7 minute read

Making A Difference One Wear Part At A Time

Metso Outotec discusses various approaches that can be taken to make mill liner design, usage, and disposal more sustainable.

Wear parts play an important role in any mining operation. Not only are they critical to protecting the equipment, but they also have a big impact on performance. Since wear parts need to be replaced frequently, considering the environmental impact of the parts that are chosen may be more important than one thinks.

There are several ways wear parts can reduce carbon dioxide (CO2) emissions and improve the safety of operations. Take grinding, for example: it is a tough, energy intensive process that results in heavy wear and tear on the equipment and parts. The mill liners, made from steel or rubber (or a combination of the two), are used to protect the machinery. If the aim is to increase

the sustainability of wear parts, the key is to focus on maximising the liner life and minimising the liner leftovers after their lifecycle.

Select the right part material to reduce waste Closely monitor wear and replace parts at the right time

The life of a mill liner can be maximised by selecting exactly the right wear part material or material combination based on specific operating conditions. The optimal design, aimed to last longer and perform better, can be verified with simulations. A quick win from a sustainability perspective is to minimise waste; when a liner wears, there is a point where it becomes too smooth to promote the right charge motion inside the mill, but there is always some excess material left in the liner.

If the leftovers can be minimised, and it is confirmed that the lining is as thin as possible when being replaced, this is a really good way to save material. For example, if 1 kg of rubber or steel is saved, there is a direct reduction in CO2 footprint. If the liner design has already been optimised to last longer, then there is no need to throw away this excess material as often, and things start adding up. The effect of saving resources multiplies further, as long-lasting wear parts mean less production, transportation and replacement parts, translating to lower energy, water, and fuel consumption.

Figure 1. Metso Outotec’s patented virtual inspection platform uses 3D scanning to offer a safe and efficient environment for technical discussions.

Figure 2. Circularity is vital in the reduction of CO2 emissions. There is an ongoing development to increase the use of recycled materials in mill liners. A lot of useful information is available when wear is closely monitored, and the wear history is analysed. Modern wear monitoring tools ensure up-to-date information on how the parts are wearing. Close monitoring of the wear also means that the parts can be replaced at an ideal time. Usually, certain areas in the mill are subjected to more impact or abrasion and thus wear out before the rest of the lining. By monitoring how the liner wears and how its profile changes over time, it allows operators to see how to best utilise the material. The material can be moved from a low-wear area to high-wear area, and increase the utilisation of materials. Furthermore, the data means the liner design can be optimised for increased efficiency, meaning less energy per produced tonne will be used. Obviously, the grinding circuit can also be optimised.

Lately, there has been a growing need for remote services and support. New tools have been developed to track liner performance, such as the Metso Outotec Virtual Inspection tool for horizontal grinding mill linings. The patented Virtual Inspection platform enables the scanned mill linings to be viewed in virtual reality and offers an efficient and safe environment for technical discussions. ‘On-site’ mill lining inspections can be safely hosted while being off site, due to the fully immersive virtual walk-throughs and the ability to comprehensively review any particular point of the mill lining. Viewing the scans in virtual reality is the next best thing to an actual site visit. This reduces the need to travel to the site and to make inspections in a risky environment, thereby improving safety and reducing

CO2 emissions. In addition, the tool promotes the creation of optimised and long-lasting liners that significantly reduce CO2 emissions because less product needs to be manufactured and transported.

Consider how the parts are produced

Another sustainability aspect to consider is the environmental footprint of the wear part manufacturing. Sourcing parts from a responsible supplier that minimises waste and uses renewable energy sources, as well as recycled materials, can help reduce the environmental impact. Transportation of the materials and final product is also something to think about.

Circularity is becoming vital in the reduction of CO2 emissions, and can help improve the environmental position of many industries, including mining. Metso Outotec strives for environmental efficiency in all areas of its operations with CO2 targets in mind. The goal is to halve its emissions by 2024 and be net zero by 2030. The key to this is to use renewable energy.

The company is working to find ways to increase the number of recycled materials in its liners. Steel is easily recycled as there is a very well-developed system of scrap collectors in most parts of the world. In addition to that, increasing the amount of recycled material in rubber is a possible development area.

Reducing chemical load can also make the production process more sustainable. That could mean replacing potentially harmful substances in products, which is something Metso Outotec has been doing for a long time for its rubber products, and has managed to do so without affecting the quality of the products in any negative way. A small step towards reducing chemical load has been to avoid painting the metallic liners. Typically, liners are painted to look nice, but this does not really do anything to enhance performance, and so is largely unnecessary.

What happens to the wear part after it is no longer used?

Like most metals, steel can be continuously recycled without any damage or degradation to its properties – no matter the product or form it takes. In fact, steel tops the list of North America’s most recycled materials, with over 60% of steel being recycled annually since 1970. The worn metallic liners are usually sold to local scrap dealers or returned to supplier foundries, melted, and recast into new liners.

With rubber and poly-met liners, the situation has been different. There has not been recycling opportunities and most material has been sent to landfill. Also, the disposal cost has been steadily growing in both Canada and the US, and the landfill legislation has become stricter. These developments have prompted companies, such as Metso Outotec, to start looking for methods to better recycle rubber and poly-met liners. The key is to separate different materials efficiently in order to make them easier to recycle. The company is now working on increasing its capabilities globally to do this and hopes to release something more concrete on this important environmental aspect soon. The obvious thing to consider is of course the transportation: in order to minimise transportation, it is always trying to look for local solutions whenever possible.

Case study

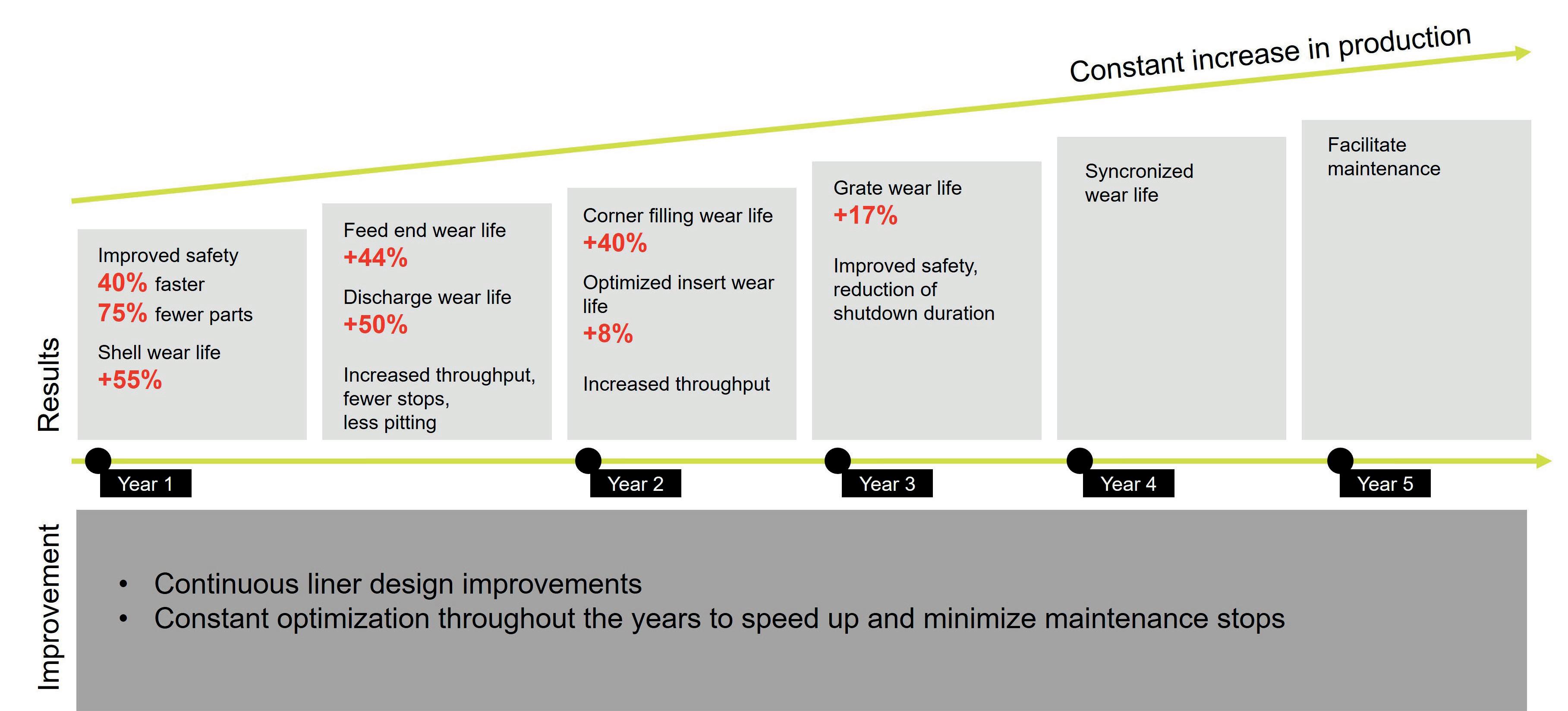

Alamos Gold, a Canadian-based gold producer, maximised the performance of its semi-autogenous grinding mill and Vertimill through optimisation efforts with a Life Cycle Services contract with

Metso Outotec. With close collaboration, the performance of the grinding process was incrementally improved each year. Environmental impact was optimised at this site by improvements on the grates and liner utilisation. The electrical consumption was also reduced by changing the liner material. CO2 reduction (kg CO2/million t) was 2.8%, and the wear life of the mill liners increased up to 120%. During the five years of collaboration, the production increased by 55%.

Long-term success through close collaboration

Figure 3. Maximising mill liner life and minimising liner leftovers significantly decreases the environmental impact and CO2 emissions of the wear part.

As stated, there are several factors that influence the environmental performance of wear parts. Thinking holistically helps to reduce the environmental impact, but it is also important to think long-term. Based on Metso Outotec's experience, if there is long-term co-operation between a company and the customer (with common agreed targets), it allows for further optimisation. This leads to more efficient production, and the company can then develop safer and more sustainable Figure 4. By working with a partner who understands the variables affecting grinding performance, products and there is an opportunity to maximise mill performance through wear part optimisation. processes.