2 minute read

Kawasaki adds line, shift, jobs in 2020

New shift gives employees new opportunity

By SKYE POURNAZARI | The Forum

Advertisement

MARYVILLE, Mo. — An increased demand for its products prompted Kawasaki Motors Manufacturing Corp., USA to increase its assembly lines and staffing opportunities during 2020.

Kawasaki customers are asking for more engines pushing the plant to increase volume both in engine production and staff.

Renee Schimming and Lacy Gladman work on an engine Jan. 22 on the newest assembly line at Kawasaki Motors Manufacturing Corp., USA in Maryville. Kawasaki added the line in August

PHOTOS BY SKYE POURNAZARI THE FORUM

The new assembly line announced in August, is now complete, staffed and in production. However, the facility also needed more engines in other areas of production. It opened two current assembly lines during second shift to help increase that production.

Robert Fry, a contract service employee, greases up an output shaft before it’s packed into the shipping unit. While customers don’t typically let engines sit around very long, said Tim Melvin, Human Resources Manager, this is one more quality assurance step Kawasaki takes to keep their engines ready for customers.

PHOTOS BY SKYE POURNAZARI THE FORUM

At the time Kawasaki only ran “Backshop” areas, such as machining and aluminum die casting on second and third shifts. The new lines mark the first time it has run assembly on any shift other than the first.

In August, the company estimated the new lines would create an additional 100 positions and as of Jan. 22, it had those employees hired and working. Melvin said the company looks to hire even more, to bulk up those lines.

The opening of second shift also allowed some employees to find a time of day that works better with their lives, he said.

“They are people who appreciate those hours,” he said, noting that some have family considerations that the shift works better for them.

Melvin estimated that 60 to 65 percent of employees at the manufacturing plant are from the Maryville and Nodaway County area. He noted the balance are people mostly from adjoining counties even stretching up into Iowa.

Kawasaki employees work at the beginning of the new assembly line on Jan. 22. In the foreground a container of crankshafts can be seen. Those are created in the facility and stored before being delivered to the assembly lines.

PHOTOS BY SKYE POURNAZARI THE FORUM

Still in hiring mode, Melvin said there “are still plentiful jobs available,” for anyone interested in a position. Many of those positions do

not require previous factory experience or knowledge. The company will teach anyone interested in assembly, starting with its training line.

Melvin said the training line offers a first look at small assembly processes to acquaint new hires with the processes on the floor.

“It just gives them a little bit of a feel, a little bit of an idea of what assembly is like,” Melvin said.

For anyone interested in a position, visit www.kawasakimaryville.com.

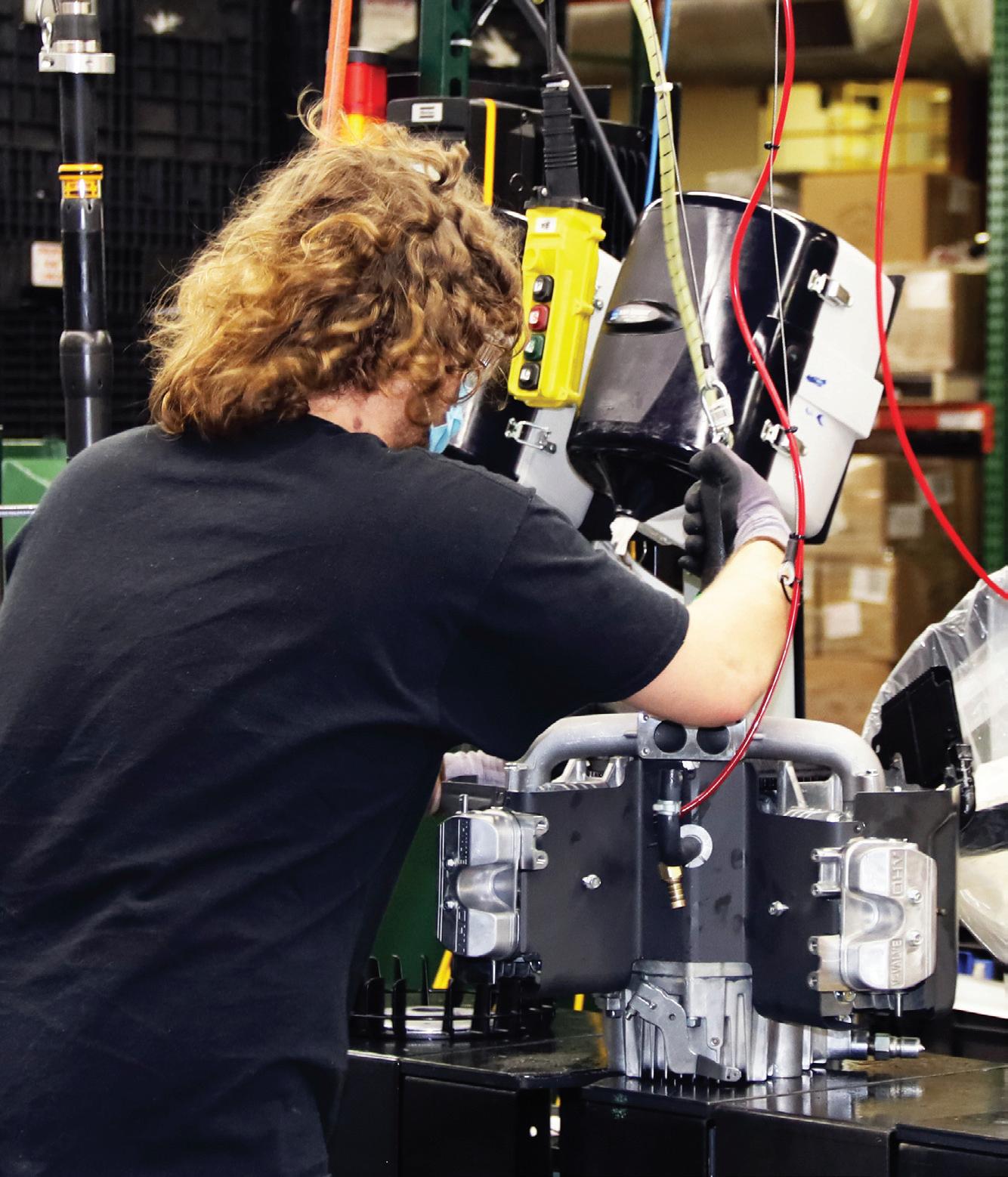

Gavin Nelson, a contract service employee, works with an engine while it’s being tested with air. Tim Melvin, Human Resources Manager, told The Forum, it is Kawasaki’s belief that if an engine leaks air it will leak oil later. This test is a check that the engine will hold air.

PHOTOS BY SKYE POURNAZARI THE FORUM

The new lines are a major addition to the progress that Kawasaki has made this year, but they’re not all that the plant had going on during 2020.

Along with regular maintenance and upkeep of machinery, Melvin said the company has also been working to build a new security entrance for employees.

Contractor E.L. Crawford has been working throughout the year to build out the new office on the southeast side of the building.

The much larger facility will allow for multiple passthru scanners that will speed up the entrance and exit of employees.

“It’s going to allow for a more efficient entrance and exit of our employees and especially enhance our security efforts,” Melvin said.

Another sign of progress at Kawasaki Motors Manufacturing Corp., USA in Maryville, is the new security office being constructed by E.L. Crawford.

PHOTOS BY SKYE POURNAZARI THE FORUM

It also will feature a heated sidewalk, steps and ADA compliant ramps, to keep ice from building up.

Contractors are looking at a mid-February completion date.