INSTALLATION, OPERATIONAL and PERFORMANCE QUALIFICATION PROTOCOL Installation, Operational, Performance Qualification of the Cartoning Machine [details with location here]

Validation No.XX and Asset No.XX Your Site Here

Ref: XXXX

Rev: 1

Page No 1 of 4

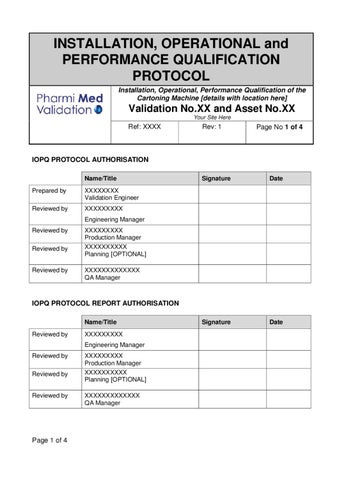

IOPQ PROTOCOL AUTHORISATION Name/Title Prepared by

XXXXXXXX Validation Engineer

Reviewed by

XXXXXXXXX

Signature

Date

Signature

Date

Engineering Manager Reviewed by Reviewed by

Reviewed by

XXXXXXXXX Production Manager XXXXXXXXXX Planning [OPTIONAL] XXXXXXXXXXXXX QA Manager

IOPQ PROTOCOL REPORT AUTHORISATION Name/Title Reviewed by

XXXXXXXXX Engineering Manager

Reviewed by Reviewed by

Reviewed by

Page 1 of 4

XXXXXXXXX Production Manager XXXXXXXXXX Planning [OPTIONAL] XXXXXXXXXXXXX QA Manager

Reference your document here

Written By:

Other references

Revision: 01

Date

Page 2 of 4

VALIDATION PROTOCOL Your Logo

Document Title: (describe here)

Introduction The Cartoning machine in XXXX will be retrospectively validated and has been running historically with production history and data. This IOQ will cover the retrospective validation of the system and its components to GMP, MHRA Annex 15/ FDA.

Brief System Description and IOPQ Rationale The cartoning machine in XXXXXX is a {Describe type of cartioning machine here) for example - vertical intermittent motion AV cartoner and has been designed by CAM offering the user an extremely compact and versatile machine. The robust construction of the machine and the feature of having all movements driven by closed profile cams with surface hardening treatment limit maintenance and guarantees a longer working life.Carton pick-off and erection carried-out by means of a moveable blade which inserts into the carton pre-opening it before completely erecting and inserting it between the transfer lugs, allows low grammage board to be used even when handling square-section formats or cartons with glueing and creasing imperfections. The ample space available in the product feeding area, allows for more operators to be employed if the machine is to be used for manual feeding. The cantilevered transfer of cartons into the product introduction area, guarantees ideal locations of the operators in addition to allowing cleaning to be carried-out with ease. The vertical introduction of product makes the AV machine particularly suitable for handling cartons into which horizontal positioning would create problems in guaranteeing the final required configuration inside the carton, or would alter the final presentation. CAM has developed a complete range of automatic product feeding systems responding to any packaging requirement, which can also be installed onto supplied machines. All systems shall be challenged in this protocol. Therefore it is imperative that checks are thoroughly documented according cGMP recommendations. All testing will be performed retrospectively, and all tests will be in accordance with [Your Company Name] Procedure for Testing [Quote this here].

Scope This protocol covers the Installation & Operational Performance Qualification for the Cartoning Machine in XXXX. The scope of this document is therefore limited to the testing for the equipment related to this and to assure that equipment is fit for use in accordance with cGMP. The protocol shall be reviewed and authorised by the stated personnel in the approval box prior to execution of IOPQ. The IQ execution shall be reviewed and approved prior to execution of the OQ, and PQ subsequent to satisfactory OQ. Upon completion of the PQ, a final review will be done and sign off. Version 1.0 Page 2 of 4

Reference your document here

Written By:

Other references

Revision: 01

Date

Page 3 of 4

VALIDATION PROTOCOL Your Logo

Document Title: (describe here)

Objectives The objectives of this Installation & Operational Performance Qualification (IOPQ) protocol is to ensure that the Cartoner has been installed and operates retrospectively and is fit for use in accordance with cGMP and Health and Safety requirements. Index of IOPQ Cartoner Test Reference

Test Name

IQ Section 1

Description and Reference Numbers

2

Mechanical, Electrical Checks

3

Critical Components

4

Maintenance and Calibration Checks

5

Availability of Software

6

Documentation Review

7

Health and Safety Checklist

8

cGMP Audit IQ Sign Off

OQ tests for execution 1

Challenge carton opening system

2

Challenge left/right hand upper side flap opening

3

Challenge Tab Insertion

4

Challenge Bottom Closure

5

Challenge leaflet insertion

6

Challenge Product Insertion - Final Closure

7

Cleaning Verification

Version 1.0 Page 3 of 4

Reference your document here

Written By:

Other references

Revision: 01

Date

Page 4 of 4

VALIDATION PROTOCOL Your Logo

Document Title: (describe here)

8

SOP Review

9

Training

PQ tests for execution 1-15

Batch Checks

PERSONNEL Record below all personnel involved in the execution of this protocol: Company

Name

Job Title

Signature

Initials

TEST EQUIPMENT REQUIREMENTS The following table details the test equipment required for the execution of this protocol: Test Equipment

Test Equipment Purpose

Serial Number

GLOSSARY IQ OQ IOQ SOP cGMP (

Version 1.0 Page 4 of 4

Installation Qualification Operational Qualification Installation & Operational Qualification (Combined Protocol) Standard Operating Procedure Current Good Manufacturing Practice