13 minute read

Preventing Conveyor Fires

R. Todd Swinderman, Martin Engineering, USA, outlines best practices for preventing conveyor fires.

Fire protection is an integral element of overall plant safety, and there are issues and best practices that are somewhat unique to bulk handling by conveyor. Belt speeds and production quotas have risen exponentially due to pressure for greater output in order to meet global demand. Total global consumption of bulk resources went from 49 billion t in 2000 to 90 billion t in 2020. This covers everything from fossil fuels, to mined minerals, to biomass.1

Greater cargo volumes and faster belt speeds increase the chances of fires due to higher operating temperatures, increased dust, more static energy, and greater friction between moving and stationary components. The consequences of a fire on a high-speed conveyor are existential – i.e. if proper measures for prevention or suppression are not taken, there is a chance of substantial destruction. Flames can be conveyed throughout the facility quickly, putting the entire operation and everyone in it in jeopardy. Beyond the obvious workplace safety issues, recovery from the insurance, production loss, and legal ramifications could take years.

Conveyor fires are not typical fires

Conveyor fires are very hard to fight if not caught right away, leading to a system-wide shutdown. The infrastructure can be long, transferring from one belt to the next, spreading a fire through a variety of enclosures and structures and potentially discharging onto large storage piles of fuel. In addition, the conveyor structure is often elevated or inclined/declined over an extended length, making access for firefighting difficult. With tonnes of fuel, widespread distribution and limited access, at times the only option is to wait until the fire burns itself out.

From a workplace safety perspective, besides the burn hazard, a major threat during a conveyor fire is the gases released as a byproduct of combustion, such as carbon monoxide (CO). Proximity to a burning conveyor belt can expose workers to CO poisoning and toxic gases, such as hydrogen cyanide (HCN) and sulfur dioxide (SO2), oxygen depletion, convective and radiant heat, and irritants such as smoke particulates.

Causes of belt fires

Most industrial processes involve large machinery and potentially combustible materials, but belt fires can be caused by a number of circumstances. Due to hotter weather, conveyor fires often happen during summer.2 However, this is only a contributing factor and operators should be aware of the triggers. Conveyor fires generally have three common elements: heat sources, fuel sources, and oxidising agents.

Figure 1. Location of water sources and lack of access roads can make firefighting impossible.

Figure 2. Friction contact can not only cause belt damage, but can also lead to conveyor fires.

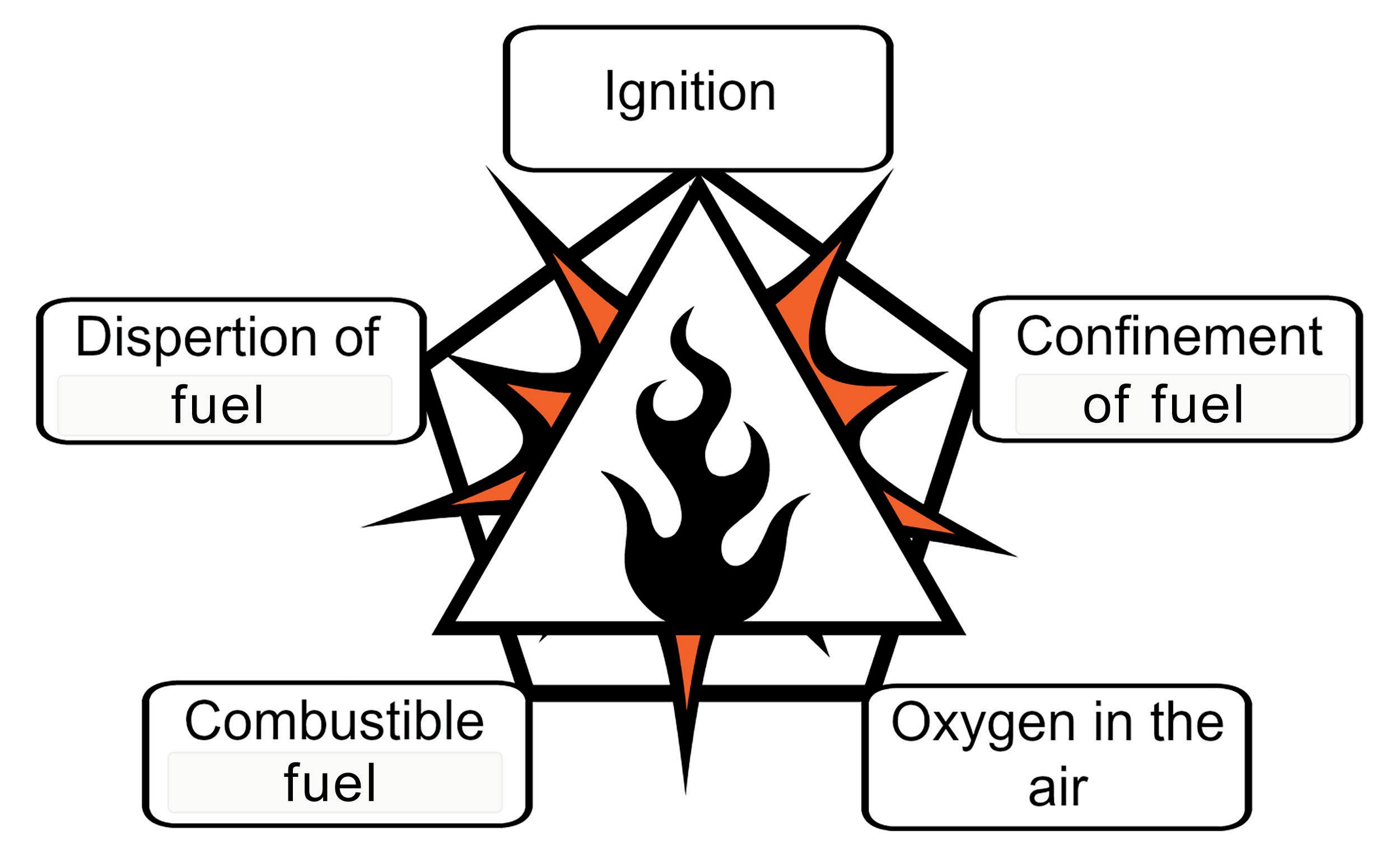

Figure 3. Explosion pentagon/combustion triangle. Heat sources

Heat from friction is estimated to be the cause of approximately 30% of belting fires.2 Seizures or failures in bearings are common, causing rolling components to freeze. As the belt slides over them, the friction raises the temperature of the belt. This type of frictional heat can also happen when the belt contacts the system structure or components, or if brakes are left partially deployed.

Material accumulation can also pose a friction hazard. Accumulated buildup on the return side of the belt or the pulley face can lead to slippage, causing friction-generated heat energy. In addition, spillage under the structure at the loading or discharge zones can pile to the level of the belt, causing it to slide across the top of the piled material rather than on the rollers. Friction heat created by the belt dragging over piles of spilled material can lead to smoldering fires, or ‘hot spots’, in the spillage piles. Hot spots can also be common in processing some materials, such as clinker or slag. Electrical fires, short circuits, or exposed electrical equipment are other potential sources. Perhaps the most common electrical source is static discharges, caused by friction.

Fuel sources

Conveyors carry potential fuel for a belt fire, either in the cargo load or in the form of combustible dust emissions. However, the belt itself can become fuel, igniting the elastomers, adhesives, carcass, and covers. Pulley materials such as lagging and coatings can also ignite.

The fire triangle and explosion pentagon

Fire requires heat, fuel, and an oxidising agent (usually oxygen in the ambient air). For an explosion to initiate, there must be the elements of the fire triangle, plus dispersion of combustible dust or liquid or flammable gas within a confined space. Many explosions start as localised flash fires caused by the ignition of a distributed fuel and oxidising agent in an open area or large enclosure. Often, a flash fire will cause a significant dispersion of combustible dust, creating conditions for a secondary ignition that may result in an explosion or spreading of the localised fire.3 Many common bulk materials that seem inert may be easily ignited in dust form or give off flammable or combustible vapours when heated. Some materials, such as brown coal, can spontaneously ignite.

Understanding and preventing combustion

Bulk material handling is by nature a dusty business, and many raw materials from biomass to mining tailings can generate combustible dusts. Airborne dust can be highly combustible and potentially explosive if sparked, which results in catastrophic damage instantaneously.

Preventing combustion begins with a good dust mitigation plan. The facility should have a housekeeping policy in place to prevent the accumulation of fugitive dust. It is important to ensure that the sealing system on a conveyor is properly maintained, in order to prevent particle emissions that can lead to a catastrophic event.

Enclosed conveyors need to be kept as tightly sealed as possible to minimise particle emissions, thus helping to prevent

a catastrophic cascading effect. Dust layering, on bearings for example, can prevent heat from dissipating, causing elevated temperatures. This could ignite the settled dust, leading to fire spreading to the conveyor, and potentially resulting in the explosion of airborne dust. To make matters worse, the primary explosion will likely cause more dust to become airborne, resulting in even more severe secondary explosions.

Combustion control plan

n Contain dust using enclosures, proper skirting, and dust curtains in the loading zone. n Collect dust using air cleaners, dust bags, and a regular cleaning schedule. n Install a fire protection system. n Install explosion mitigation devices, such as vents, suppression, or explosion isolation. n Monitor belt speed and pulley misalignment. A slowing or drifting belt can indicate a friction hazard. n Monitor bearing temperature. n If the application emits fumes or vapours, install appropriate hazardous duty ventilation and gas sensing equipment.

Figure 4. Dusty operations need to be particularly vigilant in sealing the process to avoid hazardous spillage.

Figure 5. Sufficient heat to ignite the belt can build up in nearly any environment.

Best practices for bulk handling fire prevention

Most countries have general workplace safety regulations defining fire hazards, such as the ones found in the US Occupational Safety and Health Administration (OSHA) standards.4 Further regulations can be set by local ordinances and permits or industry-specific regulatory bodies, including the Mining Safety and Health Administration (MSHA). Industry best practices, set by organisations such as the Conveyor Equipment Manufacturers Association (CEMA), should also be followed. Workplace safety should always be the number one goal.

Facility fire prevention

Designing the environment around conveyors requires understanding the needs of the specific systems and the applications involved. Enclosed conveyors mitigate spillage, but can facilitate the containment and concentration levels necessary for dust explosions. When designing the area around the conveyor, proper ventilation and the addition of heat sensors for activation of deluge systems should be considered. Near the points where the conveyor enters and exits the process or building, CO sensors can be installed to detect potential hazards (hot spots, smoldering material, toxic fumes, etc.). Facilities should have access, infrastructure, and procedures in place for quick fire response.

Conveyor fire prevention

When constructing a conveyor, a specific fire safety risk analysis should be conducted for the initial design. For rebuilds, retrofits or upgrades, conveyor arrangements, location, components, or changes in bulk material specifications outside the original material provisions need to be assessed.

It is vital to make sure the entire system is grounded and that there is control over the accumulation of static charges. Anti-static and fire-retardant conveyor belting with a surface resistance not in excess of 300 MΩ should be used and paired with anti-static lagging on the pulleys. Non-combustible enclosures around critical points, including where the conveyor passes through openings in any buildings, should also be considered. Perhaps most important is ensuring that the conveyor design is of sufficient capacity to carry the maximum expected load without excessive spillage.

Adequate access for inspection, maintenance, and cleaning should be provided in the design. Chute and structural clearances should allow for some belt mistracking to avoid friction contact between the belt and the structure. Sequential stoppage of equipment feeding or receiving bulk materials should be programmed, in order to stop the conveyor when safety devices are actuated within the process.

Using only pulleys and idlers manufactured to appropriate standards for the application is recommended. Fluids in hydraulic systems and grease in idler bearings should be specified as fire resistant or retardant. Hazardous duty-rated motors, sensors, and electrical equipment should be in use when combustible dust or flammable fumes or gases are likely.

Sensors and detectors

The following list outlines a variety of implementations of sensor and detector technologies, all of which provide valuable safety benefits:

n Smoke and gas detectors at critical locations. n Belt tracking devices where the belt enters the head, take-up, and tail pulleys. n Belt misalignment detectors. n Belt rip (tear) detection devices at the loading point and at a safe run-down distance from the delivery end. n A belt-slip detector on every drive pulley and tail pulley to alarm and stop the conveyor if the belt slips. Best practice is to calibrate the alarm to when the speed is reduced by 10% and shut down if the speed is reduced by 20%. n Heat detectors and/or hot spot extinguishers within range of bulk materials that tend to be hot or combustible. n Plugged chute detection alerts to minimise material accumulation as an ignition source. n Temperature monitoring devices on bearings, as close to the outer race as possible. n Metal detectors or magnets to identify or remove tramp metal.

Conclusion

Due to the development of fire-retardant equipment and stricter regulations, conveyor fires are relatively rare. However, these were developed to prevent the tragic events of the past. Fewer incidents lead to reduced awareness, which could result in complacency and greater risk.

A billowing blaze can be seen for miles and can potentially destroy a company that the community trusts and depends on. However, just having fire-retardant equipment is not enough. Operators and staff must be aware of the very specific fire hazards posed by the application and process and have a plan in place to avoid a crisis. It benefits the workplace, the staff, the community, and the bottom line.

References

Available on request.

Training: knowledge is prevention

According to the OSHA, “When there is a delay or setback during an incident, the risk of injury rises for facility workers as well as for emergency responders. Everyone is safer when facility and emergency personnel share information and develop safe procedures to handle incidents involving combustible dusts.”5

Firefighting is best left to trained employees for first response and professionals for fighting major fires. To reduce the impact of a fire event, staff should be trained in recognising the indicators, a clear and simple response procedure should be in place, periodic response drills should be conducted, and independent risk management reviews should be scheduled.

Specialised techniques may be required to extinguish a conveyor fire in the presence of combustible dusts. If combustible particles are present, high power water jets can send accumulated dust into suspension – leading to a subsequent explosion – and special water application techniques may be necessary.

Cincinnati Dual Sprocket Conveyor Chains are proven to be better than other mining chains. Tons better, in fact. Tests confirm our chains deliver 20 percent more strength . The result is greater durability, maximum availability and a trouble-free service life. That’s how we deliver the lowest cost per ton. For 90 years, Cincinnati has proven to be THE STRONGEST LINK .

Every situation planned. Every outcome optimized.

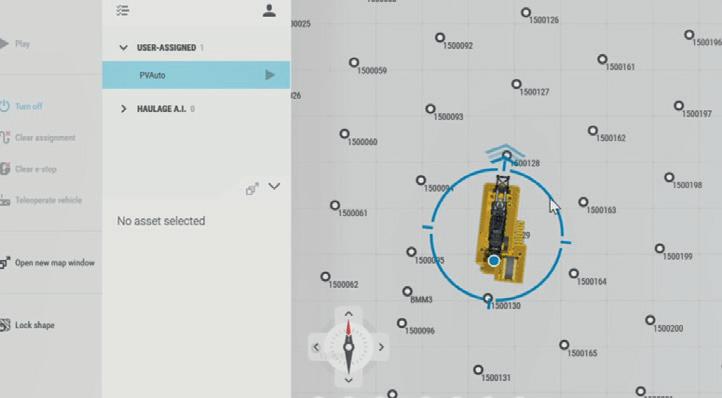

Mobius for Drills

Mobius for Drills is a new digital hub that empowers leadership and operators to plan and optimize the drill level and tie the entire value chain together with a single tool. Using embedded artificial intelligence and progressive robotics, the user-friendly Mobius for Drills system enables mines to remotely command, control, and monitor their drill fleet to maximize productivity and safety.

Mobius for Drills gives you true situational awareness through the ability to monitor the location and status of all drills and track production progress in real time.

An intuitive interface displays data in easy-to-understand dashboards and reports that provide the right information at the right time.

Valuable insights

Mobius for Drills can map drill usage, evaluate productivity, track consumables and compare planned outcomes against actual results. This data enables optimization of the drilling fleet within the mining value chain. By providing a single platform for all stakeholders in a drilling operation, leadership and operators can quickly navigate information, filter it to their needs and streamline day-to-day and long-term strategic decisions.

Mobius for Drills is designed to be flexible and scalable, ready to work on small or large operations. The system has the ability to work across Epiroc surface drills with various levels of technology. It’s also future-ready with a strong platform for development.

The digital power of Mobius for Drills

Main benefits

Connected through scalable architecture that allows the system to match your roadmap and interface points. Allows for drill OEMs to integrate easily.

Intuitive and smart design reduces the learning curve with a flexible and natural interface for effective use and navigation. A value chain perspective allows for refined decision-making.

Focused to be your primary drill fleet tool for all stakeholders. Detailed views capture valuable drilling insight in a digital environment.