COMPANY PROFILE ADVERTORIAL

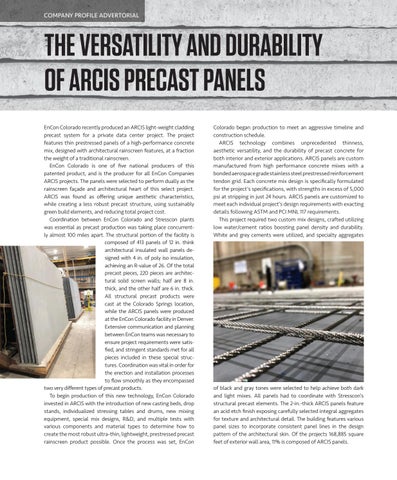

THE VERSATILITY AND DURABILITY OF ARCIS PRECAST PANELS EnCon Colorado recently produced an ARCIS light-weight cladding precast system for a private data center project. The project features thin prestressed panels of a high-performance concrete mix, designed with architectural rainscreen features, at a fraction the weight of a traditional rainscreen. EnCon Colorado is one of five national producers of this patented product, and is the producer for all EnCon Companies ARCIS projects. The panels were selected to perform dually as the rainscreen façade and architectural heart of this select project. ARCIS was found as offering unique aesthetic characteristics, while creating a less robust precast structure, using sustainably green build elements, and reducing total project cost. Coordination between EnCon Colorado and Stresscon plants was essential as precast production was taking place concurrently almost 100 miles apart. The structural portion of the facility is composed of 413 panels of 12 in. think architectural insulated wall panels designed with 4 in. of poly iso insulation, achieving an R-value of 26. Of the total precast pieces, 220 pieces are architectural solid screen walls; half are 8 in. thick, and the other half are 6 in. thick. All structural precast products were cast at the Colorado Springs location, while the ARCIS panels were produced at the EnCon Colorado facility in Denver. Extensive communication and planning between EnCon teams was necessary to ensure project requirements were satisfied, and stringent standards met for all pieces included in these special structures. Coordination was vital in order for the erection and installation processes to flow smoothly as they encompassed two very different types of precast products. To begin production of this new technology, EnCon Colorado invested in ARCIS with the introduction of new casting beds, drop stands, individualized stressing tables and drums, new mixing equipment, special mix designs, R&D, and multiple tests with various components and material types to determine how to create the most robust ultra-thin, lightweight, prestressed precast rainscreen product possible. Once the process was set, EnCon

as.sp19.arcis.indd 58

Colorado began production to meet an aggressive timeline and construction schedule. ARCIS technology combines unprecedented thinness, aesthetic versatility, and the durability of precast concrete for both interior and exterior applications. ARCIS panels are custom manufactured from high performance concrete mixes with a bonded aerospace grade stainless steel prestressed reinforcement tendon grid. Each concrete mix design is specifically formulated for the project’s specifications, with strengths in excess of 5,000 psi at stripping in just 24 hours. ARCIS panels are customized to meet each individual project’s design requirements with exacting details following ASTM and PCI MNL 117 requirements. This project required two custom mix designs, crafted utilizing low water/cement ratios boosting panel density and durability. White and grey cements were utilized, and specialty aggregates

of black and gray tones were selected to help achieve both dark and light mixes. All panels had to coordinate with Stresscon’s structural precast elements. The 2-in.-thick ARCIS panels feature an acid etch finish exposing carefully selected integral aggregates for texture and architectural detail. The building features various panel sizes to incorporate consistent panel lines in the design pattern of the architectural skin. Of the projects 168,885 square feet of exterior wall area, 11% is composed of ARCIS panels.

4/9/19 4:49 PM