2 minute read

Strength and Impact Energy in the Welded Joint

from Weldability Investigations of 120 mm TM+ACC Thick Heavy Plate Steel, designed for Offshore App.

Tensile and impact energy tests were performed in accordance with the DNV-CP-0243 program for specimens cut transverse to the weld. A welded joint with a HI of 15 ± 2 kJ/cm is characterized by: yield strength (min-max/average) of 397-412/408 MPa, an ultimate tensile strength of 503-504/504 MPa, tensile elongation at break of 16-17/17%, ultimate tensile strength, direct, of the weld metal of 600-620/617 MPa. No fundamental differences in the results for the welded joint with a HI of 50 ± 2 kJ/cm were identified: yield strength (min-max/average) of 411-415/412 MPa, the ultimate tensile strength of 503-505/504 MPa, tensile elongation at break of 15-17/16%, ultimate tensile strength, direct, of the weld metal of 605-620/616 MPa.

Advertisement

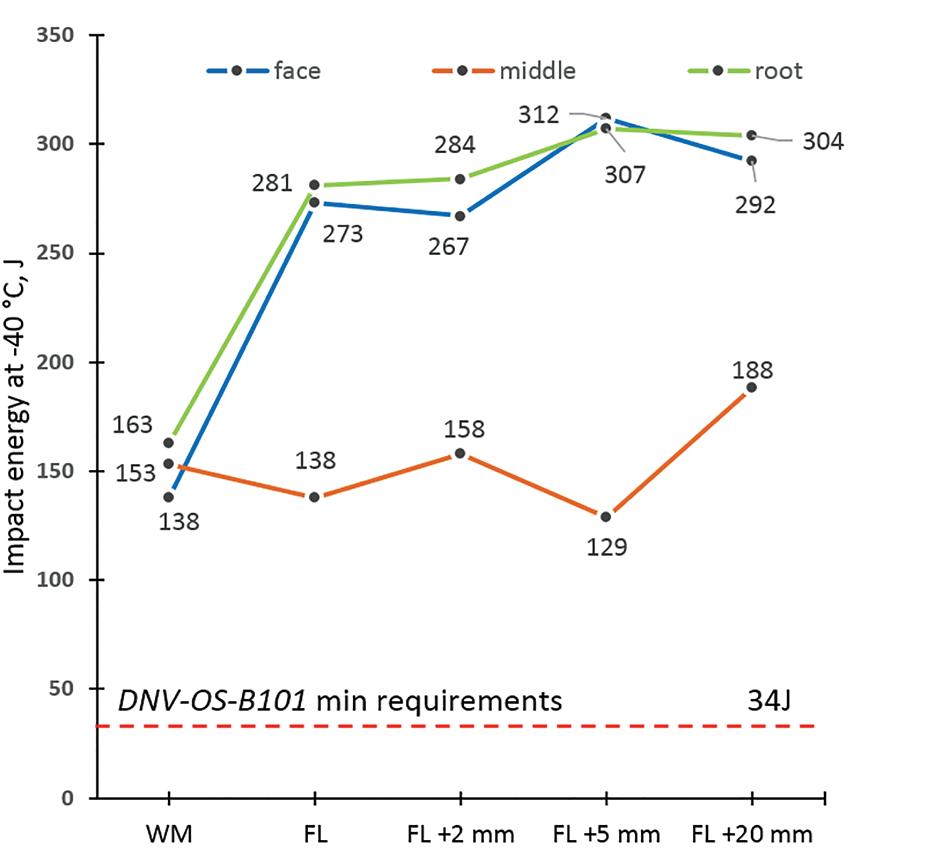

Tests to determine the impact energy in the welded joint were carried out in the transverse direction. Values obtained in 5 reference areas of the joint: weld material (WM), fusion line (FL), 2 mm from the fusion line (FL+2 mm), 5 mm from the fusion line (FL+5 mm) and 20 mm from the fusion line (FL+20 mm). Impact samples were specially made so that the axis of the V-shaped notch corresponded to each of the investigated areas.

The measurement results show that the values of impact energy in the weld metal for a joint with a heat impact of 15 ± 2 kJ/cm (Fig. 9a) at the investigated depths stand at 152-171 J. At the fusion line, where the structure is characterized by a transition from the dendritic morphology of the welded joint to a GCHAZ, average values of 264 J at the surface and 255 J at the root were obtained. In the weld middle, lower values of impact energy down to 196 J are observed, but then there is a slight increase in the HAZ, where different morphological forms of ferrite are observed in the structure, up to 134 J at a distance of 2 mm and 169 J at a distance of 5 mm from the fusion line, and then, in the zone of the base metal, an increase to 183 J is observed.

The values of impact energy at the face and at the root of the weld continue to increase after the fusion line from 255-264 J at a distance of 2 mm in the HAZ to 309-304 J at a distance of 20 mm from the fusion line, which corresponds to the base metal with a predominantly quasi-polygonal ferrite microstructure.

For the welded joint with a heat energy of 50 ± 2 kJ/cm (Fig. 9b), the distribution pattern and the range of the results obtained are generally similar to the previous welding regime. The impact energy of the weld material throughout the thickness of the welded joint ranges from 138 to 163 J. The fusion line is characterized by an average value of 273 J at the surface and 281 J at the root, which is slightly higher than in the first welding regime. In the centre along the thickness of the weld, again, a decrease in the values of the impact energy is observed. A high level of 267-284 J at the face and at the root of the weld is also maintained in the HAZ at a distance of 2 mm from the fusion line. At the core, the values are increased to a level of 158 J.

At a distance of 5 mm from the fusion line, the increase continues at the surface and at the root and reaches a level of 307-317 J, and in the centre a decrease to 129 J is observed, but at a distance of 20 mm from the fusion line, again an increase to 188 J is observed. At the face and at the root of the weld, the results remain at the same high level, and in the base metal area stand at 292-304 J.