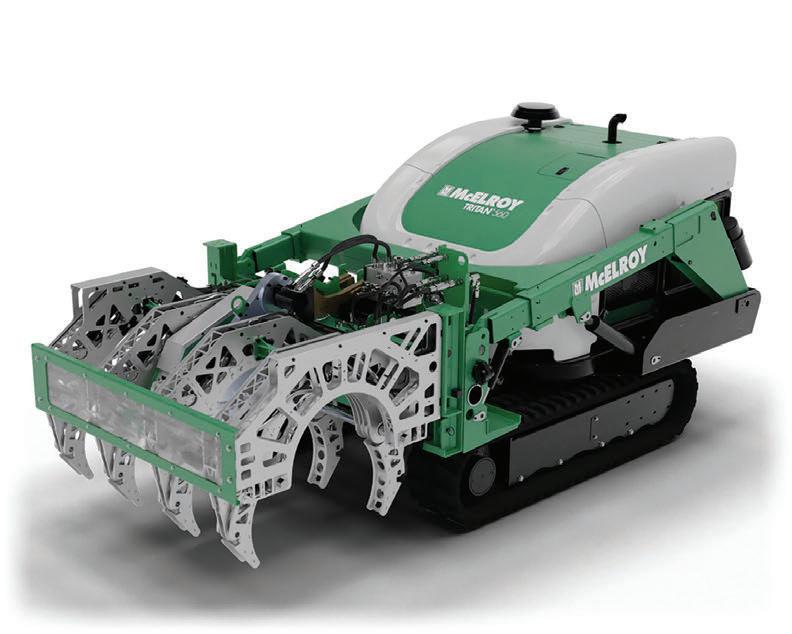

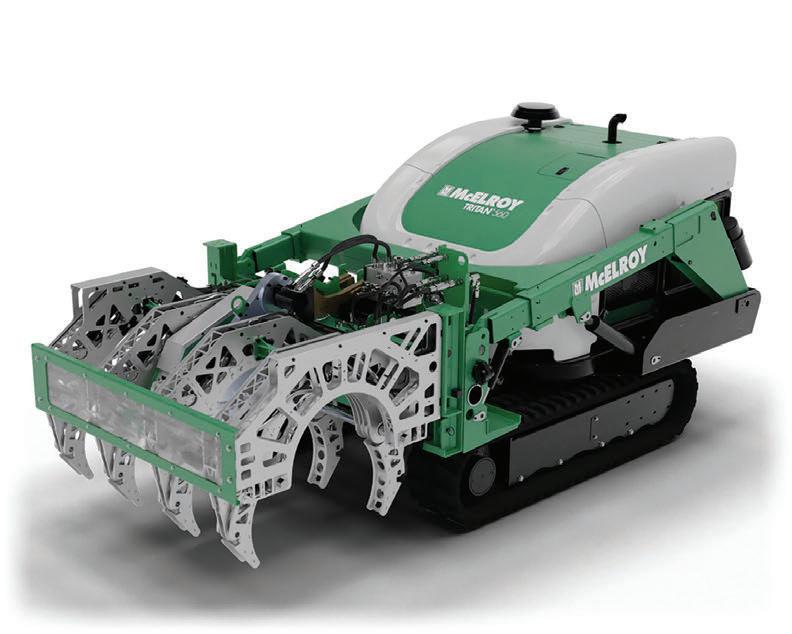

Delivering enhanced mobility and productivity in a progressing world 44 Optimising value on HDD maxi-rig projects 46 McElroy Manufacturing’s latest and greatest is here: the Tritan 560 48 Australia’s kwik-ZIP and the case of San Francisco’s sinking Millennium Tower 50

APGA CONVENTION

Convention says goodbye for another year 52 Event photos 54

REGULARS

Members & memos 10 APGA members 56

CONTENTS 4 The Australian Pipeliner | November 2022 26

Pipeline integrity Pigging services NATA pressure testing Inline inspection Live line dig ups Leak detection CCTV inspection HDD construction WE KNOW PRESSURE www.pipetek.com.au Taddam: 0432 666 917 taddam@pipetek.com.au Myles: 0417 707 729 myles@pipetek.com.au Our Exclusive Global Partner

CEO

John Murphy COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

JOURNALIST

Jenna May jenna.may@primecreative.com.au

Christian Alphonso christian.alphonso@primecreative.com.au

BUSINESS DEVELOPMENT

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert, Louis Romero

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Maximise brand awareness by connecting with thousands of industry professionals

The Australian Pipeliner brand comprises: a quarterly magazine, a news website, a fortnightly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

Printed by: Manark Printing

28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

2,600+

magazine subscribers

11,700+ social media followers

20,900+ website views each month 20,000+ e-newsletter subscribers

Want to find out more?

Contact our business development team to discuss how you can grow your business with The Australian Pipeliner. Call 0414 217 190 or email nick.lovering@primecreative.com.au

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: +61 3 9690 8766

Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065 Ph: (02) 9439 7227

enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry. The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

6 PUBLISHER

The Australian Pipeliner | November 2022

Is your pipe spacer compliant? Call us for details on ordering P (08) 9725 4678 sales@kwikzip.com www.kwikzip.com The only casing spacers successfully appraised by WSAA HDX and HDXT KWIK-ZIP’S HDX & HDXT CASING SPACERS COMPLY WITH WSAA PRODUCT SPEC #324 - CASING SPACERS; REFER WSAA PRODUCT APPRAISAL REPORT #1523

Chief Executive Officer’s report

Wow, all of a sudden, the end of the year is here. All of us have been through a change process or two in our careers and we understand how challenging they can be. 2022 has been a year of unprecedented change. If you cast your mind back to the start of the year, you might recall that COVID-19 cases were through the roof as restrictions started to lift, several states still had closed borders and the airports were largely empty well into March.

Come forward to now and while we don’t experience many restrictions anymore, we all experience the lingering effects of the pandemic in various ways. Travel is more difficult than it used to be, as airlines and airports slowly rebuild capability; projects that have been in hibernation are all waking up at the same time; a couple of years of no migration have depleted the working population of Australia so every sector is looking for people; China’s pursuit of a ‘zero Covid’ strategy and other factors continuing to impact supply chains are all big effects that continue.

Add to all this an energy supply crisis in eastern Australia this year! 2022 will be one to remember. I think it is essential that we all recognise the things we have experienced this year are not one-offs. The energy transition is going to impact projects, resources, skills, supply chains and markets for years (decades) to come. The entire globe is changing its energy system at the same time and demand will outstrip supply for a long time. Our sector is going to be very busy now and into the future.

That’s a great space for the association to be in to support members. Everyone is busy with their version of the same challenges right now. Sharing information and experiences, working on common problems and learning from successes and failures can make life a little bit easier for the whole industry. We’ve had some great examples of that in the last couple of months. APGA held a Gas Infrastructure Emissions Workshop at the start of September

and had over 100 people come together physically and virtually to share information on the common challenge of reducing emissions from gas infrastructure.

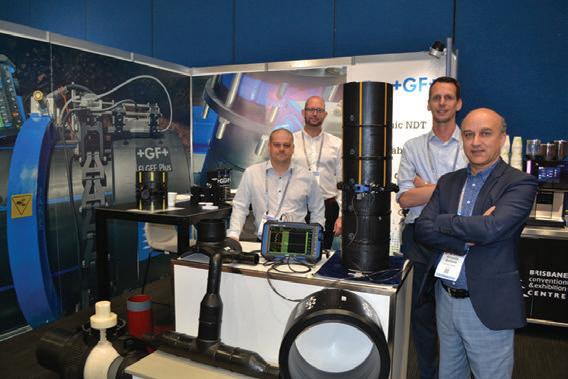

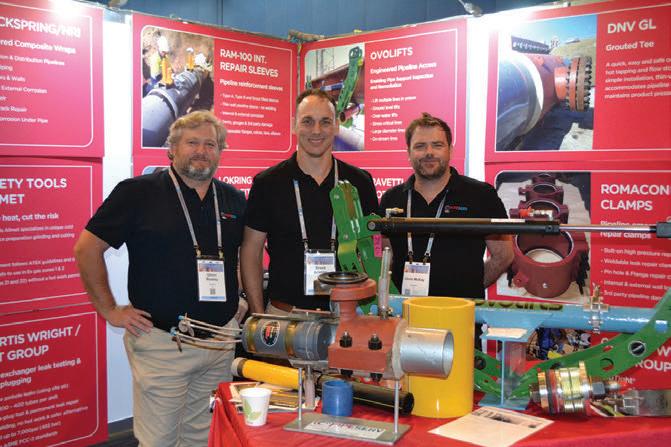

And finally, after three years, we had an in-person convention and exhibition in Brisbane at the end of September. The atmosphere was electric across the entire event and an unmissable reminder to all who attended of two things:

1. The importance of getting together to network, share information and spend time with people.

2. The unique culture of APGA and this industry.

I attend many events and there is nothing like an APGA Convention and Exhibition in Australia. Several international exhibitors told me during the event that there’s nothing like it in the world. So check out the photos in this edition, mark the calendar for 14-17 October next year and we’ll see you in Perth in 2023! Happy reading.

ABN: 29 098 754 324

APGA Secretariat Registered Office: 7 National Circuit, Barton ACT 2600 (PO Box 5416, Kingston ACT 2604)

T: +61 2 6273 0577

E: apga@apga.org.au W: www.apga.org.au

Chief Executive Officer

Steve Davies

Corporate Services Manager Peter Heffernan National Policy Manager Jordan McCollum Communications Manager Lawrence Shelton Engagement Manager Dean Bennett Membership Officer Katy Spence Secretariat Coordinator Charmaine Rees Events Coordinator Matthew Freeborough

STEVE DAVIES CHIEF EXECUTIVE OFFICER

EXECUTIVE REPORTS 8 The Australian Pipeliner | November 2022

Safety with Productivity Pipeline Plant Hire provides innovative solutions increasing Safety and Productivity We can engineer a solution to suit your project needs Not just a hire company, our extensive industry experience will match the best equipment to your project needs. We are continually adding new machines to our fleet broadening the type, range and quantity. Fully Equipped Heavy Plant Hire ONE CALL - PROBLEM SOLVED 1300 367 046 www.pipelineplanthire.com.au PIPE HANDLING? Australian Designed and Built industry leading VacLifts and Pipe Handling systems deliver more features and benefits than any other machine available. Made by Pipeliners’ for Pipeliners’. Your machine or ours, our extensive range of VacLift equipment covers from poly pipe to large diameter steel pipe weighing 15Tonne.

Senex to invest $1B in major expansion

Following years of exploration and studies, Senex is set to increase its natural gas production to 60 petajoules (PJ) per year with work planned to begin in coming weeks.

Gas production of 60 PJ per year represents more than 10 per cent of annual east coast domestic natural gas requirements, around 40 per cent of QLD’s domestic gas requirements, and is equivalent to the electricity used by more than 2.7 million homes each year.

Furthermore, Senex’s investment is anticipated to create more 200 jobs during construction and another 50 permanent roles and is expected to inject more than $200 million into local businesses and regional areas.

More than two-thirds of the capital commitment is planned to be invested over the

Senex looks to inject $200 million into local businesses.

next two years on gas infrastructure and wells at Senex’s Surat Basin developments in western Queensland, providing a major economic boost to regional economies.

“With the necessary regulatory approvals in

place, Senex can unlock more gas which Australians need, and create skilled, secure, well-paid jobs for Queensland workers and drive economic growth with this billion-dollar expansion,” CEO Ian Davies said.

Santos set to acquire Hunter

Santos has acquired Hunter Gas Pipeline which owns an approved underground gas pipeline route from Wallumbilla in QLD to

The underground pipeline route passes close to Santos’ Narrabri Gas Project. The company’s goal is to work with infrastructure developers and owners to construct the pipeline and deliver much-needed gas to east coast domestic markets. The pipeline will also be designed to transport hydrogen as customer demand evolves during the energy transition.

Once fully operational, Narrabri has the potential to deliver more than half of NSW’s gas supply demand and create a more secure, locally based and affordable supply for businesses, manufacturers and families.

Subject to receiving remaining government approvals, construction of the pipeline is expected to commence in early 2024.

Galilee and APA Group sign pipeline MOU

Galilee Energy has signed a non-binding memorandum of understanding (MoU) with the APA Group with regards to a potential pipeline to connect the Glenaras Gas Project to east coast gas markets.

APA Group’s initial concept was to potentially design and develop a pipeline from the Glenaras Gas Project to the Cooladdi compressor station on the South West Queensland Pipeline (SWQP).

Galilee’s managing director, David Casey, noted that the signing of the MoU is an important step in the potential commercialisation of the Glenaras Gas Project.

“Together with the project’s maiden reserve certification due in early 2023, continued planning on gas pipeline infrastructure could help provide a solid basis for progressing future gas sales agreements,” said Casey.

APA group took steps to commercialise the Glenaras Gas project.

10 The Australian Pipeliner | November 2022 MEMBERS & MEMOS

The pipeline passes near Santos’ Narrabri Gas project.

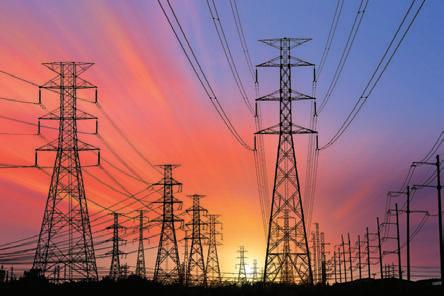

APA Group to acquire Basslink

APA Group has announced that it has entered into a deed of company arrangement (DOCA) with regard to the acquisition of Basslink and BPL.

Under the proposal, APA Group will acquire Basslink for $773 million, including current estimate of stamp duty and other transaction costs of $33 million. The proceeds of this will

be used to repay Basslink creditors, including APA Group’s existing senior secured debt of $648 million.

APA Group’s acting CEO, Adam Watson expressed that the acquisition of Basslink is consistent with the group’s strategy to increase its electricity transmission footprint and play a leading role in the energy transition.

Government legislates emissions reduction targets

The Albanese governments’ landmark Climate Change Bills have officially passed the Senate, ensuring Australia’s emissions reduction target of 43 per cent and net zero emissions by 2050 will be enshrined in legislation. The Climate Change Authority has also been made responsible for advising on future goals, including the government’s 2035 emissions target.

Net zero emissions target to be enshrined in legislation.

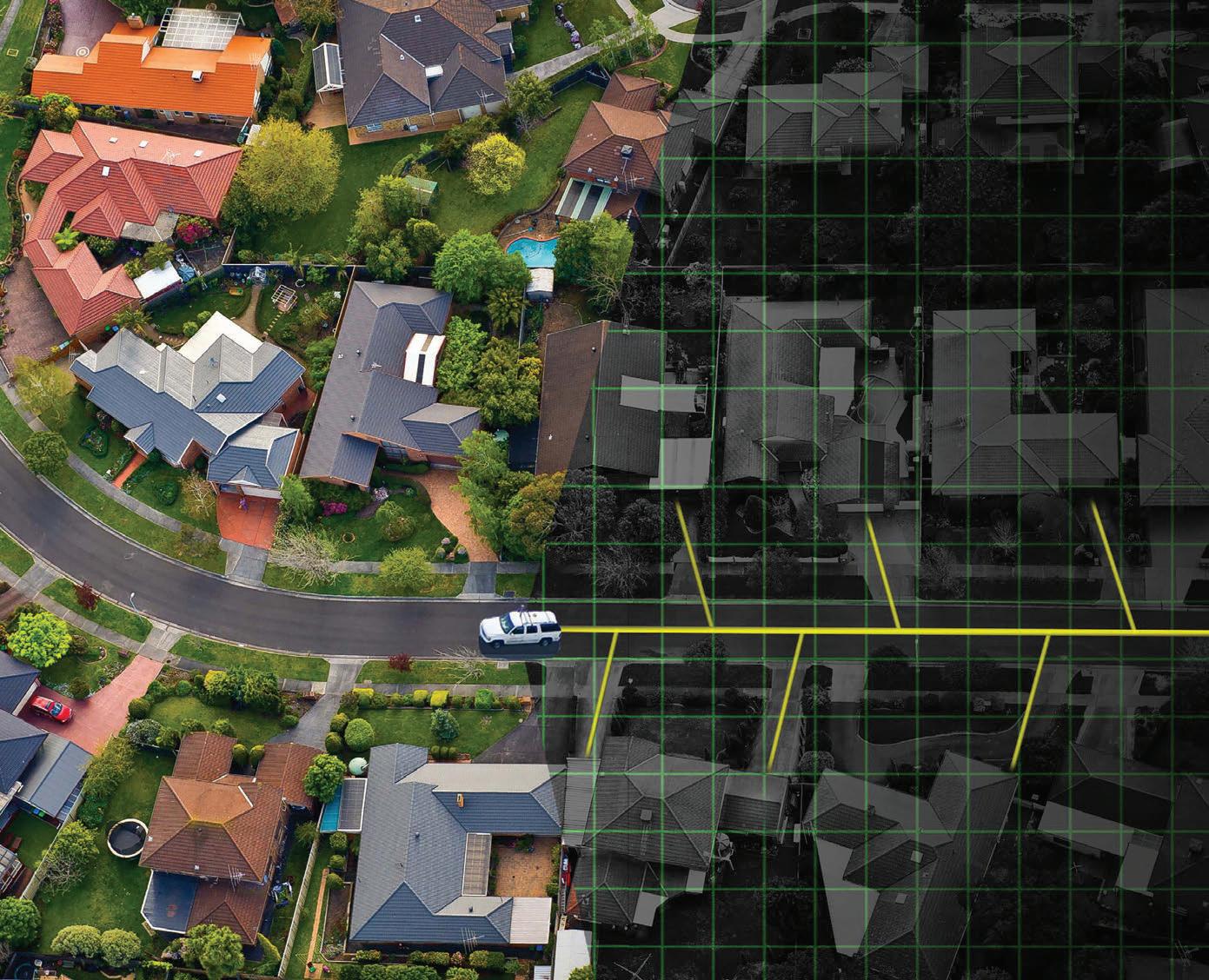

GWW mains upgrade underway

As part of a $2.8 million upgrade being undertaken by Greater Western Water (GWW), the water mains network in Moonee Ponds is being replaced.

Jaydo Construction have been appointed for delivery of the upgrade, which includes 2.8 km of water mains to be constructed in the area on Alexander Avenue, Feehan Avenue, McPherson Street, Albion Street and part of Pasco Vale Road.

Minister for Climate Change and Energy, Chris Bowen, said the legislation is set to place Australia on a credible and structured path toward net zero.

“Legislating these targets gives certainty to investors and participants in the energy market and will help stabilise our energy system. It also strengthens transparency and accountability through the annual climate change statement and will ensure public debate informs government decisions,” said Bowen.

The Albanese government has additionally proposed requiring the nation’s highest polluters to shrink emissions by up to 6 per cent per year under the strengthened centrepiece of its commitment to reduce emissions this decade.

GWW has also foregrounded community engagement with the project by including an onsite drop-in centre where residents and businesses can ask questions and stay informed. Open trenches are required for the construction of the new water mains, and work is expected to be ongoing throughout the year. The construction work should be completed, including the reinstatement of all trenches, by early 2023.

11 The Australian Pipeliner | November 2022 MEMBERS & MEMOS

CORROSION SPECIALIST Sydney I Melbourne I Brisbane I Perth Adelaide I Townsville I New Plymouth Engineering • Field Services • Products

www.cceng.com.au

AUSTRALASIA’S LEADING CATHODIC PROTECTION &

Our Experience Delivers Solutions

Moonee Ponds water mains should be replaced by early next year.

APA group will acquire the Basslink for $773 million.

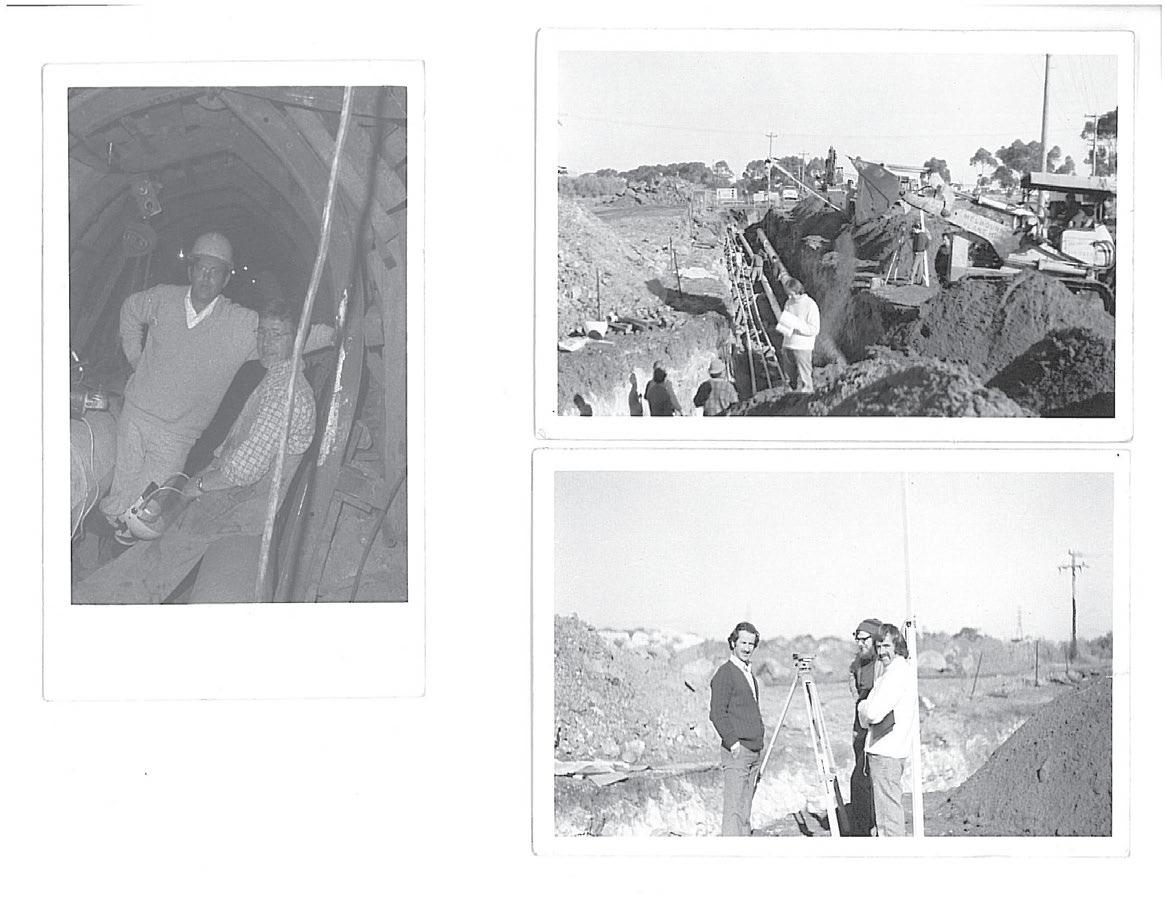

Speciality pipeline recruiter celebrates 30th anniversary

become some of the industry’s leaders

Cuic singled out changes to diversity and inclusion as some of the most significant changes during the company’s history recruiting

“Continued innovation has helped the industry become more attractive to younger people and helped establish a diversified employee base in which different people can bring with them different experiences and backgrounds,” she said.

“Whether this be more women coming into the industry through engineering or people from overseas, it’s been pleasing to watch the pipeline industry continue to evolve over the years and for Peter Norman Personnel to have played a role in that evolution is an

pipeline industry.

Founder and Director – and namesake – Peter Norman, is a well-known figure in the recruitment, engineering, pipeline, and manufacturing sectors.

Applying his attention to detail and unique industry insights, Norman set out to offer his clients unparalleled access to the industries they work in, always with a smile on his face.

Now, 30 years on, Peter Norman Personnel’s team professionally and compliantly ensure that employment engagement, occupational health and safety, payroll and statutory obligations are met for all its clients across Australia.

Senior Consultant for Contracting and Recruitment Kate Cuic said the company is proud to have been able to stand the test of time, while so much has changed in pipelines and society.

“We’ve been around since before Y2K and not only survived but thrived; it’s great to still be involved and active within the pipeline

12 APGA MEMBER NEWS

industry essentially

Friday 21 October 2022 marked three decades since Peter Norman Personnel was established.

Founder, Director and Senior Consultant for Contracting and Recruitment at Peter Norman Personnel Peter Norman.

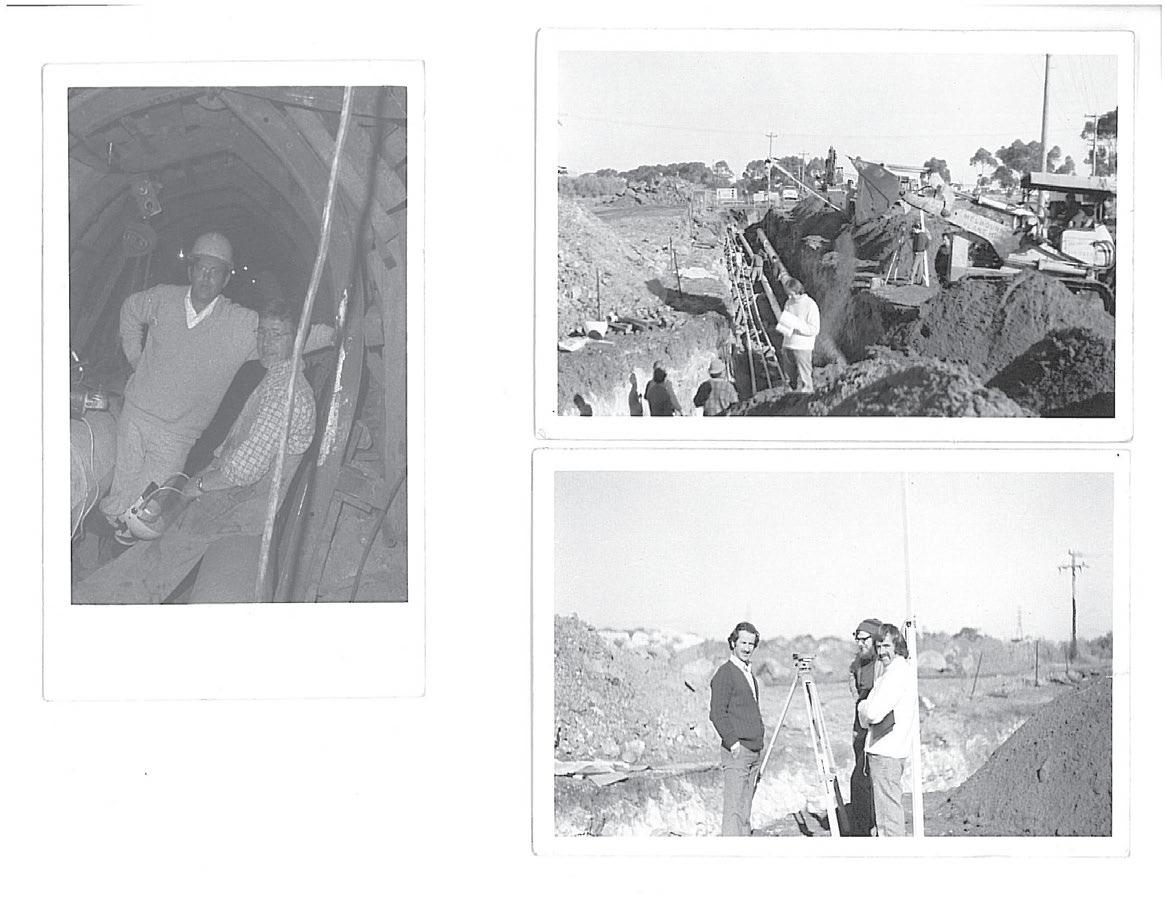

Peter Norman on the Brooklyn to Altona Pipeline.

For more information visit Peter Norman Personnel’s website, www.peternorman.com.au

Senior Consultant for Contracting and Recruitment at Peter Norman Personnel Kate Cuic.

E: info@propipeservices.com P: (03) 9330 4016 A: 49 Lambeck Drive, Tullamarine, Vic 3043 www.propipeservices.com Safe, Reliable Pipeline Solutions • Hot Tapping • Line Isolation & Bypass • Pipe Cutting • Commissioning • Decommissioning • Equipment Maintenance • Training Maintenance & repairs: • Natural Gas • Steam • Water • Chemical • Hydrocarbons

Q&A with PAC’s Matt Nash

Tell us who you are and what you do?

My name is Matt Nash, I work for Pipeline Actuation and Control (PAC). We specialise in valving, instruments, pneumatics and hydraulics for the oil and gas industry, which is what prompted us to join the APGA as a member.

Obviously, we sell pipeline valves as part of our repertoire of products. More recently however we've got into hydrogen products, so electrolysers, which we are looking to have manufactured here in Australia, and then all the associated components that go with them, eg storage, dispensing, compression, injection and metering.

Me personally, my background has always been sales. I'm currently the East Coast Sales Manager for PAC so I have the opportunity to travel up and down the East Coast, South Australia, and hopefully at some stage soon New Zealand and Papua New Guinea spruiking our products.

Historically I've been in automotive sales, in real estate, retail, basically any type of sales you can get. I joined PAC back in 2012, making this my 10th year with the organisation.

Which committees have you been a member of?

The first committee that I joined was the APGA WA chapter, I joined back in 2015 by chance actually. One of my colleagues who was already on the committee was injured at the time and couldn’t drive, I was his chauffeur and took him to my first meeting, upon him leaving PAC just kind of kept going along and getting involved.

I joined when Stuart and Spence were in charge and helped organise and run different events over in WA that was my first exposure to an APGA committee.

I was then, because I was Young Pipeliners Forum (YPF) age, roped into helping with some of the YPF events. Although I wasn't officially on the YPF committee in Western Australia, I was sort of just loaned across from the APGA Committee to help out at the time, with my first major event being the YPF quiz night which I have had the honour of hosting almost every year since.

In 2019 I moved to Queensland, to set up a new office for PAC and immediately got in contact with the presiding chair of the YPF, Chris Connor, to see if I could join the YPF committee over in Queensland. I was accepted so I got straight back into the swing of things.

In 2021, I took over as Chair of the committee here in Queensland, and I've held that position for the last two years. We were lucky enough to host the first large event after the COVID outbreak which was our golf day here in Brisbane. We had members of the YPF and the APGA here in Queensland, come along to that, it was fantastic day. So good, in fact, that's the APGA has now decided to hold an annual golf day in Queensland as an East Coast golf day.

I'm also part of the suppliers Committee, which was started by Luis Guevara in 2019. Unfortunately, again due to COVID we haven't been able to have our regular catch ups or seminar, but hopefully we will get things kicked off again pretty soon.

Thank you for those wonderful insights, probing a bit deeper, what prompted you to so quickly contact YPF when you made the move?

Being a member of the YPF over in WA was awesome fun. I loved my time on the APGA committee over the years and wanted to stay involved. I love networking, maybe it's actually just meeting new people or maybe it’s just a good excuse to have a beer. I like making friends, talking with

people getting their insights, seeing where they're from, their background, swapping stories… I'm a sucker for a good story. The more people I know the more opportunities I've got to meet likeminded people and opportunities to make friends, which is maybe why I'm reasonably good at my job.

What does the committee work on?

We host quite a number of networking events, but we also hold technical events. We will get a speaker or a couple speakers, rent a venue and run a learning session to try and increase the knowledge of our members with nearly all being a success (rain deters people sometimes on the night of the event). We have also hosted some other events as well, such as meeting some of people from the other committees and meeting board members, broadening the network. Our recent Trivia Night here had 70 young pipeliners competing against each other to see who was the smartest at The Stock Exchange Hotel, it was a fantastic event with everyone fully invested. For me it meant I got to talk on a microphone in front of everyone for 4 hours, everyone had a great time.

14 APGA Q&A

The Australian Pipeliner | November 2022

Pipeline Actuation and Control’s (PAC) Matt Nash shares his experiences in the pipeline industry and how he became involved in the Young Pipeliners Forum and the work the committee is doing.

PAC East Coast Sales Manager Matt Nash.

What is the contribution of APGA committees to the industry?

The two committees that I'm part of, the first being YPF, is making sure this association and this industry continues after we move away from our reliance on fossil fuels. This lays a heavy burden on our young people as it’s our future and we will have to deal with the consequences of it if it’s not done correctly. I think YPF in that regard holds massive responsibility in keeping people involved, invested and interested in in the industry.

The second is the supplier community. I think that 90 per cent of members at the APGA are a supplier of some sort, whether they supply product like myself, provide a service or are a constructor, the committee gives, us as suppliers, a voice to the pipeline owners to come up with more effective and efficient ways to do things as well as greater opportunities within the overall group.

Without these committees I don’t believe there would be a YPF as it’s too much of a workload for the secretariat, especially with all the different state groups, so in saying that I believe they have a huge contribution.

What has the committee done for your career?

The biggest thing for me personally is my confidence. Probably wouldn't believe this but I'm actually a bit of an introvert, most people would laugh if I suggested that, but it is true. The committees have really helped me to come out and realize that most of the people in this industry (and others) are not all that scary, they're just normal people like you or me.

A huge part of being part of a committee, is the opportunity to network. It has been amazing to meet the senior members of organisations and form a personal connection through the committee. It has been a hugely positive driver of my career over the last 10 years and hope it will continue to be so.

It’s nice to have those connections to call on, especially last minute in a pinch and know they will come through.

What would you say to a person considering joining a committee?

Just there really is no downside to joining a committee. Keep in mind I’m not saying to join for the sake of it, join if you're passionate about the industry and want to make a difference.

There have been examples of people in the past that have joined committees just to say they’re member of said committee and not really contributed, they hang around for a year or two they show up to the meetings and have a few beers but don’t really contribute, that’s not what we need. If you're a passionate person and you want to give it a go, do it! There really is no negatives to it, and you’ll hopefully meet some amazing people.

Yes, its extra work outside your actual job, there is no extra pay, but it's great fun and it's appreciated. We have such a good time and who knows what doors it will open.

What are the people like within the committee?

After each event, we'll try catch up on the

people liked or didn't like etc. Then we'll hang around and have a bit of a chat which can last few hours. The vibe of the group, it's pretty casual, relaxed and fun but when the work needs to get done, it's done. I rule with an iron fist, so you know, I delegate you a task, you do

Will you continue your work on the

I definitely would like to, but unfortunately, I've now come of age and I'm too old for the YPF as of the end of this year. This is my last year at the official YPF member, although the age group is a little bit fluid, we still have people in their 40s still hanging around, I guess I’ll be one of

I am looking forward to becoming a bigger part of the suppliers committee. Working with Luis Guevara and the rest of the team. Post that, who knows – maybe apply for the board to have a more direct impact on behalf of the young people in the industry.

Special mention – post conducting this interview Matt was awarded the Young Pipeliner of the year award at the APGA Convention and Exhibition.

APGA Q&A

15 The Australian Pipeliner | November 2022

Matt Nash has been part of the YPF in WA and QLD.

2022 APGA Young Achievement Award winner Matt Nash.

Gas and energy policy

By Jordan McCollum, National Policy Manager, APGA

Russia’s unjust war in Ukraine and unreliable coal-fired power plants both played roles in creating Australia’s 2022 east coast energy crisis. However, one elephant in the room is yet to be held accountable for the role it has played in the crisis.

An elephant which regulators and governments alike are reluctant to try to solve – the shortness in supply within the east Australian gas market.

The east Australian gas market fundamentally changed around 2015 with the introduction of the Curtis Island LNG facilities. Within a matter of years, the market went from long in supply to short in supply – from a market in which customers could set prices to a market in which producers could set prices. This change in price setting wasn’t the only change that the shortening of the east Australian gas market introduced, however.

The shortness of the gas market, positioned between the international LNG market and domestic electricity market, risks market price coupling in the event that either of the other two markets became short. Worse still, a short gas market sitting between domestic electricity and international LNG markets creates the risk that the gas market may be drawn upon by shortness in both markets at the same time, coupling prices across all three.

APGA has been highlighting this risk for at least a decade. While governments and regulators have been fixated on economic reform to address every last per cent of return in long term bilateral contracts across the gas market, we have been flagging that the true risk of price coupling

remains, and that this risk can only be solved through increased investment in gas supply.

By increasing gas supply, it is possible to close the gap between potential supply and demand, making the east Australian gas market long in supply once more. By being able to produce more than is able to be consumed by domestic and export customers, it would be impossible for all three markets to couple, and the energy crisis which occurred across 2022 would not have happened.

To be clear, the LNG exporters alone are not to blame for the 2022 east Australian energy crisis. While the development of more LNG export capacity than was able to be supplied created the short gas market, governments and regulators have had over a decade since these projects reached FID to identify and mitigate this risk.

Instead of mitigating this risk by incentivising increased gas production, governments and regulators have introduced increasingly stringent economic regulation of gas production and infrastructure, disincentivising investment in the

supply, but by more incremental transparency and control measures which disincentivise investment in new supply.

Incremental transparency and control measures have proven ineffective in protecting east Australian energy customers as they do not address the genuine risk represented by a short gas market. Only a return to a long gas market will protect customers from the types of price coupling experienced earlier this year.

Importantly, it is not only additional natural gas supply that can help solve this problem. As demonstrated by the European REPowerEU policy, the rapid development of hydrogen and biomethane production can play a substantial role in addressing short gas markets in Europe. Over 1,200 PJ of hydrogen and biomethane production are targeted by the EU policy, accounting for over 20 per cent of total European gas demand.

Australia too has this opportunity to use renewable gas uplift to help address its short east coast gas market. By setting similar targets at a federal level, well above the ACCC flagged 56 PJ shortfall could be accounted for by 2030 through renewable gas uptake alone. In this way, Australian energy consumers could see resilience returned to its energy markets while at the same time supporting whole of energy system decarbonisation.

Beyond the opportunity to address natural gas supply shortages with renewable gas development, the circumstances of the past 9 months and the decade that lead up to it can serve as an important lesson to the future renewable gas industry which may face similar risks.

east Australian gas shortfall, not by enabling new

Ensuring that investment in production development is always supported to ensure a long domestic renewable gas market is a low-regulation way to ensure that international renewable gas prices never couple with domestic renewable gas and renewable electricity prices in Australia’s netzero energy future.

16 POLICY The Australian Pipeliner | November 2022

"By increasing gas supply, it is possible to close the gap between potential supply and demand, making the east Australian gas market long in supply once more."

The east Australian gas market fundamentally changed around 2015 with the introduction of the Curtis Island LNG facilities.

ROLLER CRADLES & SLINGS | PIPE PILLO VACUWORX VACULIFT | PIPE SAK PIPE CUTTING CRADLES | PIPE ROLLER STACKABLE PLASTIC PIPE CONES AJP INDUSTRIAL SUPPLIES Available for Sale & Hire PIPE HANDLING RANGE LIGHTWEIGHT | 5:1 SAFETY RATIO | 3 SIZES PPE SAFETY WORKWEAR TOOLS & EQUIPMENT AUTOMOTIVE REFRESH SAND BLASTING & PAINTING EQUIPMENT 1300794096 | SALES@PSSSA.COM.AU MACKAY - (07) 4998 5299 TOWNSVILLE - (07) 4774 8332 We've got you covered

Our industry can deliver a global renewable gas industry

By David Norman, CEO of Future Fuels Cooperative Research Centre

the total energy mix by 2030, with Europe working to achieve a supply of twenty million tons (20 Mt) of green hydrogen by 2030, with 10 Mt produced domestically and 10 Mt imported. These are enormous quantities by current standards. This already underpinned Shell’s 200 MW electrolyser project in the Netherlands that is now proceeding to construction.

Importantly for our pipeline industry, Europe is now accelerating its European Hydrogen Backbone initiative that is developing a network of over 50,000 kms of new and repurposed hydrogen backbone pipelines covering the industrial centres of Europe, to provide cost-effective reliable transmission for this clean energy.

export emissions and is finding a vital role for renewable gas. The scale of decarbonisation is breathtaking, but our industry has a real opportunity to be a part of it.

Seing many colleagues at the APGA convention was so enjoyable. After the COVID years it reminded me of the shear breadth of the industry and how much value our colleagues create every day. This gives me confidence that our industry can meet the challenges and opportunities of decarbonising with that same combination of energy and expertise. The renewable gas industry is starting to leap forward both in Australia and globally and as an industry we need to be prepared for the opportunities and changes it could create.

Last month Engie and Mitsui reached their final investment decision on Australia's largest confirmed hydrogen project; the 10 MW electrolyser as part of the Yuri Green Hydrogen to Ammonia facility at Yara in the Pilbara. This is the first of three expected 10 MW units as part of the 2021 ARENA funding round and a key milestone in the next phase of scale-up of renewable hydrogen projects in Australia.

Over in the US the scale of their massive Inflation Reduction Act (IRA) is only just being understood. Among many other renewable energy schemes, the IRA offers an effective $3US/kg incentive for zero-carbon hydrogen, makes green hydrogen far more competitive.

In Europe the Renewable Energy Directive REDIII has made a commitment to an overall renewable energy contribution of 45 per cent to

Combined together the US and Europe will bring billions of dollars of support to the emerging hydrogen industry, necessary to bridge the bankability gap of the early investments that are the foundations of this industry.

Although there is much in Australia’s media at the moment on the decarbonisation of our electricity networks, the role of renewable gaseous fuels continues to play an important part. Future Fuels CRC is sponsoring and supporting the ground-breaking Net Zero Australia project (NZAu) that has just delivered its first public findings. NZAu is analysing net zero pathways for both Australia’s domestic and

The decarbonisation of electricity is also an important lesson for all us that every industry must bring our communities with us as we change and develop. We can give Australians a new option for how they decarbonise both at home and at work but we need to listen to them and meet their needs. This underlines the importance of our research into the social license and public perceptions of future fuels. Some of our most interesting research into public perception is already publicly available on our website and more advance work including citizen assemblies and deliberative democracy is coming soon (projects RP2.1-02 and RP2.1-07).

Future Fuels CRC has created an online training package for all pipeliners on understanding social license to operate with your community. It is available for free for APGA members, so contact the APGA, take the short course and help the industry prepare for the future.

18 FUTURE FUELS CRC The Australian Pipeliner | November 2022

You can find the latest on all Future Fuels CRC research at www.futurefuelscrc.com As Australia develops hydrogen industries in every state, it’s worth also looking at the potential of another future fuel, biomethane, to deliver our net-zero energy needs.

The renewable gas industry is starting to leap forward both in Australia and globally.

Future Fuels CRC CEO David Norman.

The leading innovator supplying cutting-edge integrity solutions. Together we can ensure sustainable decision-making. Our combination of advanced inspection systems and expert consultants delivers a comprehensive understanding of asset safety, lifetime, and performance.

Comprehensive Asset Integrity Management

www.rosen-group.com

Northern Territory gives green light for infrastructure progress

Across the Northern Territory, government bodies and industry juggernauts have undertaken projects to improve the state’s infrastructure, with gas and water security, communication, and other utilities.

Darwin Export Gas Pipeline supported by Santos

Santos has been given the green light for the Darwin Export Gas Pipeline which will extend the Barossa Gas Export Pipeline to the Santosoperated Darwin LNG facility (DLNG).

It will also allow for the repurposing of the existing Bayu-Undan to Darwin pipeline to facilitate carbon capture and storage (CCS) options.

Gas from the Barossa field, located 300 km north of Darwin, is intended to replace the current supply from the Bayu-Undan facility located in TimorLeste. First gas production at DLNG using Barossa gas is targeted for the first half of 2025.

Santos Managing Director and Chief Executive Officer Kevin Gallagher said the DLNG life extension, Darwin Pipeline duplication and BayuUndan CCS projects would promote sustainable development and jobs growth in the NT and Timor-Leste, while building momentum for a whole of region carbon reduction solution.

According to Gallagher, taking a final investment decision (FID) on the Darwin Pipeline duplication project will allow for the Barossa project to be CCS ready.

Adding the Darwin Pipeline duplication project is estimated to increase Santos’ share of capital expenditure for the Barossa project by approximately US$311 million ($453 million).

The Barossa joint venture has agreed with the DLNG joint venture partners to terminate the toll arrangement for using the original Bayu-

Undan to DLNG pipeline, reducing operating expenses for Barossa.

State Government planning major infrastructure corridor

The Northern Territory Government is investigating a potential infrastructure corridor from Tennant Creek to Darwin, which would allow for continued development of key regional areas.

The proposed corridor would provide pipelines for future services including gas, water, communications, and other utilities.

A prefeasibility study has identified a preliminary corridor alignment, which considers engineering, environmental, social and infrastructure considerations, and will be further refined and developed during consultation with stakeholders.

Consultation will seek local landowners’ input about the proposed corridor alignment and to identify the constraints that need to be considered to plan for the project.

NT Minister for Infrastructure, Planning and Logistics, Eva Lawler said that the state is in early planning and investigation phase as part of a longterm project to support growth across multiple sectors in the NT economy. This includes natural gas, hydrogen energy and digital infrastructure.

“This proposal has the potential to not only link the regions with key infrastructure but also to provide long-term, sustainable jobs for regional Territorians,” said Lawler.

INPEX signs agreement with NT for net zero targets

The Northern Territory Government has signed a non-binding agreement with Tokyo-based company INPEX to further pursue its commitment to a net zero emissions future.

The memorandum of understanding involves carbon offsets for the company’s offshore liquid natural gas (LNG) project, Ichthys, situated 820 km southwest of Darwin.

This comes shortly after INPEX’s environment plan (EP) was approved by The National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA). The EP allows the project to continue running for the next five years.

The Ichthys project is one of a handful in the world that incorporates the full chain of development for LNG: subsea, offshore, pipeline and onshore processing.

INPEX’s existing offset commitments includes a number of marine biology monitoring and conservation programs, including monitoring the conservation status of coastal dolphins in the NT.

For more information on the latest industry news, projects and products visit www.pipeliner.com.au

20 The Australian Pipeliner | November 2022

PIPELINES IN NT

infrastructure to further support a net-zero future.

C M Y CM MY CY CMY K

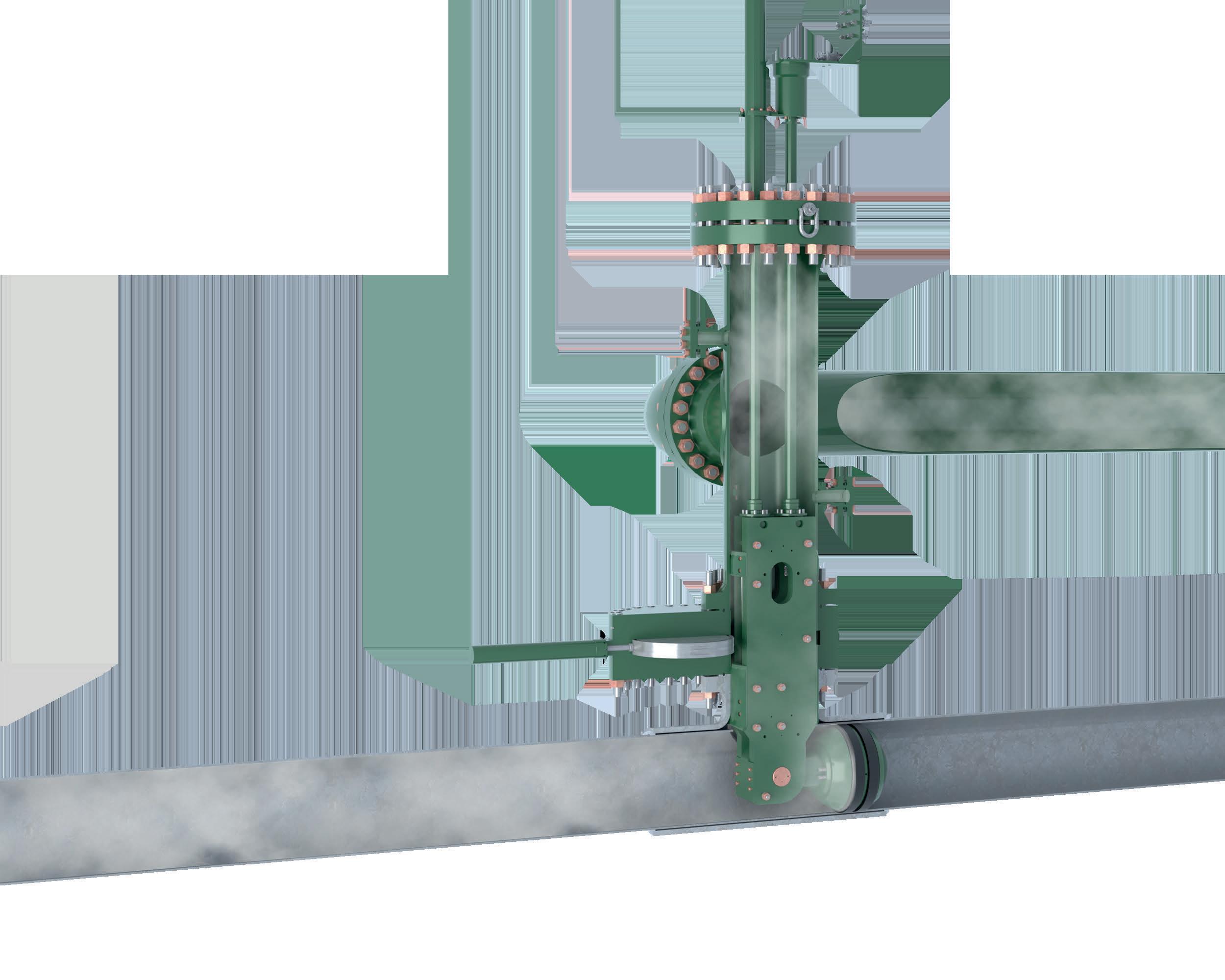

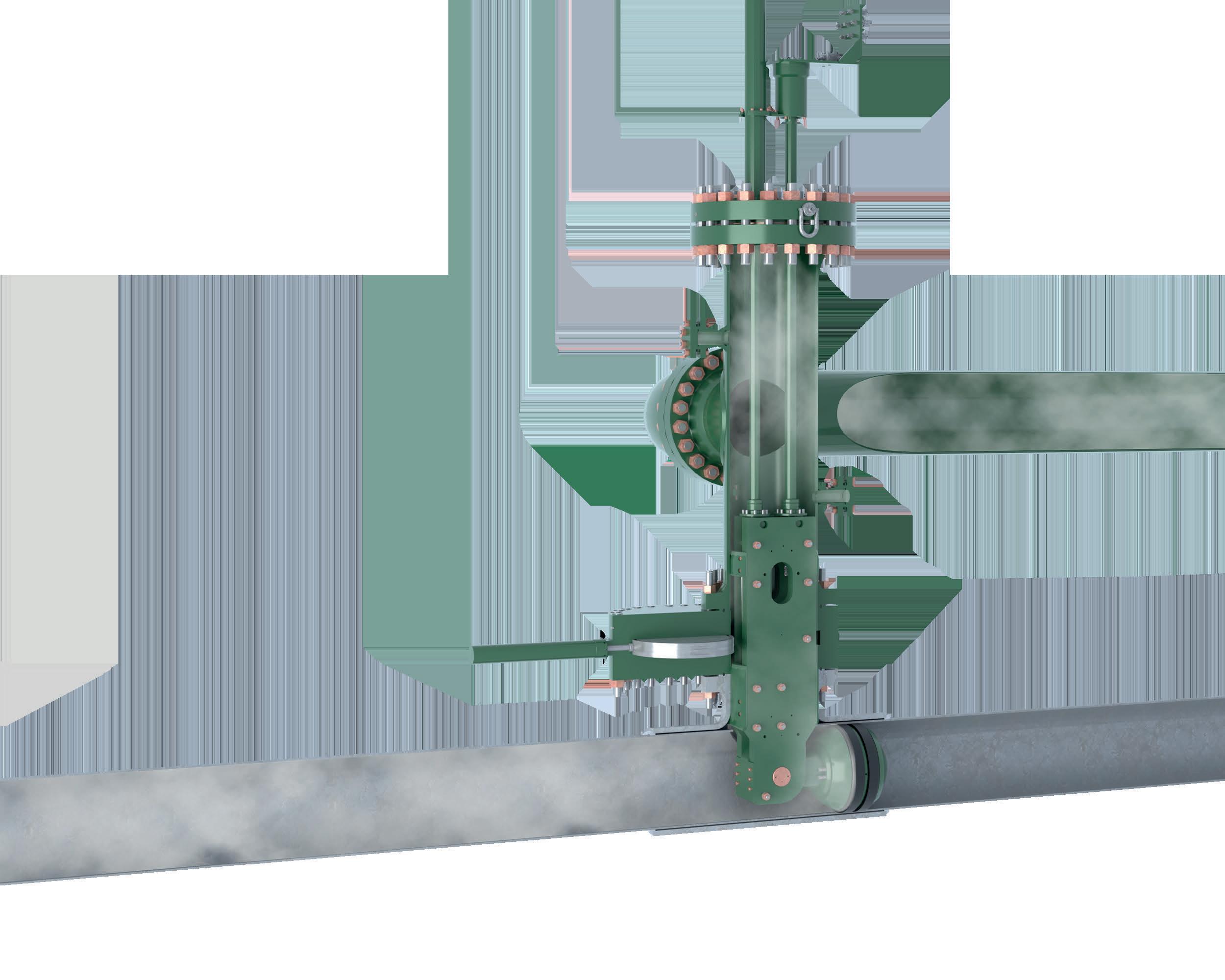

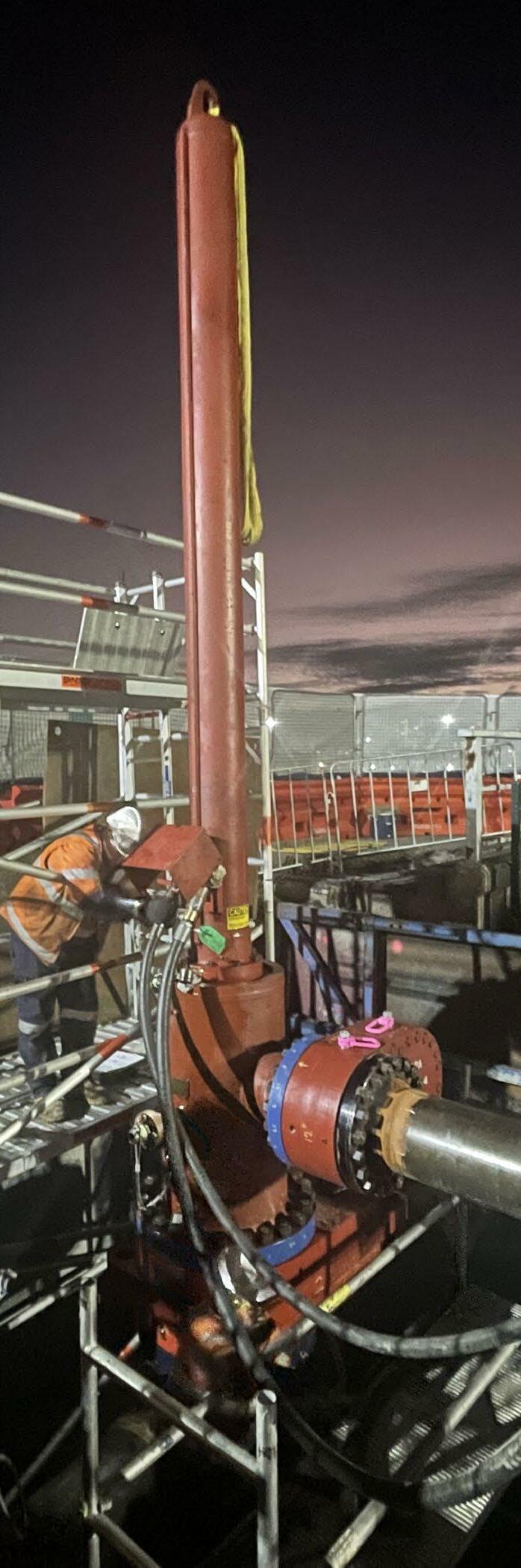

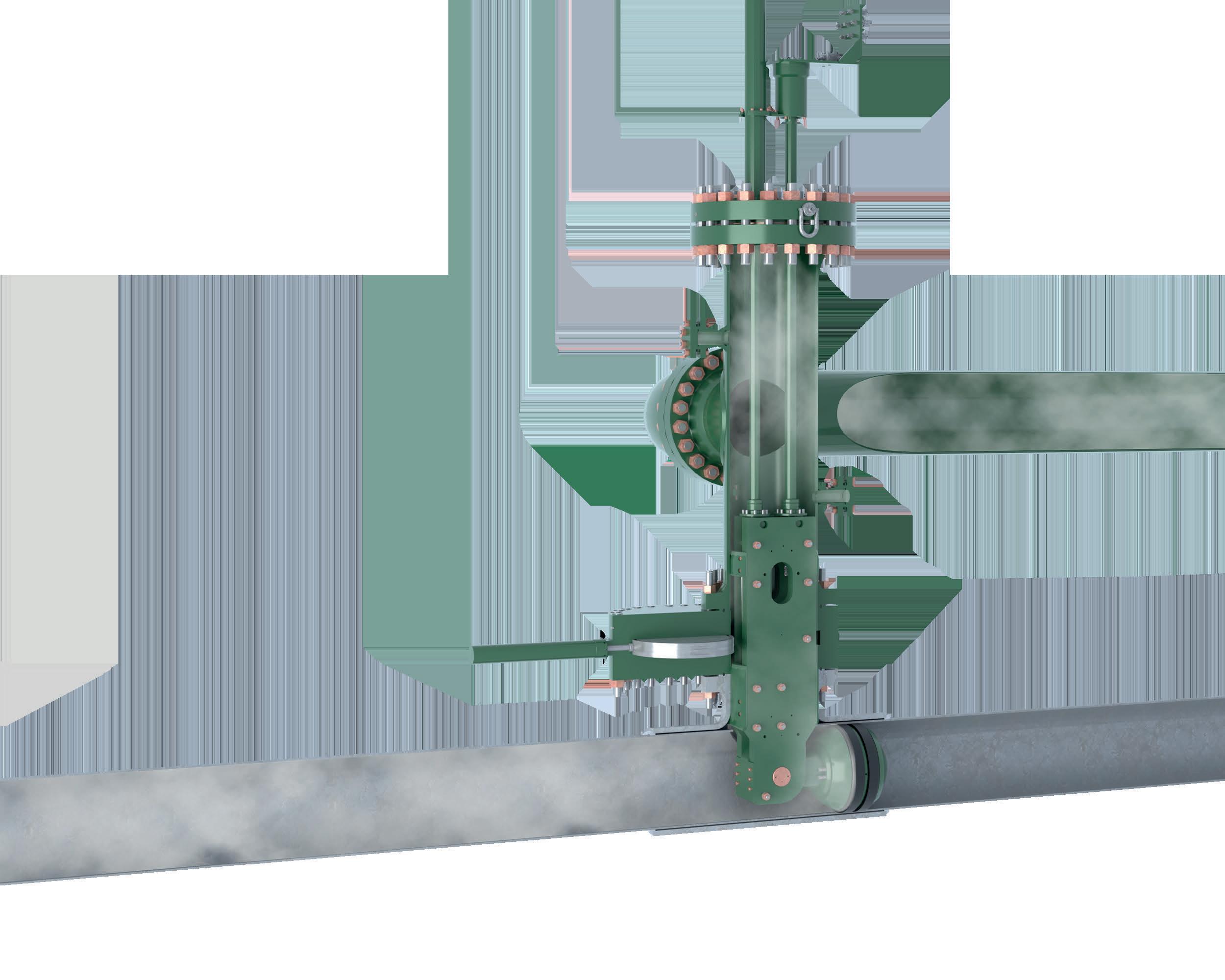

The BISEP® with extensive track record provides industry first double block and bleed isolation while maintaining production. Hydraulically activated dual seals provide fully monitored leak-tight isolation, every time, any pressure. ZERO-ENERGY ZONE SINGLE HOT TAP POINT DUAL Leak-Tight Seals double block & bleed isolation PRODUCTION MAINTAINED BISEP® Hot Tapping & Plugging ISOLATED PIPELINE

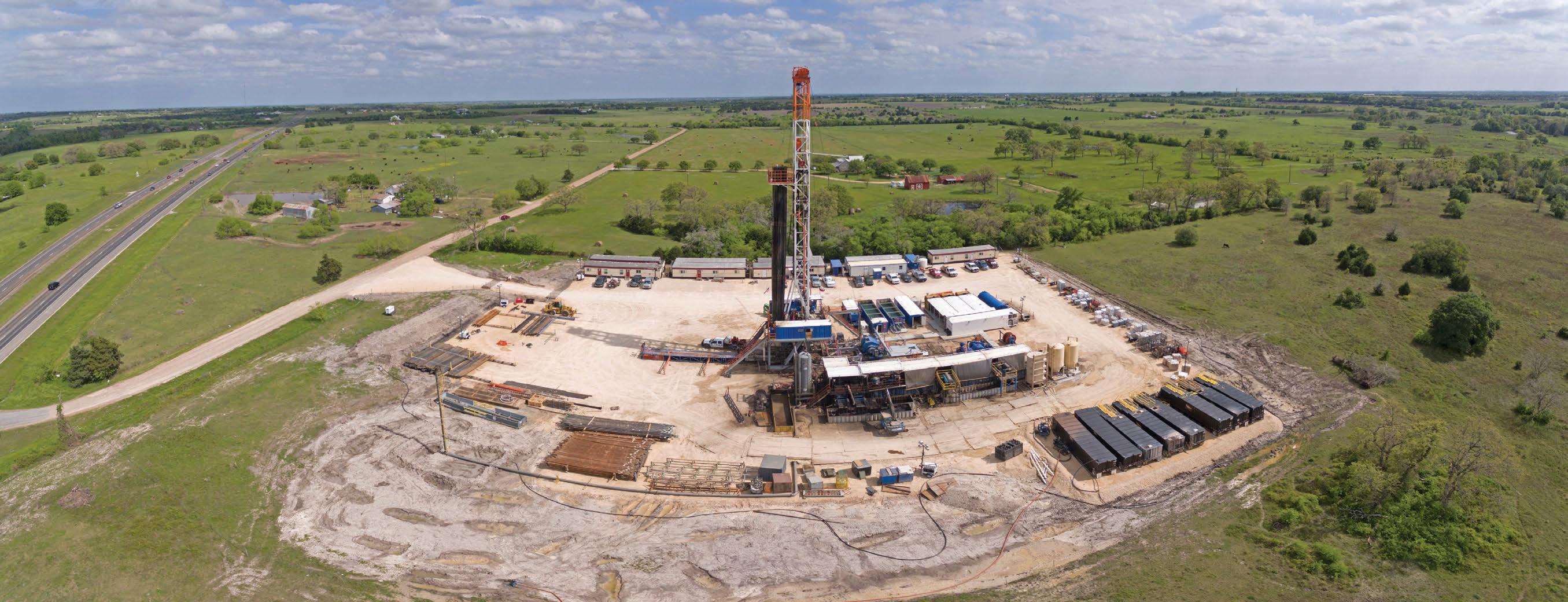

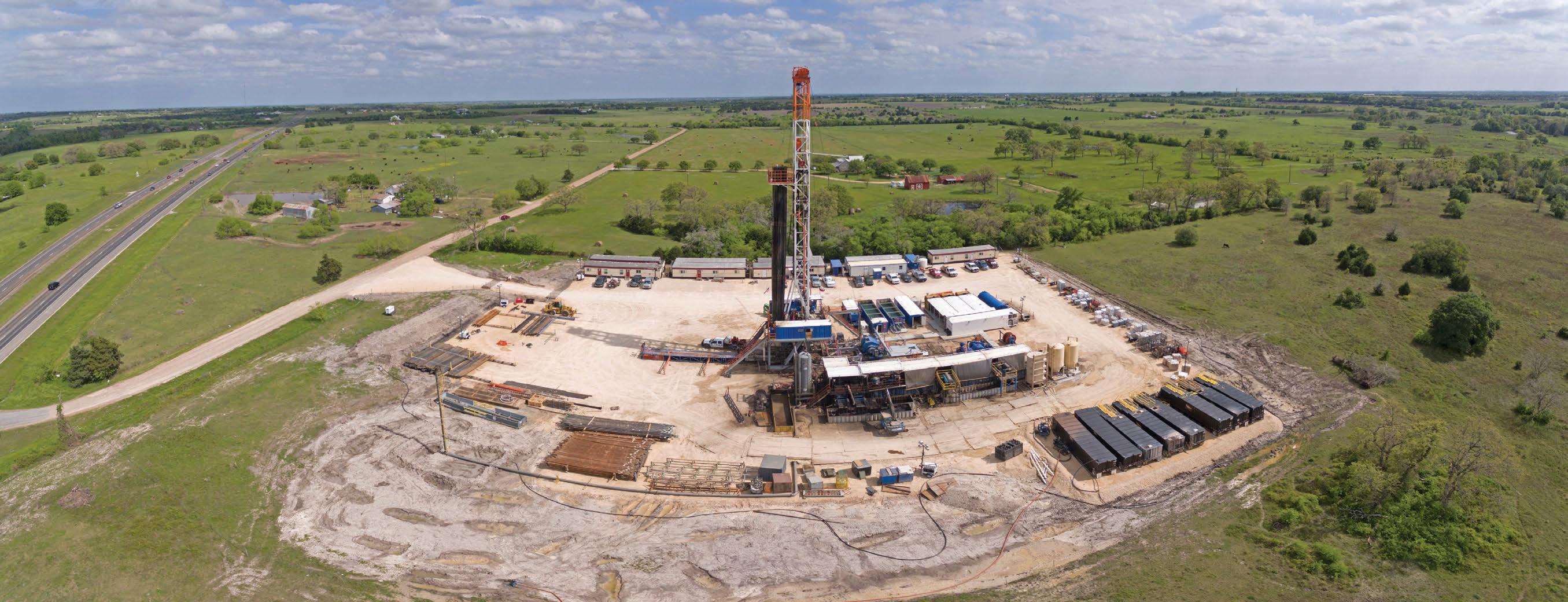

Beetaloo Basin has promise in a low carbon future

The Beetaloo Sub-Basin has the potential to rival the world’s biggest and best gas resources. The development of this resource has been subject to many complications and delays, but nevertheless has the potential to create thousands of jobs and act as a significant driving force for economic growth within the Northern Territory.

Since the strategic development plan for the Beetaloo Basin was developed, the field’s potential to spur significant downstream manufacturing opportunities, deliver cheaper and more reliable gas to households and industry and provide additional sources of gas for LNG export facilities has been evident.

Nevertheless, efforts to get the Beetaloo SubBasin running optimally have not been without its complications.

Greater gas production in areas such as the Northern Territory provides an opportunity for commercial-scale carbon offsets, as well as carbon capture and storage developments.

Empire and APA Group ramp up pipeline wars

In October 2021, gas pipeline giant APA Group intensified the competition to build the multibillion-dollar infrastructure project which would help unlock the huge Beetaloo gas resource in the NT. The group signed with explorer Empire Energy, rivalling plans by Jemena and Cheung Kong Group.

News of the memorandum of understanding (MoU) between APA Group and Empire Energy, which envisaged a new common-user pipeline to bring Beetaloo shale gas to the eastern states of Australia, came after major gas producers including Santos, Woodside and Inpex agreed to co-operate to examine the viability of large-scale carbon capture in Darwin.

The proposed infrastructure, which would also involve expanding existing pipelines and building

gas processing plants, also supported the NT government’s ambitions for a gas-based manufacturing industry and the expansion of LNG exports from Darwin.

The pipeline developers were battling to build the larger transmission lines that would move gas from the remote Beetaloo region near Daly Waters in the NT, where majors such as Santos have high hopes for commercial gas production, as do juniors Empire, Tamboran and Falcon Oil & Gas.

Successful early drilling results from September 2021 indicated that hopes that the Beetaloo could be Australia’s answer to the USA’s shale gas revolution of the previous decade. These hopes have continued and been further solidified in lieu of 2022’s global gas and energy crisis, with the need to have ample and affordable gas to back up renewable energy and supply domestic manufacturers in the market paramount.

22 The Australian Pipeliner | November 2022 NORTHERN TERRITORY

The Beetaloo Basin is one of the most promising shale gas resources anywhere in the world, but the viability of a gas resource is about more than just the volume and quality of the resource.

The project proposed by APA Group and Empire Energy involved a new pipeline connection between the Amadeus pipeline that runs from Alice Springs to Darwin and Mount Isa, where it would then link into APA Group’s existing Carpentaria pipeline that runs south to Ballina in New South Wales. Additionally, it would involve further expansion north from the Beetaloo Basin to Darwin.

The proposed new Beetaloo pipeline would become part of the existing APA Group gas distribution network and be the most capital efficient model for connecting the Beetaloo SubBasin to market.

In March 2022, then Minister for Energy and Emissions Reduction and Minister for Industry Angus Taylor called for priority actions for early works support on a feasibility study for proposed infrastructure in the Beetaloo Sub-Basin. The feasibility study would aim to determine the most efficient infrastructure to deliver natural gas from the Beetaloo Basin to the east coast gas market.

At the time of publishing, neither APA Group nor Jemena have been awarded approval to begin works on the infrastructure.

What happens next as Origin says farewell to Beetaloo

The Beetaloo Basin is now headed by Tamboran Resources alongside Falcon Oil & Gas in a joint venture (JV) under the Beetaloo exploration project after Origin announced its decision to divest its interest in the field in early September 2022.

Upon announcing its decision, Origin said it was going to sell its exploration interests in the basin to Tamboran Resources for $60 million. The company is expected to lose between $70 million and $90 million because of the move but struck deals to buy gas and receive a royalty payment of 5.5 per cent of revenue from gas if production in the field goes ahead.

Origin is set to undertake a strategic review of all remaining exploration permits (excluding its interests in Australia Pacific LNG) with the intention to exit those permits over time. The company will continue to comply with its various obligations under existing joint venture (JV) agreements and work alongside its JV partners as it works to considers potential exits.

Origin CEO Frank Calabria stated that the decision to divest its interest in the Beetaloo and exit similar upstream exploration permits over time will grant the company a greater flexibility to allocate capital to growing cleaner energy and customer solutions.

“We believe gas will continue to play an important role in the energy mix and it remains a core part of our business,” says Calabria.

“Notwithstanding the prospectivity of any of these permits, typically the experience in progressing these types of projects is that the exploration and appraisal phase can be uncertain, and it can be capital intensive to bring projects into production.

“Ultimately, we believe Origin is better placed prioritising capital towards other opportunities that are aligned to our refreshed strategy.”

The company previously described the Beetaloo as one of the most promising shale gas resources anywhere in the world and was the largest player testing commercial viability of the basin’s gas deposits.

Support continues for Beetaloo

While complications have surely staggard the progress of Beetaloo’s seemingly uphill battle toward its production goals, Federal Resources Minister Keith Pitt is among many who have continued to believe in the viability and success of Beetaloo.

In March 2022, Pitt granted another $7.5 million to the industry to continue works in the

As an energy and carbon hub, the Beetaloo Sub-Basin – and the Northern Territory as a whole – have a bright and shining future.

24 The Australian Pipeliner | November 2022 NORTHERN TERRITORY

NT’s Beetaloo Basin. The funding grant was awarded to Sweetpea Petroleum, a subsidiary of Tamboran Resources, to undertake exploration drilling.

Minister Pitt cited the continuing Russian invasion of the Ukraine and the subsequent fallout for the energy sector as a driving force behind the government’s ongoing support for expanding Australia’s gas industry.

“We should take the energy crisis in Europe as a warning of what could happen in Australia if there is not enough investment in the gas sector,” says Pitt.

“Beetaloo has the potential to provide a world-class gas resource and we are determined to support its development as part of our gasled recovery.”

Given the continued supply difficulties for gas and energy across the globe, it’s clear that Australia has been correct to continue expanding oil and gas developments but concerns over gas’ place – and therefore the place of basins such as Beetaloo – in a net zero Australia remain.

Beetaloo’s place in a low carbon future Beetaloo Basin gas, in addition to other onshore

and offshore gas, has a very integral role to play in the transition to lower carbon energy sources such as hydrogen, solar or wind.

The International Energy Agency (IEA) forecasts that the use of gas is anticipated to rise because of the shift to lower carbon energy sources.

Upon examining emissions from the full energy cycle, it’s evident that without gas, emissions from operations are not likely to reduce as quickly when utilising gas to enable a smoother energy transition as there are very limited energy and technology alternatives.

In addition to the benefits provided by switching from coal-to-gas both domestically and through LNG exports to overseas markets, there is a notable potential for development of newer and more future-oriented industries which are built around the development of the Beetaloo – such as carbon offsets, carbon capture and sequestration.

Greater gas production in areas such as the Northern Territory provides an opportunity for commercial-scale carbon offsets, as well as carbon capture and storage developments.

As an energy and carbon hub, the Beetaloo Sub-Basin – and the Northern Territory as a whole – have a bright and shining future.

Northern Territory is home to the Beetaloo Basin, one of the most promising shale gas resources in the world.

25 The Australian Pipeliner | November 2022 NORTHERN TERRITORY

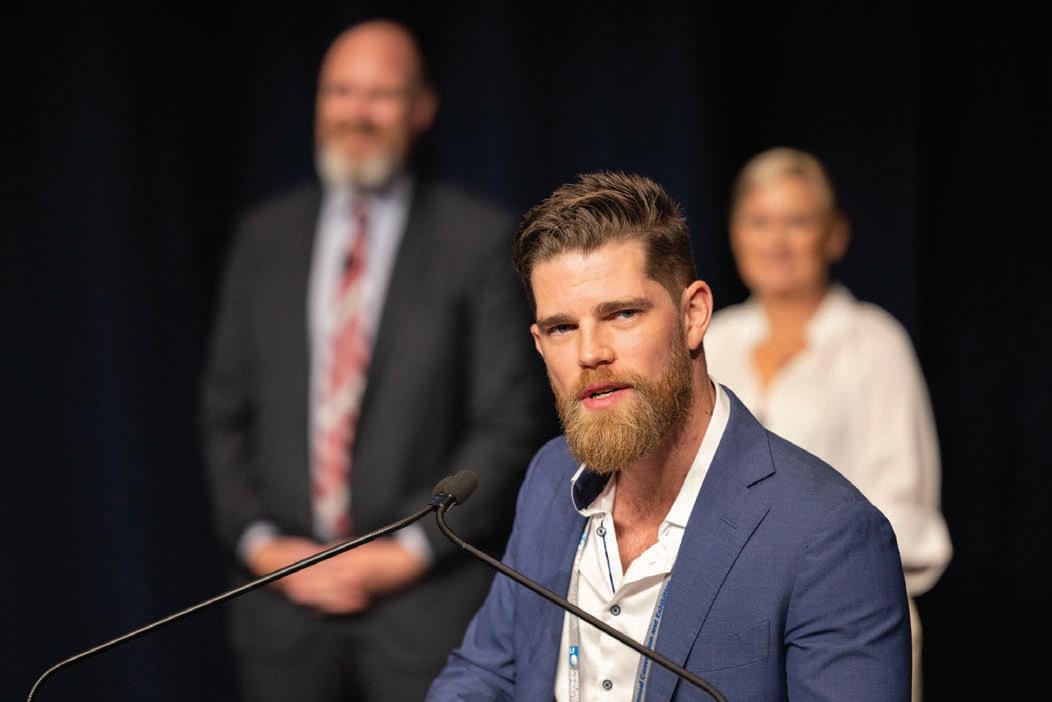

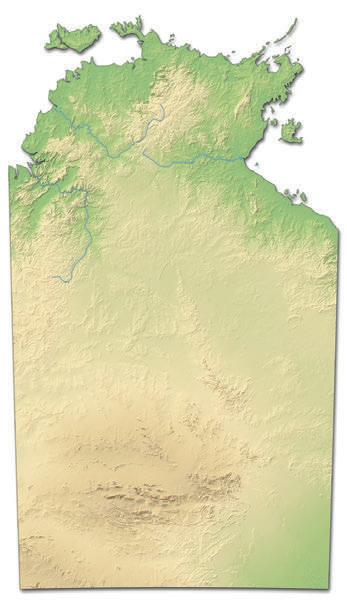

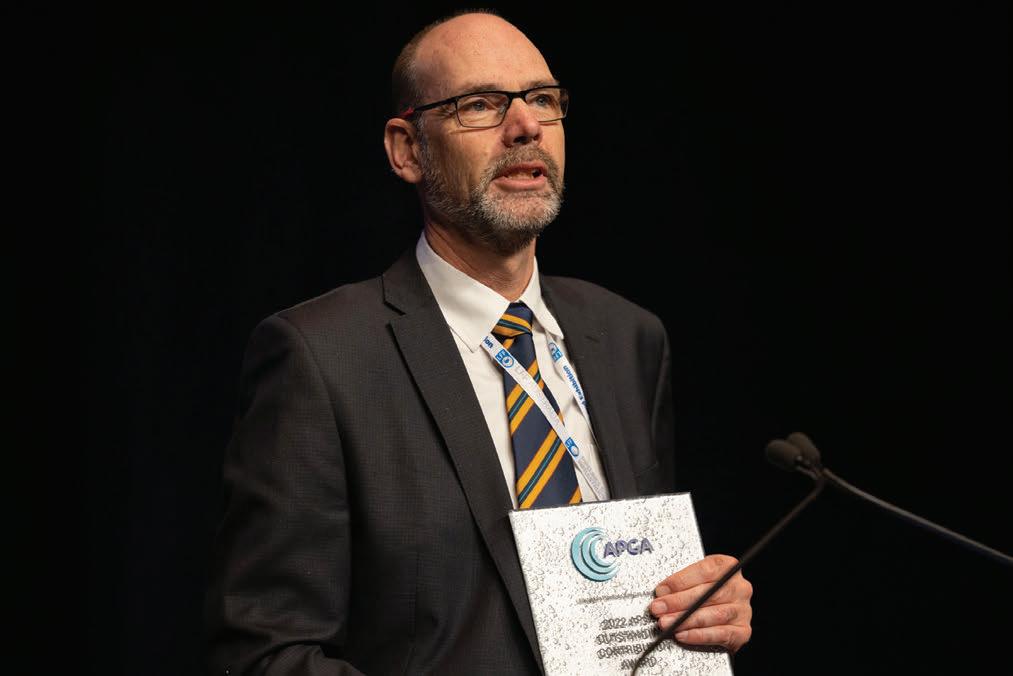

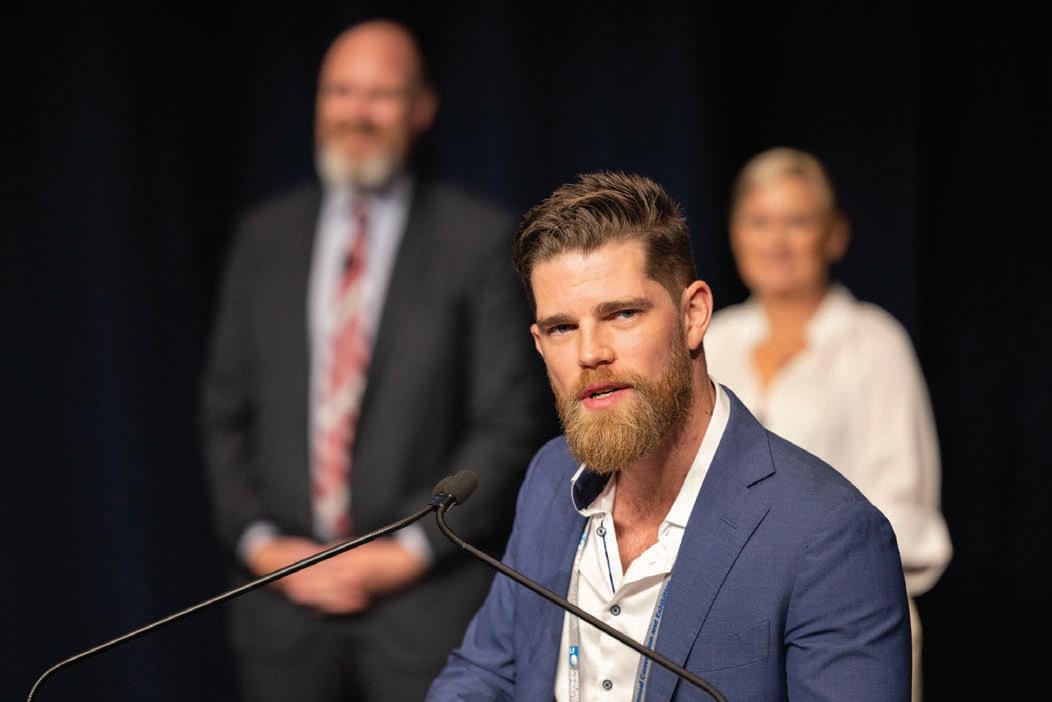

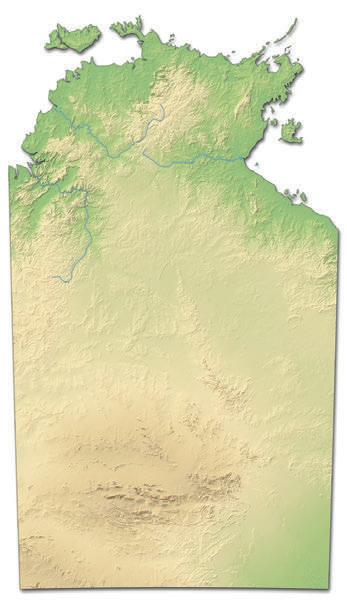

Industry veteran’s contribution recognised with prestigious APGA Award

As part of the Australian Pipeline and Gas Association (APGA) annual conference and exhibition, it hosts an annual awards ceremony to acknowledge and celebrate the services of companies and individuals in the pipeline industry.

This year, the winner of the APGA award for Outstanding Contribution to the Australian Pipeline Industry went to Peter Cox, the Vice President Energy & Chemicals – Australia East & PNG for Worley.

Cox has spent more than three decades working with Worley. First as a mechanical design engineer and eventually attaining his current role,

as well as becoming a member of the APGA board.

As well as continuously exceeding in his career, Cox has given time to mentoring young engineers just stepping into the industry, ensuring a strong new generation for the future.

Cox shares with The Australian Pipeliner about his career, the past, and his thoughts on the future of the pipeline industry.

How would you describe your career so far?

My career has been very rewarding as I have taken the opportunities when presented. When Bruce

Andrews started to step back from managing the Worley pipeline business, he gave me the opportunity to step up and succeed in the role, including taking on an APGA Board position. I’ve always put my hand up to contribute to or lead industry initiatives, which has given me the opportunity to work with passionate people across all facets of industry and enabled me to take pride in the achievements made along the way.

Have you always been interested in the strategy and business side of industry, or are you still an engineer at heart?

26 The Australian Pipeliner | November 2022

Peter Cox, one of the winners at the 2022 APGA Awards, offers his perspective on the pipeline industry as it is now, and what may be in store as Australia, and the rest of the world, make moves to lower emissions.

PIPELINE PEOPLE

APGA CEO Steve Davies (left) and Peter Cox (right) at the APGA awards 2022.

Building the world under your feet Bringing trenchless solutions to Australia Australia-based operations with permanent local resources Fully integrated with our global team at international headquarters Multiple NASTT Project of the Year awards Horizontal Directional Drilling · Completed a 4.7 km drill · 235 Intersect crossings completed since 2000 · Rigs available with push/pull capacity up to 815 Tonne · Drill diameters up to 1.5m 8,000 people strong founded in 17,000 pieces of equipment Pioneering HDD since 1988 Direct Pipe · 13 Installations since 2010 · Leading Direct Pipe Installer · Land-to-water outfalls · Installations up to 1.5m in diameter MichelsTrenchless.com.au

I believe that the two cannot be separated. To succeed in business with successful strategy, a detailed knowledge and understanding of the engineering is essential. The real opportunities to find faster and more efficient ways of achieving business objectives can only be done safely through engineering. I’ve been lucky to always have a network of subject matter experts in Worley to test ideas and improve strategies.

The APGA award that you won was for outstanding contributions – which of these contributions are you most proud of?

Helping to steer both APGA and the Future Fuels CRC to successful outcomes through my roles with the board has enabled me to influence many initiatives. Probably the most significant ones, those that I am most proud of, would include producing the Code of Practice for PE Gathering Systems, and mentoring early-career engineers – getting them involved in the many research projects through the Energy Pipelines and Future Fuels CRCs.

Are there any highlights from your career that you’d like to share?

One of the more memorable highlights would be leading the Worley response to the Longford Gas Plant incident back in 1998 which curtailed Melbourne’s gas supply. Firstly, I was involved in designing and constructing a temporary compressor station at Young to boost NSW gas

to Victoria which we got operational within two weeks after the incident. Then I led the design and construction of three permanent compressor stations at Bulla Park, Young and Springhurst which we had operational within six months.

Have you achieved everything you wanted to in your career yet? If not, what’s left?

Definitely not. My passion currently is steering the energy transition to a net zero future through development and implementation of new technologies. It is a major societal change, and it is very exciting to be at the forefront of delivering it.

How do you think the future of the pipeline industry will change in the next 10 years?

We will see major change in the next 10 years through modifying our pipelines to transport blends of hydrogen, carbon dioxide, ammonia, biogas, sustainable aviation fuel and water – to name a just a few. If we don’t make these major changes in the next 10 years, we will not achieve the climate targets set.

What is next for you?

For me personally, I am committed to helping commercialise these new technologies needed, which requires the necessary social licence – and Government policy --- needed to enable the energy transition. My position in Worley and the Future Fuels CRC uniquely provides me the opportunity to play a role to enable all of the changes necessary, and to influence this new and exciting future.

The Outstanding Contribution to the Australian Pipeline Industry award is clearly a well-earned one for this respected and pioneering member of the pipeline industry. It is Cox, and those industry operators like him, who offer the best chance of succeeding in the energy transition faced by Australia in the coming years.

28 The Australian Pipeliner | November 2022 PIPELINE PEOPLE

Peter has been improving the pipeline industry for more than 30 years.

Peter Cox receives his award for outstanding contribution from APGA President Donna McDowell.

With more that 25 networking and technical events every year, the APGA events team is committed to providing the best opportuninty for sharing experiences, information exchange and finding out the latest developments in the pipeline and gas industry. Scan for the latest events schedule

COMMI T TEES EVENTS

EVENTS

P: 02 6273 0577 E: APGA@APGA.ORG.AU

The industry through MPK’s eyes

As part of the People in Pipelines feature, spoke with MPK’s team in the Surat Basin CSG fields, Queensland, to gain an insight into how the industry has changed for them and where they see the industry placed in the future.

Name: Cathy Carragher

Name: Cathy Carragher

Role: Plant and Maintenance Lead Years in Industry: 15

Most of my industry career has been spent in plant and maintenance roles, originally in civil construction and plant hire companies, but since 2013, I have been with MPK in the Surat Basin.

I have witnessed a lot of changes in this time, particularly the shift from paper-based processes to the digital online tools we use today. I believe this advancement has made the discipline I work in far more effective by ensuring we’re continually compliant, our maintenance monitoring is more accurate, and our reporting more informative and timely, and ultimately more beneficial to MPK and its clients.

We have 700 items in our fleet, which all require a comprehensive maintenance schedule, so it is imperative we have the correct systems in place to ensure we keep on top of it. In recent years, 'Safer Together' has become a large focus for our plant and maintenance team, with 90 of our 700 maintained assets needing to fully comply with new Safer Together requirements.

Chain of Responsibility (COR) has also become a large focus within plant and maintenance, as our team arranges the external transport for initial mobilisation and demobilisation. To ensure we have a better understanding of our roles and responsibilities, we have run our team through COR courses, and I think these courses have been

highly beneficial, as they’ve enabled our experienced and qualified personnel, MPK as a business, and our Project as a whole, to develop a culture of “future thinking”.

Name: Scott Bourne

Role: Senior Project Engineer

Years in Industry: 9

I started my career in 2013 as a Graduate Engineer with MPK and have spent most of my working life on projects across the Surat Basin CSG fields. In this time, I’ve been presented with some great opportunities and have been fortunate enough to have worked with one of the leading LNG pipeline companies in Australia, and also gained an immense amount of knowledge from some of the best likeminded and highly experienced engineers and pipeliners in the industry.

Now, as a Senior Project Engineer, and thanks to the mentorship I’ve received by peers over the years, I’m tackling the day-to-day challenges of running a pipeline construction project. While the elevation through the company ranks has been great, I’m always conscious of ensuring I provide our new graduate engineers with the same support I received when entering the industry. I think it’s important to do that, as over the last few years I’ve witnessed an ever-growing need for engineers and have seen firsthand the integral part they play in making largescale projects successful. What I like about MPK and our industry in general, is our engineers aren’t

pidgeon-holed and are able to become familiar with every stage of the project from design through to handover, which means they can develop a solid understanding of all the works involved in a project. It’s a winning formula and not only makes engineers valuable assets for companies, but also ensures there is a clear pathway for career progression into senior engineering and management roles.

Name: Cameron Holland Role: Supervisor Years in Industry: 17

I’ve spent most of my working life within the oil and gas industry and for the for past seven of those with MPK as a supervisor. I'm a proud Aboriginal man and was recently asked to join an MPK working group of other Aboriginal, Torres Strait Islander and non-indigenous employees to help develop the company’s reconciliation action plan.

It’s been an honour to be part of this reconciliation initiative and play a part in the development of a plan that will guide MPK in its positive engagement with Aboriginal and Torres Strait Islander employees and communities. The main goal of our plan is to increase the level of workforce awareness of Aboriginal and Torres Strait Islander culture and traditions, increase the opportunity for Aboriginal and Torres Strait Islander People to gain employment and training with MPK, and for MPK to increase its use of

30 The Australian Pipeliner | November 2022 PIPELINE PEOPLE

Plant and Maintenance Lead Cathy Carragher.Senior Project Engineer Scott Bourne.

a number of NAIDOC Week events. MPK actively encourages all employees to be involved in these events and to give feedback on reconciliation, so that our planning is better informed and also fully inclusive.

It’s personally important for me that we have positive, two-way relationships built on trust and respect between Aboriginal and Torres Strait Islanders and non-Indigenous Australians, and I look forward to playing my part in helping MPK achieve the positive outcomes it wants to reach as a company.

Name: Garry

Muldowney

Role: Electrical Lead Years in Industry: 20 plus

My industry career began in the U.K. before I moved to Australia and joined MPK as an electrician in Chinchilla, right as the coal seam gas sector was taking off. To say it was a contrast to my life back home, would be a massive understatement.

Since starting with MPK, I’ve progressed into the role as Electrical Lead, and now working on sites right across the Surat Basin.

When I look back at the last decade, it’s quite amazing to see the massive progression of the CSG sector in the Surat Basin, but also to see how contractors like MPK have also developed their capacities and capabilities as the CSG sector has grown.

MPK started out as just a pipeline construction company, but even in those early days there was a drive within the company to do more, and as new

opportunities arose, MPK were in a great position to make the most of those opportunities.

One of those key areas of growth for us was in the mechanical and electrical space, and soon after obtaining our electrical contractors’ licence, we were undertaking more complex scopes and working with a much broader client base. To this day, our contract scopes and the skillsets of our ever increasing workforce are broadening too, and does not look like slowing down in the near future.

As a long-term employee, it’s good to see us doing well and winning more work, but importantly, winning new types of work and in new sectors as well, so we can broaden our depth of services and continue to grow as a company into the future.

Name: Bart Robertson Role: HSET Manager Years in Industry: 18

I have spent much of my career in the safety profession, and in that time, I’ve witnessed a lot of changes. But making the move three years ago to work in an organisation that values its people and ensures their skills and abilities are fully utilised is refreshing, and I believe this type of approach delivers positive change.

I know MPK and the wider industry is now moving away from programs that require defined processes, and KPIs that rely on quantity not quality. MPK is now shifting its focus on systems like Step 7, which is heavily geared towards fostering structured conversations and having good communication and culture within a workforce.

Using these types of systems, which have realistic risk management controls, is key to constantly building and maintaining a positive safety culture within the workforce and hopefully the wider CSG industry.

Name: Alan Dunphy Role: Construction Lead Year in Industry: 15

I’ve spent most of my life within the pipeline construction industry and it’s been great to witness the positive changes that have come about over these years across all areas of our operations - from production and quality, to the safety and culture of our employees.

One of the big step changes I’ve noticed over the past few years is the way we’ve moved from the big and very expensive `first gas’ push, where we had massive workforces and big kms of pipe to get into the ground and wells coming online as fast as humanly possible. Moving on from those heady years, our industry is now focusing all of its energy and the skills of its people on working smarter, not harder.

We’re refining the plant, equipment and processes we use, in order to get better outcomes for us and our clients. I think that’s a good place to be in as an industry and makes us far more sustainable for the future. I also see a lot more collaboration within our industry, with companies like MPK now able to work closely with its clients to come up with better ways to do things. When I say better, I mean better ways to do things across every discipline in our industry – not just production, but better for our employees, our host communities and our environment.

As an industry collective, we’re coming up with, and embracing, some very innovative ideas and they’re all coming in from the coal face thanks to developers and companies investing in their people and enabling their R&D to be fully realised. If there was a single thing that has resulted in better retention, it’s having faith in people and their smarts, and giving them the opportunity to develop themselves, ensuring the industry’s future.

31 The Australian Pipeliner | November 2022

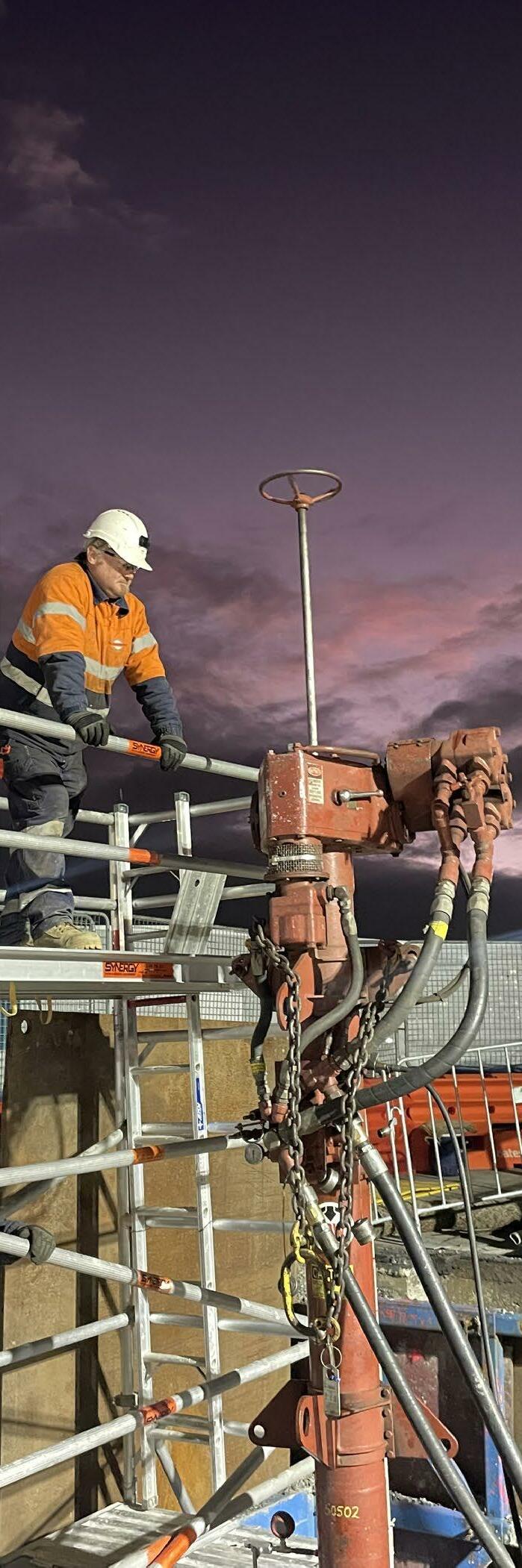

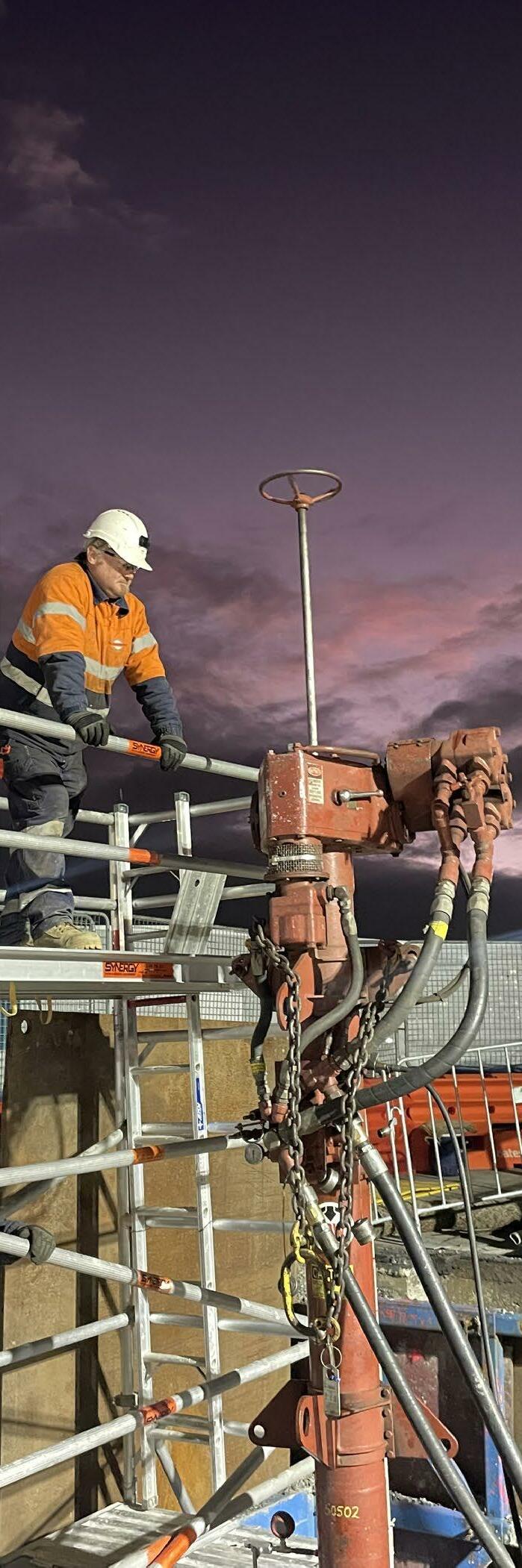

From filling sandbags to COO: Taddam Farrant is no longer a new kid on the block

After getting his start in pipelines as a labourer, Taddam Farrant has experienced every stage of the pipeline lifecycle, rising from the tools to the Chief Operating Officer (COO) of one of Asia-Pacific’s

and testing contractors.

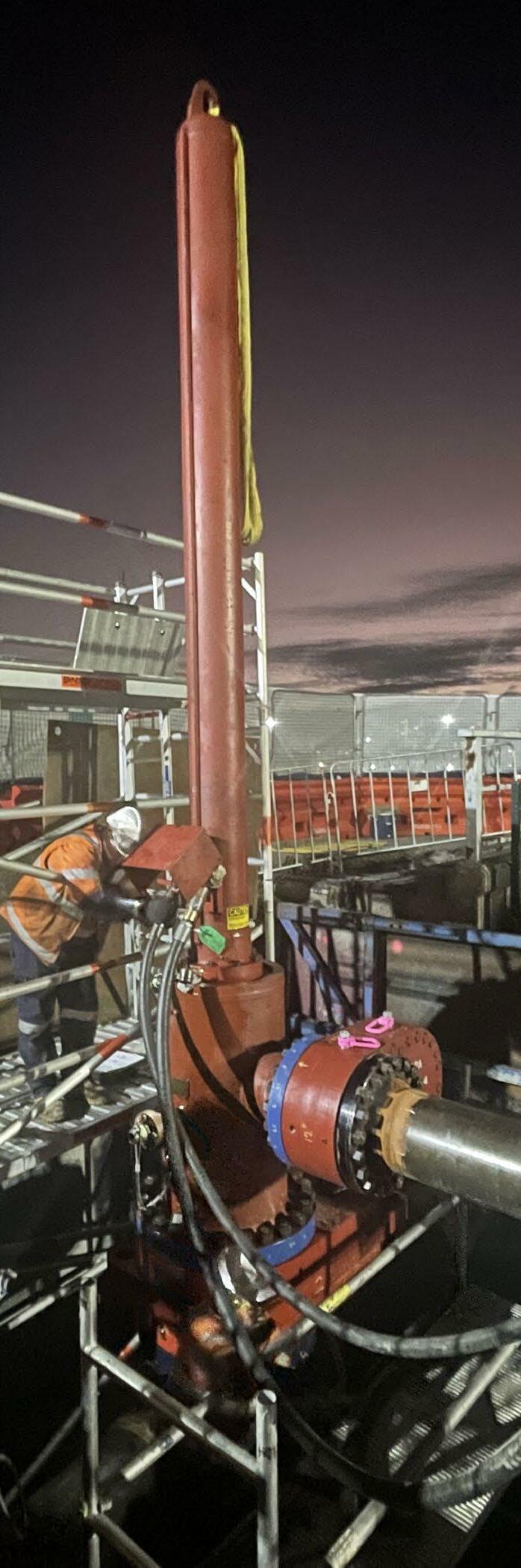

Ahard-working pipeline testing firm based in Brisbane, Queensland, Pipe Tek was initially established in 1953 as Tank Calibrators. Known Australia-wide as Pipe Tek since 2015, the company has made a name for itself with its direct approach to safety and its drive toward innovation.

The company offers large scale solutions and project management, delivering its clients the full package. For more than six years, Farrant has acted as Pipe Tek General Manager, before moving into the role of COO alongside his business partner and Pipe Tek’s Managing Director Myles Brannelly.

Like many pipeliners, Farrant got his start labouring. His first job was with AJ Lucas, filling sandbags and throwing skids.

“I needed a change from what I was doing at the time,” Farrant tells The Australian Pipeliner

“When the opportunity came up to get started in the industry, I took it. It was the best decision I’ve ever made.”

From there, Farrant’s work ethic led to opportunities working on major projects, including the Eastern Goldfields Pipeline, the Curtis Island QCLNG, stage three of VNIE and extensive work in the Cooper Basin on behalf of oil and gas producer Santos. He delivered a number of varied roles across these projects, including coating, testing and pigging, cleaning, gauging, MFL and UT, as well as acting as a hydrostatic test technician and supervisor.

This experience working alongside major industry stakeholders and asset owners like AJ Lucas, Spiecapag, McConnell Dowell, Nacap, APA Group, Santos, Jemena, Ampol, Chevron, Puma, Shell and UGL gave Farrant the knowledge and experience to step into the role of Pipe Tek General Manager in 2016 after meeting his now business partner, Brannelly, while testing and pigging together.

At the time, Brannelly was working for himself and Farrant for a construction company. It didn’t

PIPELINE PEOPLE

leading inspection

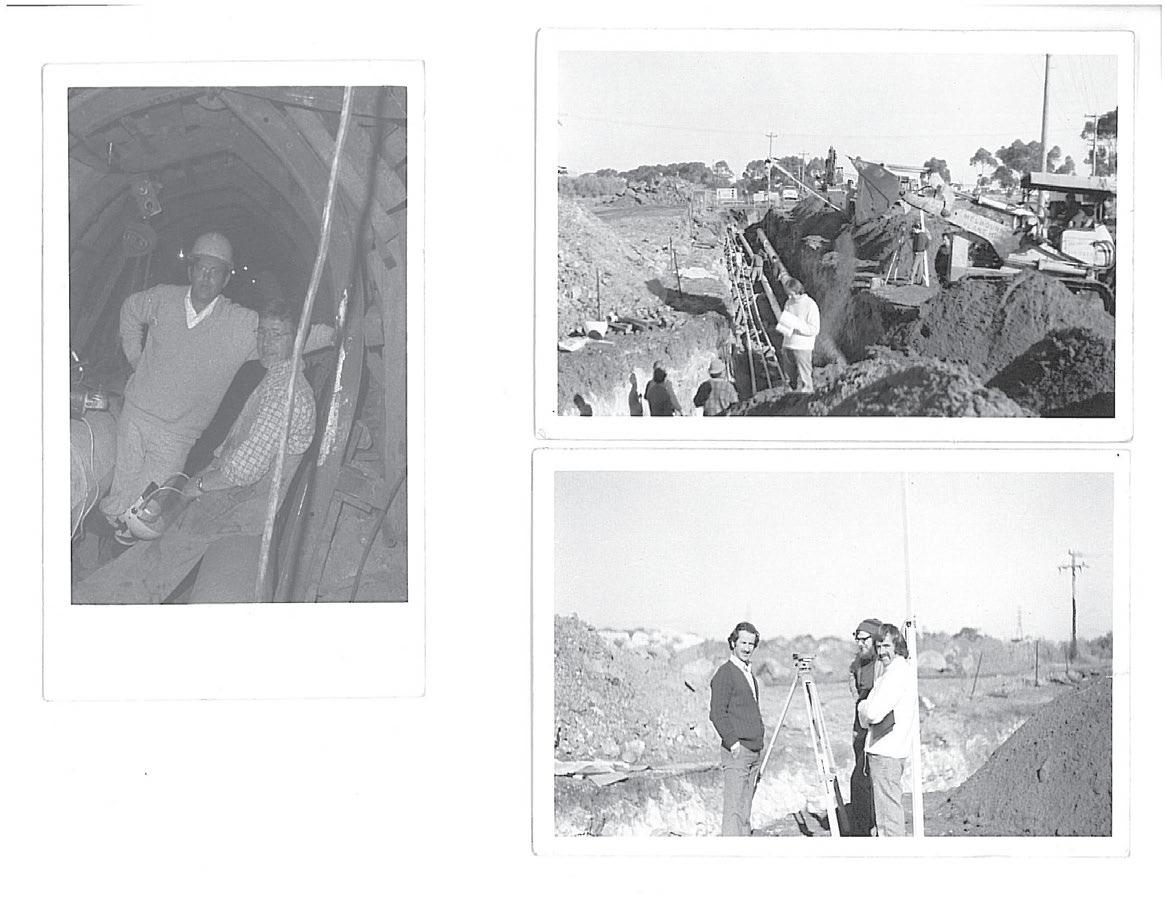

HDD upgrade 8-inch in Brisbane.

NPPL1 with Ampol – HDD upgrade 8-inch in Brisbane.

take too long before the pair noticed a gap in the industry when it came to testing and commissioning. Backed by their years of culminative experience and a newfound drive, they established a plan to fill that space in the industry – and haven’t looked back since.

In charge of a multitude of crucial responsibilities, Farrant and Brannelly split the main duties of the company. Describing their respective responsibilities, Farrant explains that while Brannelly tends to take on many of the computer and IT related tasks, he prefers to manage things on site. This tends to include organising tools, equipment, the scope of works, the execution of projects and overall resources for a job.

After six years, the two now complement each other like a well-oiled machine, but that’s not to say there hasn’t been challenges along the way.

“Being the new kid on the block was challenging in a lot of ways,” says Farrant.

“While this industry is great, it can be full of places that just do what they’ve always done. Trying to change the way that people think towards a more efficient and effective way of testing, cleaning, and commissioning has been a challenge that through time, hard work and patience we’ve been able to overcome.”

“We have had a lot of support from key industry people to assist us with this. Bringing Enduro Pipeline Services to Australia has been a prime example of this.”

“Enduro were a company we had a keen interest in for a long time before we approached them. We had been doing a lot of research in the different tools available and the technology they can provide. To us it was an easy decision because they have the best tools in the industry, globally, and now we can bring those tools to Australia and the Australian market.”

Conference event in Houston and approach them to become their global partner. Describing the event to The Australian Pipeliner, Farrant admits that the team was nervous; having been working towards solidifying the partnership for several years.

“Their reception was incredible, and they were open to discussing the idea,” Farrant says.

“We’ve been working with them now for four years and look forward to a very exciting future with several things to come in the pipeline.”

Being awarded the Australian Pipelines and Gas Association (APGA) Young Achievement Award in 2021 was yet another moment of recognition that solidified the work he’s put in, not just at Pipe Tek, but in the industry as a whole.

The Young Achievement Award, which was

work and innovative contributions to the industry.

“Being recognised by winning the award felt incredible,” he says.

“To start from filling sandbags to being recognised by all my industry peers for being an integral part of the industry has given me so much to be proud of, and such a sense of achievement. It proves that people can see what we are doing and trying to achieve here at Pipe Tek and the hard work we are completing everyday means something.”

“This industry is incredibly hard to break into and to grow to what we are now from nothing has not been easy on us or our families, and we wouldn’t be here without their support.”

Coming into and rising through the ranks of such a tight-knit and challenging industry has been a daunting task, but over his career Farrant has taken the obstacles to success in his stride. Ensuring that the team around he and Brannelly have always shared the same passion for working and getting jobs done safely, Farrant says helped overcome almost every hurdle he has come across.

Speaking on the importance of getting younger people involved with the industry, he says young people bring a level of enthusiasm and energy to the business that is wholly contagious.

“We’re lucky enough as an industry to have some of the most knowledgeable pipeliners in the world,” he says.

“It’s incredibly important that their experiences and knowledge are passed onto the next generation of young pipeliners to ensure the continued sustenance of the industry into the future. We wouldn’t be here without them.”

www.pipetek.com.au

33 The Australian Pipeliner | November 2022 PIPELINE PEOPLE

the Pipeline Pigging & Integrity Management

Mardi to Warnervale HDD with Spiecapag – the first lot of drinking water after the pipe was commissioned.

Pipe Tek on 8-inch pipeline for Santos.

Corrosion Control Engineering and the outstanding contribution John Kalis has made to the Australian pipeline industry

As a principal engineer with a degree in chemical engineering, and as an ACA corrosion technologist, John Kalis has over 45 years’ experience in corrosion and cathodic protection engineering, primarily in oil and gas pipelines.

From as early as the 1930’s, cathodic protection (CP) has been widely used around the world to protect buried or immersed steel pipelines from the potentially devastating effects of corrosion. As the pipeline industry developed in Australia throughout the 1960’s, so did the cathodic protection industry.

At the forefront of this movement was John Kalis, one of the true pioneers of the CP industry.

Kalis has dedicated many years of committed service to the pipeline industry. His corrosion engineering expertise has influenced and bettered Australia’s outstanding corrosion related pipeline safety record.

He has been involved in the corrosion industry for over 45 years, beginning his journey as a young graduate chemical engineer with Wilson Walton International in 1977. Following which he joined Corrpro before finally finding his place as Chief Executive Officer (CEO) at Corrosion Control Engineering (CCE). Kalis has been at the helm of CCE and has dedicated himself to the company for the past 20 years.

Nevertheless, the years with Wilson Walton would prove to be crucial in Kalis’ development

as a corrosion engineer, he would gain experience on several large and renown projects such as the Sydney to Moomba and Dampier Bunbury Pipeline.

One of Kalis’ most memorable projects was as a young, city born and bred, 25 year-old engineer in charge of the installation of the impressed current CP systems on the Moomba to Sydney Pipeline. A massive job, Kalis had initially been tapped to perform the initial survey of the pipeline and had not expected to be placed in charge of such a comprehensive and expansive job.

“Initially my task was to survey all the CP sites for the pipeline and perform soil resistivity tests so the company could perform the CP design work,” he says.

At the time, Kalis notes, he wasn’t slated to go out and perform the installation on-site; however, due to issues with team cohesion, Kalis was asked to step up into the role of leader.

“I didn’t think too much about it,” says Kalis. “I probably could’ve let myself be daunted by the size and needs of the project and what we were setting out to do, but I saw it instead as another challenge.”

Kalis had only been with the company for a year and a half by this stage and this was only his first real experience working in the field.

“To this day, being able to deliver such a large project on time and on budget and knowing that the systems have performed well over their life is definitely a highlight of my career.”

It’s clear that Kalis did more than just a good job on the Sydney to Moomba Pipeline project, because a year and a half after the completion of his work on the project he was promoted to the role of manager of Wilson Walton’s New South Wales division.