1 minute read

CUMBERLAND COFFERS

January 2023

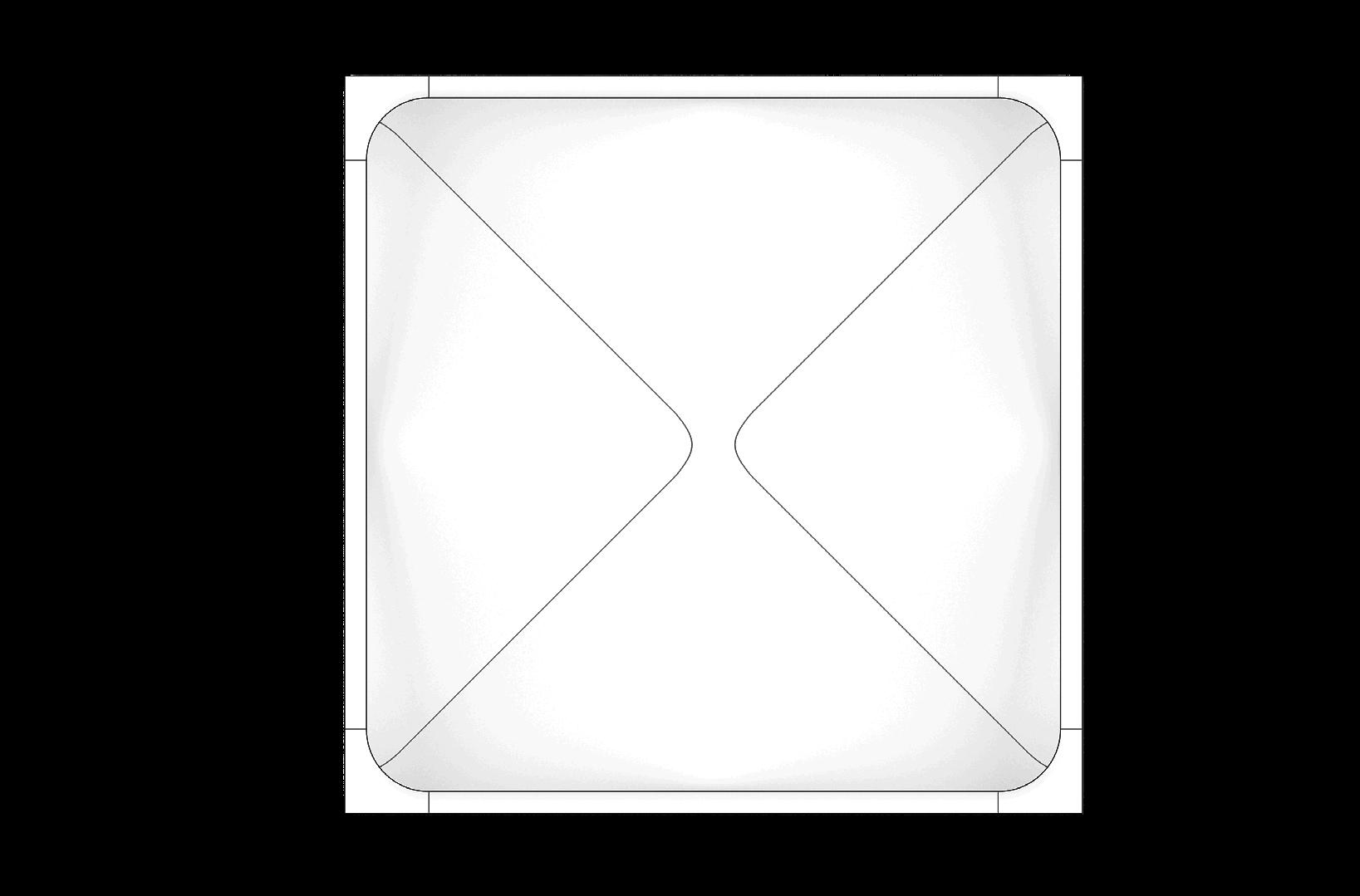

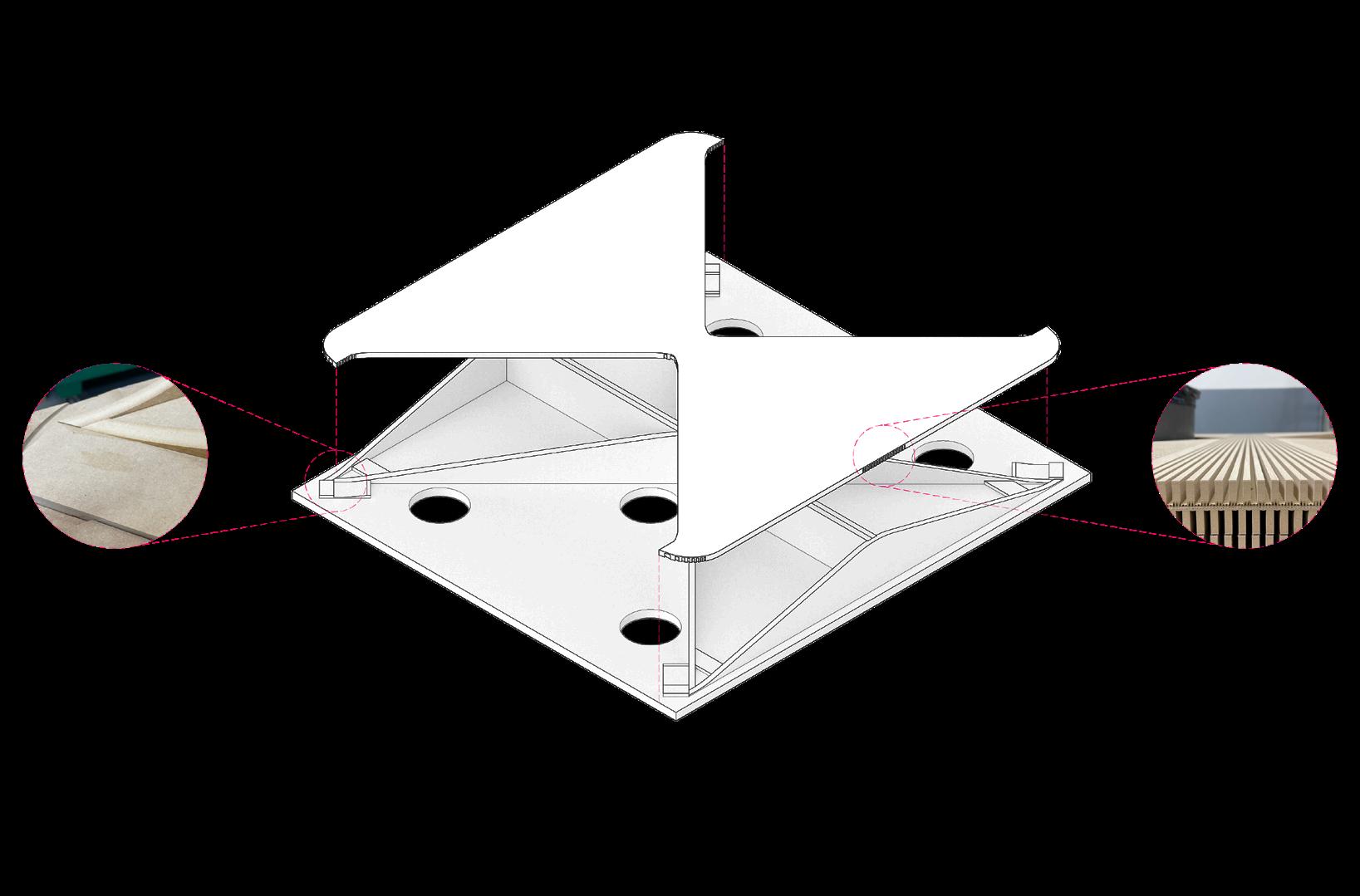

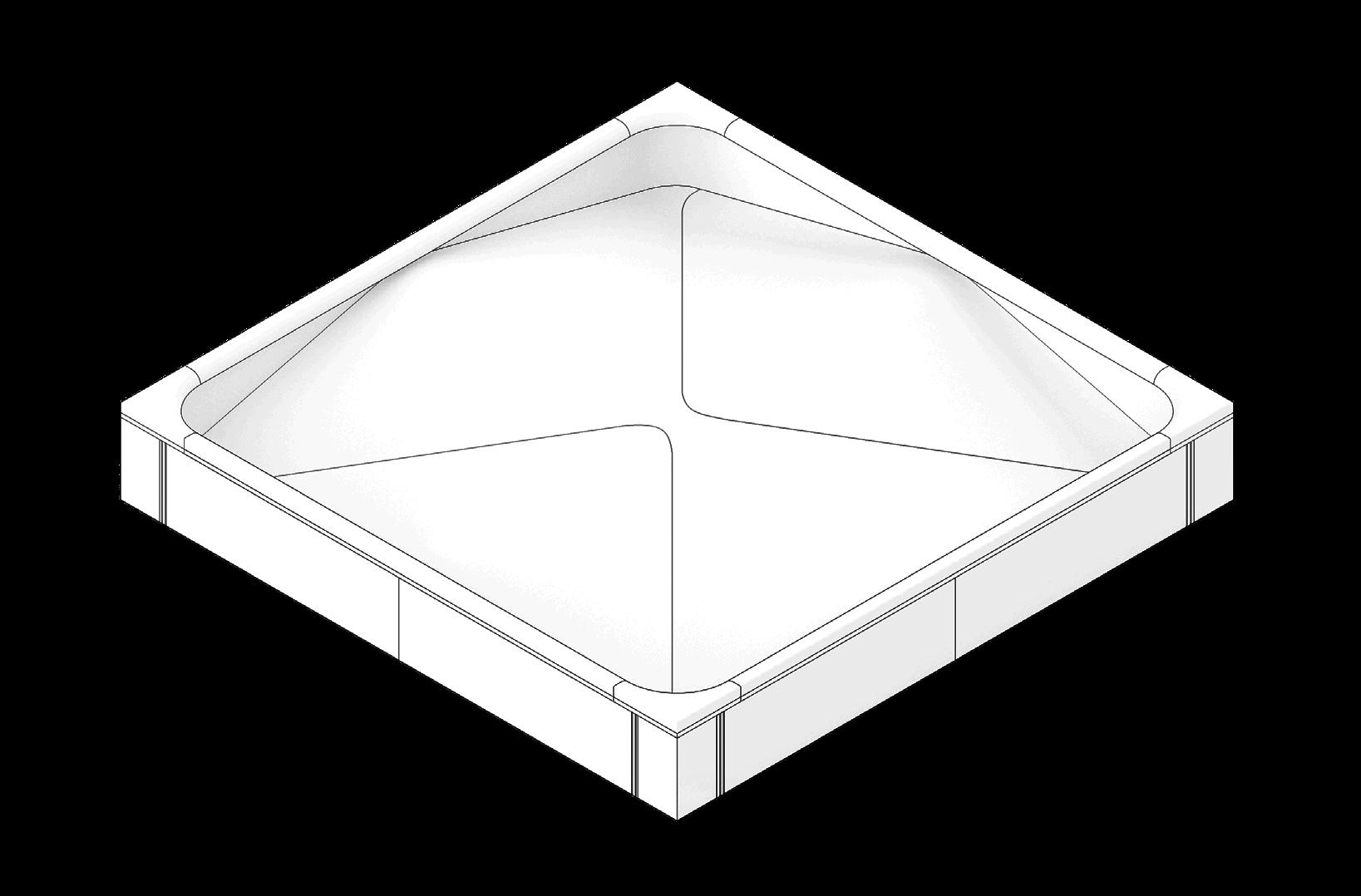

The Cumberland ceiling consists of multiple coffers stacked next to each other to form a ceiling. These coffers are paramaterically design by Shim-Sutcliff Architects and manufactured by MC2001. My part in this project consists of managing and and preparing the production files and production flow of these modules.

Advertisement

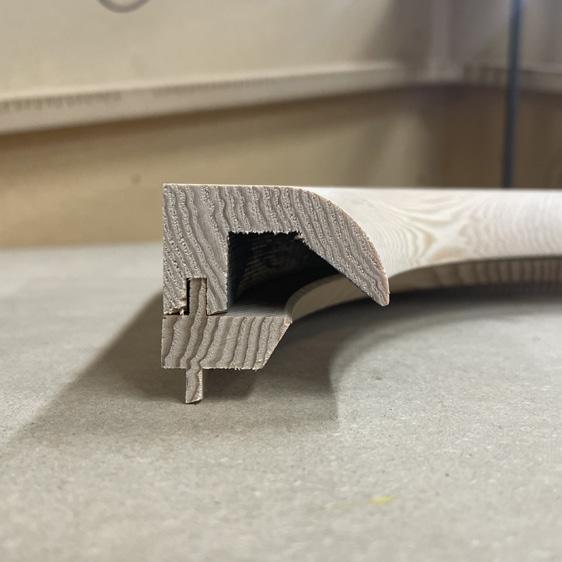

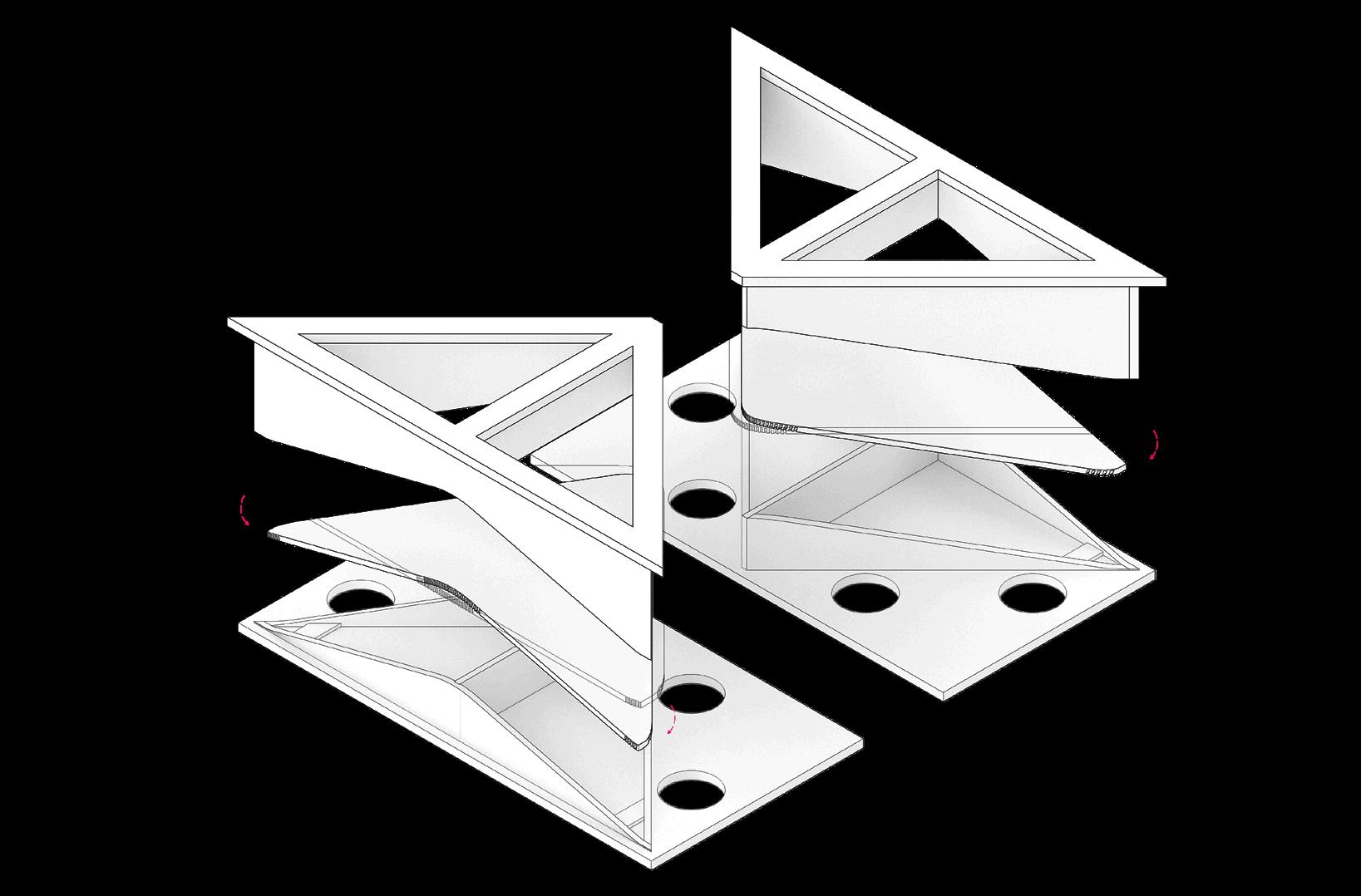

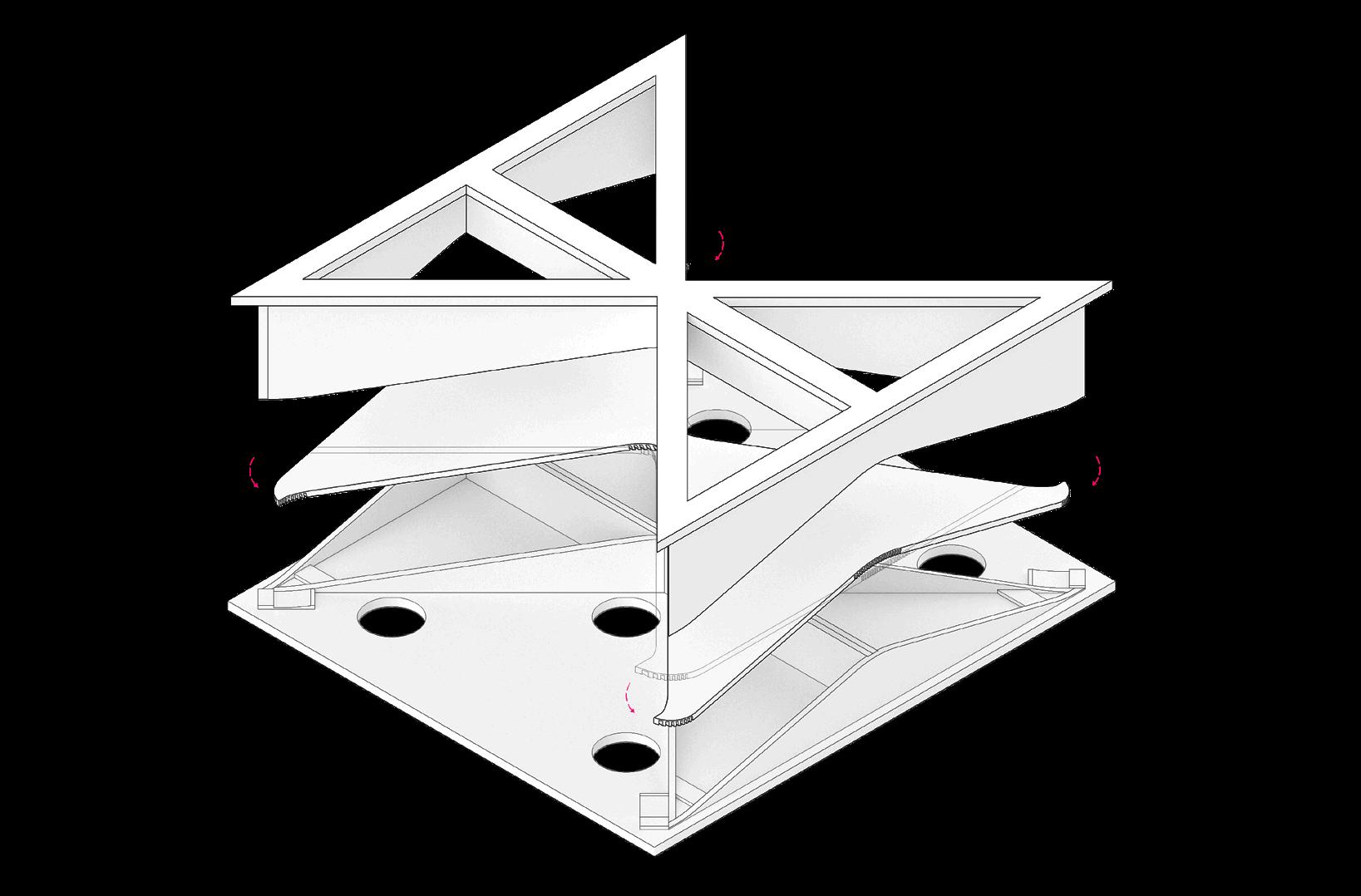

A. Strips of solid wood are cut through the moulder

B. Corners fabricated using a 5-axis CNC

C. Corners fabricated using a 5-axis CNC

D. Strips of solid wood are cut through the moulder

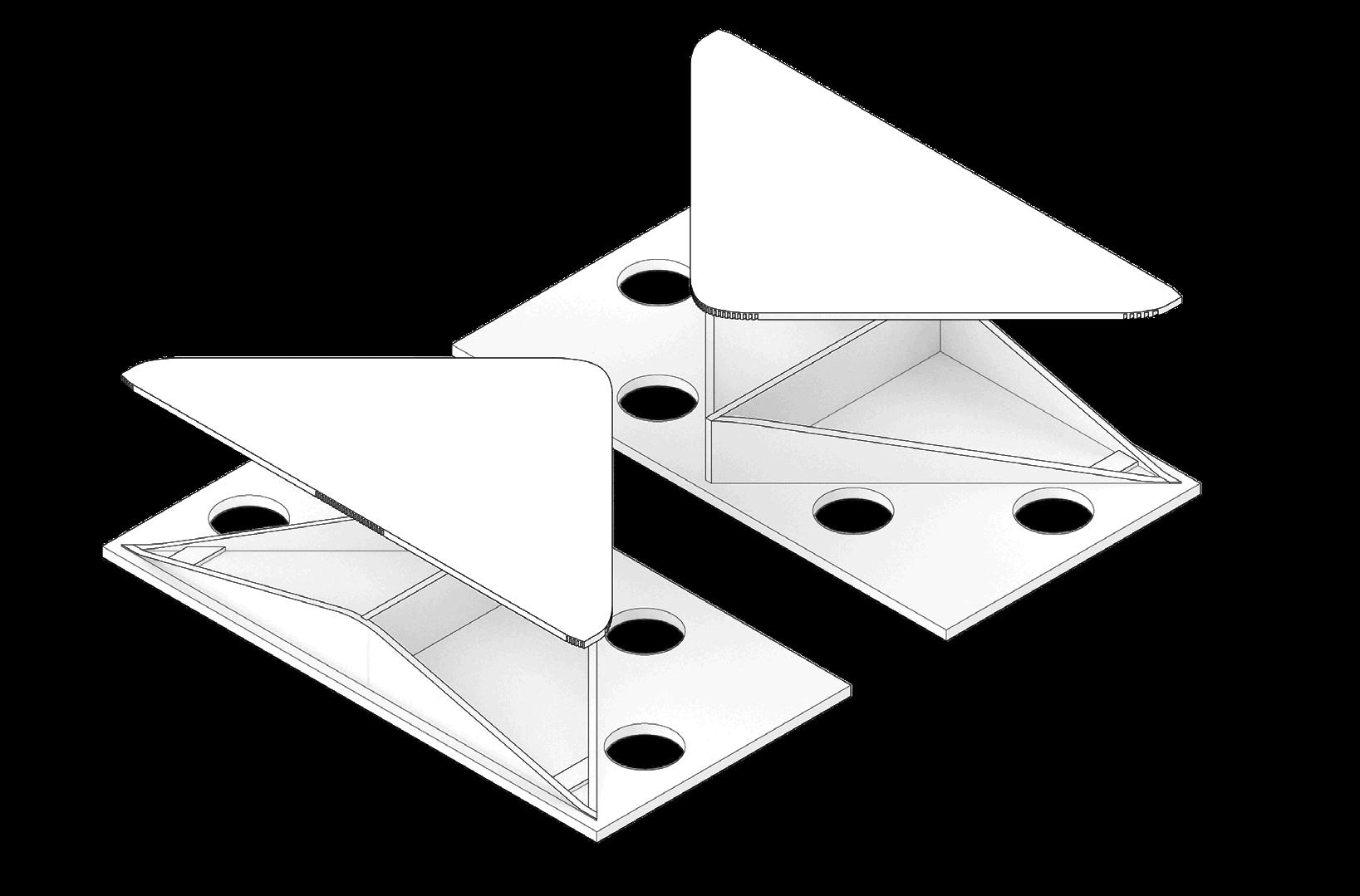

E. Panels undergo multiple operation process on a 5-axis CNC

F. Individual pieces of the internal frame are fabricated on a 5-axis CNC

G. Strips of solid wood are cut through the moulder

H. Vertical panels are fabricated using a 3-axis CNC.

The Cumberland

The Cumberland Ceiling consists sizes that go on the ceiling. three main parts.The first acoustical wood panels that The second is the vertical module and finally,

Microperferated

The microperferated panels

First, the veneer and backer MDF boards. The board is then These panels then go on the an oversized cut, and kerfing. made to mold onto the internal frame is cut on a 5-axis match the curvature of the The panels are then sandwiched and negative, and then cut shape and

Final assembly includes sliding two small panels into each by the vertical pieces and

Cumberland Ceiling Module consists of modules of varying ceiling. These modules consists of is the microperferated, bent that intersect with one another. vertical panels that sourround the the solid wood trims.

Microperferated Panels panels undergo multiple steps. backer are pressed to full sized then cut into smaller panels. the CNC for microperferation, kerfing. The panels are then internal frame. The internal 5-axis CNC to have their top the final shape of the panel. sandwiched between a positiove on the CNC to their final and size. sliding the big panel and the each other, surrounding them finally gluing on the trims.