It’s that time of year again and trade show season is officially upon us. The annual AHR Expo was held this past January in Chicago, Illinois, CMPX is making its triumphant return at the end of March, and the MEET Show is back on in Moncton. You know what that means! New products to become familiar with and maybe a little extra training to boost your confidence working with the new technology.

Trade show season might just be my favourite time of year. Albeit, an exhausting time, there really isn’t any like it. There are times during the year when I start to feel a little lost at what is going on in the industry. These trade shows are such a great way for us to reconnect with our amazing readers and to actually see firsthand the technology that we write about. Getting to ask some pretty smart people questions about the products or initiatives currently underway in the industry is also an extremely beneficial part of these events.

This past AHR Expo was amazing. It was the first time I was able to attend the show in Chicago, which I had heard in the past was the best venue location for it. And it did not disappoint. During one of my meetings, I was walking around the show floor with someone who has been attending the show for well over a decade. I was sharing my thoughts on the attendance and he agreed that in his many

Facebook: @PlumbingandHVAC

LinkedIn: Plumbing + HVAC Magazine

years that he’s been attending the show, this year looked like one of the best attended shows he had ever been to. I’d say in the four shows that I have been to now that I would have to agree! I do feel sorry for the poor soul who tried to walk in front of me on my way to one of my meetings. I used to work downtown Toronto for a time, so I know how to maneuver through a crowd and I can’t stress enough when I say, we don’t appreciate a slow walker.

North of the border, CMPX and MEET will either be in full swing (some people might even be reading this column on the show floor of CMPX) or in full preparation mode.

I am excited to be able to catch some of the educational sessions and panel discussions at the show. We even have our booths, so if any of our lovely readers find themselves walking around the show, please make sure that you stop by our booth (CMPX: Booth #3; MEET: Booth #126). I’d love to have some conversations about the state of the industry and what are some topics that you’d like to learn a little bit more about. There is a lot going on in the industry and there is a lot that you need to stay up-to-date on. Check out our article on CSA B52 on page 20 to learn about what is going on in the world of refrigeration. The world of HVAC/R is changing. Do you feel ready?

X: @Plumbing_HVAC_

Instagram: plumbing_hvac_ YouTube: @plumbing-hvacmagazine

March/April 2024

Volume 34, Number 2

ISSN 1919-0395

Publisher

Mark Vreugdenhil

(289) 638-2133 ext.1

Cell: (416) 996-1031

mark@plumbingandhvac.ca

Editor

Leah Den Hartogh

(289) 638-2133 ext. 2

Cell: (289) 830-1217

leah@plumbingandhvac.ca

National Sales Manager

Chris Luttrell (289) 797-2138

Cell: (365) 662-4112 chris@plumbingandhvac.ca

Assistant Editor

Francesco Lo Presti (289) 638-2133 ext. 3 francesco@plumbingandhvac.ca

Contributing Writers

Glenn Mellors, Greg Scrivener, Michael Ridler, Ron Coleman

Design and Production

Tim Norton/Janet Popadiuk production@plumbingandhvac.ca

All articles and photos by Plumbing & HVAC staff unless noted.

PLUMBING & HVAC Magazine is published seven times annually by Marked Business Media Inc. and is written for individuals who purchase/ specify/approve the selection of plumbing, piping, hot water heating, fire protection, warm air heating, air conditioning, ventilation, refrigeration, controls and related systems and products throughout Canada.

Marked Business Media Inc.

286 King Street W, Unit 203, Oshawa, ON L1J 2J9

Tel: (289) 638-2133

Postmaster: Send all address changes and circulation inquiries to:

Plumbing & HVAC Magazine, 286 King Street W, Unit 203, Oshawa, Ontario, Canada L1J 2J9. Canadian Publications Mail Sales Product

Agreement No. 43029513. Postage paid at Toronto, ON.

Annual Subscription Canada: $40.00 plus applicable taxes, single copy

$5.00 plus applicable taxes. Annual Subscription United States: $60.00

U.S. Annual Subscription foreign: $90.00 U.S.

Copyright 2024. The contents of this magazine may not be reproduced in any manner without the prior written permission of the Publisher.

A member of:

• Canadian Institute of Plumbing & Heating

• Mechanical Contractors Association of Canada

• Ontario Plumbing Inspectors Association

• American Society of Heating Refrigerating & Air Conditioning Engineers

• Heating Refrigeration and Air Conditioning Institute of Canada

• Refrigeration Service Engineers Society of Canada

The 2024 CMPX is anticipating a larger turnout to its three-day tradeshow. In 2022, there was 9,000 people and over 500 exhibitors in attendance.

The Metro Toronto Convention Centre will open its doors again to the skilled trades industry as the CMPX show makes its return. Running from March 20 to 22 in the South Building, the tradeshow will offer industry professionals the opportunity to explore the latest products, attend educational sessions, and network.

The previous edition of the show, held in 2022, saw around 9,000 people and over 500 exhibitors.

“CMPX 2024 is our biggest, best and boldest show yet, with more hands-on exhibits, more real-world solutions and more groundbreaking products than ever before,” shared Joanna Woo, CMPX Show committee chair.

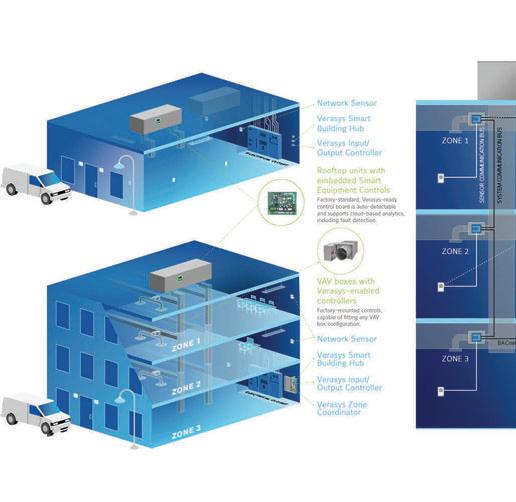

When attending the show, guests can access over 500 exhibitor booths showcasing the latest and best products in heating, cooling, refrigeration, ventilation, plumbing, indoor air quality, building automation & control, sustainability, software, tools & instruments, technology and more.

The New Product Showcase and Demo Stage offers attendees an interactive display of the newest equipment, tools and technology heading to market.

CMPX 2024 will also present its HVAC/R Skills Competition, where secondary and post-secondary students can compete and showcase their skills. The competition will last all three days, each featuring a different

theme. Day one will feature a heating systems gauntlet, day two features a refrigeration/ air conditioning showdown, and day three features a heating systems and refrigeration/ air conditioning challenge.

All competitions will offer hands-on practical challenges that allow the students to showcase their HVAC/R proficiency, whether with their hands or their ability to understand and follow wiring diagrams and manuals. Students will also be able to conduct mock interviews, giving them professional and realworld feedback.

Competitions will take place in two time slots, 7:30 a.m. to 12:00 p.m. and then 12:30 p.m. to 5:00 p.m. Each competition day will end with an award ceremony at the Heating, Refrigeration, and Air Conditioning Institute of Canada’s (HRAI) booth.

The show will host its Learning Forum, displaying educational programs. The Learning Forum will host over 50 sessions, the largest in the show’s history, according to HRAI. Sessions will cover topics such as the latest trends, the newest applications, and regulation updates.

Participants of the show will have their pick of sessions to attend. There will be 25 sessions available on the first day (9:00 a.m. to 5:00 p.m.), 27 sessions on the second day (9:00 a.m. to 6:00 p.m.), and 11 on the final day of the show (9:00 a.m. to 2:00 p.m.).

Some sessions that are available during the first day of the show include “Incorporating Hydronic Heat Pumps into Hybrid Designs” by John Goshulak, vice president of sales and marketing at Weil-McLain Canada, David Hughes, technical advisor at the Canadian Institute of Plumbing and Heating (CIPH), Jerry Leyte, president and general manager of Viessmann Manufacturing, Michael Ridler, general manager of Eden Energy Equipment, and Mike Miller, vice president of sales Canada for Taco Comfort Solutions, “CO2 Control Strategies” by Ryan McAndrews, manager of controls and energy solutions at Copeland, “Adopting the National Model Codes” by Rainier Bratsch-Blundell, plumbing professor at George Brown College, and Kevin Wong, Canadian codes manager at Uponor, “The Rise of Geothermal Heat Pump Systems” by Jeff Hunter, co-founder and president of Evolved Thermal Energy, and Tim Weber, CEO of Diverso Energy, and “Navigating the Challenges in Retrofitting Cold Climate AirSource Inverter Heat Pumps in Residential Applications” by Dany Caron HVAC technical advisor at Gree Canada.

Day two of the show will feature sessions such as the “Refrigerant Transition in Canada” by Emilie Boyer, applied hydronics product director at The Master Group, Michel Gauvin, head of ozone layer protection programs at ECCC, Sandy MacLeod, president and CEO of HRAI, Pushpindar Rana, product director of engineering and services for its HVAC division at Mitsubishi Electric, Martin Rego, director of product management at Rheem

Canada, Phil Simeon, policy director at the Technical Standards and Safety Authority (TSSA), and Devin J. Thomas, general manager of Refrigerant Services, “A2L Refrigerant Transition and New CSA B25 Mechanical Code” by Rana, “Reducing the Carbon Footprint of the Homes You Work In” by Gord Cooke, president of Building Knowledge Canada, “The ABCs of ECM Circulators: Navigating the Alphabet Soup of Variable Speed Circulators” by Dave Holdorf, product and application instructor at Taco Comfort Solutions, and “Gas Heat Pump Solutions for Cold Weather Climates” by Bo DeAngelo, service manager at Stone Mountain Technologies.

On the final day of the show, guests can attend sessions such as “Hydronic Balancing and the Effects of Low Delta-T” by Rick

CMPX 2024 is our biggest, best and boldest show yet, with more hands-on exhibits, more realworld solutions and more groundbreaking products than ever before.

Decarbonization Training course, run by Doug Cochrane, P.Eng., ASHRAE distinguished lecturer, will “demystify the primary sources of carbon emissions in buildings and explain the critical drivers for decarbonization.” The course will run on the show’s first day from 9:00 a.m. to 12:00 p.m. in Room 703. This paid course costs $179 for ASHRAE members and $236 for nonmembers.

The second training course, “The Heat Pump Advantage: Leverage Net Zero Goals to Drive Your Business,” will be run by Gord Cooke. This course will run on the show’s second day from 1:00 p.m. to 4:00 p.m. in Room 703 and will cover strategies and opportunities so businesses can adapt to the growing demands of low-carbon options from homeowners. This course will be free to CMPX attendees.

In addition, the show will also feature its Social Hub and Podcast Theatre, where guests can connect, swap stories, and give tips on the industry.

“CMPX offers HVAC/R and plumbing professionals unparalleled access to the people, products and perspectives that are shaping the future of indoor environment systems, water systems and refrigeration processes. If you work in the mechanical and plumbing industry, you can’t afford to miss CMPX 2024,” said Woo.

Mohammed, regional application consultant at Belimo, “Future Proofing Hydronic Systems” by Gilles Legault, hydronics manager at CB Supplies, “The State of Net Zero in Canada and its Implications to the Mechanical Industry” by Hughes, “CO2 Compression for Cold Storage” by Dennis Kozina, director of sales at Copeland Canada, and “HVAC/R’s Role in Decarbonizing Canada’s Largest Buildings” by Mark Hutchinson, vice president of green building programs and innovation at the Canada Green Building Council, Kit Milnes, vice president of sustainability and resilience at Kingsett Capital, and Dan Stranges, principal of engineering and design at Continual Energy.

There will also be two training courses during the show. The ASHRAE

As always, the show will host the CIPH Gala supporting Habitat for Humanity the day before the show. The reception will run from 6:00 p.m. to 11:00 p.m. at the Intercontinental Toronto Centre. Guests will be treated to a three-course dinner and entertainment. This year’s entertainment is David Merry, a Canadian comedic magician. CIPH has been in partnership with Habitat for Humanity since 1994, and during that period, members have raised more than $16 million in cash and products. Since 1972, the CMPX show has been jointly produced by HRAI and CIPH.

We’ve put together a round-up of some of the products that will be on the show floor at this year’s CMPX. Take a sneak peek at some of the products!

The NPF Advantage: The NPF heats water by burning the gas in a sealed combustion heat exchanger, completely isolated from the airstream. The heated water is then pumped through a hydronic heat exchanger that gently transfers the heat into the air. The fully enclosed Ultra-Low NOx premix burner provides extremely quiet operation, high efficiency of 97% AFUE, and allows for an industry-leading variable capacity that can modulate down to 15% for a next-level comfort experience.

Explore the new NPF at Navieninc.com.

NPF Horizontal NPF Upflow

NPF Horizontal NPF Upflow

Standalone or connected to a BACnet automation system, the HyperStat by 75F, Minneapolis, Minnesota, brings IAQ data forward by bundling eight sensors into a single, connected device. The HyperStat comes packed with four analog inputs, three analog outputs, and six relays that leverage softwaredefined control capabilities for all types of standalone multi-stage and modulating packaged HVAC equipment, from PTAC units to heat pumps and fan coils found in commercial buildings.

Yorkland www.yorkland.net

Navien, Vaughan, Ont, announces the release of its new high-efficiency NPF Hydro-Furnace, available in up-flow and horizontal configurations. It comes in 60,000 BTU/h and 100,000 BTU/H sizes that meet the requirements of SCAQMD rule 1111 for ultra-low NOx performance. The NPF uses Navien’s stainless steel heat exchanger to heat water in an isolated compartment out of the airstream. Heated water is circulated through a hydronic coil, which transfers the heat into the airstream. It can modulate down to 15 per cent to meet year-round comfort needs.

Navien www.navieninc.ca

Continental, Barrie, Ont, introduces a new line of ductless systems for heat pumps, heating down to -30 C and cooling up to 50 C. Available in one ton, 1.5 ton and two-ton capacities. The multi-zone series offers 28,000 or 36,000 BTU/h capacities, with two, three, or four indoor unit connections. All systems feature Wi-Fi, auto restart, defrost, louver memory, and intelligent humidity control for optimal performance. With an energy-efficient DC compressor, these Energy Star and NRCan-listed units qualify for federal and provincial rebate programs.

Continental www.continentalcomfort.com

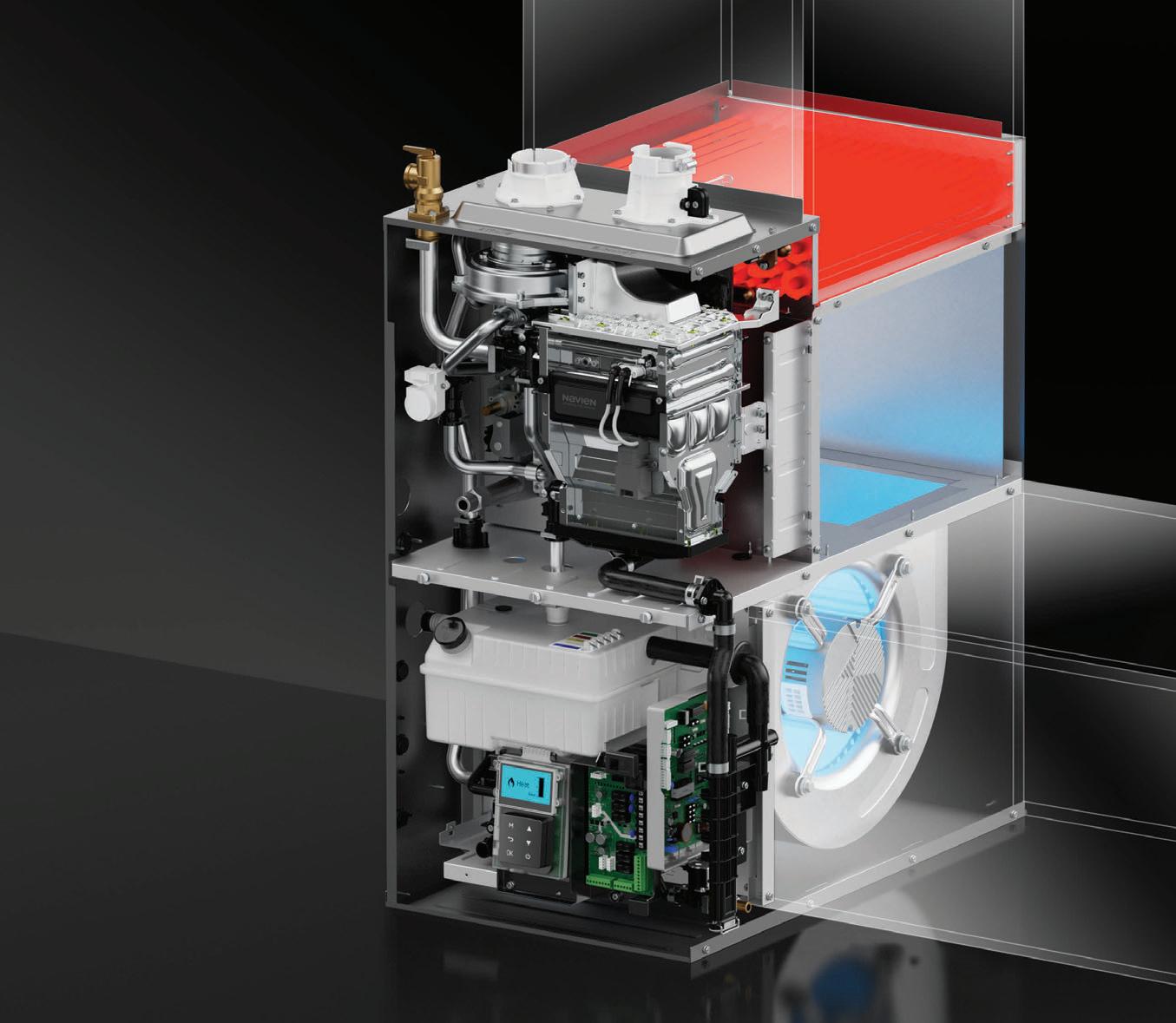

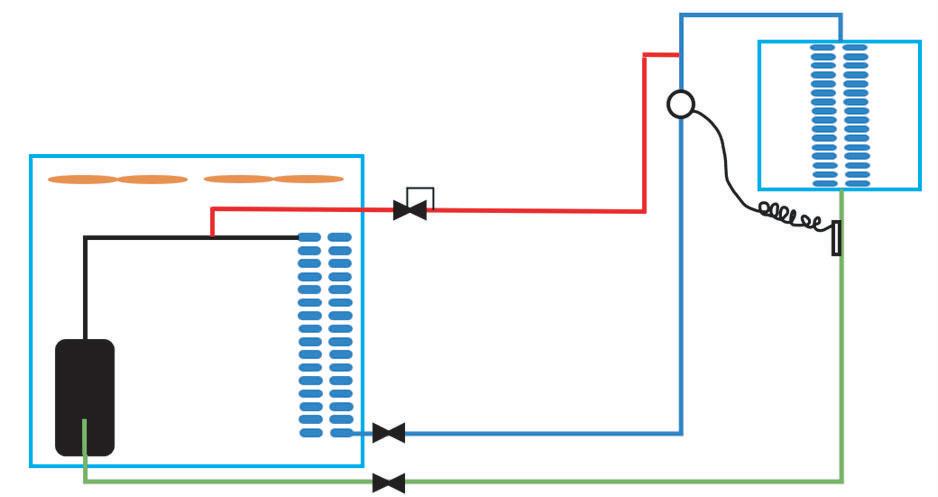

Viessmann, Waterloo, Ont, introduces its new total hydronic heat pump solution for heating, cooling, and domestic water.

The Vitocal 100-AW is a residential air-to-water heat pump system featuring an all-in-one kit consisting of an outdoor unit, an indoor unit, and a steel buffer tank (20 gallons). It comes in three different sizes – 1.5, 3.0, and 4.3 tons for cooling and 20.5, 34, and 58 MBH for hearing. The optional domestic indirect tanks come in three sizes. They are designed to pair with the Vitocal 100-AW, and the buffer tank can be physically mounted on top of the domestic tank to save space.

Viessmann www.viessmann.ca

Stone Mountain Technologies, Piney Flats, Tennessee, announces the introduction of its Anesi branded heating products for residential and commercial customers into the North American market, starting February 2024. Anesi gas heat pumps are air-to-water heat pumps and use natural gas, propane, or renewable gas as its primary fuel source. The Anesi gas heat pump and all refrigerants, combustion, processes, and venting are all located outside. Only a warm water/food-grade glycol mixture enters the home through standard PEX or copper piping.

Stone Mountain Technologies

www.StoneMountainTechnologies.com

Aquatherm, Lindon, Utah, announces its Aquatherm blue, a new standard in commercial and industrial piping systems. Made from proprietary polypropylene resin, Aquatherm blue is ideal for pressure piping heating and cooling systems in commercial and high-rise residential buildings, schools and universities, data centers, hotels, hospitals and government buildings, as well as process cooling systems in industrial and manufacturing plants. Available sizes from 1/2-in to 24-in, Aquatherm blue can handle any size commercial heating and cooling.

Aquatherm www.aquatherm.com

Taco Comfort Solutions, Milton, Ont, announces its Zone Sentry zone valve. It features a bidirectional ball valve design with quick release powerhead, and a visual flw indicator. The Zone Sentry is available with press fittings and multi-voltage powerhead. It provides on-off, normally open or normally closed control in closed hydronic systems. The valves can be used in a variety of heating and condensing cooling applications, primarily designed for use with baseboards, fan coils, radiators, convectors, air handlers, heat pumps, and radiant applications. It features 12 valves on one 40VA transformer and a push button actuator replacement. Taco Comfort Solutions u www.tacocomfort.com

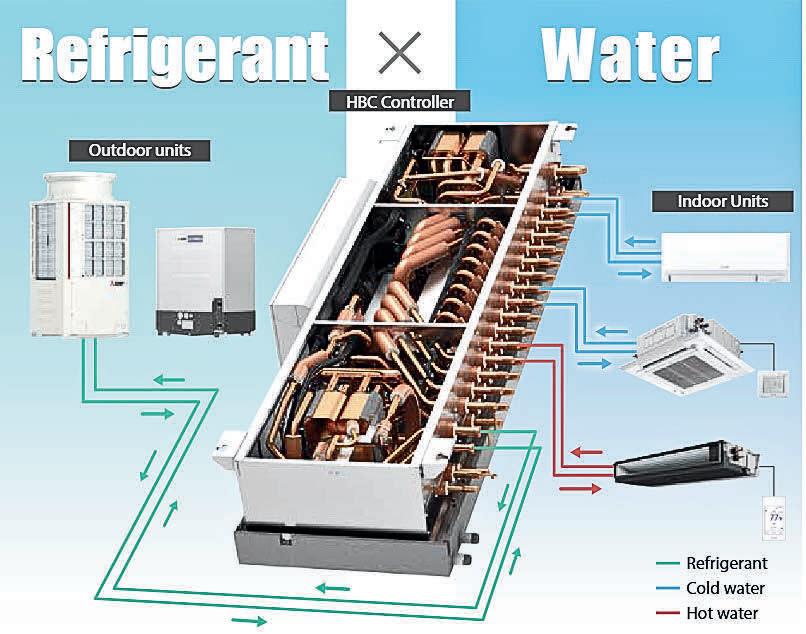

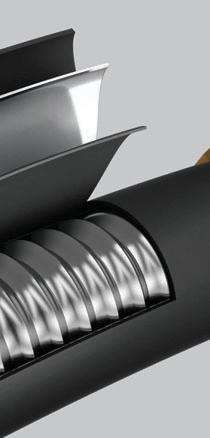

Mitsubishi Electric, Markham, Ont, announces the launch of its Hybrid Heating and Central Cooling system for residential applications. This new Mitsubishi Electric system connects with any thermostatically controlled furnace and is available in capacities from 18,000 to 42,000 BTU. The Hybrid System allows for homeowners with a furnace to still utilize an electric heat pump and switch over to the furnace during more frigid conditions. The switchover automatically occurs when the temperature outside drops below a specifid point, which is pre-set during installation. The Hybrid System comes in standard heat pump or Hyper Heat, Mitsubishi Electric’s cold climate heat pumps. It features smaller copper tube diameter with a grooved design to provide efficit heat transfer. Flare piping connections are required, with no need for brazing.

Mitsubishi Electric u www.mitsubishielectric.ca

Proflo, Burlington, Ont, introduces its Calhoun toilets, designed for high performance. It features a three-inch flush valve, 1.28 GPF HET rating, and a 1,000 MaP performance. Quickly install the toilet with only a two-bolt tank to bowl installation. Bowl heights are available in 15-1/2-inches to 17-inches. It is also available with a chrome trip level.

Proflo u www.proflocanada.ca

AO Smith, Fergus, Ont, announces the release of its new Adapt premium condensing gas tankless water heater. It features its X3 scale prevention technology. Available in 160,000, 180,000, and 199,000 BTU/h inputs, these Energy Star certifid water heaters deliver reliable on-demand hot water. Flexible venting options and integrated recirculation pumps make these models ideal for any residential application.

AO Smith u www.hotwatercanada.ca

FGI Industries, East Hanover, New Jersey, launches its new Flush Guard. Leveraging a patented anti-overflow drain system, Flush Guard anti-overflw toilets feature three holes to allow water to escape through a secondary drain. The anti-overflw drain is self-cleaning with every flush. Both primary and secondary drains empty into a standard waste pipe and utilize standard fittings. When used as a replacement, the Flush Guard toilet completely covers the area of the old toilet, any marks or tile discolouration are hidden.

FGI u www.FlushGuardToilets.com

Napoleon, Barrie, Ont, announces the release of its low velocity hydronic air handler unit, which enables the integration of two primary mechanical functions – space heating and domestic hot water – in a residential setting. When connected to a wall-hung tankless water heater or a combi boiler, it eliminates the need for a storage water tank and large gas furnaces, thereby freeing up usable space. It can be incorporated with Napoleon’s cold climate air-source heat pump as a dual-fuel hybrid heating option.

Napoleon u www.napoleon.com

LG.ca

* LG UNVEILS CUTTING-EDGE WATER SOLUTIONS ENABLED BY ADVANCED HEAT PUMP TECHNOLOGY. https://www.prnewswire.com/news-releases/lg-unveils-cutting-edgewater-solutions-enabled-by-advanced-heat-pump-technology-302040331.html

The annual AHR Expo has come and gone for another calendar year. North America’s largest HVAC/R trade show was packed with new technology and plenty of opportunities to sit in on educational seminars or network with fellow industry experts.

“The industry showed up for business in Chicago,” said Mark Stevens, show manager. “Throughout the year we’ve followed discussions regarding regulation rollouts, decarbonization trends and various other tracks about the way we conduct business as an industry. It was evident in the halls that the professionals in attendance are primed to create solutions and drive business forward”

Some of the main themes from this year ’ s show include decarbonization, energy efficiency, lower global warming potential

(GWP) refrigerants, and heat pumps. There were a lot more new air-to-water heat pumps on the show floor at this year’s show compared to previous years.

Attendance was up from previous years, with a total of 48,034 attendees at the show looking to interact with the 1,875 exhibitors spread across the North and South halls.

The Podcast Pavilion was a hit of the show, which hosted 20 podcasters covering the latest topics. Each podcast was recorded and will be released by the individual podcaster in the coming weeks.

“The network transformation is resulting in incredible visibility and partnership for professionals,” said Nicole Bush, director of marketing for the show. “There is a true line of two-way communication

between the professionals in the field and the manufacturers creating products and technology. Having an in-person forum like AHR Expo to strengthen the social relationships formed online is proving to be immensely beneficial to our industry.”

The 2024 educational schedule highlighted topics within the industry with the “goal of addressing pain points, opportunities and applications to increase efficiencies, business, and relationships,” reports AHR. At the 2024 show, there was a total of 120 free sessions, 153 new product presentations in the New Product Theatres, and seven panels in the AHR panel series.

In the “2024 State of the Industry” panel, the speakers highlighted decarbonization, including gas bans, grid capacity, heat pumps, and dual-fuel options. In addition, the panel focused on building automation and AI, refrigerant updates, and workforce development.

Other well-attended sessions included topics featuring heat pumps, business strategy, emotional intelligence adeptness, building automation, controls and AI, social media and industry growth, A2Ls, and codes and standards.

In 2025, the AHR Expo will be heading to warm and sunny Orlando, Florida, which will be an appreciated switch up from this year’s chilly and windy Chicago weather. The next show will run Feb. 10 to 12 at the Orange County Convention Center. Hotel blocks are expected to open for attendees in late spring and registration will go live early summer.

“Each year, we come away from the show withvigourforwhattheindustryhasinstore,” shares Stevens. “We are honoured to continue to provide the best all-industry meeting place and forum to learn, discuss, prepare and calibrate goals for the future of HVAC/R. We hope to see everyone in Orlando.”

At the 2024 AHR Expo, the Plumbing & HVAC team made its way around the show, shooting our Walk n ’ Talk video series, highlighting some of the new innovations making its way to the North Americanmarket.In addition, we met with manufacturers to discuss the latest trends and get our hands on some of the newest products. Take a look at some of the highlights.

Franklin Electric, Fort Wayne, Indiana, expands its line of condensate pumps by introducing the VCMA-20-PRO series. The vertical-type pump measures 6.5 inches by 10.2 inches by 4.8 inches and features a 3/8 inch O.D. barbed with a 1/4-turn quick-release locking discharge adapter plus a built-in check valve. The unit also features three 1-1/8 inch diameter inlet openings, allowing the pump to be used with multiple types of equipment, including air conditioners and furnace systems. Franklin Electric www.franklin-electric.com

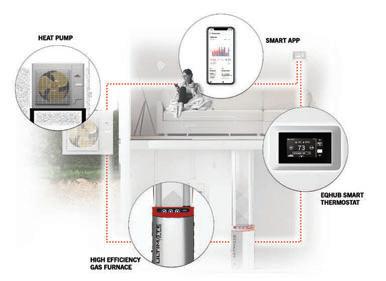

Napoleon, Barrie, Ont, debuts its EQHUB smart thermostat, which can be installed with a dual-fuel hybrid heating solution. The system cools and heats at 100 per cent efficiency up to 46 C/115 F and down to -20 C/-5 F in select configurations. Users can also connect humidifiers and dehumidifiers via the EQHub for operation with a furnace or heat pump to regulate the indoor environment.

Napoleon www.napoleon.com

Fujitsu, Pine Brook, New Jersey, announces the development of ducted and ductless residential, light-commercial, and applied products utilizing R-32 refrigerant. These products will be available in North America under the regulatory and compliance timelines. The installation process and necessary tools used for R-32 are very similar to R-410A.

Fujitsu www.fujitsu.com

Bell and Gossett, Chicago, Illinois, introduces its new line of smart pump systems. The hydrovar X-enabled products feature a common interface and drive platform for easy commissioning and installation. The pump plus smart motor combinations are launched with Bell and Gossett’s e1510 end-suction pump, e-80 vertical in-line pump, and Technoforce e-HV packaged booster system.

Bell and Gossett www.xylem.com

Midea, Markham, Ont, debuts its new Evox inverter heat pump and air handler system to market. The inverter heat pump is available in 1.5 to 5 ton models and features a low ambient heat output of 100 per cent at -4 F with a COP up to two. The air handler features an algorithm that measures static pressure issues such as dirty filters and kinks in ducts. The air handler is compatible with both 24V and 485 communication modes.

Midea www.mideaevox.com

Nibco, Elkhart, Indiana, expands its line of carbon steel fittings to feature more press options for plumbing, mechanical, fuel, and gas carbon steel pipe applications. The BenchPress and BenchPressG fittings are available in 1/2-to-two-inch sizes and require no threading equipment and lubricants while maintaining joint integrity and professional appearance.

Nibco www.nibco.com

Taco Comfort Solutions, Milton, Ont, offers customers its U-tube style shell-and-tube, steam-to-liquid or liquid-to-liquid heat exchangers. The heat exchangers are available in four- to 30-inch diameters and have a wide range of materials to fit various applications. The heat exchangers are NSF/ANSI 372 certified and provide typical working pressures/temperatures of 150 PSI and 375 F.

Taco Comfort Solutions www.tacocomfort.com

By Francesco Lo Presti

By Francesco Lo Presti

The plumbing and HVAC industry is going through changes. If you’ve been paying extra attention, you might have seen that there has been an increasing number of companies that are being acquired.

More prominent manufacturers or wholesalers typically acquire smaller or local companies to add to their product offerings. Just this past year, the industry has seen Carrier acquiring Viessmann, Oatey acquiring Lansas B.V, and GF acquiring Uponor, to name a few.

However, this surplus of change has also been finding its way into those with their hands on the tool. “Private Equity Groups (PEGs) generally manage money for

insurance funds, pension funds, charitable trusts, and sophisticated investment groups. They have money to invest, and plumbing and HVAC companies are the new target,” explains Mark Borkowski of Mercantile Mergers & Acquisitions Corp.

Traditionally, the private equity market had been restricted to acquiring or investing in larger companies, but “PEGs are now becoming attracted to fragmented business segments with lots of little players, with stable cashflows that are recession-proof and have opportunities for operational improvements. Plumbing and HVAC checks those boxes,” said Victor Hyman, executive director at ClimateCare.

Why are plumbing and HVAC companies

viewed as great investments? Well, for one, the skilled trades sector is filled with information and, “Acquiring plumbing and HVAC companies allows for PEGs to gain access to emerging technologies and energyefficient solutions,” adds Borkowski.

PEGs see the industry as an opportunity to expand and grow. “The industry is comprised of a lot of small and medium-sized businesses that are owned independently. But PEGs see that as an opportunity to consolidate those businesses and create larger, more efficient entities,” adds Borkowski.

While there are financial and technological benefits to acquiring plumbing and HVAC companies, the simple fact is that the sector is seen as stable and resilient. “There is always a need for these services, which is attractive to PEGs. There is a lack of skilled workers, and it’s hard to find new workers in this industry, so acquiring current workplaces with these skilled workers is seen as a win for PEGs,” said Borkowski.

So, we’ve examined why the sector is seen as an opportunity. Now let’s flip the question and ask, what is the benefit of companies in our sector being acquired by PEGs? For starters, “PEGs offer flexibility as a liquidity source which gives entrepreneurs the ability to take some cash off the table, recapitalize their company, or simply sell and move on,” explains Borkowski.

The financial backing from PEGs also allows companies in our industry to, “Fund growth initiatives like expanding service

Continued on page “18”

Continued from page “16”

areas, investing in new technologies, or pursuing acquisitions of complementary businesses,” said Borkowski.

PEG acquisitions can also contribute positively to the growth of a business by, “Creating a stronger sales culture, releasing employees who don’t buy into the new messaging (often at the previous owner’s unexpected expense), and getting out of unprofitable segments,” explains Hyman.

Additionally, Borkowski adds how private equity firms bring in management resources that can help companies become more efficient and leaner. This can be crucial for business owners who are potentially looking at the next step in their life.

However, there are considerations that industry business owners should keep in mind. The first is that these PEG groups are primarily interested in valuation arbitrage. “PEGs want to buy companies at a valuation X and sell them for two to three times that in three to five years,” said Hyman. “They do this by packaging the companies together, improving efficiencies and reducing costs, which usually involves the consolidation of the backroom operations of many small companies, resulting in the loss of local decision-making and autonomy.”

In the last two issues, we've discussed succession planning from a few different angles; one was about the difficulties that can come with it, and the other focused on alternative options. PEGs are another approach to succession planning.“There are quite a few business owners that are older and looking for a way out, and a lot of people don’t know how to get out,” explains Borkowski. “Many people don’t know how to go about selling their business and will enlist the help of real estate agents. This isn’t real estate. These are highly sophisticated deals requiring people with experience in this field.”

If you are a business owner looking to

sell your business, there are a few things to keep in mind. To start, a seller needs to understand where and what their position is. As Hyman explains, “Many small business owners don’t plan for the future because they are too busy working in their business. One day, they get a knock on the door from a PEG waving a big cheque, sign an NDA and start a process without stopping to ask if it is really what they want.”

For an owner who is ready or interested in exploring this possibility further, the process will start with meeting someone to evaluate the company. “In this evaluation, there will be a normalization of income, which is a very

I encourage all residential plumbing and HVAC contractors to take the time to think about what they want for their business beyond the dollars.

extensive company audit. Once the evaluation is completed, the owner is presented with the value of their business, and what a deal could look like, explains Borkowski.

Another thing to keep in mind is the type of deal that is being made. “Most, if not all, of the transactions in plumbing and HVAC companies involve the current owner staying for some time. In most cases, the acquiring company will require the owner to keep a 10 to 20 per cent equity ownership in the business,” adds Borkowski.

The reason for this is so the acquiring company can ensure a positive transition period within the company and, “In these cases, as the company hopefully gets new capital and growth, the owner gets a second bite and an increase in value,” said Borkowski.

Of course, with any transaction, there are potential risks. “One thing is that a lot of plumbing and HVAC owners have been sucked into selling the assets of their companies and paying exorbitant amounts of tax. There are deals on the table where PEGs will offer a premium to the business owner. They’ll buy 100 per cent of the company but offer shares in the company’s potential growth with owners. Quite frankly, these deals end with lots of promises being made and not a lot of them being met,” adds Borkowski.

Business owners need to consider what the acquisition means for the long-term future of the business and what it means for its employees and customers. “Many small business owners live in the communities they service, and their names and reputations are tied to the business Are they comfortable withhowthePEfirm will operate the business after they exit,” said Hyman.

Going through with a sale, or evening just tipping your toe into potentially selling your business, can affect the workflow at your company It can be a bit of a distracting process.Assuch,"Wehaveaverystrictprocess that guides our engagement to ensure all expectations are set and appreciated," explains Travis Allan, CEO at Eclipse Home Services. "This process starts from our first conversation all the way down to what time of role or not the seller may want to partake in posttransaction."

That’s why it is crucial to understand who you are working with and do the research. “Ask about the PEGs track record in similar transactions and how many other sellers received all the funds they were promised. They should ask to speak to other owners who have sold their businesses to the PE firm,” adds Hyman.

There isn’t just one option when selling a business. There are many and selling via, “Private equity is just one option. I encourage all residential plumbing and HVAC contractors to take the time to think about what they want for their business beyond the dollars,” said Hyman.

The Canadian refrigeration sector has finally receivedguidanceonhowtoproperlyinstall equipment using A2L refrigerants. CSA B52 was released in December 2023, following its five-year review cycle. The last update was in 2018, one year prior to the release of ASHRAE Standard 15, the American mechanical refrigeration code. “Canada neededtoplaycatch-uptotheU.S”explains Tim McRae, account technical manager of thermal and specialized solutions for Chemours Canada.

Oneofthebigtakeawaysfromtherelease of B52 is the requirements for installing A2L refrigerants, whether for residential, industrial, or commercial applications. “It’s pretty much in alignment with ASHRAE Standard 15 because up until now, what was in the 2018 version of B52 had similar requirements for A2Ls as those for A3s,” explains McRae. “Certainly, A2Ls are very, very different than A3s – lower flame velocity, less ignition energy. You’d need much higher leakage quantities to get into a flammability regime. They’re much safer than A3s. That was really the big change as we transitioned to the new version, which was to properly represent the A2Ls and provide guidance on that.”

Now that the code has been released, the next step will be for the provinces and territories to formally adopt it. “When CSA adopts a new version of the code, nationally, that’s just the first step. It doesn’t become law until it's referenced in a regulation and that happens at the provincial level,” explains Martin Luymes, vice president of governmentandstakeholderrelationsforthe Heating, Refrigeration, and Air Conditioning Institute of Canada (HRAI). “The next step is for every province to adopt it Every province has a different process for doing that. It's very encouraging that every province across the country has committed under the

Canada Free Trade Agreement to the timely adoption of standards and codes, which generally means within a year of the code being finalized.” It is expected that each of the provinces will have formally adopted B52 into code within the next six to 12 months.

“Getting the code published was number one,” shares Luymes. “Number two is getting it adopted and recognized in every province. A third problem is for the B52 code to be referenced in building code, so it will apply to new building construction.” For new construction, the National Building Code references B52 as the standard to follow. But the current dilemma is that the B52 version referenced is the one released in 2018, which doesn’t include installation requirements for A2L refrigerants. “That’s going to present a problem for new construction,” explains Luymes. “That’s the last hurdle we have to overcome. I think we’re going to be able to get B52 as the law of the land in every province by the end of 2024. The next stage will be getting it referenced in building codes.”

When first looking at working with A2L refrigerants, it can be a bit daunting. “Certainly, there’s going to be somewhat of a learning curve and certainly, training is going to be an important part,” explains McRae. “But from a technician perspective. It’s really about doing what you’ve been trained to do because even with the non-flammable refrigerants, you’re not supposed to vent them. You’re supposed to recover refrigerant before you do any braising or welding. So really, all those practices that they’ve been taught to do, you just can’t skip the steps.”

Training will inevitably be an important step for any technician working with A2Ls. “We realized there’s going to be a need for retraining even existing refrigeration mechanics,” shares Luymes. HRAI went across the country and spoke to its members about training on A2Ls and almost all agreed

that training would be beneficial, but many also suggest that unless the coursework was mandatory, many technicians might not do it – think of Canada’s Ozone Layer Protection Awareness Program (ODP). “I think contractors will need to continue to educate themselves as they’ve always done as we’ve gone through many transitions over the years," said McRae. “There is some education I think on that side and it’s going to be a little bit daunting for some of the techncians at first, but for this industry, once you’ve done it a few times, it will be pretty straight forward, and they’ll get there pretty quickly.”

One piece of advice McRae would give to any technician who might be in the market for new service equipment is to make sure that it is A2L approved. “The equipment that the contractors will need to use can already be found on the shelves of Canadian wholesalers,” explains McRae. “If they’re out there today and their recovery machine fails, make sure you buy the right one. The fittings are going to be different. They are 1/4-inch flare, left hand thread, so there’s special fittings on the cylinders.” If the technician works with some type of electronic gauge, it might be a good idea to upgrade the software. Make sure it has an A2L-approved sticker on it.

There are some important dates coming up that technicians need to be familiar with in the refrigeration sector. The big one will be in January 2025, when chillers in new builds will be required to have a GWP below 750. Albeit solely applying to the U.S. refrigeration market, packaged air conditioning units will also no longer be manufactured with a GWP greater than 700 by January 2025.

One of the things that the industry wants to see moving forward with these codes and regulations is some type of predictability. “Certainly, that’s what everybody’s feedback has been to Environment Canada. We don’t want to see the numbers keep going down and changing every six months or every year,” explains Luymes. B52 works on a fiveyear release schedule, with the next release anticipated for 2028.

AQUATECH™ offers innovative Lochinvar® commercial and residential space and water heating solutions that engineers, specifiers, builders and contractors can depend on. Turn to AQUATECH for heating and hot

water value and support.

Over 40 years Experience.

Represented by

Interconnected

systems are expected to become the new normal for commercial spaces.By Leah Den Hartogh

Commercial spaces tend to be high-traffic areas. There can be a merry-go-round influx of people that come into and out of an area of a building. “Each commercial plumbing industry has its own unique set of needs depending on a variety of factors such as the nature of operation and specific regulatory requirements,” explains Anny Ang, director of wholesale marketing at Moen. “For example, healthcare facilities often have stricter sanitary regulations than other industries, meaning they require products that keep hygiene top of mind.”

However,allareasofcommercialplumbing share this higher-than-normal amount of traffic. As such, the plumbing products that are installed within the building need to have a high level of durability to be able to handle the frequent use it must undergo. If not taken

Continued on page “25”

Continued from page “23”

into consideration, this can result in wear and tear occurring quickly. “The best way plumbers can mitigate damage over time is to recommend products that can withstand a high volume of usage,” explains Ang. “These products must be built to withstand the highest-traffic environments like stadiums and schools, where they may be getting as much use in one day as a residential home fixture gets in a year.”

Not only do plumbing products have to maintain a level of durability, but in the commercial sector, they must also be easy to cleanandmaintain.Fromacommercialfixings perspective, this idea of easy maintenance is crucial when looking at the complexity and scale of some of these buildings.

“Maintenance is actually much more important on the commercial side. It’s important to have equipment maintained,” explains Gregory Hunt, product manager commercial at Chicago Faucet. The frequency of the maintenance is typically dependent on how often the products are being used

The best way plumbers can mitigate damage over time is to recommend products that can withstand a high volume of usage.

One of the bigger headaches that plumbers have to deal with on-the-job site can occur during maintenance calls. When a commercial building has faucets or fixtures from different brands, this can make the job significantly longer as brands tend to have different components that may have to be serviced, “This is where a lot of buildings fall short on maintaining a brand. If you have two different brands, you’re going to have two different sets of repair parts. So, maintaining one brand is something I would push.Iwould

even push for a type of faucet that uses the same handles, the same outlets in the same cartridges,” shares Hunt.

If the plumber can play a part in the decision-making process, choosing faucets or fixtures that have some type of self-cleaning or self-lubricating feature can help prevent issues from occurring down the road. “A pivotal strategy contractors can take is to recommend products that require minimal maintenance to customers,” shares Ang. “Commercial plumbing fixtures are standardized, so it’s easier to replace parts and fittings when necessary. Still, it’s important to select the appropriate faucet for the environment as they need to be easily adaptable and easy to use for all people.”

Touchless technology remains the main feature that customers are looking for out of their faucets and fixtures. The pandemic has increased the number of people who are conscious of their personal health and hygiene. But the technology has been there since prepandemic times. “Touchless fixtures will

continue to be a popular option as hygieneconsciousness will remain top of mind post-pandemic, as well as a continued desire for style in these spaces,” shares Ang.

Low to no touch has become the norm for commercial applications. This trend has started to make a big push into other areas of the commercial restroom. For instance, touchless soap dispensers, faucets, hand dryers, or even towel dispensers, where you just have to wave your hand over a sensor, and the towel comes out, have become a staple in commercial restrooms.

“They’re even removing doors and putting in divider walls. Airports figured that out a long time ago, rarely do you have to open a door to go to the restroom in an airport. You can go through a couple of little dividers and you’re right there. Everything flushes touchless,” explains Hunt. Touchless technology within the sphere of commercial applications isn’t exactly new. It has been around now for somewhere close to 20 years.

Another lesson taken from the pandemic

Continued on page “27”

Similar to how the residential market operates, the commercial market features a variety of different finishes for plumbers to choose from.

Continued from page “25”

was the benefits of flushing the system. Albeit more important within the health care industry, there can be benefits to flushing the building any time there is stagnant water. “To mitigate bacteria growth, it’s important to choose products that are conducive to easy cleaning and maintenance and can proactively facilitate processes, such as regular flushing of water lines to remove stagnant water,” explains Ang.

Any type of chemical disinfection utilized within the plumbing system shouldn’t be stagnant either as it is corrosive and can start breaking down with connections or pipes. “As the sophistication and understanding of your water system becomes better, facilities have a better idea for when it needs to run at a certain time,” shares Hunt. “It could be time-based, or it can be run after a certain number of litres have gone through the plumbing system.”

The future of commercial plumbing is heading in quite a fascinating direction. Like the mechanical room, commercial plumbing faucets and fixtures are looking towards

connectivity. “It’s been around. It’s not a new concept for sure,” explains Hunt. “We’re dipping our toes into it a little bit. A lot of our touch and most of our touchless have Bluetooth in them.”

This idea of integrated connectable faucets as a unified system is something that should be anticipated to be in the market. Adding Bluetooth is kind of the first step. The next step will be finding a way to let all of the faucets within the commercial space communicate to the building management system. “Residential is going to be a lot easier because they’ve what maybe five faucets in a house depending on the size of the house. It’s going to be a little bit easier to communicate between the different types of fixtures,” explains Hunt.

“But when it comes to commercial, it’s like monster applications. Then it’s going to be a lot more complicated, but it will also allow the building experience to be a little better for the occupants because they can keep up on maintenance.” Plumbing is kind of doing a slow roll into connectivity, but it’ll allow for the guesswork to be taken out of any required maintenance or water quality questions. It is something that plumbers can expect to be coming within the next few years. :

Residential Air-to-Water Heat Pump System featuring an outdoor unit, an indoor unit and a steel buffer tank (20 gal). Pairs with Vitocell 100 V 53 and 66 gallon indirect tanks. 3 sizes available: 20 to 51 MBH for cooling / 28 to 78 MBH for heating.

PCM batteries represent a step forward in reducing carbon emissions.

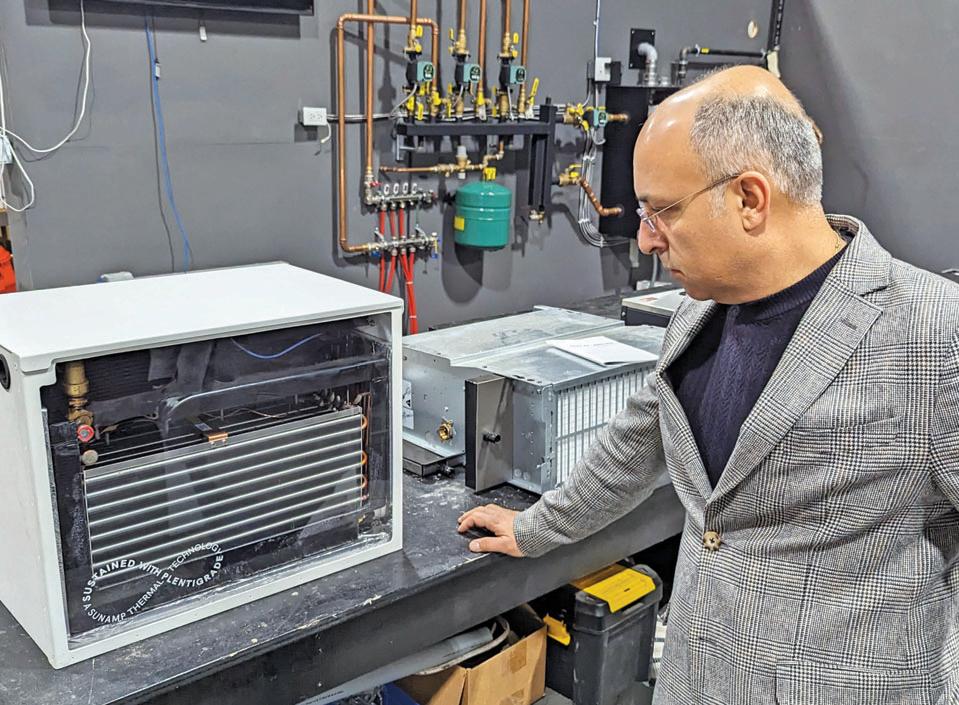

PCM batteries store latent energy and leverages the absorption or release of heat as it transitions between solid and liquid phases.By Michael Ridler

As someone deeply passionate about HVAC systems, my enthusiasm for the wave of innovative technologies emerging in recent years knows no bounds. I have been travelling across the United States and Canada meeting some incredible people and getting my hands on some truly innovative technologies. However, my recent introduction into phase change thermal batteries marks a standout moment in my career that truly signals a leap forward in the field of HVAC. My journey into phase change material (PCM) batteries began about a year ago while researching dual-source heat pumps.

I had recently installed an air-to-water in my home and specifically, I

was exploring ways to design an efficient ground source heat pump for residential use that would allow me to install a water-to-water with a small loop without compromising performance or relying on the more traditional but highly effective district heating systems. This led me to a fascinating patent overseas, detailing a dual source heat pump that incorporates phase change thermal storage. This discovery propelled me on a journey, connecting me with some brilliant minds.

So, what exactly is a phase change thermal battery? This battery harnesses the power to store latent energy with remarkable efficiency, leveraging the absorption or release of heat as it transitions between solid and liquid phases.

The unique aspect of contemporary PCM batteries lies in their ability to undergo phase changes at non-industrial temperatures. Innovations

Continued on page “31’

Continued from page “29”

in the market now include products capable of phase-changing at temperatures under 138 F. This advancement opens the door for charging thermal batteries in residential settings, allowing the storage of usable heat that can be charged with boilers, waterto-water and air-to-water equipment and renewables.

From my firsthand experiences visiting sites, I’ve observed PCM batteries in residential homes no larger than a small filing cabinet.

Despite their modest 80-litre physical size, these units effectively store the energy equivalent of 300 litres. This translates to the ability to store nearly four tons of capacity within a compact footprint. As cool as this is, the distinctive advantage of PCM batteries is their minimal standby losses, setting them apart from other energy storage methods by preserving energy more efficiently for extended periods.

PCM battery technology exhibits

significantly reduced heat loss due to its compact size and the use of vacuum-insulated panels, a feature not typically found in conventional thermal storage methods.

The distinctive advantage of PCM batteries is their minimal standby losses, setting them apart from other energy storage methods by preserving energy more efficiently for extended periods.

Vacuum-insulated panels offer extremely high thermal resistance in very thin thicknesses (e.g., 0.5 to one inch). Recent measurements made at Queen’s University for NRCan have confirmed that the standby losses measured on a PCM battery were negligible over a few days.

When comparing a PCM battery to a traditional electrical battery, such as those

used with solar photovoltaic systems for power storage, the advantages of PCM batteries are significant for several reasons. PCM batteries are considerably more cost-effective than their electrical counterparts. The ones I have seen are also free of moving parts, eliminating the need for maintenance, and don’t require special permits for installation. A PCM battery can be retrofitted into an existing home in less than an hour (something that is not achievable with traditional electrical battery storage).

The question then arises: how can we

Continued on page “32”

Continued from page “31”

best utilise PCM batteries? One immediate application is harnessing solar PV systems not just for generating electricity, but also for producing usable heat. A small PCM battery can be fully charged in under five hours, storing a significant amount of thermal energy in a compact footprint. This stored energy can then be used in a variety of applications, including radiant floor heating and domestic hot water systems.

I made a visit to a residence last year where the owners had installed a PCM battery, linking it to a small solar PV array. This particular battery was equipped with a 2.8kW electric element that was charged by the PV system. Over two years, this setup provided the household’s domestic hot water, with the local utility company keeping track of its performance. The capacity of the PCM battery in this scenario matches that of an 80-litre hot water tank. The PCM battery I’m currently examining in my live fire lab includes a dual pass heat exchanger, allowing for charging via both solar PV and solar thermal sources.

The aspect of PCM batteries that truly captivates me is their capability for load shifting. During a discussion with a colleague employed at a local utility, I explored the practical applications of a PCM battery. He quickly highlighted its effectiveness in transferring the timing of heating or the generation of domestic hot water to offpeak periods, thereby capitalizing on the

considerably reduced energy costs during those times. The compact yet efficient nature of PCM batteries allows for the accumulation of a significant thermal energy reserve with barely any energy loss when not in use. By charging these units overnight, when energy rates are at their lowest, and deploying the energy during high-demand periods, we unlock a strategy that not only optimises energy consumption but also competes favourably in cost against traditional fuels like natural gas. This innovative approach promises a shift towards more economical and efficient energy use.

In my live fire lab, instead of utilising solar PV or solar thermal systems, we are using a unique approach by charging our PCM battery using an air-to-water heat pump. This setup is part of a custom control strategy that enables us to explore a hybrid heating application. The air-to-water heat pump, capable of delivering five tons of heating, charges the PCM battery during off-peak hours and when there is no need for heat in the home. On the coldest days, the battery serves as a secondary heating stage, utilizing the energy stored during off-peak periods. A feature of our system

is its automatic recharge mechanism; once the battery’s charge level falls to 40 per cent, it begins to recharge itself either through the air-to-water system or its integrated electric element.

While our goals include minimising energy consumption, smoothing out grid demand, and reducing our carbon footprint, we prioritize maintaining occupant comfort above all else in the design of heating and cooling systems. This principle guides our experimental approach, ensuring that innovation in energy efficiency does not come at the cost-of-living comfort.

From an environmental perspective, the adoption of PCM batteries represents a significant step forward in reducing carbon emissions. By leveraging renewable energy and reducing reliance on fossil fuels for heating, these systems underscore a commitment to a more sustainable and environmentally friendly energy future. :

Michael Ridler is the general manager at Eden Energy Equipment. He started out working for a Ont-based HVAC company and now focuses on providing field support and technical training to contractors, engineers, and builders on heat pumps, boilers, and all things hydronics. He can be reached at edenenergymike@gmail.com

Today’s gas-fired boilers have greatly improved in terms of efficiencies compared to older systems and the return on investment should be expected quickly.

n Primar y/secondary piping design

n Intuitive pumps

n Future proofing the boiler

n Condensing vs non-condensing

CB Supplies VIPERT™ Potable & Radiant PE-RT OXY barrier tubing o ers industry leading performance with improv exibility, lowest Greenhouse Gases (GHG) emission footprint and tubing is 100%

INDUSTRY LEADING FLEXIBILITY FOR EASIER & FASTER INSTALLATION

With relaxed memory you’ll experience less spring

Come visit us at booth #507

100% RECYCLABLE VIPERT is 100% recyclable, requires less energy to produce compared

EXPAND, CRIMP OR PUSH VIPERT Potable and Radian exible for your preferred tubing does it all!

NO NONSENSE 25-YEAR WARRANTY

We stand behind our VIPERT with a transparent 25-year warranty

STRENGTH, DURABILITY & BUILT FOR EXTREME TEMPERATURES

temperatures and burst pressures, maintains excellen exibility in both cold and hot environments

EASY LINE IDENTIFICATION BY COLOUR

White, red and blue choices for Potable and VIPERT green for Barrier, available tubing sizes: 3/8” through 2”

Potable:Radiant:

1-800-665-1851

salesinfo@cbsupplies.ca

cbsupplies.ca

POTABLE

RADIANT

POTABLE

RADIANT

Just a few years ago, I remember walking around the Canadian Hydronics Conference in Saskatoon, Saskatchewan and looking at all the gas-fired boilers that were on the show floor. At this point, all of the industry experts I knew were already starting to tell the rest of the industry that heat pumps were the future.

I remember thinking to myself, “Well, if that was the case, why were there so many gas boilers still being sold and marketed?” I figured there was three potential outcomes that could occur. The first was that the industry was wrong and heat pumps would fizzle out. We know just how wrong that idea was; just look to our January/February cover page – we are in the “Year of the Heat Pump” after all.

The second potential outcome was that there would be some type of hydronic heat pump monopoly within the market. To me, this could have been almost as bad as if heat pump technology just dropped off the face of the earth. This could have seen extreme delays in adoption as anyone that has taken a business class in their lifetime can understand the principle of supply and demand. With little supply but high demand, the cost would be on the high end for owners. I also expect we’d see an exodus of manufacturers going out of business simply because they wouldn’t adapt.

But encouragingly, the future looks like it will be following my third theory, which is that companies realize that there is a shift

Increasing the efficiency of the system with circulators

coming to the hydronic sector and now is the time to prepare. Almost all of the companies that I was concerned would potentially close their doors forever because they were too stubborn to change their business plan have realized this shift and are planning for it.

Heat pumps are here to stay and it’s time for the industry to realize this. The best example that I can give would be the recent AHR Expo in Chicago, Illinois. The number of air-towater and water-to-water heat pumps on the show floor was impressive. You should have seen our hydronics writer, Michael Ridler,

walking around the show. He was like a kid in a candy store when looking at all this new technology coming into the North American market. It was interesting to even compare the number of hydronic heat pumps at this past year’s show to previous years. The technology that has been much more popular over in Europe has found its way into our market, and I suspect it’ll be here to stay.

With all that said, there are applications where a heat pump wouldn’t be the ideal system to install. Boilers will remain an integral part of hydronics and will remain an attractive option for back-up heat if the owner wants to go the heat pump route, or as the sole heat source as has been done for decades.

My goodness, it’s an exciting time to be in this industry. I wonder what is going to be next.

Hydronic boilers are popular due to the fact that they can modulate heat output based off of the heating demand within the space.By Francesco Lo Presti

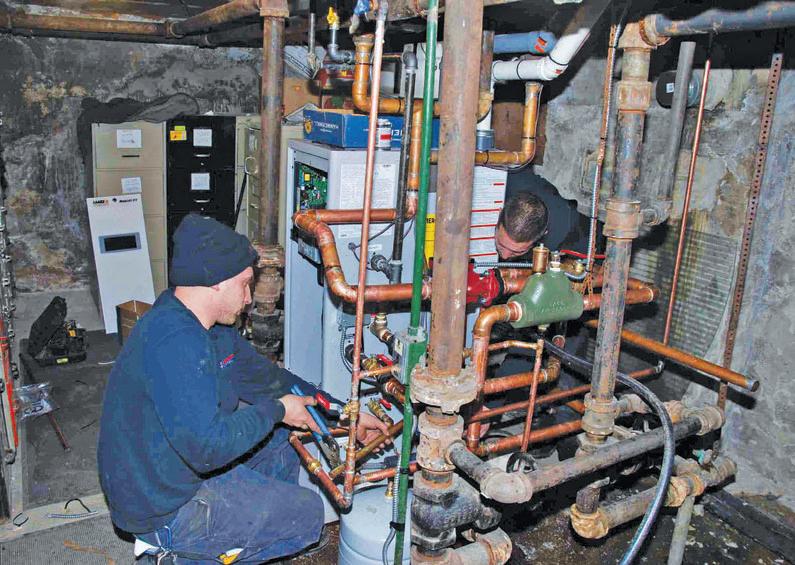

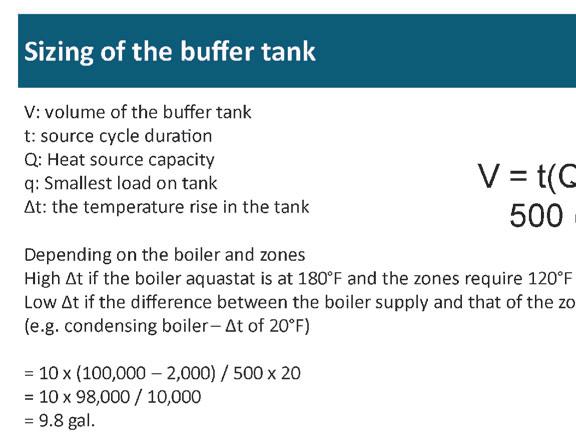

Information taken from Grant Erickson’s, agency sales manager at AquaTech, presentation on “Condensing Boiler Design Information and Hydronic Application” on Feb. 7. Watch here:

Ensuring the boiler has high quality incoming water will help the system run more efficiently, with a longer lifespan.

Gas-fired hydronic boilers are a revolutionary technology transforming how homes heat their water systems. These boilers, powered

by natural gas, are designed to efficiently heat water for household use and play a crucial role in maintaining comfort and convenience within a home.

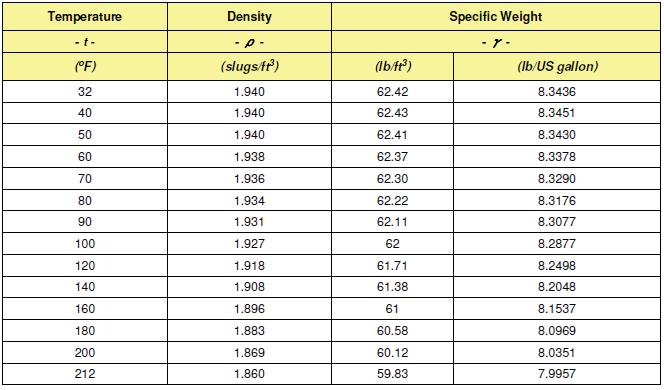

Hydronic boilers use water as the heat transfer medium, circulating it through pipes to radiators or underfloor heating systems. Gas-fired hydronic boilers are particularly popular because they can modulate heat output based on demand. These boilers ensure optimal energy usage by only heating water when needed, reducing energy consumption.

Gas-fired hydronic boilers can also provide consistent and reliable hot water throughout a home. They are especially effective in achieving an even and comfortable heat distribution, eliminating hot and cold spots that may occur in traditional heating systems.

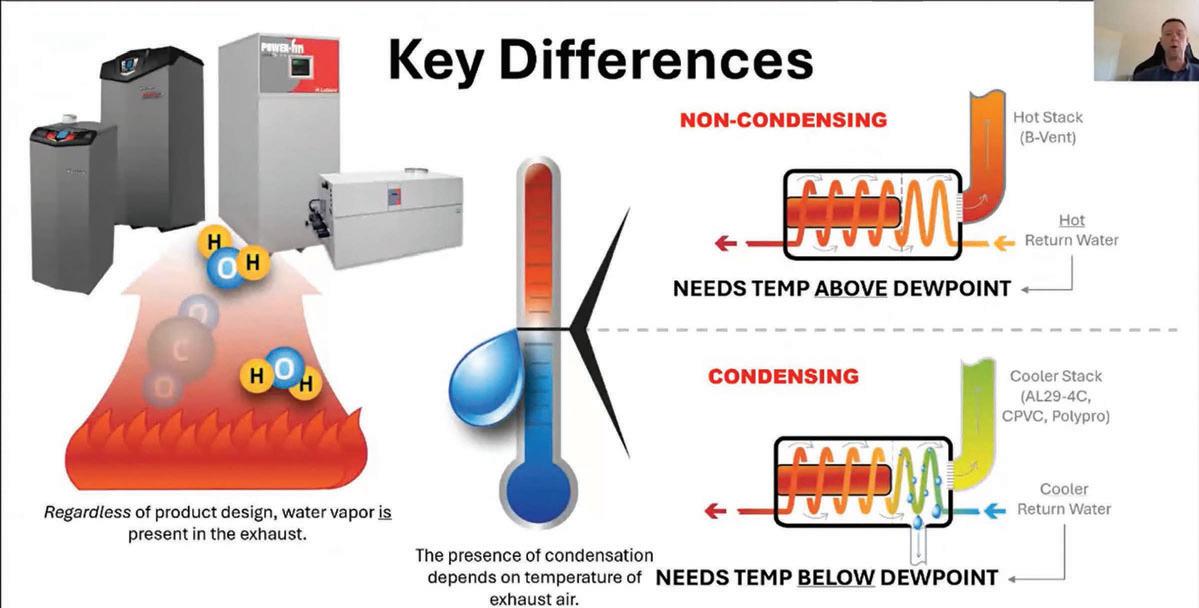

Now that we understand how gas-fired hydronic boilers operate and what their role is, let’s discuss the differences between a condensing and a non-condensing boiler.

Condensing boilers are made with materials that can handle condensate, while noncondensing units are made from materials that cannot.

Essentially, all boilers are condensing units, but some are better equipped at handling combustion than others. What typically makes one better equipped than the other is the materials or the types of heat exchangers used.

Condensing products are made with materials that can handle condensate, like stainless steel, aluminum or a dual heat exchanger. Non-condensing products are made with materials that are a little less expensive, such as copper, steel, or cast iron.

Next is understanding what happens with combustion. With stoichiometric combustion, you have a fuel source; for this conversation, it will be natural gas. So, you take the natural gas, which is the methane, and you’re going to combine it with oxygen from the air. Then, you’ll get a source of ignition, a source of heat, which starts that chemical reaction. Ideally, what you will produce is water vapour and CO2. Now, since there is no such thing as true

stoichiometric combustion, there will be other things happening, but the main thing you have is CO2 and H2O. The water will then take the form of gas.

From there, the focus turns to flue gas

Gas-fired hydronic boilers can also provide consistent and reliable hot water throughout a home.

which allows you to get higher efficiency with condensing boilers.

Notably, the dewpoint of natural gas will vary depending on the fuel used and the type of combustion you have. For example, a fan-assisted product with natural gas will have a dewpoint of 130 F, which represents your return water temperature. Anytime you operate above that number (most manuals will say 140 F, whether a condensing or non-condensing boiler), you will be in the non-condensing mode, and you will have an efficiency of about 86 to 87 per cent. Anytime you operate below that number, you will be in condensing mode, and that water vapour will condense and turn to liquid. Again, this varies depending on the fuel source. Additionally, the combustion type will depend on the amount of CO2 in the stack.

dewpoints. With condensing boilers, you’re getting below the dewpoint where that water vapour will condense down from a gas into a liquid, which releases energy. That energy gets put back into your thermal balance,

The key focus is on changing state and getting latent heat, as that’s where the extra efficiency comes from. When we look at

Continued on “page 39”

Continued from page “37”

water vapour, roughly one lbs. will give you about 1,000 BTUs. In terms of gallons of condensate, one gallon of condensate can produce approximately 9,000 BTUs. When we look at how this latent heat is applied, for every 100,000 BTUs of input, approximately one gallon of condensate is produced per hour. A 600,000 BTU unit will produce approximately six gallons per hour, and a six million BTU unit will produce approximately 60 gallons per hour.

The stack is another key thing to remember with condensing and non-condensing. If you are operating in that condensing mode in a condensing boiler, you will need a stack that can handle condensate, usually stainless steel, CPVC, or polypropylene. Many noncondensing boilers will not have those types of stacks; they typically have B-vents. That is fine in non-condensing mode, but the stack can rot when condensing.

Typically, the three main heat exchangers you see in condensing boilers are recuperative (dual), aluminum, and stainless steel, which feature water and fire tubes.

A dual heat exchanger is essentially a two heat exchanger design. You will have a primary heat exchanger that doesn’t condense and a second one that can condense. In this type of product, the return water will go into that second heat exchanger and be exposed to those flue products, which will have cold temperatures. The flue products will then condense, and that water vapour will go from a gas to a liquid. The latent heat will go into the primary noncondensing heat exchanger.

Cast aluminum heat exchangers also work well in condensing situations. They can handle condensate, and these products typically mimic cast iron. Cast aluminum heat exchangers have various heat transfer

Commissioning

pits. The flue gas products are found at the top and are forced downwards. As they get closer to the bottom, a counterflow design will start to condense and pool up at the bottom.

Low-mass boilers have a low water volume in the heat exchanger and generally tend to be water tube appliances. Water will be found in the tube, with flue product surrounding it. These appliances tend to have very specific flow requirements and a narrow range of minimum and maximum flow rates. For that reason, primary and secondary piping is recommended. In this setup, the boiler loop is typically referred to as the primary loop, while the system loop is commonly used as the secondary loop. The key to making this system work is having closely spaced T’s.

Naturally, high-mass boilers are the opposite. They have more water volume and tend to be fire tubes in condensing applications. In this design, the flue products are in the tube and are surrounded by water. This allows for more flexibility with flow rates, as they generally have a much larger flow range. As a result, you tend to have more flexibility with piping schematics.

It is important to remember that if there are issues with water quality, there will usually be issues with the boiler. Especially in retrofit applications with things like magnetite, as soon as you start to replace the boiler or rattle the pipes, all that magnetite and other things will come out of the pipe.

The fresher water being taken on with untreated water results in more scale forming. When heating water, scale will precipitate out. When there is a heat source, scale will adhere to it and form a hard substance. This will result in a loss of efficiency and uneven heat transfer.

The first steps in water protection can be done prior to the initial fill and start-up by isolating the heating appliance and flushing the entire system. You can also clean the system with an approved pre-commissioned cleaner and clean all the water filtering devices.

Another step can be monitoring your makeup water. Typically, there should be less than five per cent of your total system volume per year in your makeup water. If there is more than that, you will know there is a leak and scale accumulation in the hydronic system. :

If the circulator is properly applied and programed, one of these babies can help enhance the overall efficiency of the system.By John Barba, Rick Mayo, and Dave Holdorf

View the full presentation on “ECM Circulator Technology – The Myths and the Realities” here:

If you’re anything like me, the first thing that comes to mind when you think about variable speed circulators is the 1970s rock band Supertramp. No? Maybe you’re not like me. Either way, allow me to explain.

Supertramp’s 1979 hit “The Logical Song” is one of the decade’s best, with one of the greatest lines ever: “Watch what you say, or they’ll be calling you a radical.” Well, in hydronics, there is no radical, cynical, fanatical, or criminal. I guess there’s sometimes the fanatical, but that’s not the point.

The point is that hydronics is logical. It's downright Spockian if you think about it. There’s a beautiful logic to how all your parts and pieces work, both on their own and especially in how they work together within the dynamics of the system.

However, when it comes to variable speed circulators, sometimes “The Logical Song” goes right out the window. All we’re left with is “Goodbye Stranger” and Mr. Spock on his every seven-year pon farr sabbatical back to Vulcan.

Let’s consider the logic behind variable speed circulators, both Delta-T and Delta-P.

The prevailing attitude is that they always give you the right flow, no matter what. You can go ahead and call me a radical, but that’s not logical.

For a variable speed circulator to always give you the right flow, it would have to have some way of knowing what the Btu/h load of each room and the system is at any given point in time. It would also need an idea of what the outdoor temperature is at any given point in time, as well as how much radiation is installed in each room. Spoiler alert: It doesn’t know any of those things.

For some reason, the industry has insisted on calling these things smart pumps. The reality, unfortunately, is they’re not all that smart. What they are, however, is obedient.

For a variable speed circulator to always give the right flow, it would have to have some way of knowing what the Btu/h load of each room and the system is at any given point in time.

circulator will always work at 10 ft. of head on what’s called the control curve. It’s the ultimate flat curve circulator.

Use the same circulator in the same operating mode in a zone pump application and it will still work on its control curve. The difference, however, is it won’t vary its speed because there’s nothing in the single zone that will change resistance against the impeller. Once the circulator finds its happy place on the control curve, that’s where it

The point is hydronics is logical. Downright Spockian if you think about it. There’s a beautiful logic to how all your parts and pieces work, both on their own and especially in how they work together within the dynamics of the system.

For example, if you program a residential Delta-P circulator to operate in the constant pressure mode at 10 ft. of head, well then, by golly, that’s what it’s going to do. As zone valves open or close, the circulator will “feel” either less or more resistance against the impeller. Algorithms kick in and tell the circulator to either speed up or slow down. The result is the

will work because that’s where you told it to work.

Now, don’t read that as saying you shouldn’t use a variable speed pump as a zone pump. Far from it. The ability to program the circulator will allow you to set the speed to operate as closely to a zone’s flow and

head requirement as possible. That can help reduce over-pumping, which leads to short cycling, which leads to all kinds of bad things.

If you set the circulator to proportional pressure (those funky-looking curves that slope down and to the left), the only thing that changes is the system will work on whichever funky curve you select.

In neither of these instances is the circulator giving you the right flow. If you program them accurately, you might get close.

And one more thing, in both applications, the circulator will run at the same speed in October or April as it does in January. Again, because that’s what you told it to do. Like I said, obedient.

Delta-T circulators will at least give you a fighting chance at the right flow. What a Delta-T circulator does is vary its speed in order to maintain the designed system Delta-T. If you design for a 20-degree Delta-T, well then give it a 20-degree Delta-T. Boilers like it, radiators like it, and systems like it.

As zones close, the system needs to take fewer Btu out of the water through the radiation. That makes the return

Continued on page “43”

The Central-Moov NEEP and AHRI listed add-on heat pump system consists of a Moovair M20 condenser and matched Moovair A-coil meets the NRCan ccASHP requirements.

Continued from page “41”

water temperature want to increase (and the Delta-T, or temperature difference) decrease. The logic will tell the circulator to slow down to maintain the designedfor temperature difference. The opposite happens when zones open.

Delta-T circulator

Additionally, as the heat load changes with the weather, the circulator will continue to speed up or slow down to maintain the design for Delta-T. That is, until it can’t.

At some point, the circulator will reach its minimum speed and logic dictates that you can’t go any slower than minimum, no matter what anyone says. The circulator won’t be able to maintain the design for Delta-T anymore. The good news, however, is it’ll still be wide enough to minimize bad things like short-cycling and higher-thandesirable return water temperatures to a modulating/condensing boiler.

Just about every variable speed pump manufacturer has a Delta-P circulator with an automatic function. And while it sounds cool, we do need to check in with Mr. Spock and Supertramp, as well as reality, to understand what auto really does.

It’s nice to think that slick little function does all the work for us and takes the thinking out of circulator selection. Unfortunately, that’s utter nonsense.

It’s the professional’s ability to think and to make sense of all this technology that separates him from the handyperson. It takes a pro to understand how all these operating modes work and to select the right one for each job.

That slick little button does do a slick little job. However, for small residential circulators, that job is limited to continuous circulation applications with modulating thermostatic radiator valves and panel radiators. In that case, given time (like, a lot of time), the circulator will adjust its proportional pressure curve up or down if it experiences a significant change in overall flow (due to TRVs being mostly open or mostly closed) for a significant period of time (20 minutes up to an hour).

So, what’s the takeaway? It’s this: It’s important to understand how variable speed circulators work and what they do. There’s no magic involved. These things are logical and obedient.

A poorly programmed variable speed circulator is, at best, an electricity saver.

That’s not a bad thing at all, but a poorly programmed variable speed circulator is still an oversized circulator that limits the overall efficiency of a system.

But if you properly apply and program one of these babies, well, now you have a circulator that can help enhance the overall efficiency of a system.

And that, mon ami, is a very good thing. If you don’t mind me saying, it's pretty darned logical. :

John Barba is the director of training at Taco Comfort Solutions. He has been in the plumbing/ heating industry for most of his career, having grown up in his family’s plumbing and heating business. He has trained over 30,000 contractors on the fine art and subtle science of hydronic heating design and installation.

Rick Mayo is the western product and application instructor at Taco Comfort Solutions. He started his career in the hydronic heating industry as a plumber in 1977. He runs regular training sessions that stretch from Alaska to San Diego and into four provinces in Western Canada.

Dave Holdorf is the residential trainer at Taco Comfort Solutions. He has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business. Starting in the technical support/design role and then taking over as engineering manager, overseeing technical support.

1-888-290-6318

www.wolseleyinc.ca Canada

1-800-661-5615

www.bartlegibson.com

BC, AB, NWT, & Swift Current, SK

1-604-270-7173

www.pacificcleanair.com BC

1-404-286-7467

www.klassmechanical.ca AB

1-905-238-1888

www.heatsaversltd.com MB

1-306-937-7741

www.andersonpumphouse.com SK

1-800-561-6192

www.pedcosupply.com ON

1-306-242-1567

www.aquiferdist.com SK

1-519-364-7550

1-905-670-7966 Mississauga,

1-519-455-1010

www.diamondhvac.ca/

1-905-728-6216

www.southernsupplies.ca

•

• 24V AC interface for easy thermostat connection

• Increased reliability with few moving parts