1 minute read

The microstructure

from Weldability Investigations of 120 mm TM+ACC Thick Heavy Plate Steel, designed for Offshore App.

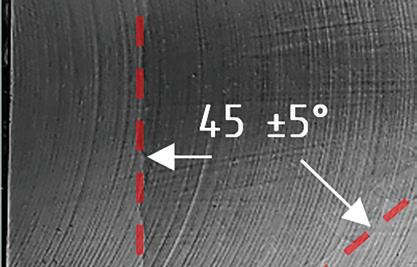

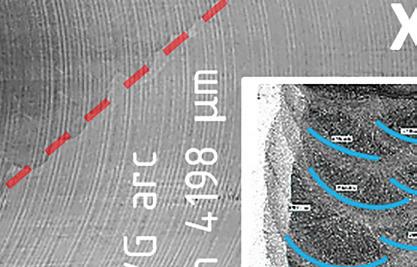

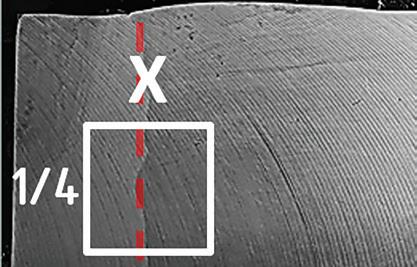

The microstructure of the steel was studied using automated optical microscopes Leica DMiC, Carl Zeiss Axio Observer 7 MAT and scanning electron microscopes Tescan MIRA 3SBH and Scios 2. One-fourth of the thickness of the welded joint in Zone X was examined and described as shown in Figure 2.

Advertisement

The tensile test was performed on transverse circular specimens in accordance with ISO 6892-1 taking into account the requirements of DNV-OS-B101 and DNVGL-CP-0243. The low-temperature impact toughness of welded joints was determined based on the results of impact using Charpy samples in the transverse direction along the weld metal, fusion line (FL), and at a distance of FL – 2 mm, FL + 2 mm, FL + 5 mm and FL + 20 mm.

The HAZ tendency to brittle fracture was assessed based on the results of Crack Tip Opening Displacement (CTOD) tests, which are described in ISO 15653 and ISO 12135. The grain-coarsened heat-affected zone (CGHAZ) was tested. Test temperature: minus 10 °С.