AWARDS

2018 SIDNEY FREEDMAN CRAFTSMANSHIP AWARD USC VILLAGE, LOS ANGELES

USC VILLAGE IS A VISUAL TESTAMENT TO THE VERSATILITY AND COMPLEX ARCHITECTURAL DESIGN OF ARCHITECTURAL PRECAST CONCRETE CONSTRUCTION The Oxford-inspired USC Village project is a multiple-building complex that encompasses the many facets and intricate details of Collegiate Gothic architecture. The project provides University of Southern California students and faculty retail and dining options on the ground floor, with student support services and housing on the remaining floors.

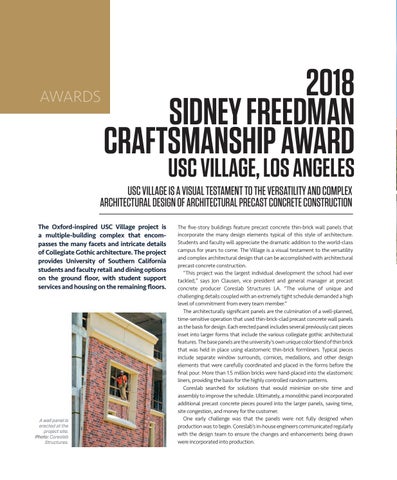

A wall panel is erected at the project site. Photo: Coreslab Structures.

The five-story buildings feature precast concrete thin-brick wall panels that incorporate the many design elements typical of this style of architecture. Students and faculty will appreciate the dramatic addition to the world-class campus for years to come. The Village is a visual testament to the versatility and complex architectural design that can be accomplished with architectural precast concrete construction. “This project was the largest individual development the school had ever tackled,” says Jon Clausen, vice president and general manager at precast concrete producer Coreslab Structures LA. “The volume of unique and challenging details coupled with an extremely tight schedule demanded a high level of commitment from every team member.” The architecturally significant panels are the culmination of a well-planned, time-sensitive operation that used thin-brick-clad precast concrete wall panels as the basis for design. Each erected panel includes several previously cast pieces inset into larger forms that include the various collegiate gothic architectural features. The base panels are the university’s own unique color blend of thin brick that was held in place using elastomeric thin-brick formliners. Typical pieces include separate window surrounds, cornices, medallions, and other design elements that were carefully coordinated and placed in the forms before the final pour. More than 1.5 million bricks were hand-placed into the elastomeric liners, providing the basis for the highly controlled random patterns. Coreslab searched for solutions that would minimize on-site time and assembly to improve the schedule. Ultimately, a monolithic panel incorporated additional precast concrete pieces poured into the larger panels, saving time, site congestion, and money for the customer. One early challenge was that the panels were not fully designed when production was to begin. Coreslab’s in-house engineers communicated regularly with the design team to ensure the changes and enhancements being drawn were incorporated into production.