2 minute read

Mass timber technology takes root in the Bay

Mass tiMber

A composite crew from Elevated Construction places a wall panel at Sacred Heart High School in Atherton. Once the panel components are assembled, installation takes about 15 minutes per panel.

Advertisement

Whether it’s modular construction, 3D printing, computer modeling, robotics or any other new technology, the Carpenters Union is committed to the modernization of the construction industry, while maintaining union wages, benefits, safety and other standards.

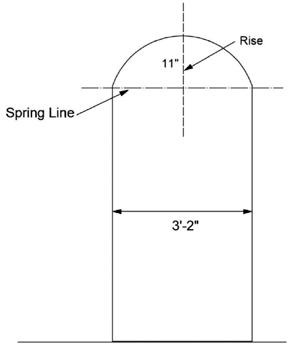

Mass timber construction is among the cutting-edge technologies. It’s popular in Europe and Canada, and beginning to take hold in the U.S., especially because of its good looks and environmental benefits. The engineered wood is harvested from sustainably managed forests, and mass timber projects emit far less carbon in construction and over their lifetime than conventional steel and concrete structures. In recent years, union Carpenters have worked on a number of mass timber projects around Northern California. At the Sacred Heart High School in Atherton, for example, Carpenters recently put up a new 4,000-square-foot classroom structure in record time, using prefabricated cross-laminated timber panels imported from Canada.

Carpenter work on this project, performed by a crew from Elevated Construction, included assembling the prefabricated panels, affixing weatherproofing and insulation, furring strips, blue skin, siding, flashing and plywood. The project also involved layout and the installation of 64 anchor bolts. XL Construction is the general contractor, while Bradley Concrete is the primary subcontractor.

“The engineering has been very thoughtful and well done,” says Brian Kitchen, Local 152, superintendent for Elevated, “so you get what amounts to a mass timber tilt-up.”

Working with mass timber is also fast. Once the panels are assembled, “it takes about 15 minutes to put one panel up,” according to Foreman Juan Ledezma, Local 713. “You blink and it’s done. I got here June 7, and we’re going to be ready for move-in when school opens in September. We’ve got to hit that date.”

It’s not exactly traditional carpentry, “but we’re learning every day,” says Jesus Zarate, Local 405. “It’s exciting to be part of it.”

The teamwork is evident as a crew gets ready to place and bolt another panel— one goes up every 15 minutes.

technology takes root in the Bay

Crew members at Sacred Heart High school include Everisto Sera and Ivan Patino, Local 713; Alejandro Solis, Local 405; Jesus Zarate, Local 713; Jorge Vences, Local 713; Jesus Zarate Barajas, Local 405; Francisco Arias, 605; Rogelio Bautista, 405; Eduardo G. Cardenas, Local 217; and Brooks McLean, Local 405

Juan Ledezma, Local 713, is the general foreman at the Sacred Heart Construction.