1 minute read

DESERT PAVILION

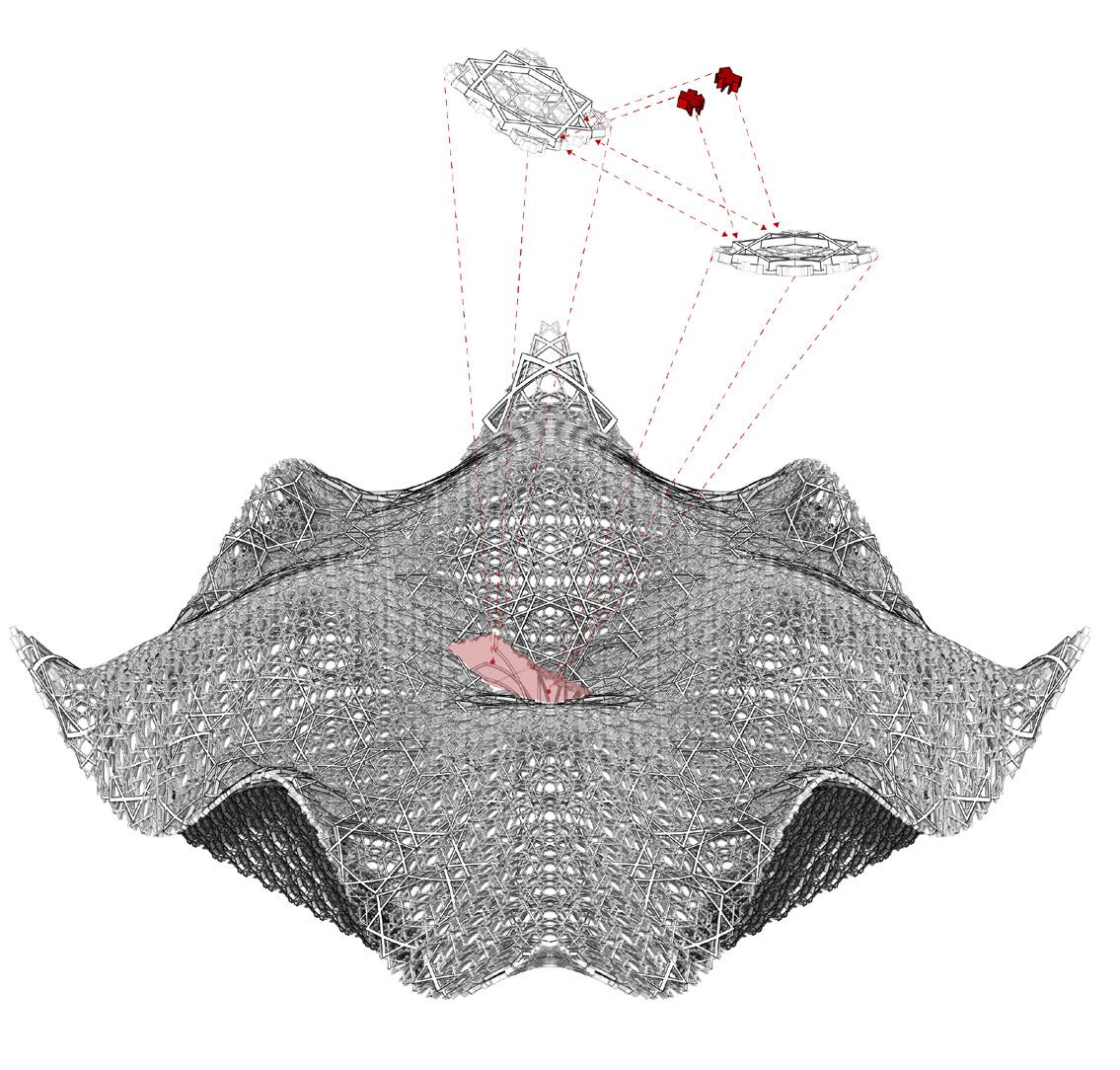

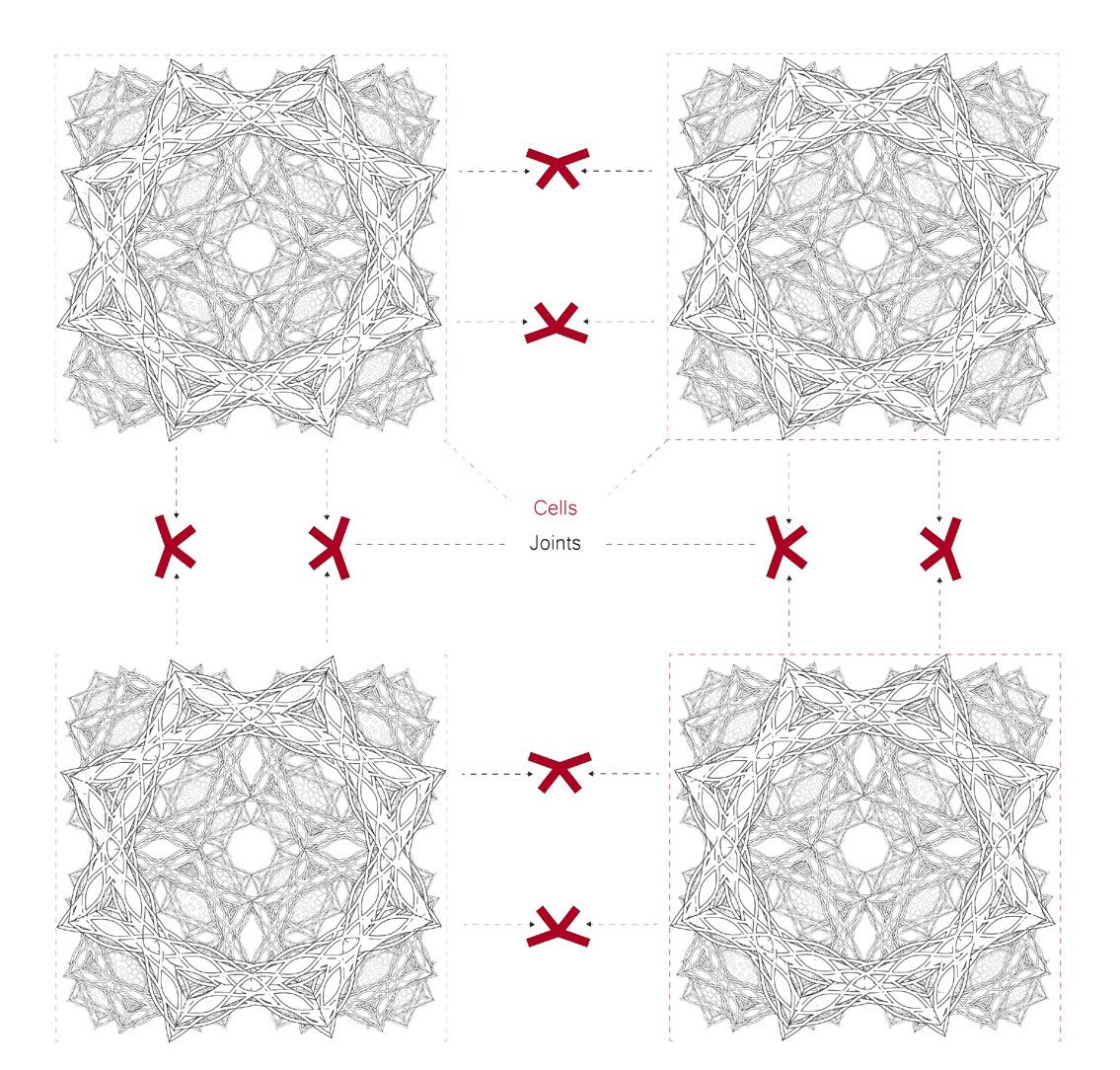

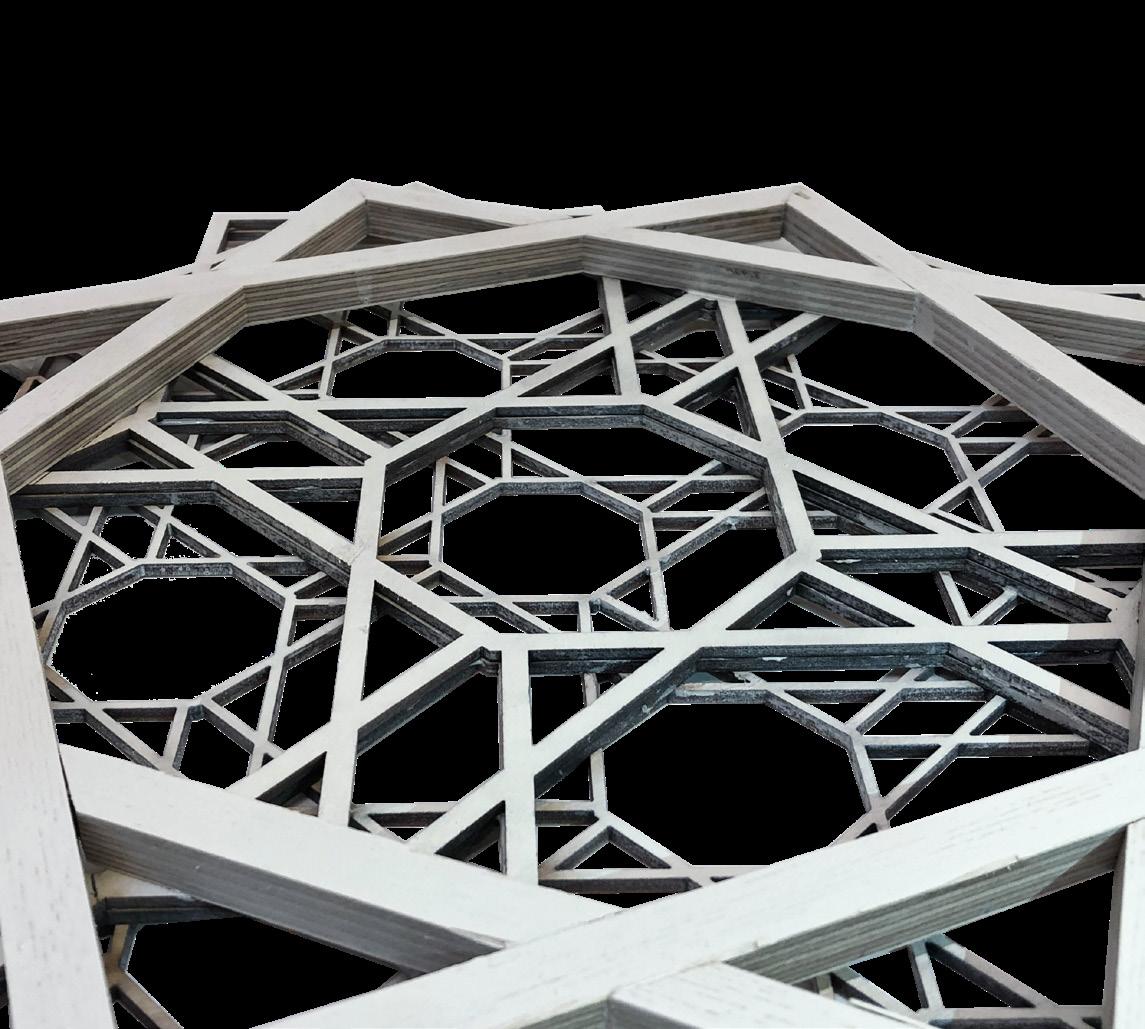

The Desert Pavilion is a lounge area located in Egypt. The roof structure is parametrically designed using grasshopper with three layers of the same repetitve pattern. Each layer doubles the ratio of the previous layer. The three layers come together to form one complex module, which was later 3D printed. My main focus on this project was the fabrication of different modules, material testing and assembly.

Advertisement

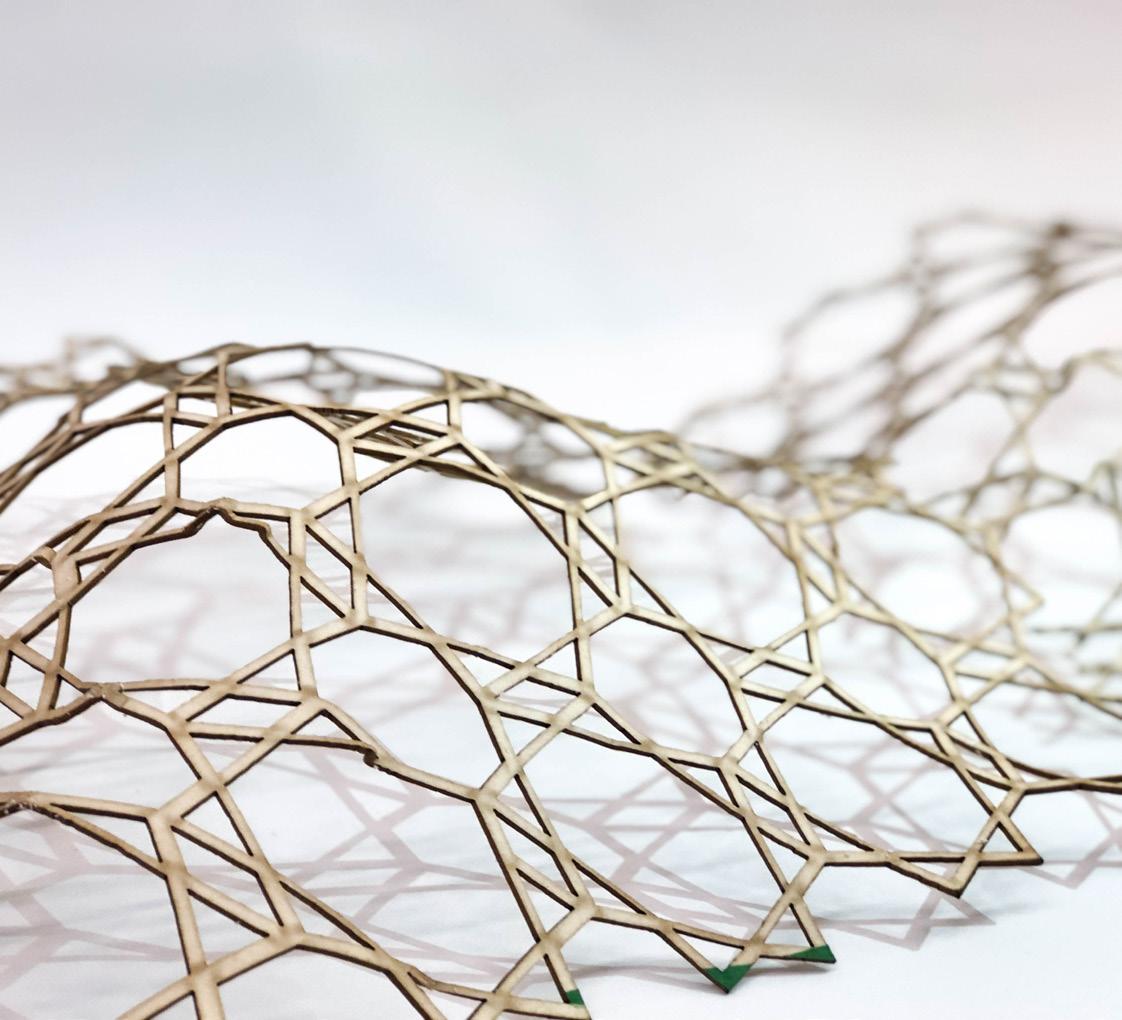

The curvature of the layers was achieved by laser cutting two layers of thick cardboard. The boards were then placed between two CNC milled foam blocks, which act as a cast. The boards were drenched with water and made to perfectly mold to the curves of the foam blocks. When dry, the curvature of the boards resembled the curvature of the structure.

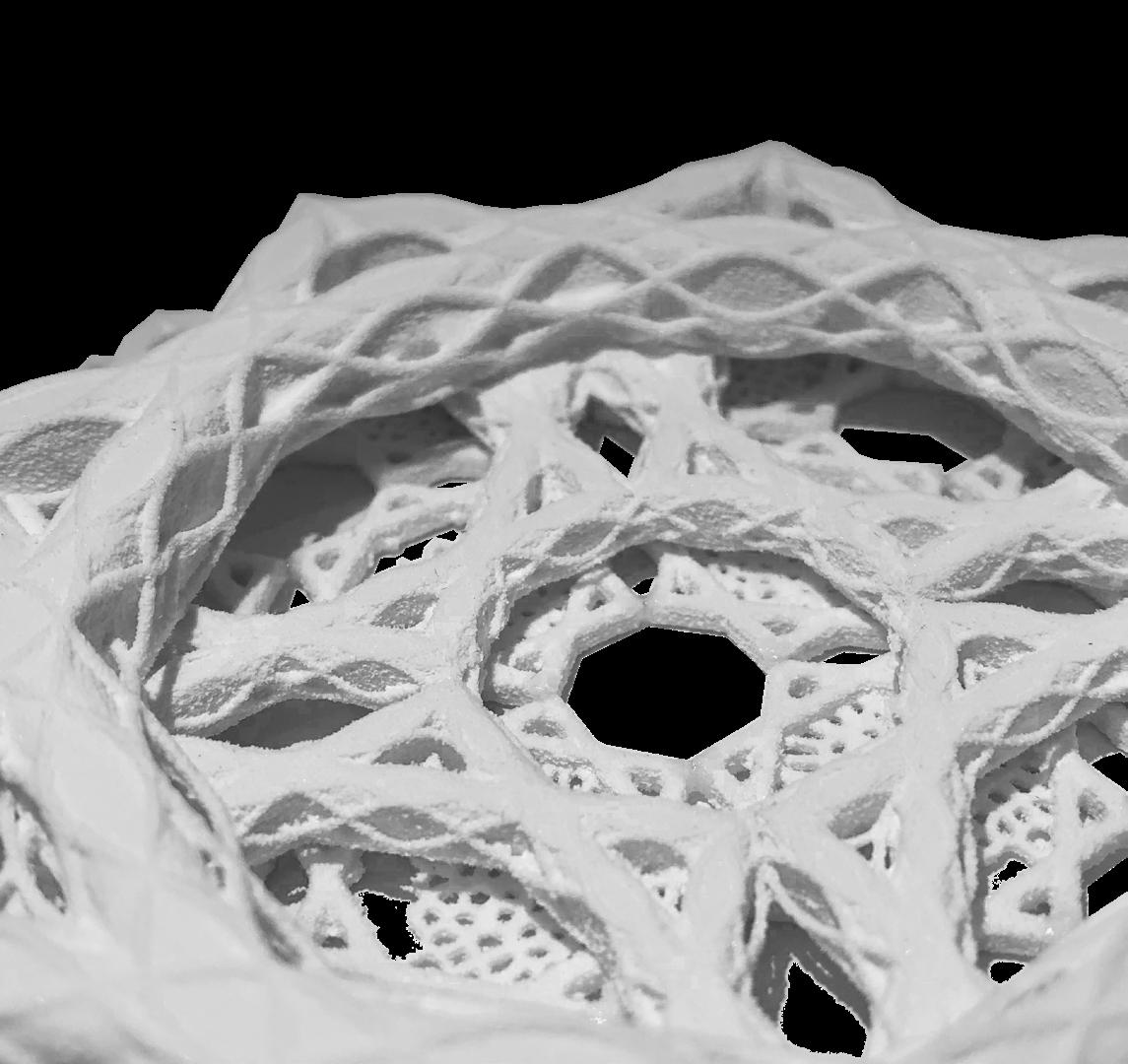

Resin 3D printed Colum at a scale of 1:100

Testing the limits of a resin printer in comparison to PLA plastic. Resin required little structural support while printing in comparison to the PLA printer.

Lasercut Screen at a scale of 1:100

Testing the limits of the lasercutters at the Daniels Faculty, Dertiming how thin the material could be cut withount it breaking down.

Wooden Module

The top most layer was done at the Daniels faculty shop in which strips of wood were cut using the table saw and then angled to come together. However, the second and third layer were laser cut. These seperate layers were then pressed and glued together whithout the use of a jig.

A detailed 3D model of the module was made and sent to the 3D starch printer. This module came out very detailed in comparioson to the wooden one. However, it was more fragile. Starch 3D printing required no support for the module, in compariosn to a PLA 3D print.