19 minute read

Technology

TECHNOLOGY

Building virtual infrastructure with flexible manufacturing system

The shift from mass production to mass customization is constantly becoming a more common approach in the heavy steel industry. As the Industry 4.0 technologies evolve, companies can leverage the benefits, such as organizational performance and flexibility, and build an entire virtual infrastructure.

The new approach to manufacturing

While transformation opens new opportunities, it also challenges the status quo. Currently, the manufacturing industry is challenged by varied factors, such as a widening portfolio of different types of products, increasing production costs, and the growing lack of a skilled workforce. Furthermore, as Gen Z has entered the workplace, the structures of work are at their culmination point.

During the past years, one of the most appealing trends in the manufacturing industry has been the shift from mass production to mass customization. The centralized mindset that has guided manufacturing during the three previous industrial revolutions is now yielding and replaced with a more reactive and dynamically altering approach. Now, these changes in the market require reinvention from the manufacturers, and utilizing the available smart technology becomes a must to respond to the progressions. The purpose of the Flexible Manufacturing System (FMS) is to economically permit the creation of varied workpieces in small (or even a single piece) and repeatable batches The system allows altering the type of produced workpieces efficiently and flexibly. In the context of heavy manufacturing, FMS is a software-controlled tool that includes production lines capable of automated material handling and welding processes based on a predefined schedule while mitigating manual interventions.

Initially, FMS has been built on the core idea that it ensures adaptive manufacturing. Hence, the minimum expectation is that it smoothly adapts to changes in production by integrating varied automation machinery that communicates and collaborates directly with each other.

As an example, in the PEMA FMS manufacturing cell, tack-welded workpieces are inputted to the work queue. The solution allows altering workpieces since they are

FMS and virtual infrastructure

TECHNOLOGY

identified individually by the robot cell. The applied welding program is selected by utilizing the PEMA FMS control for each piece. The tackwelded workpiece is loaded with an automatic pallet changer. Fastening the structure to a positioner through an automatic pallet changer enables a fast and safe set-up of palettes and workpieces. Finally, the welded workpieces are transported out of the cell with their conveyor.

Enhancing FMS with Industry 4.0.

Industry 4.0, in other words, the digital transformation of manufacturing to produce value processes, has firmly made its way across industries. It is known as a developmental trajectory in which traditional manufacturing and industrial operations are combined with digital technologies. The main objective in adopting Industry 4.0. technologies are to enable people, machines, equipment, logistical systems, and work-in-process components to communicate and collaborate directly. Reports show, that companies who have successfully incorporated the technologies into their manufacturing procedures have gained improved organizational performance and sustainable competitiveness.

When it comes to flexible manufacturing systems, the 4.0 technologies, such as IoT, big

In the heavy fabrication industry, the shift from mass production to mass customization is

constantly becoming more popular. Advanced robotic solutions along with smart software enable more reactive and flexible manufacturing.

TECHNOLOGY

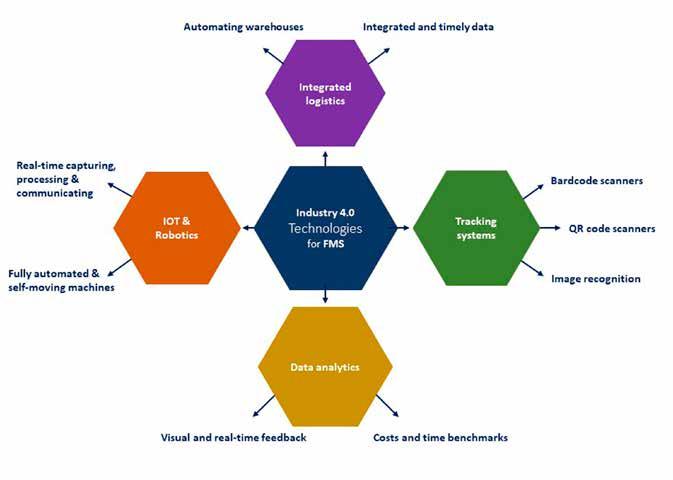

Figure 1. The innovation trajectories enabled by Industry 4.0 for Flexible Manufacturing System.

Pemamek already has FMS solutions available that incorporate advanced 4.0 technologies. The figure design was adopted from Javaid et al. (2022).

data, advanced robotics, additive manufacturing, and virtual reality, enhance machines’ altering capability throughout the entire manufacturing process. Smart automation can collect a vast amount of data and generate it into algorithms to execute the optimal course of action. Furthermore, machines can precisely detect and forecast which aspects will affect production or assembly line speed and quality.

According to some reports, the first FM system has been patented in the 1960s by Theo Williamson who developed numerically controlled equipment. Throughout the decades the concept of FMS has evolved and grown tremendously bringing along new capabilities and features. The integration of Industry 4.0 technologies has taken FMS several steps further towards significant betterment while creating novel innovation and R&D trajectories. Figure 1, adapted from Javaid et al. (2022), presents the fundamental strategies and 4.0 technologies for enhancing FMS. These technologies are IoT & robotics, integrated logistics, tracking systems, and data analytics.

Smart routing

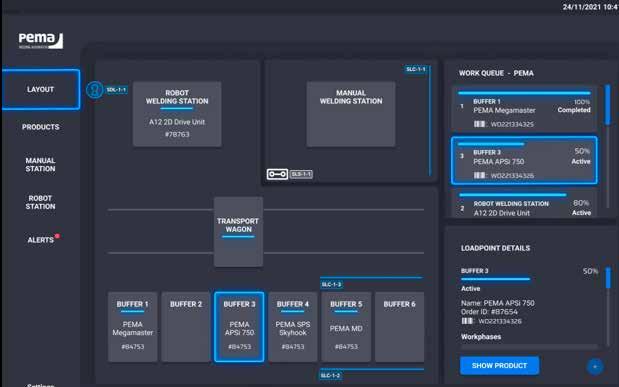

As a company, Pemamek distinguishes itself by designing and developing the software included in the PEMA automation machinery. Some of the masterpieces are PEMA WeldControl 200 for shipbuilding, PEMA WeldControl 300 for robotic stations, and PEMA WeldControl 500 for managing heavy fabrication with Column & Boom. When it comes to PEMA FMS, the strategy has been no different. The freshly updated software for Pemamek’s PEMA FMS has turned out to be one of the most advanced in terms of altering and adapting the routing. In the system, each workpiece is first identified by RFID or QR-code, after which the transport system takes the structure to the right station.

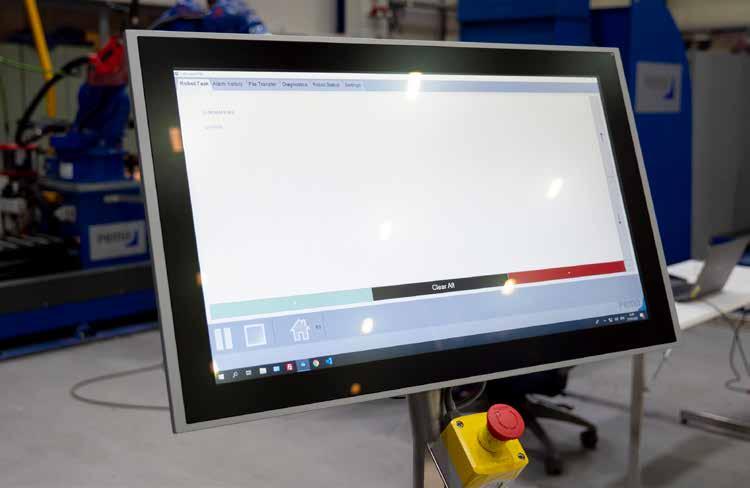

Throughout the process, the FMS tracks all work phases and provides information on the progress presented in the visually streamlined interface. Furthermore, the interface provides the constant status of the complete line, provides a view of the work queue, and sends possible alerts, among other features. TECHNOLOGY

Towards the future

In the globalized world, the pool of potential competitors enlarges. Thus, manufacturers’ top priority should be to maintain and develop their operative competitiveness. In heavy steel industries, maintaining a conventional manufacturing environment is many times inefficient, time-consuming, and costly. To flourish in an operational environment with increasing turbulence and unexpected discontinuities, manufacturing is required to become more flexible through digital transformation.

Today’s cutting-edge technologies have proved that increasing production or welding speed is no more equal to sacrificing production (Müller et al., 2018). For companies that have significant product variations, but short product life cycles, PEMA FMS is an optimal solution to gain consistent manufacturing with high quality – and to stay ahead of the competition.

References: Javaid, M., Haleem, A., Singh, R., Suman, R. (2022). Enabling flexible manufacturing system (FMS) through the applications of industry 4.0 technologies. Internet of Things and Cyber-Physical Systems. Volume 2, 2022. Pages 49-62. ISSN 2667-3452. https://doi.org/10.1016/j.iotcps.2022.05.005.

A layout example of PEMA FMS. The system is a software-controlled set of equipment consisting of production lines that automize material handling and welding processes based on a predefined

route. The system mitigates manual interventions while increases performance and flexibility.

Pemamek is known for developing user-friendly and visually appealing software in-house. The PEMA FMS line control software is one of the most advanced routing systems.

CUSTOMER STORY

TEN’s facilities are located in the Jacobina, nearby the majority of Brazil’s wind farms.

PEMA customer

Torres Eólicas do Nordeste, TEN

LOCATION

Jacobina, Brazil

CUSTOMER SEGMENT

Wind energy

TEN levels up its production machinery

TEN, Pemamek’s long-term customer, has made strategically significant investments in its wind tower manufacturing processes. The company has gained more productivity and future competitiveness by investing in modern PEMA production automation technology.

The Brazilian steel tower manufacturer, Torres Eólicas do Nordeste (TEN), has been systematically increasing its production capacity, and safety. During the past nine years, the company has invested in three PEMA solutions as a part of a wider strategy to maintain competitiveness in constantly growing green energy markets.

TEN is located in the Jacobina, state of Bahia, nearby the majority of Brazil’s wind farms. Since the first investment in the PEMA solution in 2013, Pemamek and TEN have maintained close collaboration to improve the tower manufacturer’s production capacity, productivity, and safety while decreasing manual work at the same time.

“For us, the quality of our products is very important. The advanced technology and high productivity are the foundation for us to be the number one in the Brazilian market”, tells Carlos Konopatzki, General Director at TEN. CUSTOMER STORY

Watch a video of PEMA WS2 welding platform

TEN and Pemamek have a fruitful longterm partnership and it was easy to work together on the latest project with the WS2 welding platform.

CUSTOMER STORY

Natural choice

The first machinery that the company ordered was twelve PEMA Assembly stations, integrated with six PEMA HD Column&Booms. In 2019 TEN placed another order for the PEMA Flange Fitting (FF) station to increase the stability of processes for tower manufacturing and to maintain the high quality of the products. PEMA FF station is designed to enable fast, safe and, accurate fitting and welding of flanges to the wind tower and tower foundation sections without turning the shell.

As the tower structures constantly get bigger and heavier, TEN needed to search for the most effective solution to produce the new onshore towers in Brazil. Konopatzki continues:

“We already knew Pemamek’s team very well and it was easy to work with everyone. Pemamek was a natural choice for us, because of the wide knowledge of their welding experts and high technology solutions.”

Partnership bears fruits

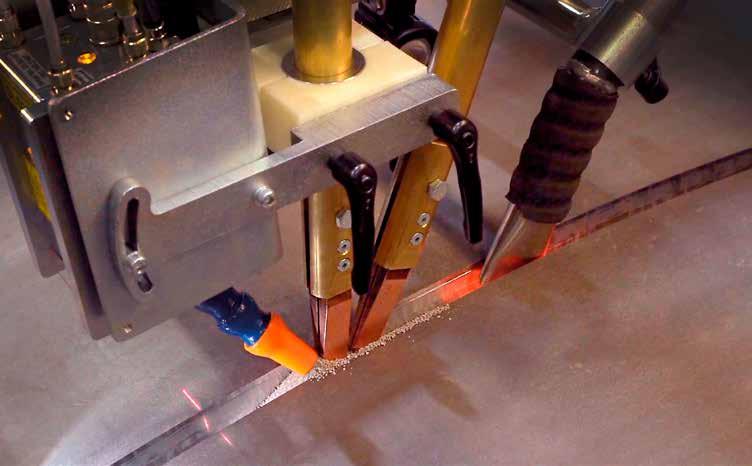

As a part of the company’s wider future strategy, TEN made yet another investment in PEMA welding solution and ordered the PEMA WS2 Welding Platform. The solution, equipped with two tilting and simultaneously working welding heads, makes the welding process even more efficient. The platform saves time in TEN’s manufacturing process and it also reduces the need for manual work. Additionally, it releases the human workforce to other crucial preparation and operative production tasks. “We have reached the most important technological improvements with the software. The multipass welding functionality measures groove shapes and volumes. It also gives higher productivity when working with bevels on the outside and welding two seams at the same time with consistent quality.“

TEN’s tower production is getting more efficient since the arc welding process is fully automated.

CUSTOMER STORY

Pemamek’s in-house software WeldControl 500 plays an important role in TEN’s wind tower manufacturing as it gives a remarkable boost to production efficiency.

“The diameter of our workpieces is about five meters while the material thickness is up to 60 mm. In the future, we expect the tower manufacturing to be even more demanding”, Konopatzki describes.

The WS2 welding platform is equipped with Pemamek’s in-house designed software PEMA WeldControl 500. The software is an advanced and visual tool that gives a remarkable advantage to TEN’s tower production since the arc welding process is fully automated.

“We have reached the most important technological improvements with the software. The multipass welding functionality measures groove shapes and volumes. It also gives higher productivity when working with bevels on the outside and welding two seams at the same time with consistent quality“, Konopatzki continues.

Future in green energy solutions

For TEN, precise and stable production, but also reliable handling equipment, and efficient welding solutions are factors to reach more productivity and future competitiveness with a fast return on investment. Prospects for renewable energy production look good and the demand for wind energy is increasing.

“In the coming years, we are processing with bigger workpieces and welding thicker plates. With this investment, TEN prepares for the future to operate in any type of onshore projects”, Konopatzki summarizes.

CUSTOMER STORY CUSTOMER STORY

Volvo extends machine lifetime with retrofits to PEMA stations

One of the world’s leading manufacturers of haulers and wheel loaders knows what drives their business forward. Swedish company Volvo Constructions Equipment is committed to the goal to be the best supplier in the industry. By trusting in partnership with Pemamek and investing in the latest technology they keep on succeeding at full speed.

Volvo Construction Equipment Ab, established in 1832, has had its main wheel loader factory in Arvika, south-western Sweden, since 1966. During its long history, the company has created an innovative and safe working environment that inspires to reach targets sustainably. Volvo utilizes the latest innovations and technologies in its manufacturing processes and has constantly developed new solutions for better fuel economy, improved safety, increased productivity, and a more comfortable operator’s environment.

At the Arvika hauler and loader business line the company manufactures frames and booms with 900 employees at this moment. Heavy machines require heavy welding equipment and Volvo has trusted in PEMA production automation for 30 years already. The fruitful partnership between companies started in the early 1990s with an automated welding station for lifting frames. Multilayer welding made the production 10 to 15 times faster than manual welding, providing good and solid quality.

In 2006 three PEMA robot stations were installed for front frame welding and they have been running smooth and well for 15 years in four shifts. Last autumn manufacturing capacity got a boost in the shape of the new upgrades, which extended the machines’ lifetime at least ten years forward. This not only decreases the need to invest in new machinery but also increases the energy efficiency of the existing machines remarkably.

Welding heavy frames

In Volvo’s machinery manufacturing, the core philosophy is to always maintain superior performance. Investing in modern technology ensures that the job can be done with high quality. With the front frame welding process, the company decided to invest in the retrofit and upgrade all the three existing PEMA robot welding stations.

“A typical weld measure for us is about A5, A6, or A8. We have quite much large joints, so multipass welding is very typical for us. The welding cycle is approximately from 2,5 to 4 hours per frame, so there’s a lot of welding included to manufacture these heavy frames”, tells Martin Elvén, Project Manager at

Volvo Construction Equipment Ab.

PEMA customer

Volvo Constructions Equipment Ab

LOCATION

Avrika, Sweden

CUSTOMER SEGMENT

Heavy equipment

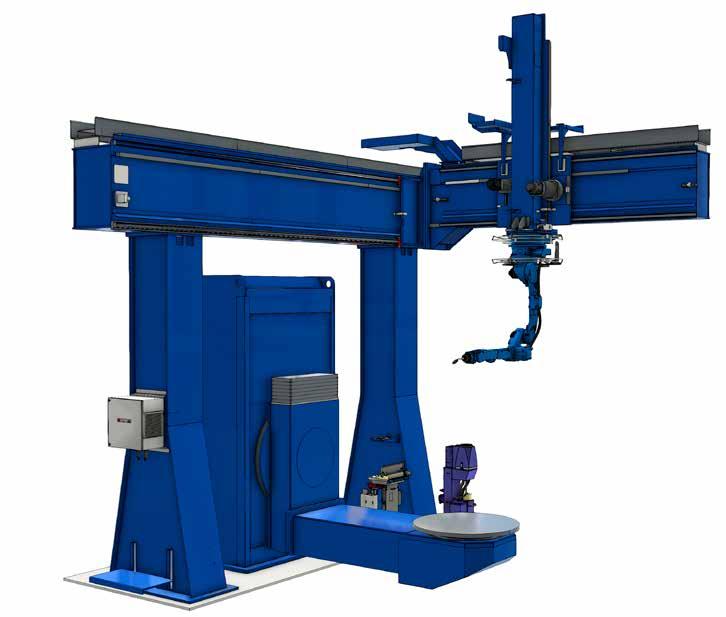

These stations are customized especially for Volvo’s needs and are a result of the development work of both companies together. PEMA X-Y-Z gantry robot stations with the 3-axis Skyhook type of positioners have worked over 50 000 hours arc-on-time in multilayer MAG welding. Final products can be over two meters long and weigh several tons. Front frame parts are made of steel plates with thicknesses varying between 10-40 mm.

Such heavy parts require the manufacturing machines to be capable to handle them without effort. An appropriate environment creates efficient and safe working circumstances for operators. As the weld seams are big, Pemamek’s inhouse software makes the multilayer programming easy and fast offering data collecting and development tools to track and optimize the production process.

The main factory for Volvo wheel loaders locates in Arvika, south-western Sweden.

Prolonging machine lifetime

The existing three similar PEMA robot welding stations will serve Volvo Arvika’s wheel loader front frame manufacturing for at least the next ten years with normal maintenance. The refreshed stations have updated mechanical parts, wear parts, also a new robot, and welding equipment. The software was upgraded with PEMA CellControl 700.

The control system is tailored especially for Volvo’s production needs. “We upgraded the process equipment to give us the possibility to take advantage of the improved processes. Our investment included three offline programs and with them, we could easily do the final programs in the robot cells for eight different models”, Elvén says.

With the PEMA software and assistance of welding and robot engineers, the knowledge and welding experience was turned into practice in robotized MAG

CUSTOMER STORY

welding very smoothly and fastly from the start. Among the new programs, the existing ones were fine-tuned to meet the current needs. Updated Volvo’s offline program tools ensure a fast and visual method to control the robots giving more efficiency. The control system gives a flexible way to combine different functions, controlling the work cell at the same time. Production monitoring and data collecting give tools to minimize risks and develop the production process further.

Smooth transition to future manufacturing

Minimizing the production downtimes and having a quick ramp-up was important to Volvo due to the high production volumes. From the start of industrialization, it took six weeks for the company to take over the equipment and continue to trim the products. “After eight weeks the production started in two shifts and programming was carried out in the daytime. Since December all the products have been produced in this cell”, Elvén tells.

“The results have been really good. We have much fewer adjustments after the robot welding. Our long-term target is zero adjustments after robot and this project was a big step in that direction. We have also managed to decrease the cycle times by around 10%”, he continues. The improved working environment ensures effortless facilities for operators. Robot stations are producing good quality products reducing manual work and finishing tasks. Shifting to new updated robotic welding stations keeps the

Volvo Arvika has three similar PEMA

robot welding stations. All of them are getting retrofits with new robots, power sources, welding equipment, and some mechanical parts and components. CUSTOMER STORY

company competitive as they can utilize the collected data in multiple ways in the wheel loader manufacturing process. Volvo also had support via remote assistance in their route to implementing the new solution.

“All the expectations were fulfilled with two first welding stations, and we managed to reach all the goals we had with this implementation. It was easy to work with Pemamek and we were on the same level. We appreciated the way we were taken care of and we are ready to plan our next summer project with the third robot station”, Elvén summarizes.

Volvo’s software was upgraded with a visual and easy-to-use PEMA CellControl 700 control system.

CUSTOMER STORY

Steel in, ships out: ANI reinforces Australia’s future shipbuilding capabilities

Strong, sustainable, and innovative. The words that describe the Australian Government’s vision for the country’s naval industry. In 2016, the island nation published the 2016 Defense White Paper, which laid the framework for the largest expansion of the Royal Australian Navy since the Second World War.

• Around $90 billion in new naval ships and submarines

• More than $1 billion in modern shipyard infrastructure

• Up to $62 million in workforce growth and skilling initiatives to enable the delivery of these platforms.

*Naval Shipbuilding Plan (2017), Department of Defence, Australian Government.

Fun fact: ANI’s logo is based on the silent communication called Morse code, and directly translates to “ANI”.

PEMA customer

Australian Naval Infastructure

LOCATION

Adelaide, Australia

CUSTOMER SEGMENT

Shipbuilding

Osborne Naval Shipyard is owned by the Federal Government business enterprise, Australian Naval Infrastructure Pty Ltd.

CUSTOMER STORY

CUSTOMER STORY

The main objective of the investment was to create an end-to-end shipyard capability.

The solution provider was selected based on the capabilities to provide leading-edge capabilities.

Pemamek’s delivery included high-tech shipbuilding automation, such as robotized block and curved panel welding stations.

Forefront of shipbuilding

One of the extensive upgrading initiatives in the country’s maritime domain involves the Hunter Class Frigate program, among others.

“Current activities in the Osborne Naval Shipyard, since the completion of upgrade works in mid-2020, have focused on the progression of the Hunter Class Frigate Program ‘prototype’ phase works. This program is being undertaken by BAE Systems Maritime Australia on behalf of the Australian Government. The first of the nine Hunter Class Frigates is scheduled to commence production from 2023”, says Cornish.

Pemamek’s extensive welding and production automation delivery included a vast amount of high-end shipbuilding technology, such as advanced PEMA flat panel and micro panel lines, PEMA T-beam manufacturing line, PEMA profile processing line, and robotized block welding stations, as well as plate milling

technology.

The entire investment in the maritime domain is estimated to total approximately $75 billion AUD (Force Structure Plan, 2016). The large-scale initiative has already contributed directly to the nation’s workforce growth but also brought economic and strategic advantages.

To fulfill the commitment and regenerate the nation’s naval industry, in 2017, the Australian Government established a government business enterprise, Australian Naval Infrastructure (ANI).

“ANI’s primary function is to be the owner, developer, and manager of the infrastructure and related facilities. Our motto ‘steel in, ships out’ encapsulates the strategy of the shipyard and is used nationwide.”, tells Phil Cornish, the

Project Director of Australian Naval Infrastructure.

As a part of the program, ANI was requested to develop the Osborne Naval Shipyard to support the Australian Government’s ‘Continuous Naval Shipbuilding Plan’. This envisaged the delivery of naval combatants, up to 10000 t destroyer size vessels, in a 2-year drumbeat.

Among the key enablers

In its Naval Shipbuilding Plan, the Australian Government had listed the development of modern, innovative, and secure shipyard infrastructure as one of the key enablers to achieving the naval shipbuilding objectives. The total investment to develop future shipbuilding capabilities were more than $500 million AUD in total.

“The key objective of this investment was to create an end-to-end shipyard capability. Before the Osborne Shipyard used to be a consolidation shipyard, so it was relying on components coming from other locations in Australia or internationally”, Cornish continues.

To follow the “steel in, ships out” motto and make a shift from a consolidation shipyard to having leading-edge shipbuilding capabilities, the search for an equipment provider started. The solution provider was expected to be capable of providing leading-edge machinery and supporting the Government’s objectives. According to Cornish, a tight tendering process was completed after which Pemamek was selected as the partner due to its high expertise in shipbuilding automation and production technology.

Cornish continues: “Ultimately, Pemamek was selected as the key subcontract partner to our Managing Partner, Lendlease. The company was able to introduce new processes for future naval shipbuilding with a focus on high levels of accuracy, reliability, and automation. These were not previously available at Osborne.”