NASA Turns to AI to Design Mission Hardware

Spacecraft and mission hardware designed by an artificial intelligence may resemble bones left by some alien species, but they weigh less, tolerate higher structural loads, and require a fraction of the time parts designed by humans take to develop.

“They look somewhat alien and weird,” Research Engineer Ryan McClelland said, “but once you see them in function, it really makes sense.”

McClelland pioneered the design of specialized, one-off parts at Goddard using commercially available AI software at Goddard through a process he has dubbed Evolved Design.

To create these parts, a computer-assisted design (CAD) specialist starts with the mission’s requirements and draws in the surfaces where the part connects to the instrument or spacecraft – as well any bolts and fittings for electronics and other hardware. The designer might also need to preserve a path so the algorithm doesn’t block a laser beam or optical sensor. Finally, more complex builds might require spaces for technicians’ hands to maneuver for assembly and alignment.

in this issue:

Winter 2023

11

About the Cover

A far cry from the geometric shapes and straight lines produced by human designers, spacecraft parts designed by artificial intelligence take on an organic appearance, like bones or connective tissue: something evolved. Goddard Research Engineer Ryan McClelland is leading the charge for Evolved Structures – adapting commercial AI and milling to produce some of the thousands of bespoke mission hardware elements NASA produces for spacecraft, instruments, and other hardware each year. Evolved Structures weigh less, tolerate higher stress loads, and require a fraction of the development time as traditionally designed parts.

(Image Credit: Henry Dennis)

COMMENTS & SUGGESTIONS

Your comments and suggestions are welcome and will assist us in continuously improving the CuttingEdge. The Office of the Chief Technologist at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, solicits your feedback and comments, please write to: Karl.B.Hille@Nasa.gov.

Once all off-limits areas are defined, the AI connects the dots, McClelland said, producing complex structure designs in as little as an hour or two. “The algorithms do need a human eye,” he said. “Human intuition knows what looks right, but left to itself, the algorithm can sometimes make structures too thin.”

These evolved parts save up to two thirds of the weight compared to traditionally designed components, he said, and can be milled by commercial vendors. “You can perform the design, analysis and fabrication of a prototype part, and have it in hand in as little as one week,” McClelland said. “It can be radically fast compared with how we’re used to working.”

Parts are also analyzed using NASAstandard validation software and processes to identify potential points of failure, McClelland said. “We found it actually lowers risk. After these stress analyses, we find the parts designed by the algorithm don’t have the stress concentrations that you have with human designs. The stress factors are almost ten times lower than parts designed by an expert human designer.”

McClelland’s evolved components have been adopted by at least eight NASA missions in different stages of design and construction, including astrophysics balloon observatories, Earth-atmosphere scanners, planetary instruments, space weather monitors, space telescopes, and even the Mars Sample Return mission.

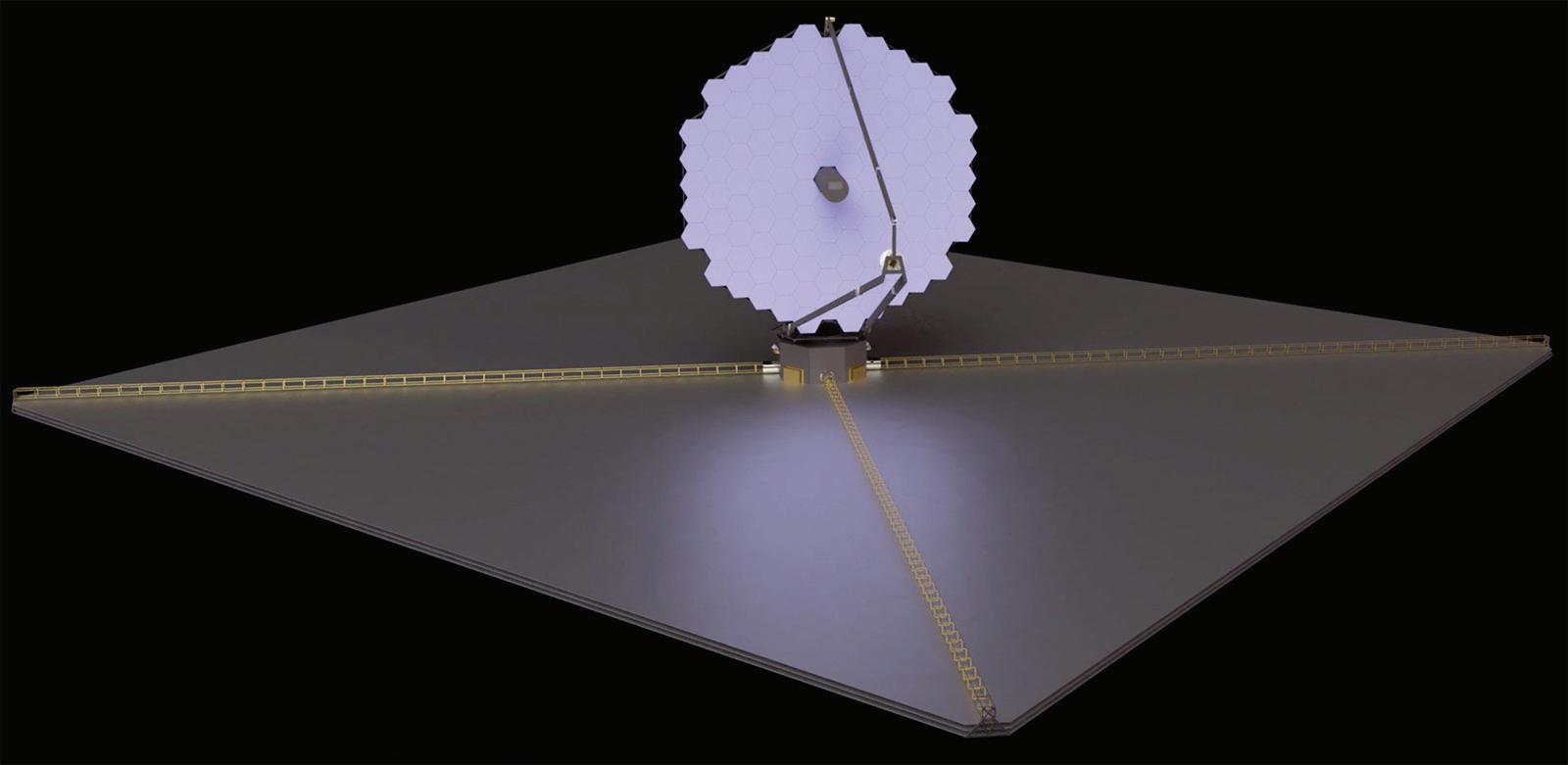

Goddard physicist Peter Nagler turned to evolved design to help develop the EXoplanet Climate Infrared TElescope (EXCITE) mission, a balloonborne telescope designed to study hot Jupiter-type exoplanets orbiting other stars. Currently under construction and testing, EXCITE plans to use a near-infrared spectrograph to perform continuous observations of each planet’s orbit about its host star.

“We have a couple of areas with very tricky design requirements,” Nagler said. “There were combinations of specific interfaces and exacting load specifications that were proving to be a challenge for our designers.”

McClelland designed a scaffold for the back of the EXCITE telescope, where the IR receiver housed inside an aluminum cryogenic chamber connects to a carbon fiber plate supporting the primary mirror.

“These materials have very different thermal expansion properties,” Nagler said. “We had to have an interface between them that won’t stress either material.”

Additive manufacturing, also known as 3D printing, made titanium available. “This design was significantly lighter and stiffer than anything we would have been able to come up with,” he said. “In addition, we were able to have our part designed and produced in days instead of months.”

A long-duration NASA Super-Pressure Balloon will loft the EXCITE mission’s SUV-sized payload, with an engineering test flight planned as early as fall of 2023.

Ideal Design Solution for NASA’s Custom Parts

AI-assisted design is a growing industry, with everything from equipment parts to entire car and motorcycle chassis being developed by computers.

The use case for NASA is particularly strong, McClelland said.

“If you’re a motorcycle or car company,” McClelland said, “there may be only one chassis design that you’re going to produce, and then you’ll manufacture

a bunch of them. Here at NASA, we make thousands of bespoke parts every year.”

Reducing the time to get parts into the cleanroom could be a force multiplier for the agency, but it’s not going to take away jobs, McClelland said. “In fact, we’re experience a bit of a skills gap and a labor shortage for designers and analysts. This technology allows each skilled person to produce more work by reducing the time they spend finishing the design. You get more science per dollar in the end.”

A secondary savings comes from reducing the mass of structural parts and reserving that payload capacity for science instruments, particularly for planetary missions which are tightly mass-limited.

McClelland is also considering the possibilities of generative design for manufacturing parts and equipment in space. So far, he has primarily produced parts by milling the empty spaces from aluminum blocks. 3D printing with resins and metals will unlock the future of AI-assisted design, he said.

These techniques could produce larger components such as structural trusses, complex flexible systems that move or unfold, or even advanced precision optics,” McClelland explained. “These techniques could enable NASA and commercial partners to build larger components in orbit that would not otherwise fit in a standard launch vehicle, they could even facilitate construction on the Moon or Mars using materials found in those locations.”

Merging AI, 3D printing, and in-situ resource utilization in this way will advance In-space Servicing, Assembly, and Manufacturing (ISAM) capabilities. ISAM is a key priority for U.S. space infrastructure development as defined by the White House Office of Science and Technology Policy’s ISAM National Strategy and ISAM Implementation Plan. v

NASA Gathering Tools to Assess Damage, Verify Parts Made in Space –

An ensemble of microscopes, medical-style equipment, and other 3D scanners is providing insights that could help human and robotic explorers survive the harsh environments of deep space, the Moon, Mars, and beyond.

Earth’s atmosphere protects us from the threat of tiny meteors – micro-meteorites no bigger around than the thickness of a fingernail and traveling faster than a speeding bullet – because they burn up in our atmosphere. However, explorers traveling beyond our protective blanket of air need strategies to protect from micro-meteorites collisions, as well as technologies to evaluate the damage they can cause.

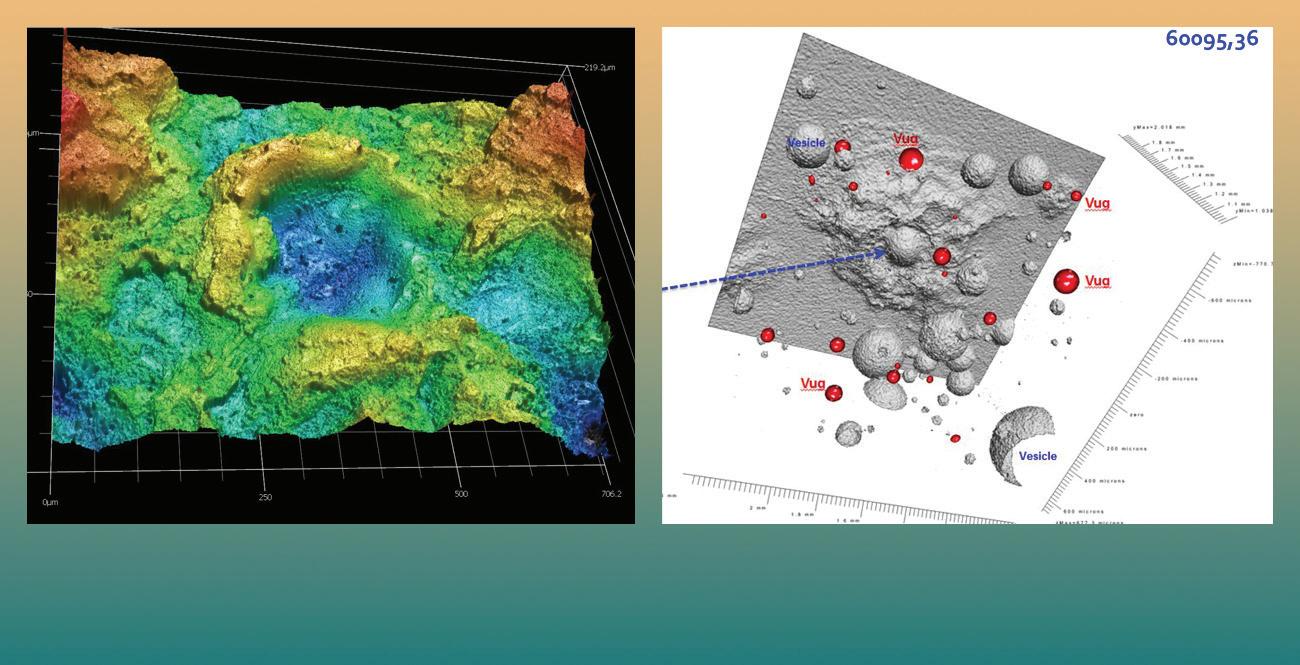

“Studying micro-meteorite impacts in lunar samples helps to find materials and methods to build habitats and protective gear for future Moon and Mars explorers,” Materials Scientist Dr. Justin Jones said. Jones has spent the last several years at Goddard investigating a variety of 3D scanning technologies, most recently for their ability to analyze tiny micro-meteorite impact craters on Apollo-era Moon samples. He obtained high-resolution 3D scans (i.e., as micro-topographic maps) and measurements of the so-called zap pits, or micro-craters left behind by these collisions.

As NASA considers long-term exploration of deeper into our solar system, in-situ resources found on

other worlds will be used to build shelters and provide building materials. Jones’ work focused on technologies allowing explorers and scientists to examine and even look inside a material without destroying it. These non-destructive scanning technologies will also help evaluate the strength and suitability of items made in space and assess the science value of materials and samples found on other worlds.

His team, including Goddard Chief Scientist James Garvin and Materials Engineer Stephen Lebair, examined and cataloged dozens of zap pits in the Moon samples while evaluating the strengths and weaknesses of different technologies for assessing materials, responses, and damages.

They found laser confocal microscopy (LCM) performed better at characterizing the shape and form of the zap pits, Lebair said. The confocal microscope focuses a laser in a tight spot, one depth-level at a time, allowing finer spatial resolution than other technologies.

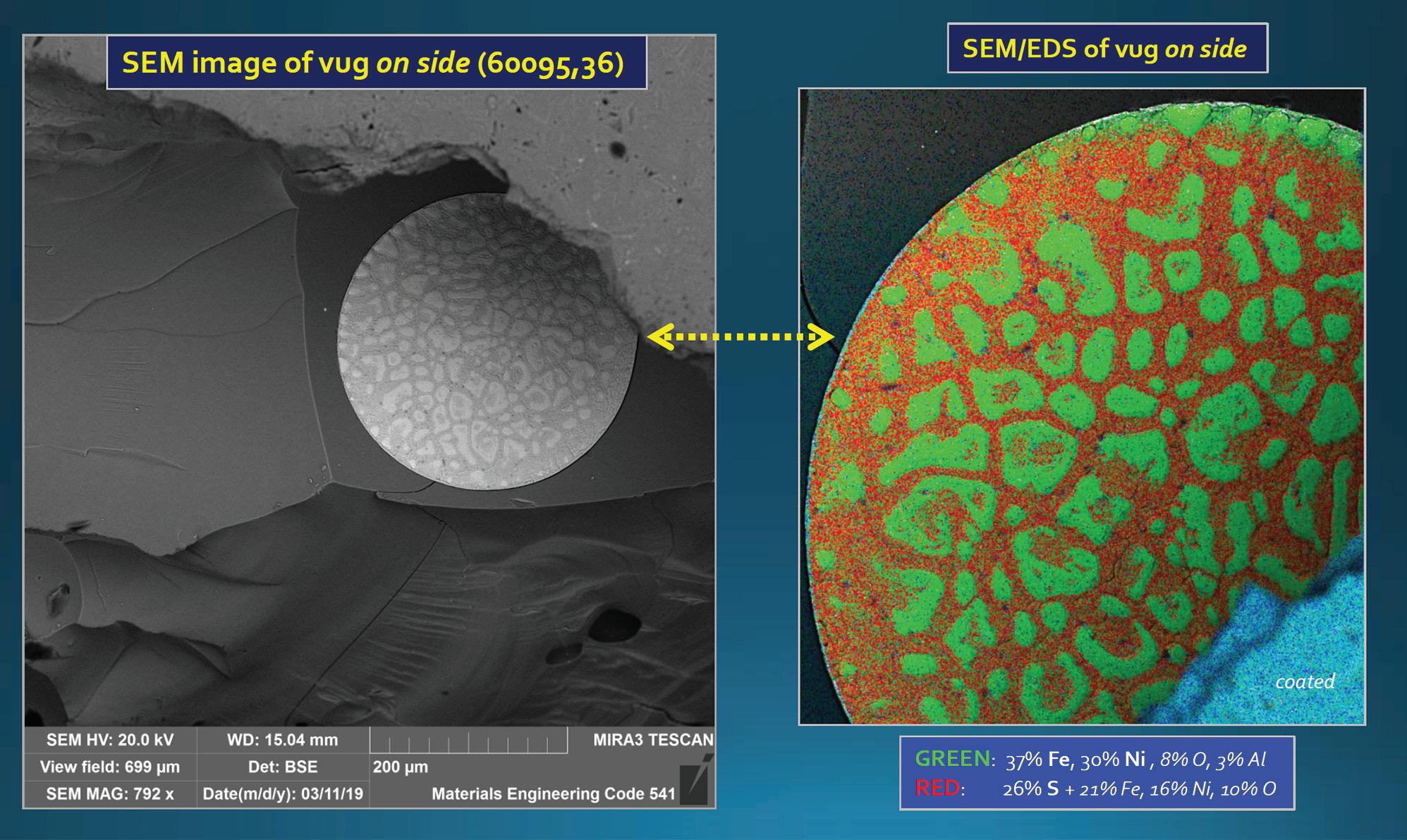

“Scanning electron microscopy (SEM) was the best imaging technique,” Lebair said, “since you don’t have to worry about reflections or artifacts of optical microscopy.”

SEM scans the surface with a focused beam of electrons, which as an added benefit can interact with

atoms in the sample. This interaction provides data on the composition of materials through a technique called energy dispersive X-ray spectroscopy, or EDS

To look beneath the surface, X-ray computed tomography (xCT) reveals the depth and topology of the micrometeorite impact and stresses and deformation caused within the material, Jones said. In addition, it can determine the potential for future failure of equipment after an impact.

The deep imaging enabled by xCT can verify the structural suitability of tools 3D printed in space or shelters built using local materials.

“We want to know the best materials to use,” Jones said, “and how thick should we make these structures. If we’re looking at designing a structural material for habitats, clothing, or other protective materials, we need to understand the depth of an impact beyond what we can see on the surface.”

The beauty of an xCT scanner, Jones said, is that it provides information that otherwise would require difficult, often destructive sample preparation such as cutting or the use of chemicals to analyze subsurface structures Goddard’s laboratory xCT system provides details as small as a couple microns in size: several times smaller than a human hair.

The beauty and complexity of the images produced by these non-destructive scanners also illustrates the violent forces that turn stone to glass, create cavities within the surface, and even force tiny spheres of metal to coalesce within the surrounding material. Micrometeorite impacts are a common-

place reality on the Moon and in deep space, Jones said. “It is important for NASA to be able to rapidly identify and understand the extent of deformation and mechanisms involved with micrometeorite cratering. We also want to know how this extends to larger impacts out there.”

The International Space Station has an electron microscope as well as a one-sided xCT that can be used on one of its robotic arms to evaluate damage from micrometeorite or debris strikes.

Jones is working on a potential bread-box-sized CT scanner that could operate on the space station. These scanners must operate without the massive rotating ring used in current medical scanning technologies, which could disrupt the orbital platform’s stability. Jones’ project would use the instant on/off X-ray sources developed by Goddard Astrophysicist Keith Gendreau (CuttingEdge, Summer 2019) to develop a scanner using few or no moving parts.

Non-destructive scanning can also help explorers select the best specimens to gather as scientific samples for return to Earth, Jones said, revealing some of their history, internal structure, and component materials.

“NASA’s Artemis Program will benefit from Jones’ work,” Garvin added, “as it plans lunar-surfacebased systems for the human basecamp on the Moon.” v

Atomic Layer Deposition – One Element at a Time

The shifting boundary between Earth’s outer magnetic field and the fluctuating solar wind generates a haze of soft X-rays, which can be a tantalizing target of observations or a source of frustrating noise, depending on what phenomena scientists want to observe.

Goddard engineer Dr. Vivek Dwivedi said the solution to both problems may be found in new coatings applied just atoms thick to an existing X-ray lens technology.

“Heliophysicists lack techniques to image the dynamic response of the Earth’s magnetosphere to varying solar wind conditions,” Dwivedi said, “while astrophysicists have frequently noted foreground emissions from the Sun or noise from its interaction with interstellar space interfering with observations of targets far beyond the solar system.”

His latest atomic-layer deposition (ALD) work involves bonding nickel and carbon onto glass substrates, improving their ability to properly reflect and focus lower energy or soft X-rays onto a receiver. As Dwivedi refines new techniques to improve ALD coatings, more applications for science come into focus.

Dwivedi uses commercially produced lobster-eye optics, which mimic the structure of the crustacean’s eyes. Composed of glass formed into long, narrow cells, they provide a wide-angle view, as each cell funnels a tiny amount of light from a slightly different angle toward a sensor. Lobster optics can focus difficult wavelengths like X-rays, which only reflect at very shallow angles.

Dwivedi said the nickel coating he perfected last year could greatly improve their performance for soft Xray observations needed for some investigations.

For heliophysicists like Goddard’s Dr. David Sibeck, observing the soft X-ray environment around our planet reveals how the solar wind affects Earth’s outer magnetosphere.

“The magnetosphere forms a kind of bubble or cocoon around us that extends tens of thousands of miles into space,” Sibeck said. “The boundary of that bubble is only a few hundred miles across, which on that scale is very sharp. It’s constantly being buffeted by solar wind, so it moves in and out. We would dearly love to be able to find and track

this boundary at any given time to see how it’s being affected by our Sun.”

The only way scientists can measure that boundary now, Sibeck said, is to cross through it with instruments that measure the magnetic fields and charged particles present there. “This kind of wide-angle soft X-ray imager is a new concept,” he added, “and nickel has reflective properties we need to study the relevant wavelengths.”

For X-ray astronomers like Goddard astrophysicist Dr. Scott Porter, the interaction between Earth’s warm, enveloping atmosphere and the solar wind is a source of noise to be overcome.

Lobster-optics provide a tool for wide-angle scanning for X-ray sources across the cosmos, Porter said, and Vivek’s nickel-coated optics could collect 30% more X-rays than the state-of-the-art, goldplated iridium lenses.

His quarry is among the universe’s largest but shortlived eruptions, including the collisions of neutron stars and black holes.

“They’re very far away and not bright enough to see until they collide and emit gravitational waves and other high-energy light,” Porter said. “They are not predictable in terms of when or where to look.”

Working in tandem with gravitational wave explorers and satellites like NASA’s Fermi Gamma-ray Space Telescope, a wide-field, burst-detecting X-ray observatory could scan constantly for flashes. Other, observatories would then follow up with higher-resolution views of the event.

Soft X-rays could also reveal information about how the solar wind pushes out against the galactic environment of the Milky Way, how planets like Venus and Mercury lose atmosphere to the solar wind, and how that wind affects comets.

This year Dwivedi is working to develop an atomiclayer carbon deposition process to further augment

the lobster optics. Dwivedi said the combination of nickel and carbon layers could have powerful applications for X-ray optics.

His ALD chamber recently flew on a parabolic flight to demonstrate the possibility of atomic-layer deposition in zero gravity, and Dwivedi plans to fly it again on a Blue Origin New Shepard rocket this summer.

“ALD in space opens new frontiers in the semiconductor industry where contamination control is paramount,” Dwivedi said. “Having a factory in space to manufacture ultraclean microprocessors could potentially open up a multibillion-dollar industry, and this ALD demonstration will lay the groundwork for that manufacturing ecosystem.”

Goddard’s ALD wizard said there may well be a use for many other elements on the periodic table once chemists master the techniques for controlled deposition.

“Whether for optics or dust-repellant coatings,” Dwivedi said, “we’re finding opportunities for all kinds of applications. For instance, gold may be a useful coating for probes exploring Venus as a shield against the acidic atmosphere because gold doesn’t corrode.” v

New NASA Safety System Enables Rocket Lab Launch From Wallops

Arevolutionary flight safety system enabled a new era of space transportation with the successful flight of Rocket Lab USA’s Electron rocket Jan. 24, from NASA’s Wallops Flight Facility

This mission, the first Electron launch from the United States, was enabled by the NASAAutonomous Flight Termination Unit (NAFTU). Internal Research and Development, or IRAD, funding helped develop this critical flight safety technology

“In taking NAFTU across the finish line, NASA has delivered an autonomous flight termination system like no other in operation today, filling a critical gap in modernizing our nation’s launch ranges,” said David L. Pierce, Wallops Flight Facility director.

“We’re proud to have made this and future U.S. Rocket Lab Electron launches possible with our game-changing flight safety technology.”

While other, proprietary autonomous flight termina-

tion systems are in use today, NAFTU is different in that it was designed to be used by any launch provider at all U.S. launch ranges to ensure public safety during launch operations. To date, 18 companies have requested the NAFTU software through NASA’s technology transfer process Rocket Lab was among the first applicants for the software, enabling their launch from Wallops.

Wallops, in collaboration with NASAHeadquarters, NASA’s Kennedy Space Center, the U.S Air Force and Space Force, as well as the FederalAviation Administration, began development of NAFTU in 2020, when the program became fully funded. Provisional certification of the unit was granted for Rocket Lab’s first U.S. Electron mission and full certification is expected by Jan. 31, 2023. v

NASA’s Future Ultraviolet Telescope Needs Dependable ‘Mirrors

A large ultraviolet telescope orbiting outside Earth’s UV-protective atmosphere will give scientists new ways to understand how stars, planets, and even galaxies form and interact in space.

To do so, said Goddard Astrophysicist Paul Scowen, this NASA observatory will require optics that can measure the polarization of UV light without changing it.

“The space between stars and galaxies is not exactly empty,” he said. “Measuring the polarization of that interstellar medium will show how particles line up there based on the magnetic fields of stars around them. We’re going to be able to measure magnetic fields of another star with better than 0.1% accuracy.”

The Astrophysics Decadal Survey released in early 2022 recommended observations ranging from ultraviolet, through optical and infrared light to study questions such as how planets form and look for signs of habitability. The Habitable Worlds Observatory (HWO) mission concept will provide high-resolution, wide-field imaging surveys over time. Teaming up with NASA’s wide-field Roman Space Telescope, these missions will answer questions about the formation, development, and survival of stars and planets, map the motions and evolution of stellar jets and accretion

flows, and identify sources of ionizing radiation. Scowen received an Internal Research and Development, or IRAD, grant to study how UV mirror coatings developed by Manuel Quijada (CuttingEdge, Spring 2017) and microshutter arrays like those developed for the James Webb Space Telescope can rise to the challenges of these explorations.

Challenging Reflections

Toward the high-energy end of the spectrum, UV light does not reflect efficiently off traditional mirrors. Quijada pioneered new materials and coatings to bounce high-energy light at very shallow angles towards a detector. Their mirrors stack almost parallel to the incoming light in concentric rings funneling high-energy light towards the sensor.

Scowen builds on Quijada’s work, literally, adding layers of metal flourides to his mirrors that allow reflectivity down to wavelengths of 100 nanometers. Over the past year, his team acquired an ion gun and hardware to test a vapor deposition process to improve the coating’s precision. Next, Scowen plans to develop techniques to assess and validate those coatings.

“If your instrument changes the polarization,” he said, “you’re going to miss a lot. We need to be

able to measure the polarization of our coatings for sensing in the far ultraviolet.”

The team also created six different microshutter array wafers to test different designs, building on a decade of IRAD-funded innovations. Each tiny shutter in this type of array can individually open or close to block out bright foreground stars that might overwhelm distant worlds the telescope is trying to capture. Next, they will test the arrays to identify their reliability.

Scowen worked with optical engineer Mateo Batkis, from St. Michaels College in Vermont, who de-

scribed the HWO missions as the future of spacebased astrophysics.

The polarization of UV light will allow scientists to study how planets form, how stars’ magnetic fields compare to our Sun’s, and what’s happening in the interstellar medium as well as in between galaxies, Batkis said.

“If we’re trying to build a true Hubble successor,” he said, “we need to do polarization spectroscopy.” v

CONTACT

Paul.A.Scowen@nasa.gov or 301.286.8771

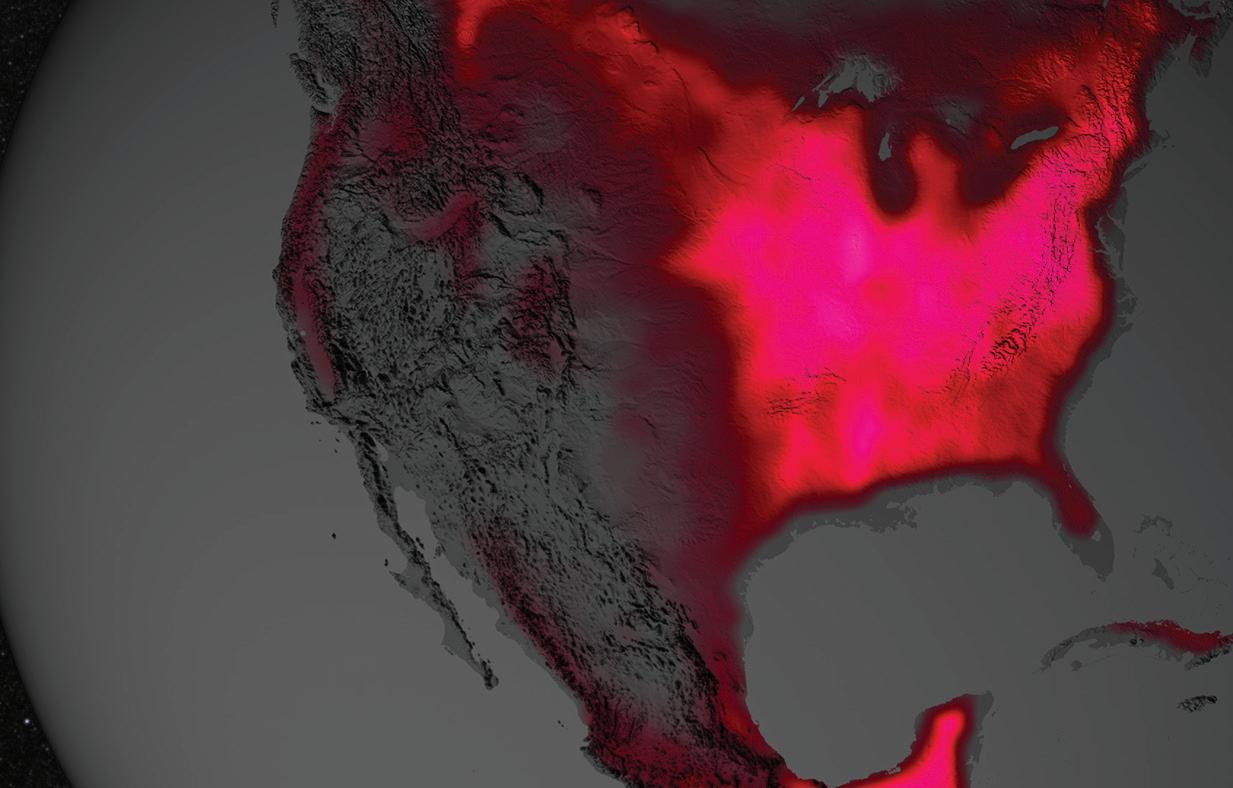

Measuring Forest Health from Above

In places across the U.S., tree cover is shrinking– forests are burned by wildfires on the West Coast and drowned by rising sea levels along the East. From the ground, it’s hard to assess the scale of the losses and the effects disappearing trees have on atmospheric carbon dioxide levels and climate change.

Goddard research scientist Jon Ranson is working to improve new technologies for studying trees from above, so future Earth observing missions can more accurately assess forest health.

“Trees do a huge service for the planet, in terms of sequestering carbon dioxide, taking it out of the atmosphere and putting it into wood,” Ranson said, “but trees are very sensitive to our changing climate. We’re trying to see the changes going on in forest ecosystems. If you detect things early enough, you might be able to do something about it.”

Measured from aircraft and satellites, the wavelengths of light reflected by plants tell scientists about the amount of photosynthesis occurring, and how much atmospheric carbon dioxide trees take up and store. The current standard for studying vegetation is called NDVI, or Normalized Differential Vegetation Index, which is the average of two broad portions of the infrared spectrum. NASA’s NDVI record goes back 40 years, providing a low-resolution but useful chronicle of forest health.

While NDVI is good at assessing photosynthesis broadly, Ranson said, breaking down infrared and visible light into many more wavelengths, or hyper-

spectral imaging, can provide information related to plants’ water content, chlorophyll and even changes in health.

“Vegetation has these broad spectral properties,” explained Ian Adams, Goddard’s Earth Sciences Division Technologist “with hyperspectral imaging, you get lots of different measurements at smaller, closer together frequencies. There is a lot more information we can pull out if we can get better spectral resolution.”

By dramatically increasing the number of frequencies available for researchers to study, Ranson’s new technology serves the priorities of the National Academies of Science’s most recent Earth Science decadal survey, which determines the field’s longterm priorities. The survey lists “surface topography and vegetation,” which includes forests, as a key area of study in need of more advanced technology.

“Strategically for NASA, and more broadly for the remote sensing community, hyperspectral is one of the areas we see as the future,” said Adams.

For future orbital missions to make use of hyperspectral imaging, data analysis techniques first have to be proven closer to the ground.

Ranson’s team fitted a Skyfish uncrewed arial vehicle (UAV) provided by partner institution Virginia Tech with a visible and infrared (VIS/ IR) hyperspectral camera and lidar equipment. Working with students, he flew the imaging equipment over forests near Blacksburg, VA, in a region called Mountain Lake. Comparing their remote sensing observations with actual CO2 levels recorded by sensors on a National Ecological Observatory Network tower helped the team refine calculations about how much carbon the forest removed from the atmosphere. First they had to characterize what the hyperspectral data could show.

Plants stressed by too much sunlight may release pigments to shield their chloroplasts, a condition his sensors can detect. If they are shaded, the sensor can overestimate plant productivity based on leaf surface area. Ranson wants to add short-wave infrared sensors to better tell apart reflections from leaves and other parts of plants, eliminating another possible source of error.

The view from space: Seeing the forest for the trees

Ranson’s ultimate goal is to study forests on a global scale from space.

“We’re trying to get the complete picture,” Ranson said. “So that when we go to space, we know how to find the answer to the question, ‘Are our forests healthy? And if not, why not?’”

A Goddard mission concept called Concurrent Artificially-intelligent Spectrometry and Adaptive Lidar System, or CASALS, would send an instrument into space with lidar and hyperspectral cameras to do just that. A constellation of these satellites could take the frequent measurements necessary to assess changes in forest productivity over time, using models perfected by Ranson’s UAV flights.

“Forests take up as much carbon as the ocean does, yet forests cover only 9% of Earth’s surface,” said Ranson. “So, if something goes wrong with our forests, it’s a dramatic issue. We’ve got this great, great resource in forests, and we need to care for them, so they’ll care for us.” v

CONTACT

Kenneth.J.Ranson@NASA.gov or 301.614.6650

CuttingEdge is published quarterly by the Office of the Chief Technologist at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. The publication describes the emerging, potentially transformative technologies that Goddard is pursuing to help NASA achieve its missions. Contributors include Christian Elliott and Jeremy Eggers. For more information about Goddard technology, visit the website listed below or contact Chief Technologist Peter Hughes, Peter.M.Hughes@NASA.gov. If you wish to be placed on the publication’s distribution list, contact Editor Karl Hille, Karl.B.Hille@NASA.gov.

Publication Number: NP-2023-2-010-GSFC