13 minute read

Return to spender

Following a major investment in his business, Mick Caruso made the welcome discovery that the return on investment came with far more than just a shiny new workshop.

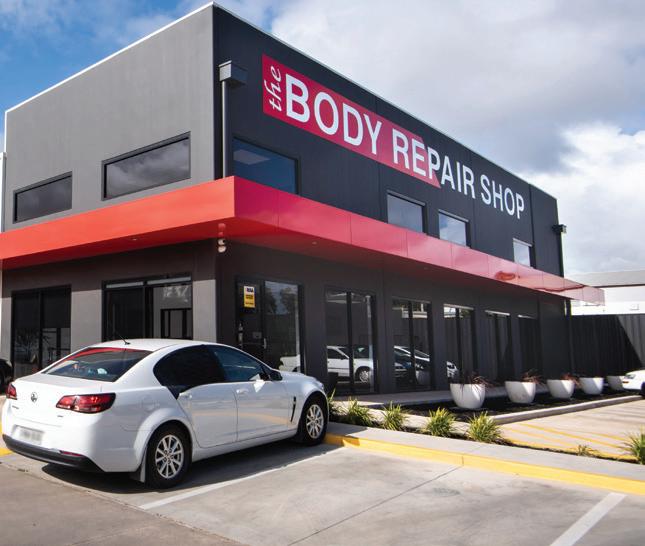

In the year 2000, when Mick Caruso and his wife Sandy established The Body Repair Shop, it was a two-man operation in a tiny 360m² workshop doing mostly fleet work. As time went on and the business began doing insurance work, Mick estimates that it grew at an impressive rate of up to 30 percent per year. However, by around 2017, he felt it had reached its limits in its original workspace.

“We had about 2500m² of space but it was spread across three different buildings. It got to the point where we had done everything we could with the old workshops and I was ‘over it’, so we built an additional brand new building on the same site and did it exactly the way I think it should be done. If we had not made the investment I probably would not still be in the business. The biggest benefit is time for myself. In the past I was working ‘in’ the business during the day and trying to work ‘on’ the business after hours. Now I can do things I enjoy doing on weekends and even take days off, if I want to.”

Situated in the Adelaide suburb of Salisbury Plains, the overall 20,000m² property is owned by the Caruso Family Trust and Mick reckons this is a win / win because the trust gets the best possible tenant – The Body Repair Shop! A large proportion of the increased rental cost has also been offset by installing a huge 100kW solar electric system on the roof. Mick project-managed the construction of the business’ spectacular new premises with a design that incorporated a lot of experience, along with research from a variety of sources.

“The most important factor was flow. The old workshop had a type of flow but there were always little roadblocks and hinderances from using existing buildings. I got lots of different input for the new layout. For example, from going to PPG MVP Business Solutions seminars over the years where I listened closely and picked up lots of pointers. Firstly, the flow in the new workshop is exactly what you dream of. Jobs do a full loop, the floor is fully marked out for vehicles, equipment, etc. and each technician has their own space and they are generous spaces. As each vehicle enters it’s filmed from five different angles and there are over 40 cameras throughout the premises. It lets us follow the car from the time it arrives, right through the repair process, to the point where the customer picks it up.”

The light filled reception area is both welcoming and efficient at dealing with customers, while four spacious, undercover

quoting bays make that task quicker and easier. Tall panel-lift doors lead inside, where the paint area features four prep bays and two larger (3m high by 8.5m long) Lowbake spray booths. Although designed to cater to the high roofed vans that come through, Mick says they also benefit regular jobs because it’s possible to paint a vehicle and all its parts at the one time. One booth is also fitted with Lowbake’s RADS – Rapid Air Drying System.

“RADS is an extra cost but it works really well. The PPG Envirobase waterborne system we use dries quickly on its own but RADS takes it to the next level when we are doing a larger job or want to push something through quickly. I am a painter by trade and when PPG first demonstrated Envirobase it made perfect sense. Being affiliated with PPG is not just about products. For example, our Territory Manager, Rob (Allevi), not only helps us with the latest and best processes, he also monitors the guys to make sure they are following the correct steps. It takes the load off me and I think any large shop today needs that sort of close affiliation.”

As part of his long term partnership with PPG, Mick also works with MVP Business Solutions specialist, Michael Green, who has supported the implementation of 5S and Lean methodologies. Although it was expected, the new workshop’s immediate productivity gains actually caught the team by surprise, according to Mick.

“In late 2018, we literally closed for Christmas in the old building and, two

Below: Mick and Sandy Caruso

Return to spender

weeks later, started back in the new workshop. To settle in we cut the workload by 10 percent but by early on the first Thursday, the boys had finished everything – it was that much of an improvement! Currently, there are 25 staff and they enjoy the new workshop, too. It’s spacious, airconditioned and well organised so it’s a pleasure to work in.”

While the new building spans 2200m², it has been supplemented by one of the existing 1260m² workshops. This combined floorspace of almost 3500m² fits nicely with the triage system of allocating jobs.

“When we assess each job that comes in, it’s rated on a scale from a ‘bar scrape’, to a small hit and a medium hit, through to a large, heavy hit, and it’s booked in accordingly. The new building can deal with any type of job but, predominantly, we do anything up to medium jobs. The main building of the old workshop is still running and it’s used for larger hits. It made sense because it’s a ready to go workshop

SHOP

FACTS

The Body Repair Shop

Owners: Mick and Sandy Caruso Staff: 25 PPG Product: Envirobase High Performance Territory Manager: Rob Allevi

with benches, prep bays and two booths. This system gives us big savings because big jobs and small jobs don’t mix. For example, a bar scrape can be fast tracked without potentially being held up by a large job which moves around the workshop more slowly and holds up the booth for longer.” These days, The Body Repair Shop is a real family affair encompassing, Mick and Sandy, along with their three

grown up children who have their own careers but get involved in their spare time. For example, their son, Raffaele, has helped make adjustments to the management structure, Mick explains.

“Raff pointed out that I micro manage to the max. I know I do but it’s a hard lesson to learn. In the past, I found I would be bombarded with questions that I think staff should know the answers to. My aim is to make sure the place can run without me by putting a management structure in place that allows staff to manage themselves. Every person in the workshop also needs to know there is a pathway for their career. I have lads who have worked for me for over 10 years and they have now progressed up into management. They know the way I think and the heartbeat of this place and, over the past couple of years, I have noticed how they have stepped up and made a real difference.”

After years of putting in long hours running his business, with little time off, Mick admits he was feeling burned out. However, the opportunities created by the new facility have given the 55-year-old a new outlook on his own career.

“At the moment, I am content that the next five years or so are pretty much set in place. After that, we will see. Seeing this place develop and now work smoothly is very rewarding. It makes it a real pleasure whenever I look out of my office window.” R

Star training opportunities

Mercedes-Benz invited PPG personnel from around the globe to a special training program in order to reinforce their skills as Mercedes-Benz Qualified Paint Specialists.

From the new vehicles that roll off its global production lines, through to a lifetime of use on the roads, Mercedes-Benz is a company absolutely committed to providing and maintaining a premium level of paintwork. In particular, it aims to ensure that its customers have easy access to high quality refinish solutions that will return their Mercedes-Benz to the very best pre-accident condition, should a mishap occur. Given PPG’s close partnership with Mercedes-Benz at the OEM level, where it supplies a range of coatings technologies to Mercedes-Benz manufacturing facilities across the world, it’s no surprise that PPG was also invited to take part in the prestige marque’s latest refinish qualification program. John Hristias (PPG Business Support Manager Asia / Pacific) was one of 15 PPG technical staff who assembled at the stateof-the-art PPG training facility, at Hilden, Germany, for the week-long course.

“Our PPG training team in Germany has worked closely with Mercedes-Benz personnel to put together a complete, global training program that is aimed at ensuring a consistent delivery of the Mercedes-Benz message right across the different world markets. It’s a very comprehensive program which meant we had a ‘full on’ week going through all the finer details. The course was broken down into four overall modules – a basic training module, a topcoat module, a special colour training module and a paint diagnosis training module. As we progressed through them, the modules covered everything from the Mercedes-Benz OE factory process, through to the EH&S criteria to follow. It touched on all the substrates that are used, the Mercedes-Benz standards and procedures, all the different two and three layer paint systems used on their vehicles, as well as the specialty matt finishes, Alubeam Silver, etc. Even though the PPG trainers are all very experienced, there were lots of handy tips we picked up, such as safety measures to take when dealing with the company’s current and future hybrid electric and full electric vehicles. I think we all really enjoyed the week working closely with the Mercedes-Benz trainer. The key factor is that, now we are Mercedes-Benz Qualified Paint Specialist, we have all returned to our PPG regional markets where we are busy passing this information onto our fellow PPG training staff. Best of all, this puts the entire PPG training network in the perfect position to spread the precision Mercedes-Benz message on to any refinish repairers who need it.” R

Colour and coverageFrom ancient man to today,

pigments have evolved to become complex and sophisticated pieces of chemistry that give us unprecedented coverage, colour and special effects.

Pigments versus dyes

The use of pigments follows the history of man. Employing pigment materials dug from the ground or produced from plants or animals, our distant ancestors created cave art which is still visible tens of thousands of years later. As paints got more sophisticated, so did pigments, says Kevin Woolerton (Refinish Marketing Director ANZ) who is a qualified paint chemist. The simplest way to explain the difference is that, despite being extremely similar in structure, a dye is soluble in the medium it’s used in – like dissolving sugar in water. In contrast, a pigment consists of tiny particles suspended in a matrix, such as a binder.

As a result, pigments are much more durable.

Natural to synthetic

Until towards the end of the 20th century most pigments were created from naturally occurring materials, often mined from the ground. For example, iron oxides have been used as pigments since ancient times. However, modern versions are man-made (essentially carefully made rust!) and there are four types: Red, Yellow, Transparent Red and Transparent Yellow. The transparent pigments have extremely small particle size and are used in metallics and other effect colours. The non-transparent reds and yellows have large particle sizes, are opaque, but bring a degree of dirtiness to a colour match.

Early pearls were made from a mineral call ‘muscovite’ which was dug from the ground. Thanks to the natural irregularity of the crystal structure, it produced the colour change you would expect from a pearl (or mica – they are the same thing). As modern, synthetic pearl technology has developed, it produces a much deeper and stronger flop, compared to muscovite. Indeed, pigments used in today’s automotive coatings are almost entirely synthetic (man‑made). Where natural, organic origins produce a random, inconsistent result, the move to synthetic pigments is all about consistency.

One important exception is titanium dioxide (TiO2) which is a naturally occurring ore that is still mined. Its major use is in solid colours where it imparts whiteness, as well as opacity due to its large particle size.

The synthetic age

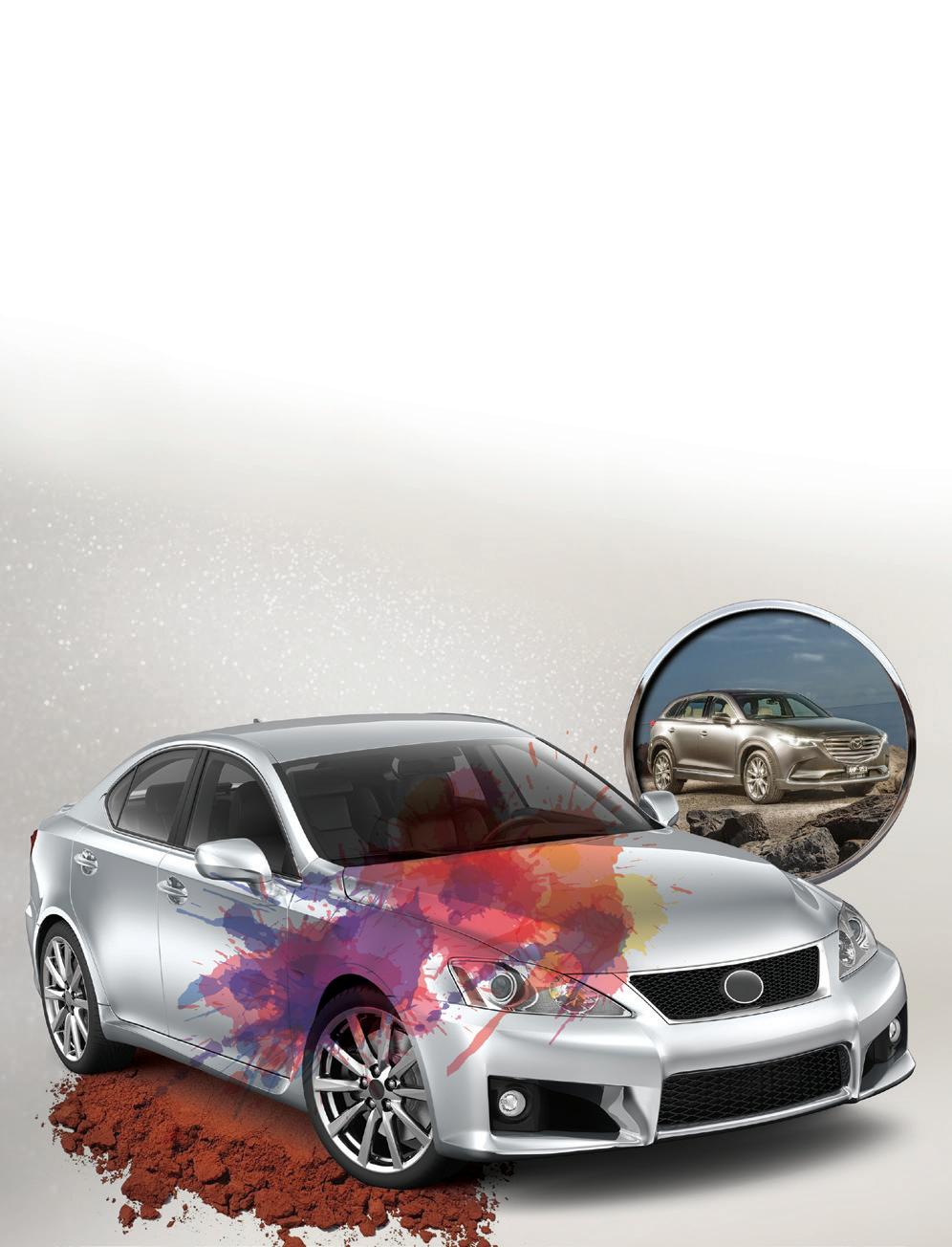

Virtually all modern automotive pigments are synthetic and, therefore, much more consistent. Chemical engineers start with a range of different substrates which are then treated in various ways to achieve a particular end result. For example, aluminium effect pigments are basically made by spraying pure aluminium to produce a very, very fine powder. In contrast to regular pigments, which produce colour by absorbing some wavelengths of light rather than others, aluminium pigments are full of tiny mirrors that reflect light. As a result, you get a brighter face and a dark flop. It’s interesting to note that aluminium pigments need to be treated differently for solvent-borne and waterborne automotive coatings. Allowing aluminium and water to mix produces oxidisation which creates gases so, for waterborne applications, the tiny particles get a special coating to prevent water getting to the aluminium. Pearls micas are different, again. They create colour through interference – it’s essentially the same effect you see on a fish scale, a pearl or a spill of petrol in a puddle of water. To achieve a strong colour change, these pigments use a smooth, flat substrate and coat it with an incredibly thin layer of highly reflective material.

Durability

When it comes to developing synthetic pigments, they are every bit as complex and difficult to make as a pharmaceutical product. We are talking about very complex chemical structures that are fine tuned for different applications. As a result, although there is a vast overall range of pigments available, the automotive coatings industry only uses a very narrow selection which offer sufficient durability to cope with constant exposure to road and weather conditions, as well as harsh UV. Achieving that durability means passing extensive and extreme testing and that brings complexity and cost. The good news is that modern pigment technology has virtually eradicated the durability issues seen with certain colours, such as reds, yellows and oranges.

Size counts

One big difference between solid colours and effect colours is pigment particle size. In basic terms, solid colours use larger sized particles, while effect colours feature tiny particles. The larger particles in solid colours are virtually spherical which effectively absorbs or scatters light to get the best opacity with no angle effect. It’s worth mentioning here that lesser opacity is

sometimes a good thing. With effect colours, it lets us achieve a bright, clean face colour – which larger particles would dull – and a dark flop when viewed on an angle. Some effects particles are so small they are almost nano in size and this produces transparent pigments. Using these highly transparent colours in combination with a strong colour changing effect pigment is responsible for some of the latest exotic colours, such as Mazda’s 46V Soul Red Crystal and 46G Machine Grey and Ford’s Ruby Red. R