Working with our supply chain New suppliers to Nilorn are to be reviewed by the CSR department. The first assessment includes looking at social audits that the factory may have been subjected to previously, as well as other areas such as their production capacity and quality of products. A supplier is preferably visited prior to production. We do our own inspections in combination with relying

supply base by a further 30 suppliers. It is important for us

initiatives. ISO 9001, ISO 14001 and OHSAS 18001 are also

visibility, improved communication and buying power.

on third party audits, through BSCI, SEDEX and other

to continue reducing our supply chain for greater control,

certification schemes used among suppliers, which we take into c onsideration when choosing a supplier.

We seek to continue working with reliable, reputable,

Most importantly we focus on having a very close dialogue

reducing our supply chain we also build on the relationships

environmentally and socially conscious suppliers. Whilst

and frequent meetings with all prioritised suppliers.

we hold with suppliers, some of which have been over 20 years. A stronger relationship equals a better partner.

Reduce to increase has been one focus for supply chain

management in 2017. An analysis was done after the result

SEDEX

our supplier base by around 50. The reason for this reduction

profit membership organisation dedicated to driving

of the supplier evaluation in 2016 and in total we reduced

Sedex, the Supplier Ethical Data Exchange, is a not-for-

was to increase our efficiency in the management of suppliers

improvements in responsible and ethical business practices

and part of our strategy of working closer with the chosen

in global supply chains. Sedex is an online database, used

suppliers. We are pleased to see that in 2017 the production

by more than 50,000 members in over 150 countries, which

with those suppliers has moved to others in the approved list.

allows companies to store and view data on ethical and responsible business practices. Sedex does not set any

For 2017, we conducted the same review, this time extending

standards or determine the policy of its members.

to group companies outside China. The results were again collected and the list reviewed. In 2018, we will reduce our

Sedex provides a place to store any and all ethical a udit

reports, with a summary of non-compliances held in a

common format. However, Sedex has created the Sedex Members Ethical Trade Audit (SMETA) – a common audit

methodology and report format aiming to drive consistency

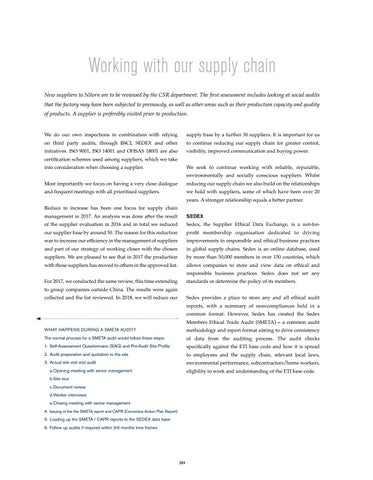

WHAT HAPPENS DURING A SMETA AUDIT?

of data from the auditing process. The audit checks

The normal process for a SMETA audit would follow these steps:

specifically against the ETI base code and how it is spread

1. Self-Assessment Questionnaire (SAQ) and Pre-Audit Site Profile

to employees and the supply chain, relevant local laws,

2. Audit preparation and quotation to the site

environmental performance, subcontractors/home workers,

3. Actual site visit and audit

eligbility to work and understanding of the ETI base code.

a. Opening meeting with senior management

b. Site tour

c. Document review

d. Worker interviews

e. Closing meeting with senior management 4. Issuing of the the SMETA report and CAPR (Corrective Action Plan Report) 5. Loading up the SMETA / CAPR reports to the SEDEX data base 6. Follow up audits if required within 3-6 months time frames

30