Solutions for Embedded Applications

White Paper

Introduction

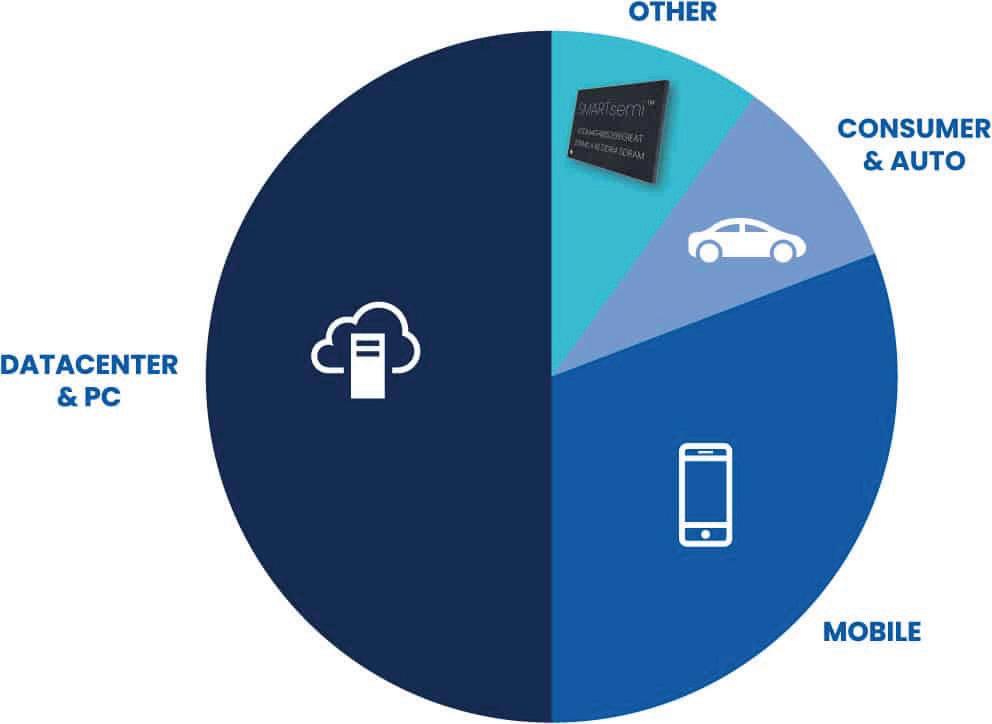

Only 15% of the total memory market is comprised of industries that use embedded memory in their applications. They are substantial industries, however, and include large segments of the automotive, industrial, communications, and defense industries. Solutions for these markets are sold in device component-level packaging and characterized by the need for an extended supply lifecycle with testing to operate in more extreme environments. While these markets are important because they only make up a fifth of manufacturing, consistent supply to this market can be unreliable from mainstream suppliers that focus on the 85% mass market demand.

Suppliers such as SMARTsemi, a specialty memory arm of SMART Modular Technologies, focus on embedded memory markets and offer long lifecycle components. These types of products are often characterized as a generation or two removed from the leading-edge memory and storage components, have extended end-of-life (EOL), use commodity and customized packaging, and are temperature-tested to commercial, industrial, wide, and automotive grades. SMARTsemi distinguishes itself from other memory component suppliers by additionally offering custom device packaging, testing, processing services, and design assistance, using the deep application expertise from SMART through the entire product deployment cycle or for specific stages in the cycle.

SMARTsemi Embedded Memory Solutions

The most critical aspects for delivering a memory solution to embedded applications address the following:

• Packaging:

o Embedded applications are typically space-constrained or form-factor challenged. A motherboard may have only one or two memory components attached. The physical space of the board may also require customized packaging. Mainstream packaging such as Dual-Inline-Memory-Modules (DIMM) for DRAM or Solid-State Drives (SSD) for flash cannot be used. Companies like SMARTsemi, which is dedicated to long-life cycle products, are geared to respond to packaging requirements from their customers.

• Reliability:

o Embedded applications typically require reliable operation in extreme environments or have higher thresholds against failure. Mainstream memory is tested for 0°C to +70°C operation. Embedded memory can be tested for -40°C to +105°C, an operating range more than twice that of mainstream memory. Embedded memory components can also be tested and processed for reliability because in-field service can be difficult and costly when they are placed on the motherboard. To ensure reliability, certain applications may require extended testing, burn-in, or other custom processing.

• Longevity:

o Embedded applications may have a 5-10 years or more in-service lifetime. As a result, components must be processed to last reliably for many years. It’s not uncommon for a customer to work with a qualified supplier like SMARTsemi to customize packaging design, testing, burn-in processing, and thermal modeling to support the long product lifecycle. The churn of new system designs is also significantly slower than mainstream products. Both of these conditions, longer product development cycles and longer in-service lifetimes, make the selection of the suppliers critical. You don’t want to design a 20-year telecom switch located in the Arctic to fail in the field or run out of supply for new equipment.

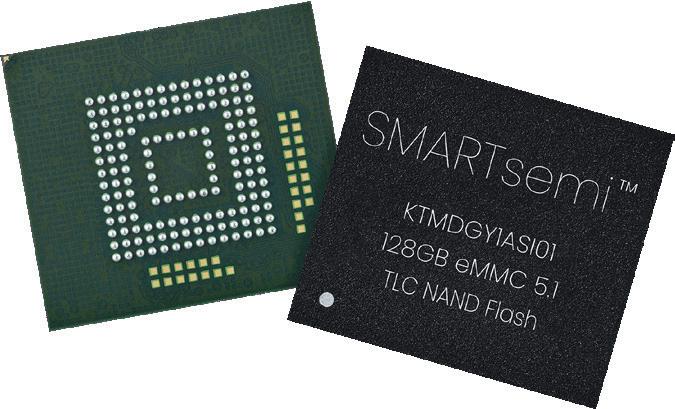

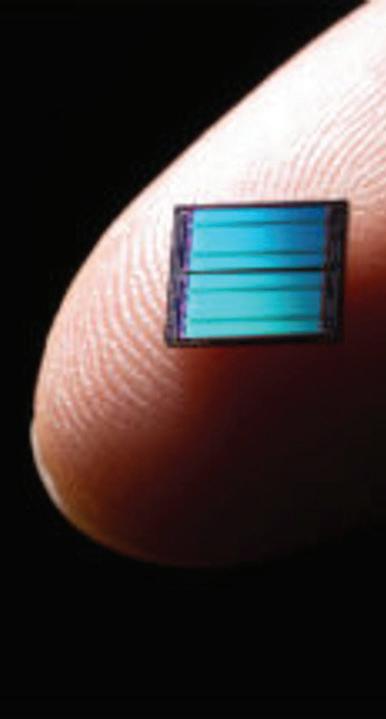

Packaging

The most economical packaging choice is standard packaging due to its volume production and multi-sourcing. SMARTsemi delivers DRAM and FLASH components in industry-standard packaging including BGAs for DDR2, DDR3, DDR4 Synchronous DRAM and Embedded Multimedia Memory Cards (eMMC). For portable memory, SMARTsemi devices are packaged as SD and microSD Cards. An eMMC package can include up to 128GB FLASH storage, a FLASH controller, and interface functions in only 0.5” square on a mother board. An SDRAM component up to 4Gb takes even less space, as little as 0.17” square.

However, depending on the application constraints, space may be at a premium. For example, where there is minimal space on the application’s motherboard, multiple die can be packaged in a device or devices can be stacked vertically. Custom packaging, particularly integration of multiple dice in a package, also improves performance by reducing lead lengths and eliminating electrical characteristics that slow signals as the transit to/from the packaged device. A third reason for custom packaging is to improve thermal conductance. The faster the component, the more heat it creates, and as junction temperatures rise, performance is limited. Custom packaging can help conduct heat off the die.

Where custom packaging is a necessity, or a competitive advantage, it’s especially important to work with a supplier that has application expertise and the ability to design and process components. SMARTs engineering and packaging can be called upon to develop and process devices in custom packaging or with variations of die-stacking or System-in-Package. SMART has developed packaging and manufacturing technology over years of experience geared towards specific embedded applications. For example, SMART had a customer whose memory was failing because of exposure to oil and other contaminants. SMART worked with the customer to develop a more reliable memory that fits the space of the old memory. Thus, the manufacturer did not have to reverse design or redesign their equipment to work with the new memory

Reliability

SMARTsemi offers memory components designed, processed, and tested to commercial, industrial, wide, and automotive grade temperature ranges. SMART also offers application expertise for new designs to help determine system layout to accommodate thermal and system performance and develops specific test and burn-in processes such as Zefr™ Memory Processing to meet design objectives.\

Using Zefr, SMART memory consistently performs at <200 DPPM, (defective parts per million) . The industry standard for acceptable fallibility is 3,000 to 5,000 DPPM, so SMART can save its customers from costly shutdowns, maintenance and having to ramp up production again, by providing much more reliable memory than its competitors

Design and Delivery Services

SMART engages customers to understand the design requirements and evaluate a memory solution for the application. Mechanical modeling, performance modeling, thermal modeling, and state-of-the-art tools are used to evaluate the proposed solution for its suitability and throughout the product lifecycle. Where possible, SMART aims to ensure that a system designer can use standard devices. When that’s not achievable, SMART’s capabilities are comprehensive and include:

• Design: Requirements and potential solutions are discussed and agreed upon for the end-product

• Model: Modeling tools are used to evaluate the following:

o 2D- and/or 3D-models for mechanical suitability

o High-speed simulation with FPGA and ASCI-based memory for functionality

o Thermal modeling for heat dissipation and management

• Test: The following test capabilities are available:

o Design Verification Testing (DVT)

o Firmware and RTL design and test

o Automated Test Equipment (ATE)

• Analysis: Power consumption

Standard parts can also be customized through the manufacturing and testing processes for individual embedded applications. Some of the customizations that SMARTsemi provides are:

• ASR – Anti-Sulfur Resistors for use in high-pollution environments

• Conformal Coating to support reliable operations in moist and contaminated environmental conditions

• Advanced error detection and correction (EDC) for single event upsets (SEU)

• Zefr™ processing for ultra-high reliability

Even after the product is deployed, SMART can support field-updates. eMMCs can be pre-programmed and tested prior to shipping. Testing and labels can be reflective of specific compliance needs. Laser marking of components is also an option. In short, SMARTsemi offers services for the entire product development cycle based on your requirements.

Summary

Embedded applications memory requirements often have power, space, performance, reliability, and longevity criteria that are best addressed by package and process technologies outside of those supported by the main memory suppliers. SMART Modular Technologies is in a unique position to support the embedded marketplace through its expertise in memory devices and their processing technologies and business relationships with key wafer manufacturers in the memory space. Please contact your SMART Sales Representative to learn more about how SMARTsemi products can help address your embedded application needs.

(Frequently asked Questions – FAQs)

Q: What kind of products does SMARTsemi provide?

A: SMARTsemi provides DDR2, DDR3, and DDR 4 SDRAMs from 512Mb to 4Gb and FLASH based memory products targeted for the embedded marketplace. Flash products include eMMCs 5.0 and 5.1 from 4GB to 128GB and portable SD/ microSD Cards from 8GB to 256GB.

Q: Are these available for automotive applications?

A: Yes. At the time of this writing, selected DDR3 devices are available tested for Automotive AEQ-100 Class-2 compliance. Numerous DRAMs and FLASH components are offered in the automotive temperature range.

Q: What kind of supply guarantee can I expect as embedded applications tend to have longer lifecycles?

A: SMARTsemi understands the need for longer availability and works with memory suppliers to extend the lifecycles of memory devices for its customers by as much as 3 to 5 years.

Q: What kind of packages do these come in?

A: In addition to standard memory BGAs, we can customize the package for your needs including labeling, retention clips, and marking.

Q: Can you integrate our ASIC with memory in a single package?

A: Yes. Our Applications engineering team can work with you to design a custom solution.

Q: We need parts with very high reliability. How can you help us achieve that?

A: We recommend our Zefr™ processing to achieve ultra-high reliability. SMART Modular developed Zefr processing techniques to eliminate devices susceptible to infant mortality and other failure mechanisms. Contact us for more details.

Q: Do we need to outsource the entire development to SMARTsemi?

A: You can engage with us for as much or as few of the services that you need. We can share certain customer-experiences with you to highlight aspects that are most relevant for your application. For example, in one application, the design was extremely form-factor constrained as well as environmentally challenged, and we delivered a solution by working in close association with the customer’s engineering team.

For more product details, visit our website.