4 minute read

News

Highlighting below the surfaceSATA’s exterior spray gun design is well-known for its incredibly high degree of craftsmanship and styling but the latest limited-edition model gives a glimpse into the precision engineering below the surface. Dubbed the SATAjet® X 5500 Bionic, it features colourful and highly detailed graphics that appear to peel back the surface to reveal the internal technology that makes a SATA gun so special. Beneath the special graphics, this is a fully functional spray gun with all the features of the current premium model so it can

Win, lose or draw, the annual PPG Colour Matching Competition is all about participation but, unfortunately, that can’t happen in 2020 due to the coronavirus pandemic. As a result, a special Facebook Group has been created to provide a pathway to the 2021 event. It’s open to previous competitors (regional, state or final level), along with trade instructors and be used every day or it makes a marvellous addition to a display collection. The SATAjet X 5500 Bionic is available in HVLP or RP technology and in DIGITAL® (with built-in air pressure gauge) or non-digital format. SATA special editions are available in strictly limited numbers and have a history of selling out very quickly so reserve yours now at your SATA distributor

Colour Matching Comp goes 24/7 on Facebook

to avoid disappointment. R spray-painting apprentices who wish to participate in future competitions. The Colour Matching Competition Facebook Group is already providing a handy platform to access colour theory and other technical information, as well as a forum to discuss a range of topics and link with PPG colour experts. Request to join by filling out the short questionnaire at www.facebook.com/ groups/PPGcolourmatching/. Register interest for the 2021 PPG Colour Matching Competition at www.ppgrefinish. com.au/Training/colour-matching-comp or contact your PPG Training Manager or Territory Manager. R

Curtain call for a local favourite

After almost three decades in action, the Cobra refinish system is being phased out. Unveiled via a series of spectacular launch events in 1991, Cobra took the market by storm. Initial estimates were that 150 collision repairers would convert in the first year but after three months over 700 had switched to Cobra! Three years of intensive research by the local development team at PPG’s Clayton headquarters really paid off. Not only was

Following the strong response to the SATAjet X 5500 Setup Guide poster, PPG training managers and technical staff have been at it again creating a handy setup guide for its little brother, the SATAminijet® 4400. Available now, the SATAminijet 4400 Setup Guide include comprehensive guidelines, suggestions and tips that take the guesswork out of the setup process. Designed to make life easier for paint technicians, the setup guide covers a range of Cobra an instant hit thanks to its colour capability, ease of use and quality, its flexibility has seen it go through a number of major upgrades to cope with the extraordinary changes in automotive coatings technology. However, modern, new generation refinish systems which have a more global reach, such as Deltron® GRS and Envirobase High Performance®, have bid a fond farewell.

R

Setup to perform

now overtaken Cobra and it’s time to popular PPG products, detailing the recommended fan, fluid and pressure settings for a variety of application situations. Ultimately, it’s about helping to consistently get the best from SATA’s versatile, compact spray gun. To get your own SATAminijet 4400 Setup Guide poster simply contact your PPG Territory Manager, your PPG Training Manager or calling PPG’s Customer Service Hotline 13 24 24 (Aust) or 0800 320 320 (NZ). R DRIVETHROUGH

with Paul Galea

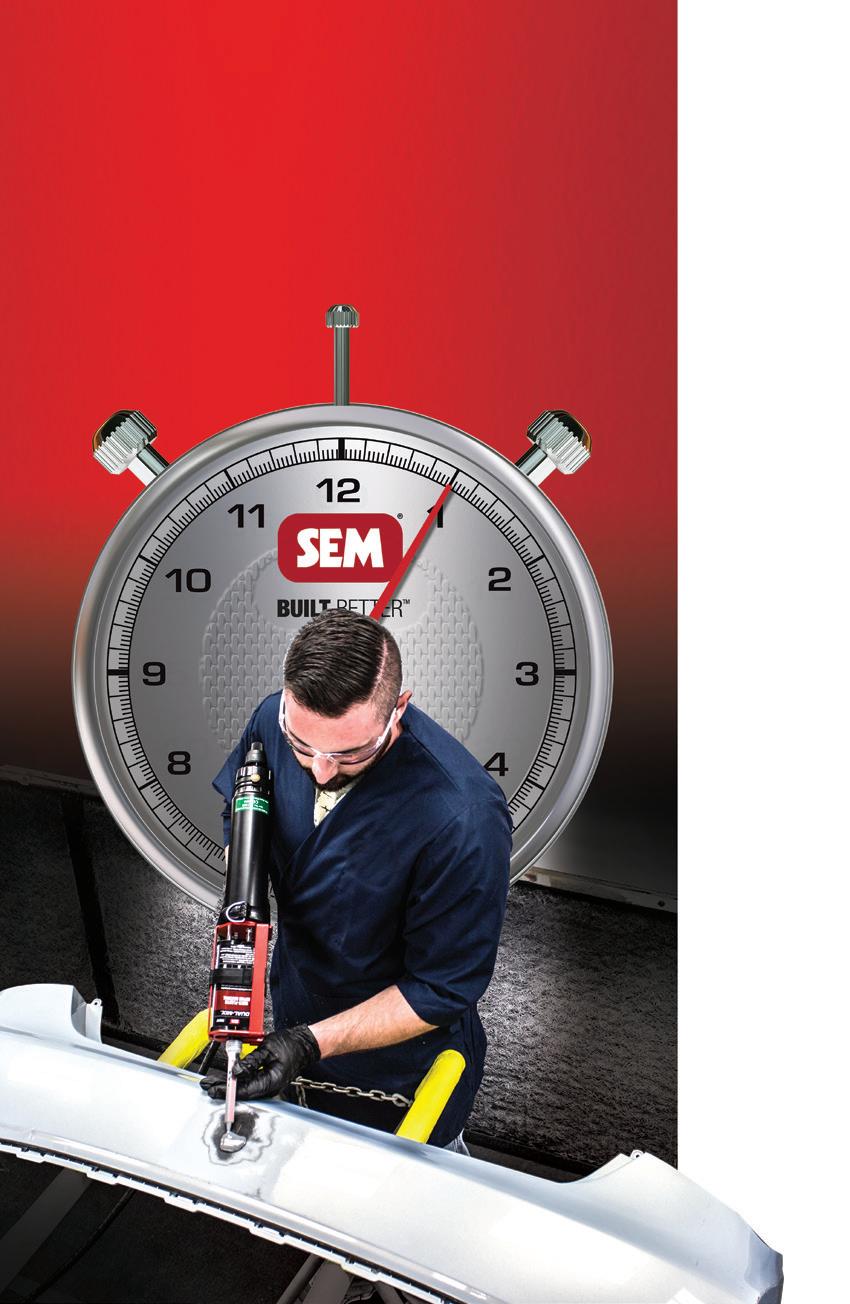

As I put pen to paper, Melbourne’s hard lockdown is coming to an end and the sense of relief is obvious. However, whilst the easing of restrictions can be almost instantaneous, the impact on the collision repair sector will take much longer to overcome. I used to believe the industry was isolated from economic factors – after all, nobody chooses to have an accident according to the economy. Who would have thought a virus could impact the collision business like nothing before? It sounds obvious now but how people move around (mobility) has a direct and swift impact on our industry. Indeed, we have seen repair volumes almost directly mimic the movement of vehicles on the roads. On a positive note, we are seeing vehicle movement recover significantly faster than the use of public transport. If I had to single out one article in this issue, it would be our local launch of SEM Products plastic repair solutions (page 6). As a result of this easy-to-use, two-pack, Dual-Mix™ technology we have already seen an uplift in collision centres wanting to target in-house repairs rather than subletting or replacing with a new part. As well as compensating for potentially lower repair volumes, there are many more benefits that may not be obvious at first glance. Admin time to manage the replacement part or subcontracted repair is almost completely eliminated, paint material usage is reduced, in some instances there is the opportunity to blend within the component, assembly time is reduced, as is the storage space required for new parts, waste dispose cost and all-important key-to-key cycle-time. What’s not to like! R