SMART Memory for Liquid Immersion Servers

Application Examples

• Liquid Immersion Servers in Data Centers

• High-Density Computing Environments

• Hyperscale Cloud Providers

• Edge Data Centers and HPC Clusters

Problem Statement

Data centers face major challenges related to power consumption and heat dissipation. Traditional air-cooled servers rely heavily on fans and extensive cooling infrastructure, which consume significant power and occupy valuable space. The adoption of liquid immersion cooling drastically reduces power overhead by eliminating fans and minimizing cooling infrastructure needs. However, using standard RDIMM memory modules in liquid immersion servers introduces reliability risks such as corrosion from liquid exposure, fading of component markings making identification difficult, and degradation of module labels that complicates tracking and maintenance.

Solution Overview

• Advanced conformal coating applied as a thin polymeric film (25–250 µm thickness) protects PCBs and components.

• Coating materials include high-quality acrylic, polyurethane, silicone, and epoxy for robust protection.

• Automated, precision in-house spray application ensures consistent, reliable coverage.

• Protection guards against liquid, moisture, dust, and corrosive chemicals like sulfur dioxide.

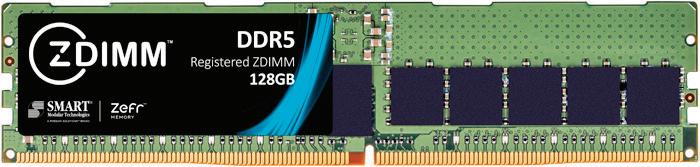

• Maintains full DDR5 RDIMM functionality at speeds up to 6400 MT/s and densities from 32GB to 256GB.

• Modules also operate reliably in ambient temperatures from 0°C to +70°C.

• Addresses common liquid immersion issues such as corrosion, fading component markings, and label degradation.

Product Summary Overview

Headquarters/North America: T: (+1) 800-956-7627 • T: (+1) 510-623-1231 F: (+1) 510-623-1434 • E: info@smartm.com

Individual part nos. can be found on www.smartm.com

For more information, please visit: www.smartm.com

*Product images are for promotional purposes only. Labels may not be representative of the actual product.

Latin America: T: (+55) 11 4417-7200 • E: sales.br@smartm.com EMEA: T: (+44) 0 7826-064-745 • E: sales.euro@smartm.com Asia/Pacific: T: (+65) 6678-7670 • E: sales.asia@smartm.com

Customer Service: T: (+1) 510-623-1231 • E: customers@smartm.com