4 minute read

Foam For The Win

Tuz Caner and Jean-Luc Scmitter, Weber Mining & Tunnelling, explore the use of phenolic foams to prevent spontaneous combustion in the Soma region coal mines.

This article will review the potential safety issues of spontaneous combustion and roof collapse arising from unstable strata at the Soma coalfield in Türkiye, and how the application of phenolic foams for ventilation control and cavity filling improve safety and production.

Case study: Soma coalfield, Türkiye

Coal in the mines at the Soma coalfield is very sensitive to spontaneous combustion.

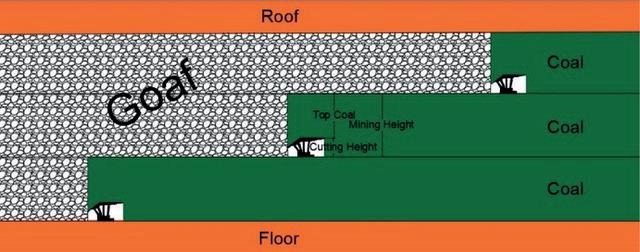

The mining method used is longwall top coal caving (LTCC) (Figure 1). The Soma Eynez coal seam is a large seam, bearing a thickness of up to 30 m, and is produced by running three longwalls at different elevations at the same time. Each longwall has a cutting height of 3 m. The first longwall runs near the roof, while the other two stay approximately 30 m behind. With this mining method, the longwall that moves at the bottom encounters the most issues, due to the 30 m of loose goaf material above.

Managing spontaneous combustion

The most critical issue to manage is spontaneous combustion. It is important to stay on the move with the longwall and to seal the goaf as soon as possible, in order to prevent fire issues.

If the longwall stops long enough, the air present behind the shield line can ignite the coal.

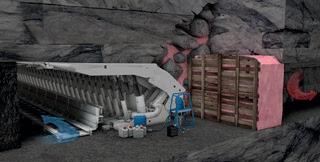

At the intersection between the coal face and the gate road, the airflow from the bottom roadway has a tendency to head straight for the caved goaf. Therefore, it is important to control the airflow entering the goaf area and to direct it instead through the longwall face – this can be achieved by constructing an air barrier at the bottom end of the face line. In order to prevent this situation, an airtight barrier is constructed with foam on the maingate and tailgate of the coal panel (Figure 2). This system also reduces the risk of spontaneous combustion within the goaf area.

Roof collapse

Another common issue is the possibility of the roof collapsing. This occurs often when the longwall advancement slows down. In this situation, the coal face has time to destabilise and wash out, leaving an unsupported portion of roof which starts to collapse.

To continue production and to restore workplace safety,

these cavities have to be filled as fast as possible. Reducing downtime is critical to prevent the situation from becoming worse (Figures 3 and 4).

It is important to treat cavities as soon as possible, stabilising smaller cavities before they become larger. The speed of filling is also critical, as it should not slow down the longwall advancement. Therefore, the cavity filling material for this situation should have the following properties: A high expansion rate to: � Maximise cavity fill capacity. � Reduce pumping times. � Reduce the transport time of filling material. A fast-setting time in order to avoid the shuttering of the cavity. Pumpable from a distance to save transport time and to improve safety.

Figure 1. Mining method at Imbat (SOMA Region). Source: JANGARA, H. and OZTURK, C. A., ‘Production alternatives’, Ground control conditions of the mechanized longwall mining at Alpu lignite deposit, Istanbul Technical University.

Figure 2. Use of foam to construct an airtight barrier.

Figure 3. Use of foam to restore safety to unstable roof. The solution

Phenolic foam resin cavity fillers meet all of these requirements.

State-of-the-art phenolic foams expand up to 80 times, with immediate foaming and a setting time of minutes. Recent developments have also been made to improve the safety aspects of these chemistries. These modern foam formulations represent significant improvement for safety in use.

Compressive strength is also an important factor when it comes to filling big cavities. When compressive strength is required, there are alternative versions of phenolic foams with less expansion and higher compressive strength.

This foam is also used to control ventilation.

Sealing behind shields, especially on the corner between the air entry and the longwall, minimises the oxygen in the goaf significantly, thereby reducing the spontaneous combustion threat.

Having this foam on site enables rapid action to close or seal the intake air roadway in case of fire in the longwall.

Figure 4. Use of foam for cavity fill. Results

Weber Mining’s Mariflex LS1 is the phenolic foam used for ventilation control and cavity filling at IMBAT (Soma Region).

Using Mariflex LS1 helped the mine to reduce the incidence of production downtime, improving the productivity and, most importantly, the safety of the miners working in very harsh conditions.

Conclusion

At Soma, the use of phenolic foams with high expansion and fast setting times has provided rapid filling of cavities and ventilation control, improving safety and production.