California’s 2023 Wine

Grape Outlook: Smaller Supply, Mixed Demand

Bourbon Barrel-Aged Wine Grows in Popularity

Learn by Doing: New Cal Poly Viticulture Center

January 2023

Volume 1:

1

Issue

The world’s leading raisin processor has achieved record sales over the past several years and has more room to grow! Get industry-leading returns, continuing education opportunities, and payment stability Interested in Joining a 100-year-old Cooperative That Returns All its Proceeds to its Growers? CALIFORNIA RAISIN FARMERS : IF YOU’RE INTERESTED IN BECOMING A SUN-MAID GROWER call our Grower Relations Department at (559) 825-3633 or email growerservices@sunmaid.com • 100-Year Old Stable Cooperative • Sustainable and Innovative Practices • Outstanding Production Facilities • Average +20% Returns vs Industry • Dedicated Growers Services Team • Ongoing Education and Training BENEFITS INCLUDE : Become a Sun-Maid Grower Today!

CALIFORNIA’S 2023

WINE GRAPE OUTLOOK: SMALLER SUPPLY, MIXED DEMAND

PUBLISHER: Jason Scott

Email: jason@jcsmarketinginc.com

EDITOR: Taylor Chalstrom

Email: article@jcsmarketinginc.com

PRODUCTION: design@jcsmarketinginc.com

Phone: 559.352.4456

Fax: 559.472.3113

Web: www.grapeandwinemag.com

CONTRIBUTING WRITERS & INDUSTRY SUPPORT

Vicky Boyd

Contributing Writer

Taylor Chalstrom Editor

Sean Jacobs Senior Agronomist, Technical Sales and Marketing Representative, Agro-K

Julie R. Johnson

Contributing Writer

Catherine Merlo

Contributing Writer Steve Pastis Contributing Writer

Beth Vukmanic Executive Director, Vineyard Team

Cecilia Parsons Contributing Writer

BOURBON BARREL-AGED WINE GROWS IN POPULARITY ATTENTION TO IRRIGATION SYSTEM MAINTENANCE PAYS DIVIDENDS NEW CLAIRVAUX VINEYARD AND WINERY LESSONS FROM SUSTAINABLE VINEYARD FARMERS

UC COOPERATIVE EXTENSION ADVISORY BOARD

Surendra Dara Director, North Willamette Research and Extension Center

Kevin Day UCCE Pomology Farm Advisor, Tulare and Kings Counties

Elizabeth Fichtner UCCE Farm Advisor, Kings and Tulare Counties

Katherine Jarvis-Shean UCCE Orchard Systems Advisor, Sacramento, Solano and Yolo Counties

Steven Koike Tri-Cal Diagnostics

Jhalendra Rijal UCCE Integrated Pest Management Advisor, Stanislaus County

Mohammad Yaghmour UCCE Area Orchard Systems Advisor, Kern County

The articles, research, industry updates, company profiles, and advertisements in this publication are the professional opinions of writers and advertisers. Progressive Crop Consultant does not assume any responsibility for the opinions given in the publication.

January 2023 www.grapeandwinemag.com 3

THE

POCKET GOPHERS IN THE VINEYARD LEARN BY DOING: NEW CAL POLY VITICULTURE CENTER 04 8 18 20 24 28 12 32

THE FIVE RS OF NUTRITION IN

VINEYARD

California’s 2023 Wine Grape Outlook: Smaller Supply, Mixed Demand

By CATHERINE MERLO | Contributing Writer

In Jeff Bitter’s view, California’s wine grape industry can no longer rely on market patterns that were considered normal even five years ago.

Market dynamics are changing, making it harder to forecast the coming year, said Bitter, president of Allied Grape Growers. The marketing cooperative represents some 500 California producers and sells more than $100 million worth of grapes each year.

Since 2019, Bitter pointed out, yearly harvests have consistently fallen below the once-normal crush of 4 million tons. California’s ongoing drought and escalating input costs are eroding producers’ margins. Wine shipments remain flat. The struggling economy adds another layer of uncertainty.

“There’s apprehension in some wineries about what’s going to happen on the demand side,” he added.

Bitter isn’t alone in trying to gain a clearer outlook as the wine grape industry evolves.

“There’s a lot of guessing about what’s going to happen in 2023,” said Craig

Ledbetter, vice president and partner with Vino Farms. The company owns and manages over 15,000 acres of wine grapes throughout California.

Supply Side Shift

The production drop that began with the 2019 wine grape crop “was a pivotal point in the California market in terms of supply, demand and balance,” Bitter said. “That drop had to do with one thing: oversupply. Many growers were unable to sell their grapes or excess tonnage and had to leave them on the vine to rot.”

The upshot was that many growers de-

cided to pull out their vineyards or get out of the business. That reduced supply “a fair amount for the future,” Bitter added, because those acres were permanently removed.

Now, California’s 2022 wine grape harvest marks the state’s fourth consecutive crop to fall below 4 million tons. Both Ledbetter and Bitter estimate its volume at around 3.5 to 3.7 million tons, down 10% from an average crop. They attribute the decrease partly to the vineyard removals of the last couple of years. A late-spring frost in the Delta and Lodi

These industry insiders see a stable market ahead, but that’s not great news for growers.

ContinuedonPage6

Jeff Bitter is president of Allied Grape Growers, which has annual sales of more than $100 million (photo courtesy J. Bitter.)

Craig Ledbetter is vice president and partner with Vino Farms (photo courtesy Vino Farms.)

4 Grape & Wine Magazine January 2023

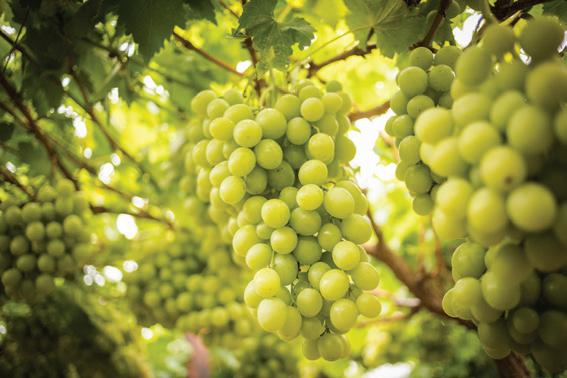

California is the nation’s No. 1 wine producer, making 81% of U.S. wine (photo by C. Merlo.)

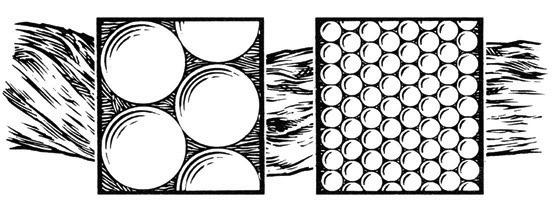

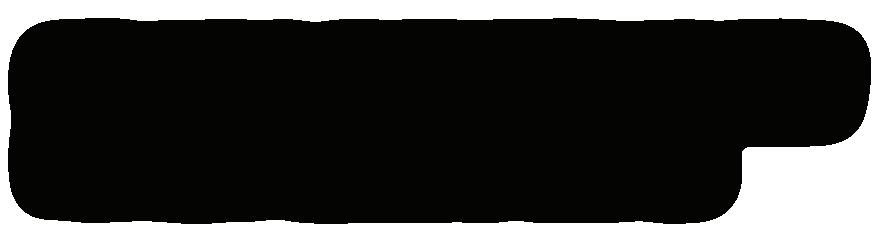

January 2023 www.grapeandwinemag.com 5 Get Ahead of Powdery Mildew for Next Seasons Grapes BECAUSE THE DISEASE HITS QUICKLY, YOU NEED TO HAVE A PRODUCT IN PLACE BEFORE THE DISEASE OCCURS. Lime-Sulfur Solu�on’s small par�cle size • Disperses more evenly • S�cks more tenaciously Giving you residual control and extended protec�on. MICRONIZED SULFUR VS LIME-SULFUR SOLUTION Learn more about Lime-Sulfur Solu�on at www.novasource.com Always read and follow label instruc�ons. NovaSource® and Lime-Sulfur Solu�on™ are registered trademarks of Tessenderlo Kerley, Inc. | ©2022 Tessenderlo Kerley, Inc. All rights reserved.

growing regions and the statewide heat wave in late August and early September also hurt yields.

Yet the reductions in recent harvests can’t only be attributed to vineyard removals, according to Bitter. Longer term are questions about the effect of California’s drought on the size of future crops.

“Something else is going on that’s causing us to have shorter crops each year,” he noted. “So, you look at the drought and its lasting impact. Is the state’s capacity for 4 million tons over? Is the average crop size of 3.6 million tons the new normal? We’re in a flat market so we’re not looking for more supply. But it does point to the reality that farmers will have to become more productive in their vineyards if they’re going to continue dealing with issues outside of their control.”

Demand Remains a Question

Underlying the effect of California’s smaller wine grape supply is, of course, the demand for wine.

“On the surface, after three short crops, you’d think the market should be stable, even strong if you’re looking at depleting inventories,” Bitter said.

But the wine market is still trying to find its bearings in the wake of COVID-19. Pandemic restrictions shifted demand for wine away from restaurants, bars, sporting events and

other public venues to supermarkets. While that hurt many businesses, those changing market channels created opportunities for lower-priced wines to regain some health. That benefitted grapes grown in the state’s interior regions, which generally produce the wine sold in grocery stores.

The boost in sales at the $15-per-bottle level and higher is important, since 70% or more of the entire wine market sells at the $20-per-bottle price point, Ledbetter said.

The big question now is how wine consumers will react in the coming year as economic uncertainty and fears of a recession persist.

“An economic decline won’t lead people to stop drinking wine, but they will trade down from their usual price points,” said Ledbetter. “If they typically drink a $35 bottle of wine, they’ll shift to a $20 bottle. That will help the lower end of the market.”

Among wineries, the flat wine market is leading to a greater focus on maintaining market share. It’s also driving more aggressive players “to try to steal someone else’s share of the pie,” Bitter said. “That’s where certain wineries and producers are growing. You don’t have a lot of strategy around growth or introducing new products or being the next greatest thing. It’s, ‘How do I maintain my portion in the market and operate my business without putting me at risk?’”

The industry also is grappling with how to market wine to different generations. The baby boomers, who helped drive market growth over the past few decades, have slowed their wine consumption.

“The biggest issue of our industry is trying to understand millennials [born from 1981 to 1996], who are the second largest segment of the U.S. population,” said Ledbetter. “They’ve been consistently inconsistent in their loyalty to wine.”

Export Optimism

Gino DiCaro, director of communications for Sacramento-based Wine Institute, said California wineries are optimistic about current and future demand for their unique and often sustainably grown and made wines.

“With a 10.6% increase in exports last year, we are seeing growing global demand, and domestically the direct-to-consumer (DTC) market has grown under expanded DTC channels,” he noted.

Wine Institute is the public policy advocacy group of 1,000 California wineries and affiliated businesses. It’s also the administrator of the USDA Market Access Program (MAP) for California vintners, representing 80% of U.S. wine production and 95% of U.S. wine exports. Under Wine Institute’s California Wine Export Program, more than 195 of the state’s wineries export to 142 countries.

ContinuedfromPage4

California’s 5,900 wine grape growers produce on 621,000 acres (photo by C. Merlo.)

6 Grape & Wine Magazine January 2023

While Cabernet Sauvignon accounts for California’s second-highest wine grape acreage, Pinot Noir has grown steadily in popularity (photo by C. Merlo.)

“California’s wine-producing community is still growing,” DiCaro said, “which means we’ll be well suited to accommodate market demand for that coveted glass of Golden State wine.”

Grower-Side Pricing

Also coloring the 2023 wine grape outlook are growers’ high input costs. Soaring prices for fertilizer, labor, energy, parts and supplies as well as increased regulations have all raised producer expenses.

“The cost of putting in a vineyard in the Lodi area has increased 35% to 40% since COVID-19 arrived,” Ledbetter said. “The numbers no longer show a positive return on investment unless we see a dramatic increase in price. It’s very difficult to make money these days.”

Pricing needs to range from $800 to $850 a ton for Lodi area growers to be economically sustainable, Ledbetter added, versus the current $600 to $650 levels.

Bitter foresees pricing at the grower level remaining stable in 2023. But that’s not good news for growers. “Stable pricing means we’re going backward,” he said. “Input costs have been rising for the last 18 months and will continue to rise. The average grower today is less profitable than [they were] last year.”

Even so, growers like Ledbetter refuse to let their immediate challenges dim their outlook. They’re looking for opportunities to help them survive. To expand their options and sustain their farming future, for example, Ledbetter and his family have planted pistachio trees east of Galt and along Interstate 5 near Elk Grove between Stockton and Sacramento. But they aren’t leaving the wine grape business.

“I’m a farmer, so I’m optimistic,” Ledbetter said.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Wine sold in supermarkets has seen an upturn in sales since the pandemic began (photo by C. Merlo.)

Wine sold in supermarkets has seen an upturn in sales since the pandemic began (photo by C. Merlo.)

January 2023 www.grapeandwinemag.com 7

Chardonnay is California’s most-planted white-wine grape and the most popular wine in the U.S., according to Wine Institute (photo by Elizabeth Brewer.)

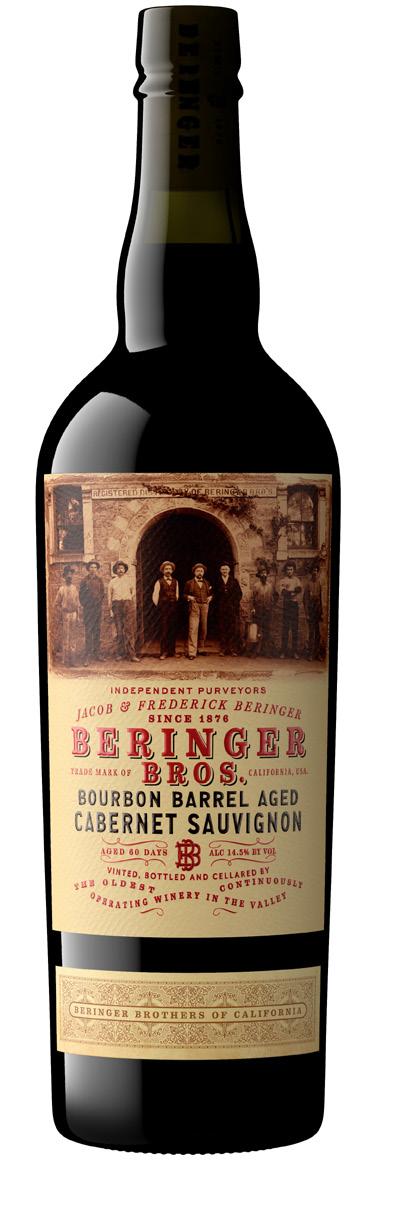

BOURBON BARREL-AGED WINE GROWS IN POPULARITY

By STEVE PASTIS | Contributing Writer

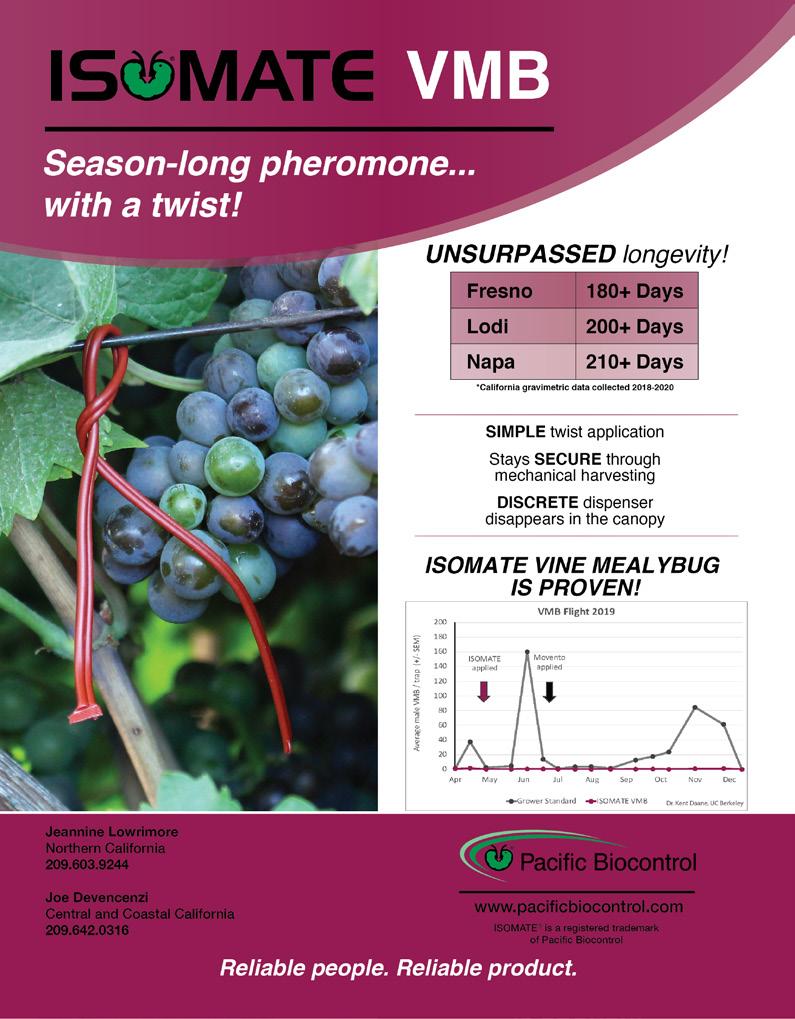

Sales of wines aged in bourbon barrels have increased dramatically in recent years. Originally a cost-saving practice for winemakers, the current popularity of these wines is a result of the way the used barrels enhance their taste and aroma.

“By using bourbon-aged barrels, we get entirely different components, smells and flavors than we do with traditional wine barrels,” said Ellie Farrell, public relations manager for Treasury Wine Estates, an international wine company based in Australia with U.S. locations in Oakland and Napa. “Our American oak barrels introduce warm aromas and flavors of vanilla, caramel, roasted hazelnuts, butterscotch and baking spice.”

Treasury Wine Estates has more than 40 wine brands, including Beringer Vineyards, one of the first companies to use bourbon barrels to age wine.

“150 years ago, brothers Jacob and Frederick Beringer left Germany to establish a winery and distillery in Napa,” said Farrell. “Historically, wine producers used whatever was readily available to ferment and even store their wines, including various wood tanks like redwood or oak. To Jacob and Frederick, reusing their spirit barrels to age wine just seemed like good financial sense, and they quickly discovered it added a whole new level of complexity.”

Bourbon barrels also reduce the time necessary to age wine, according to Farrell. “After being fermented in stainless steel tanks, our wines are aged in second-passcharred American oak bourbon barrels for 60 days.”

She added that Beringer Vineyards makes wine using traditional winemaking practices, including aging wine in spirits barrels. Even the company’s bourbon barrel aging process has remained fairly consistent.

“We’ve made a few tweaks here and there, but overall, the process has stayed the same,” said Farrell.

“Because the toasting for bourbon barrels is different and more aggressive than for wine, we only age 20% of the wine in bourbon barrels,” said Farrell, adding that red blend, cabernet sauvignon and chardonnay are among the types of wine benefitting the most from bourbon barrel aging

Beringer prefers used bourbon barrels to new, according to Farrell. “The average age of our used barrels is four years,” she said. “We’ve found by using used bourbon barrels, we get better integration of flavors as well as unique flavors, resulting in better quality wines.”

Process Also Benefits Newcomers

Even winemakers without a long history are finding success aging their wine in bourbon barrels.

“We’re new to the business,” said Rob Hendriks, co-owner of Aloria Vineyards based in Murphys, Calif., which started using bourbon barrels in 2020.

“We have four bourbon barrels and we put our port in them,” he said. “Basically, the wine we had was all finished, already aged. We put it into bourbon barrels to pick up the flavor.”

Hendriks described Aloria’s port wines as “all dry and not sweet,” and said that the bourbon barrel aging process adds “some caramel overtones to it.

“The response is usually pretty positive when people taste our fortified ports,” he said, proudly noting that the Aloria 2016 Forté Estate Bourbon Barrel Aged Syrah was one of the “seven bourbon barrel-aged wines to try,” according to Wine Enthusiast.

“It’s just a flavor category that people seem to like,” said Alison Crowe, partner and vice president of winemaking at Plata Wine Partners, the winemaking arm of Silverado Wine Growers. “It’s certainly been increasingly common in the last five-to-seven years.”

ContinuedonPage10

8 Grape & Wine Magazine January 2023

January 2023 www.grapeandwinemag.com 9

Plata Wine Partners makes three wines with the Big Six Bourbon Barrel label, a cabernet sauvignon, a red blend and a zinfandel, which are sold through Total Wine & More.

Crowe described her company’s bourbon barrel wines as having “big bold ‘jammy’ flavors, fruity and sweet with very apparent fruity flavors like blackberry, raspberry and cherry.

“Red blend and cabernet lend themselves to this style,” she added. “Everyone may have different opinions, but the consensus is the best wine tone to pair with bourbon barrels is something smoky.”

She said that wines with crisp floral aromas such as riesling are not a good match for bourbon barrel aging. “It’s like cooking; you have to think about what spices go with what you are making,” she said, noting that wineries add ingredients to give their wines more complexities.

Crowe described the flavors suggested by bourbon barrel-aged wine as vanilla, clove, warm baking spices, cinnamon, toasted coffee, toffee and caramel, but added, “Actually, it’s more complex than that.”

Only some wood is good for wine barrels, she said. “You can’t make barrels out of eucalyptus. They won’t hold together.”

Oak barrels are best, specifically, barrels made from French or American oak, according to Crowe. “Our French oak barrels are brought over by ship or airplane.

“I wouldn’t want a new bourbon barrel,” she said, explaining that bourbon barrels are flame-charred using high heat, which burns the barrel and creates a flavor that can be very dominant. Traditionally, winemakers prefer to age wine in gently toasted barrels, slightly above light to medium charring.”

Because of the charring, she advises those using bourbon barrels to age wine to test it often. “Make sure you’re not overdoing it.”

Even with the required testing, Crowe believes that the process of using bourbon barrels to age wine is here to stay. “It may seem kind of gimmicky, but there’s a long history of these vessels in our history,” she said. “What’s old is new again.”

Consistency and a Good Story

“People don’t just want Budweiser and Coors or Jack Daniels anymore,” said Marc Hillier, owner/ president of Country Connection, Inc., a company headquartered in Oroville, Calif. that supplies barrels to winemakers, brewers and distillers. “They want something unique and interesting. If you can say your wine was finished with a French oak bourbon barrel in the Napa wine region, it makes a good story.”

Hiller started Country Connection in 2005

ContinuedfromPage8

Originally a cost-saving practice for winemakers, the current popularity of these wines is a result of the way the used barrels enhance their taste and aroma.

10 Grape & Wine Magazine January 2023

because he “fell in love with the barrel, and the smell of wine and bourbon in the barrel.”

Country Connection went through some early challenges, but Hillier said his company had strong growth in 2009 and again in 2013-14, and is experiencing “amazing growth now.” He said he “learned everything through youth and hard work.”

While the demand from wineries for Country Connection’s bourbon barrels has increased, winemakers’ preferences have remained the same, at least most of the time.

“I’m not seeing a whole lot of change,” said Hillier, “but one winery asked if I ever have tequila barrels, and I have provided rum barrels.”

Sales of wines aged in bourbon barrels have increased dramatically in recent years.

The main priority of wineries is that the bourbon barrels they receive are as similar as possible.

“People like consistency,” Hillier said. “If you’re going to develop a brand, your customers expect the same flavor. Wineries also prefer barrels that are unrinsed,” explaining that some distillers

wash their barrels and use the water to dilute the alcohol content in their whiskeys. While that may be a good business practice for distillers, it causes wineries to lose the bourbon flavors in the barrels.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Contact us to see how we can help! (559)584-7695 or visit us as www.superiorsoil.com Serving California since 1983 January 2023 www.grapeandwinemag.com 11

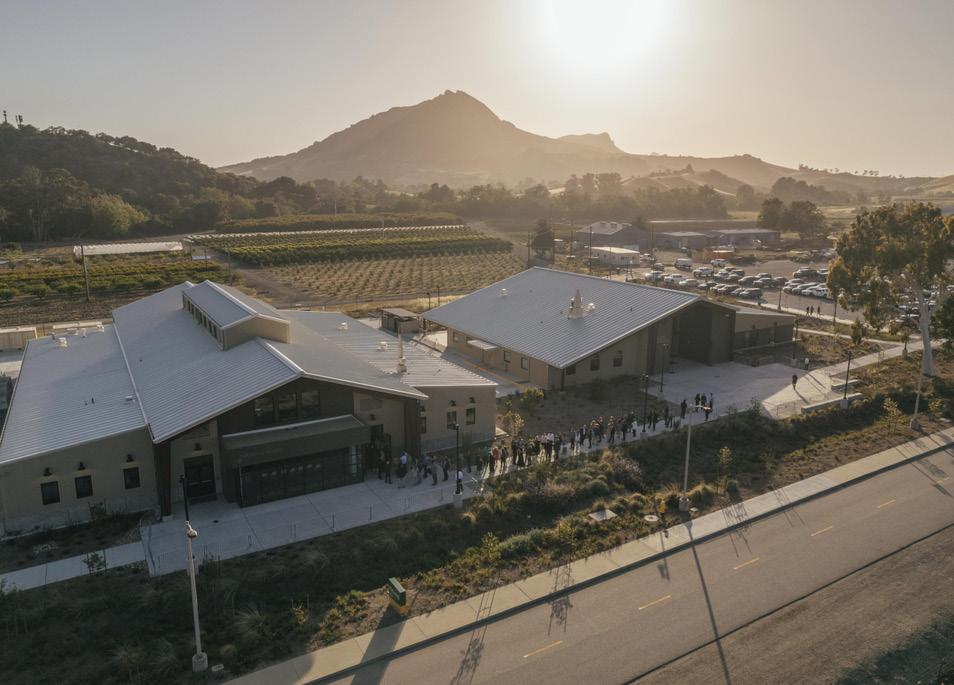

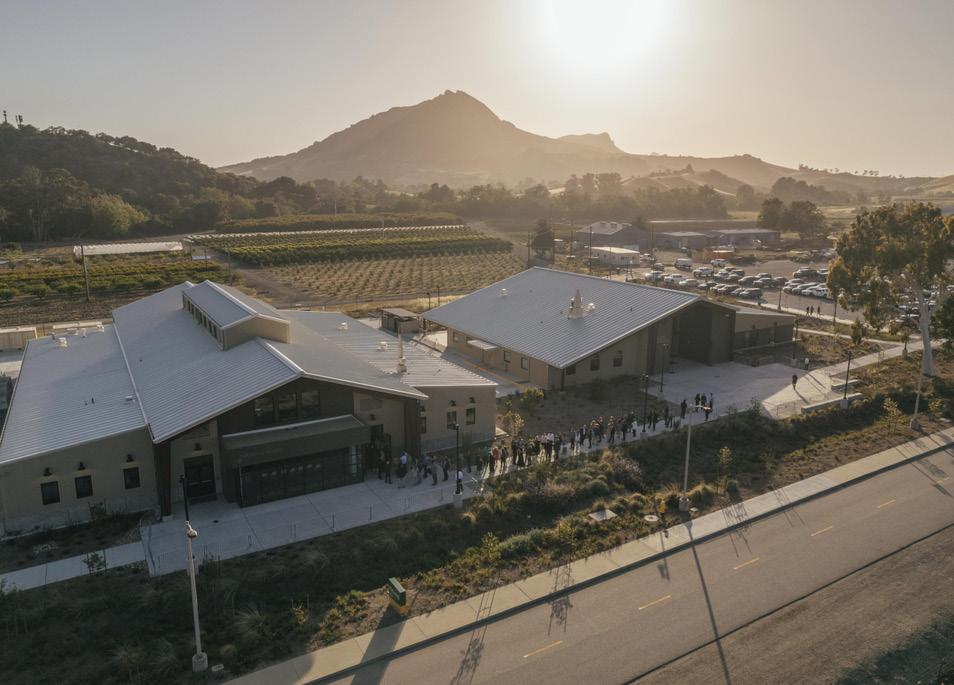

Learn by Doing Students gain real-world experience at Cal Poly, San Luis Obispo’s new wine and viticulture center.

By VICKY BOYD | Contributing Writer

By VICKY BOYD | Contributing Writer

Growing up in Napa with a father who worked at a winery, Olivia Capiaux knew what field she wanted to study in college — enology. A fourth-year student in Cal Poly, San Luis Obispo’s enology and viticulture program, she also is an intern helping make commercial wines at the college’s newly opened Justin and J. Lohr Center for Wine and Viticulture.

“Even though we’re working with (only 30 tons) of fruit, we’re still doing most of the same operations,” Capiaux said.

“We’re learning to operate pumps, how to close clamps on hoses and other types of technical things. We’re operating all of the same equipment that’s in a commercial winery. It’s invaluable. It’s just everything there that you’ll encounter

Taylor Robertson, also a fourth-year enology student and student intern, is equally excited about the opportunities the new facility provides.

“I believe this is such a unique experience that many other people

after college.”

ContinuedonPage14

12 Grape & Wine Magazine January 2023

Cal Poly students help with the grape crush at the new Justin and J. Lohr Center for Wine and Viticulture (all photos courtesy Cal Poly, San Luis Obispo.)

January 2023 www.grapeandwinemag.com 13 Maximize Your Grape Yields in 2023 Contact Ben Letizia for more information 559-284-1392 or benl@kimc1.com © 2023 Kim-C1, LLC. Kimzall is a registered trademark of Kim-C1, LLC Don’t expect Mother Nature to do all of the work, let Kimzall® take your grape production to the next level! Whether you’re dealing with Wine, Table, or Raisin Grapes, Kimzall will maximize both the yield and quality of your grape crop. with the Proven Power of Kimzall® Plant Growth Regulator

won’t get to see in their winemaking career,” said Robertson, who grew up in Nipomo but didn’t come from an agricultural background. “We have not only this new facility but a new facility on a college campus that is supported by the industry around us. They want to see the students who are making wines with their donated fruit, so the connections are absolutely amazing.”

Capiaux and Robertson are just two of the nearly 300 current undergraduate enology and viticulture students benefiting from the university’s new 15,600-square-foot bonded winery.

“There is no newer winery in the educational system as this,” said Jim Shumate, lecturer and winery supervisor. “We have all top-of-the-line equipment and tanks and everything for the students to learn on. It’s really been amazing to see how generous the industry has been to us and how Cal Poly has really promoted this university and this winemaking program. This will really give them the best real-world experience before they go out into industry and hone their skills out there.”

Shumate is joined by associate enology professor Federico Casassa, who teaches winemaking and sensory analysis and with whom he collaborates on wine production. Casassa also conducts enology

research, particularly into wine chemistry and sensory analysis of varieties that grow well in the Central Coast.

Having everything under one roof makes teaching and winemaking much easier than the previous set-up, Casassa said.

“Before, we had a much smaller winery that was something closer to a garage winery of about 600 square feet,” he said. “And honestly, it was a real hassle. We were working in this very confined space.”

Cal

Poly’s ‘Learn by Doing’ Creed

Not only does the new facility streamline winemaking, but Casassa said it will benefit students in viticulture and enology classes. If he is discussing crushing or destemming in one of his winemaking sections, he said it’s easy to take the students the 10 to 20 feet from the on-site classrooms to the production facility to show them what he was referring to.

“They’re going to benefit from this the most because they have access to really state-of-the-art knowledge that’s generated onsite, and they get to work in this facility that’s brand new and cutting-edge,” Casassa said. “This winery is 100% industry-supported, and we can give back to the industry by teaching the future generations of winemakers. We can make sure they come raring to go and hit the floor running. We also do research that’s relevant to the industry and directly applies to them.”

Shumate agreed, pointing to the student interns currently working with him in the commercial winery, reinforcing Cal Poly’s “Learn by Doing” creed.

“That’s one of the beautiful things; students get to do everything,” he said. “We have them involved in every step of the way. So right now, they’re doing the fermentations and they’re getting ready to barrel down some of the wines. As we progress during the winemaking process, they’ll be doing all of the topping

ContinuedfromPage12

Associate enology professor Federico Casassa (far left) leads discussions about freshly destemmed pinor noir, clone 96, in an 8-ton tank. They were looking at the proportion of whole berries and assessing the must post-processing.

14 Grape & Wine Magazine January 2023

Associate enology professor Federico Casassa examines pinot noir in an 8-ton tank.

of the barrels, doing more analysis.”

Shumate said learning on real equipment that’s the same size as that used in the industry gives students a leg up as they start their careers. Graduates end up working in wineries all over the world.

“It’s great for them to get a great experience here so when they do go out, they don’t require a ton of training,” he said.

‘Long Time in Coming’

With the opening of the Justin and J. Lohr Center, Cal Poly joins California State University, Fresno and the University of California, Davis as California universities with bonded on-campus wineries.

Cal Poly has nearly 300 undergraduate students alone in what it touts as the nation’s largest undergraduate enology and viticulture program. It attracts students

not only from the Central Coast but also from throughout the state and nation, Shumate said.

The new facility, which includes a fermentation hall, bottling room, barrel rooms and a research lab, crushed its first grapes this fall. The commercial Cal Poly wines sold locally and student class wines that aren’t sold will be produced there as well as faculty and student research wines. It can produce up to 5,000 cases.

Adjacent to the winery is the 12,000-square-foot E. & J. Gallo Winery & Family Building, which houses viticulture and enology labs, lecture/reception areas and shared offices for faculty and students. It also has a meeting hall that includes a full catering kitchen. ContinuedonPage16

Download the MyAgLife App for Free at MyAgLife.com Get the News that Matters to You Every Monday through Friday at 5:00 A.M.

January 2023 www.grapeandwinemag.com 15

Cal Poly produces commercial wines sold in local stores and restaurants.

ContinuedfromPage15

The university has enough land to build a brewery/distillery adjacent to the winery in the future. Shumate said planning the center started back in about 2007 and has been “a long time in coming. We knew we needed a full-fledged facility on campus, so we started the planning stages back then.”

No state moneys were used to build the roughly $22 million facility. Instead, they relied on donations, and Shumate credited Jerry Lohr of J. Lohr Vineyards and Wines for being the project’s main driver.

“He was at it from the beginning, and he’s been involved in every step of the way,” Shumate said of Lohr, a long-time Cal Poly supporter. “Not only has he donated an extensive amount of money, but he’s also been involved in the planning and working with a lot of the vendors and different people involved in the construction and design of the building. So, he has really been the main force behind this.”

Justin Vineyards as well as E. & J. Gallo Winery also were involved but not to the same degree as Lohr, Shumate said. In addition, several other companies, prominent wine industry members and

community members provided financial support.

“We have a full donor wall with all the donors’ names, and every tank and room in the building is named after a different donor based on how much they actually donated to the project,” he said.

Commercial Cal Poly Wines

The winery sources grapes from the on-campus Trellis Vineyard, which is custom farmed by a management company. It also receives grape donations from throughout the state.

For the commercial Cal Poly wines this year, Shumate said they’re making pinot noir, chardonnay, sauvignon blanc and a rosé of pinot noir. They’ll probably bottle the whites shortly after New Year’s, while the pinot will stay in the barrel a bit longer. The 2022 vintage will

be available in mid-2023.

The award-winning wines, which are sold at local markets and restaurants and through Cal Poly’s wine club, aren’t intended to compete with the industry “because they’ve been so generous in donating their equipment and money and all of this to the facility,” Shumate said. “But we want to highlight what the production facility is capable of doing and what our students are capable of doing and give them a real-world experience as they go out into their careers.

“The wines that we’re producing are fantastic. They really are high-quality wines at a reasonable price.”

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Cal Poly lecturer and winery supervisor Jim Shumate fills a barrel at the former wine-making lab, which was a fraction of the size of the new facility.

The Justin and J. Lohr Center for Wine and Viticulture (left) features three wineries under one roof: one for commercial wine production, one for student-made wines and one for experimental and research wines. The E. & J. Gallo Winery & Family Building to the right houses viticulture and enology labs, lecture/reception areas, shared offices for faculty and students and a meeting hall.

16 Grape & Wine Magazine January 2023

The 15-acre on-campus Trellis Vineyard provides grapes for Cal Poly’s commercial wines. It also offers students opportunities to conduct field trials.

As sweet a s can be

Capturing Maximum Genetic Potential

Attention to Irrigation System Maintenance Pays Dividends

By CECILIA PARSONS | Associate Editor

The squeeze on surface water deliveries and looming limitations on groundwater pumping make postharvest irrigation system maintenance critical to providing optimum irrigation during the growing season.

Cory Broad, territory sales manager for Jain Irrigation, said at a recent Sunmaid Growers education seminar that properly maintained irrigation systems will provide a more robust performance, making the most of potentially limited water supplies.

Waiting until irrigation commences in the spring to perform maintenance will add to the challenge of managing irrigation water, Broad warned.

“Looking at the water situation ahead, we need to see what can be done to make irrigation systems perform to their full potential,” Broad told grape growers.

“These systems are an expensive investment, and maintenance is necessary to protect their value,” said Steve Vasquez, technical viticulturalist for Sunmaid Growers. “They can last the life of a vineyard or orchard if maintained properly.”

Keeping the systems operating at peak performance will also save costs, Vasquez added.

Implementation of restrictions on groundwater pumping is expected in 2023 along with fallowing of more farm ground. While water amounts growers will be allowed to pump in 2023 are not clear, growers will need to make sure their systems are operating at full efficiency to make the best use of the water they have.

Broad’s presentation centered on system

maintenance following harvest. Despite efforts to prevent damage to irrigation systems at harvest, there can be damage to emitter lines, microsprinkler heads, riser connections and ball valves and air vents at flushouts. Nicks or cuts on lines will lead to loss of pressure and affect distribution uniformity (DU).

“Operate the system after harvest to see where repairs are needed,” Broad said. “The reality is that there will be places that need to be repaired.”

Flushing lines and doing a DU test postharvest can signal need for corrective action, and Broad said it will be best to find out postharvest rather than March when irrigation companies will be much busier.

Performing a DU test after harvest is a great practice for many reasons, Broad said. Many irrigation systems will continue to operate for permanent crops, so no additional pumping hours are required. In addition, corrective actions can be identified with the irrigation system, implemented and checked out again all prior to the next season.

Identify Issues Prior to Irrigation Season

Broad said larger issues with systems can also be identified, and management plans can be created with your irrigation dealer well ahead of the fall/winter installation season.

Performing a global DU test on a system is always recommended, but Broad noted those tests are not always feasible given time and labor constraints.

He suggested a modified/rapid DU test can be done as a starting place for off-season maintenance. This can be done by

Planning for next season should include water budgeting no matter what crop. The amount of water applied in the past season, how much water the crop used and efficiency of application are important metrics.

taking 36 flow and PSI measurements across the vineyard or orchard, making sure to record flows and pressures in high-, medium- and low-pressure areas of the irrigation system.

Broad said collecting the pressure data is important for diagnosing where potential issues are in the irrigation system. Areas of low pressure and or low flow from your samples should be evaluated further to identify the root cause. Supplying this information to your irrigation dealer can allow for additional insight and corrective actions as well.

At the filter station, low PSI and high flow rate means field leaks. High PSI and low flow rate mean field plugging or closed valves. In the field, low PSI signals filter plugging, low flow, a pump issue or open valves. High PSI signals valves closed or field plugging.

Broad said that throughout the course of a season, filter stations experience changing water quality, various flow rates, wearing of media/filtration elements and chemical/precipitant reactions. He advised inspecting media levels in each tank and adding more if necessary. Quality of media also needs to be evaluated. It wears during use, losing its “edge.” Media should be changed if foreign inorganic material has built up deep into the media bed.

After media maintenance is complete, Broad advised running the irrigation system and checking that the controller and solenoids are all in working order. While there, make sure all air vents are operating and all leaks are fixed. Other checks include all Cam-Lok and hose connections for cracks or leaks. Record the flow rate and pressure during operation as this can help track changes in well perfor-

18 Grape & Wine Magazine January 2023

Maintenance includes collecting the pressure data which is important for diagnosing where potential issues are in the irrigation system (all photos courtesy Jain Irrigation and C. Broad.)

mance and irrigation system operations.

Then there is flushing. Broad said that if irrigation system field components have not been routinely flushed throughout the season, that chore should be done as soon as possible.

The process begins by flushing the mainline and manifold piping segments. Zoning down sections is likely necessary to achieve proper flushing velocity, Broad said. Duration can be determined by rate and manifold length. For example, if you are flushing a pipeline at 1.5 feet per second, and the manifold is 660 feet long, the process would take 7.3 minutes to flush the entire length (divide manifold length by flush rate.) Flushing the emitter line tubing should be a common practice as well, Broad said. Correct velocity, higher pressure and duration are key to successful flushing. 60% of debris in the line is in the first 40% of the tubing. Minimum velocity is 1.5 feet per second.

If emission devices are still plugged after flushing, Broad said they will likely require replacement. In some instances, chemical treatment is necessary to protect the irrigation system from future contamination. Start with a water sample and ask your irrigation dealer for help in selecting the correct treatment for your system, field and issue. Common product types include calcium Hypochlorite, copper, sulfuric acid, chlorine and hydrogen peroxide. All recommendations should come from a certified professional and all safety and label precautions must be followed. Systems must be flushed following treatment to remove large-scale debris.

Broad stressed that planning for next season should include water budgeting no

matter what crop. Track how much water you applied this past season, he advised, how much water your crop used, and how efficiently you applied that water

Plan Overview:

▶ Water Budget

▶ Irrigation Start and Stop

▶ Flushing Protocol: How often is it necessary?

▶ Chemical Maintenance: Continuous? Shock?

▶ Materials: Couplers, Tees, Correct hose

▶ DU Testing

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

January 2023 www.grapeandwinemag.com 19

New Clairvaux Vineyard and Winery A Winner on So Many Levels

By JULIE R. JOHNSON | Contributing Writer

Is it the rich, dark loam soil or the annual Blessing of the Grapes that has lent such success to the New Clairvaux Vineyard in Vina, Calif.?

It is both, and so much more, says Aimee Sunseri, New Clairvaux winemaker.

“Really, it’s love,” she said. “Love of the land, the grapes, the winery and New Clairvaux itself. This love emanates from the monks who live here at the Abbey of New Clairvaux. They set the standard of devout positivity and love. It resonates through everything we do here.”

Nestled in the 600-acre ranch that is home to the Abbey of New Clairvaux lies the 15-acre vineyard, winery, tasting room and event room.

It is also home of the newly celebrated Double Gold, 99-point scored, Best of California for all Viognier wines,

awarded at the 2022 California State Fair Commercial Wine Competition.

There were nearly 2,000 wines from more than 440 wineries entered at the competition.

The Vineyard’s Double Gold 2021 St. James Block Viognier was released during a special event at the winery in November.

“The Viongier we chose is a Rhone variety that was actually almost extinct less than 50 years ago,” Sunseri said. “It has now become an emerging variety around the world.”

She describes the winning vintage as “an aromatic white that a lot of people describe as classic Viongier with peach and apricot aromas.

“There is no oak in that Viongier,” Sunseri added. “I like the floral aromatic

The St. James Block at the New Clairvaux Vineyard is certified organic. Eight different grape varieties are grown in the 15-acre block (photo courtesy J.R. Johnson.)

20 Grape & Wine Magazine January 2023

Aimee Sunseri is a fifth-generation winemaker who creates award winning wine at the New Clairvaux Vineyard and Winery in Vina, Calif. (photo courtesy John Adams, New Clairvaux Vineyard.)

side of it, so I don’t use oak in the viogniers.”

“Brother Luis, vineyard manager of St. James Block, grows some of the most beautiful fruit I have had the honor to work with,” said Sunseri, a fifth-generation winemaker. “When you are in an unknown region, for wine-growing that means you are the underdog, you have to work a lot harder. I cannot thank our team of lay workers and Brothers from the Abbey [enough] for all their hard work to get us so close to perfection.”

Sunseri has entered the winning 2021 St. James Block Viognier in two other competitions with the hope of receiving a perfect score.

“You can’t win if you don’t put yourself out there,” she said. “We are grower/producers. We don’t buy grapes and make it into wine. We grow our own grapes and make it into wine. That is very personal and comes with a whole different aspect of pride, dedication and devotion.”

The Connection

New Clairvaux Vineyard has been growing grapes since the year 2000 when the Abbey of New Clairvaux Abbey and Phil Sunseri partnered to create the vineyard and label, revitalizing grape growing and winemaking in Vina.

“When you are the grower and producer, a connection happens,” Sunseri added. “Walking all the blocks, I know all the little nuances, you get to know the vineyards and, believe it or not, they get to know you.

“Then you take those grapes into the winery and you watch as a personality emerges while the grapes are morphing into wine.”

Sunseri explained there are things a winemaker can predict in very certain ways. “Like tasting a wine and knowing, without looking at the label, that that is a Vina Syrah for instance because it reminds me of Christmas as it is piney,

deep and dark with a berry aroma,” she added.

Love of the land, the grapes and the winemaking develop out of those moments, according to Sunseri. “From the dirt to the wine that has been aged nine years, you go back and taste that vintage and it instantly takes you back to that experience. It is all so personal,” she said. “It is a special connection from the

ContinuedonPage22

New Clairvaux Vineyard bottles its wine about six times a year. Pictured is wine being bottled in November 2022 (photo courtesy J.R. Johnson.)

Lab Technician Eilleen Moore tests a New Clairvaux Vineyard wine in the winery’s laboratory (photo courtesy J.R. Johnson.)

COLD AIR DRAIN 471 S. Industrial Ave Ripon, CA 95366 209.599.6118 jackrabbitequipment.com Frost Protection The Cold Air Drain is designed to eliminate cold air accumulation in low lying areas. To learn more about the physics of frost visit jackrabbitequipment.com/frost-protection/ January 2023 www.grapeandwinemag.com 21

New Clairvaux Vineyard’s Bro. Luis, a Trappist-Cistercian monk, manages the winery’s vineyard. He is pictured holding a handful of the vineyard’s dark, rich Vina Loam soil (photo courtesy John Adams, New Clairvaux Vineyard.)

very beginning to the final glass.”

The Land

Due to its Vina Loam soil, the region has a rich history in grape vineyards and winemaking. Geologists attribute the characteristics of “Vina Loam” to volcanic silt carried from Mt. Lassen to the mouth of Deer Creek at the Sacramento River in Tehama County.

Vina Loam is a coarse-loamy soil that is very deep, dark and well drained. Its richness lends itself to quality growing conditions. This fact provided the Abbey of New Clairvaux to diversify its agricultural opportunities to growing grapes, walnuts and prunes.

The 15-acre St. James Block is situated on a wide alluvial fan consisting of sand and Vina loam.

The Abbey’s Bro. Luis Cortez, who manages the St. James Block with help from his Trappist-Cistercian brothers, decided to do all that was necessary to have the block certified organic. This decision was made after Bro. Luis listened to Pope Francis speak about environmental sustainability based on responsible care, respect, simplicity and austerity,

tenets of the Abbey.

“We’ve taken challenging steps to enhance the quality of our vineyards by becoming certified organic by CCOF,” Bro. Luis said. “Our increased attention to detail and heightened level of care in the vineyard translates to a finer and more wholesome product, a product that our talented winemaker, Aimee, has turned into the region’s finest wines year after year.”

The vineyard is dry farmed, only receiving water to establish roots during the first few years after being planted.

St. James Block provides the majority of the vineyard’s white grape varieties, such as Albarino, Viognier, Trebbiano, Assyrtiko and Moschofilero.

It is also home to some reds, such as Tempranillo, Syrah and Graciano. In all, the vineyard grows eight different grape varieties.

In 2011, the block acquired Assyrtiko and Moschofilero vines from Plant Foundation Services at UC Davis, making New Clairvaux Vineyard the first in the U.S. to grow and make these Greek varietals.

“We work with consultants on a very regular basis to assess and determine disease and pest pressures on the block,” Sunseri said. “We are allowed to use sulfur spray in the organic block and continually work to keep healthy, thriving vineyards.”

Along with the St. James block, the New Clairvaux Vineyard produces wine from its Sunseri partner’s Poor Souls Block. This 15-acre vineyard was once the site of an ancient riverbed and has proven itself to be perfect for many red varietals, including Barbera, Petite Sirah, Tempranillo and Grenache. White grapes of Muscat Blanc, Viognier and Trebbiano are grown in the Poor Souls Block.

This block is managed by Jose Guerrero and Aimee Sunseri. It too offers exceptional viticulture geology with a soil composition of sand, river rock and both Vina and Molino’s Loam.

“It was named the Poor Souls Block by those who labored in establishing this vineyard in such difficult and stony ground,” Sunseri said.

“While our St. James Block is certified organic, none of our wines are marketed as organic. The wines from St. James

ContinuedfromPage21

Albarino is one of eight varieties of grapes grown in the New Clairvaux Vineyard (photo courtesy J.R. Johnson.)

Led by Father Paul Mark, monks at the Abbey of New Clairvaux walk through the abbey’s 15-acre grape vineyard, which produces awards winning wines (photo courtesy John Adams, New Clairvaux Vineyard.)

22 Grape & Wine Magazine January 2023

Julia Johnstone, a New Clairvaux Vinyard wine educator, shares the 2021 Viognier that won Double Gold, 99-points and Best in California at the 2022 California State Fair. The wine was released in November 2022 during a special event at the winery in Vina, Calif. (photo courtesy J.R. Johnson.)

Block can be labeled ‘organically grown,’ but not organically made,” Sunseri explained.

“It was from the St. James Block that the Double Gold, 99-point 2021 vintage Viognier grapes were grown.”

“Any success that we enjoy in our vineyard and winery is secondary to our primary motivation as a monastic community to glorify God through our work and products,” Bro. Luis said. “Any success that we might have is a by-product of our aim to achieve the highest standards in grape growing and wine production, not merely for success, but because we strive to be authentic in our Christian witness as good stewards of the land and to honor an illustrious and centuries-old Cistercian legacy of wine growing.”

Blessing of the Grapes

Each year since its very beginnings, the monks of the Abbey of New Clairvaux have conducted a ceremonial Blessing of the Grapes.

The ceremony dates to a 1400-year-old tradition of blessing vineyards before harvest begins and at New Clairvaux consists of the Word of God, scriptures, chants, music and the blessing by the abbey’s abbot, whom in 2021 was Abbot Paul Mark.

“I don’t think it is coincidence that the award-winning Viognier came from the block where we do the Blessing of the Grapes,” Sunseri said. “That’s perfect.”

Starting out as a small ceremony with few in attendance, as the vineyard’s reputation has grown so has the attendance of the annual Blessing.,

“This harvest, we had hundreds of guests attending the Blessing,” Sunseri said. “Do I believe the ceremony makes a difference? Yes, I do.”

Sunseri

Aimee Sunseri’s winemaking roots run very deep as she is the descendant of Swiss-Italian immigrant Anton Nichelini, who established a modest homestead in the eastern foothills of California’s Napa Valley and a state-of-the-art gravity-fed winery.

Five generations later, Nichelini’s Sunseri family continue his legacy with the partnership between the Sunseri’s and New Clairvaux Vineyard.

Aimie Sunseri earned a degree from UC Davis’ renowned school of Viticulture and Enology.

“I am so grateful to be the winemaker for the only vineyard in the U.S. that is operated by monks and to know their tenets are embedded in every aspect of

what we produce,” Sunseri said. “This is a winning partnership on so many levels. Our display of award-winning wines in our tasting room is proof of that. But more importantly, what is really the winning award is what the monks and all the other people associated with the vineyard bring to our table.”

Adding to that, Bro. Luis said his brothers don’t measure the success by awards. “We measure our success by the joy we have in knowing that we honor our Creator, our land, our Cistercian ancestors and our patrons by all that we do from vine to wine,” he said.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

FLAT TOP CITRUS

ADJUSTABLE MACHINES PISTACHIOS • ALMONDS •OLIVES • VINES • CITRUS • FRUIT Ted & Gina McTeer 559-269-6730 bermmanone@yahoo.com Call NOW to Schedule Your Planting! Surveying Advantage to Grower Production BARE

MACHINE PLANTING January 2023 www.grapeandwinemag.com 23

TWO ROW PLANTERS

BERM

ROOT AND POTTED • TRUSTED BY THE INDUSTRY LEADERS

Lessons from Sustainable Vineyard Farmers

By BETH VUKMANIC | Executive Director, Vineyard Team

By BETH VUKMANIC | Executive Director, Vineyard Team

One way the wine industry is meeting demand for more sustainable products is through certification (all photos courtesy B. Vukmanic.)

While “sustainable” is a common term in agriculture today, this was not the case in 1994 when a small group of vineyard growers got together on California’s Central Coast to talk about critical resource concerns like safe pest management, soil quality and farmworker training.

Nearly 30 years later, that small group of growers has expanded to include hun-

dreds more, representing over 80,000 vineyard acres. They are members of the non-profit organization Vineyard Team. The organization continues to uphold the original growers’ mission: Bringing together experienced growers and researchers to educate the industry on sustainable winegrowing practices. Today, sustainability is accessible to growers across the globe through in-field meetings, digital resources and

third-party certification.

Founders Dana Merrill of Mesa Vineyard Management, Steve McIntyre of Monterey Pacific and Don Ackerman of Constellation Brands reflect on three decades of sustainable research and education.

Evolution of Sustainability Concept

Consumers continue to prioritize

24 Grape & Wine Magazine January 2023

their health and wellness as we enter the third year of the COVID-19 pandemic. But consumers’ health needs have evolved beyond the basics of physical wellbeing. With increasing concern for the future health of families, communities and the planet, many consumers are seeking brands and products that promise a better tomorrow. In a 2021 study conducted by Simon-Kucher & Partners, 85% of respondents indicated they have shifted towards purchasing sustainable products over the last five years.

One way the wine industry is meeting this demand is through certification. Programs like SIP Certified verify that the vineyard and winery are implementing practices that protect the people and planet. The process requires that growers and winemakers adhere to specific practices and complete audits with third-party inspectors to verify compliance.

“Within the industry and the world, sustainability has become a guide for best practices,” said Ackerman.

“Acceptance and participation have snowballed,” Merrill said. “Today, sustainability is a standard operating procedure. Most buyers expect a sustainability certification.”

Sustainability Just a Buzz Word?

Consumers today are growing increasingly environmentally conscious. WWF commissioned global research by Economist Intelligence Unit (EIU) in 2021 (An Eco Awakening) that found that searches for sustainable goods have increased globally by 71% since 2016.

Growers agree that certification is not just a marketing tactic. “We can do well by doing good,” Ackerman said.

Many certification programs began as an educational self-assessment tool. Today, certification enables winegrowers to better manage their practices. Regular peer reviews with university Extension programs and professors and industry experts ensure that the latest research and technology are incorporated into the SIP Certified program so participants implement new sustainable practices as they go through the certification process.

McIntyre reinforced that the goal of sustainability is to regularly improve at a farm level. “It is a competition with yourself.”

Wine consumer demand for sustainable products increases annually, and winegrowers should communicate their good work through certification to be visible to consumers who are looking for sustainable wines. Incorporating science-based best practices is good for the environment and communities and meets consumer demand.

Major Issues in Vineyard Sustainability Today

From integrated pest management (IPM) to irrigation efficiency to labor supply, farmers need to balance numerous issues that impact sustainability to bring a marketable

product to consumers. At its core, sustainability is a holistic approach to the business of winegrowing. A single practice can have an impact on more than just one specific area of production. A generous

ContinuedonPage26

January 2023 www.grapeandwinemag.com 25

According to Don Ackerman, owner of Constellation Brands and co-founder of Vineyard Team, sustainability has become a guide for best practices within the industry and the world.

employee benefits program will create labor stability for the vineyard and job stability for the employee. Decreasing irrigation reduces both water and electricity use.

When asked what they see as major issues in sustainability today, the founders mentioned the health and safety of workers, regenerative agriculture, technology and pest management. The resounding theme in all their responses was thinking about the cumulative impacts of a decision.

Sustainability encourages growers to consider multiple management options. Pest management is a great example of an area where the vineyard manager uses all the tools in the toolbox. IPM strategies begin with cultural practices like leafing to reduce mildew pressure. These kinds of practices in turn reduce the load of pesticides applied to the vineyard, which improves health and safety conditions for workers and often lowers costs to the vineyard.

“Farmers are continually looking for ways to do more with less,” McIntyre said. His company addresses weed control by using multipurpose equipment. This practice decreases tractor passes, thus burning less fuel and reducing pollution.

Merrill explained that good soil quality creates healthier plants so there is less need for chemical pest management. “Sustainability means farming the same ground hopefully forever because you have created a healthy system.”

Sustainability and the Ag/Urban Interface

In 2020, direct on-farm employment accounted for 2.6 million of the 19.7 million jobs related to the agricultural and food sectors, just 1.4% of total U.S. employment. Building relationships between agriculture and residential neighbors is very important because few people have direct experience with agriculture. Safe farming practices like night sprays that prevent drift and protect workers from heat stress can be misunderstood. When farmers proactively get to know their neighbors, they open the lines of communication. This builds trust that can mitigate conflict and misunderstandings.

“The more people understand sustainability, the better they feel about being a neighbor to a working farm,” Merrill said.

The requirements of being certified sustainable help to create good neighbors because sustainability necessitates consideration for the health and well-being of all members of the community. Ackerman believes that being considerate to neighbors is part of the ethos of sustainability.

“Sound farming practices protect the environment for neighbors and the community.”

Ultimately, sustainability helps farmers tell their story of stewardship.

The Future of Sustainability

In viticulture, sustainability is a grassroots movement. In three decades of promoting sustainable winegrowing, countless growers have told Vineyard Team that they continue their education, trial new practices, push the bar and get certified because, “It’s the right thing to do.” 30 years later, all three Vineyard Team founding members still see sustainability as the future because it is a doctrine that keeps evolving and improving so that winegrowers can have a positive impact on more acres, neighborhoods and communities for years to come.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

ContinuedfromPage26

At its core, sustainability is a holistic approach to the business of winegrowing.

26 Grape & Wine Magazine January 2023

Steve McIntyre, owner of Monterey Pacific and co-founder of Vineyard Team, said that the goal of sustainability is to regularly improve at a farm level.

This new free bi-monthly publication is brought to you by the leading ag news source, JCS Marketing, Inc. Make sure you continue to receive the magazine by subscribing today. Or scan the QR Code To subscribe go to myaglife.com/subscribe Enjoying the new publication?

THE FIVE RS OF NUTRITION IN THE VINEYARD

By SEAN JACOBS | Senior Agronomist, Technical

Whether your grapes are destined for wine, raisins, juice or the table, the job of the grapevine is to capture energy from the sun and use it to convert CO2 and H2O to carbohydrates and O2. Maximizing this process begins at budbreak and leads to larger, higher-quality crops. To have the greatest influence, a wholistic understanding of plant nutrition and crop production need to be engaged to ensure that every dime of fertilizer applied best serves its intended purpose. This is where the Five Rs of Plant Nutrition enters the decision-making process.

By combining knowledge from plant physiology, soil science, microbiology and chemistry, core principles of plant nutrition arise that affect fertilizer use efficiency, yield and quality. The Five Rs provide this science-driven approach in a memorable way that helps to confirm or guide nutritional decisions. A series

of checks, the Five Rs ensure that the applied nutrients get into the plant when and where they are needed with minimal unintended nutrient interactions or losses. When framed as a question, the Five Rs can be stated as:

For my application, is this the:

Right Nutrient?

Right Time/Crop Stage?

Right Form?

Right Nutrient Mix?

Right Place in the Plant?

The order of the Five Rs is easily re-organized to fit a given scenario, and when focusing on a specific growth period, considering the right time/crop stage first has the most value.

Right Time/Crop Stage

Early spring is a critical period for grapevine growth and development as the foundational support components of the plant and crop (xylem, phloem, initial leaves and new roots) are created. This timing is also very challenging because the ability of the plant to obtain and move the needed nutrients from the soil is hindered by low soil temperature and low atmospheric evaporative draw.

Cold soils inhibit microbial growth and function, preventing the cycling of nutrients from plant-unavailable to plant-available forms. Similarly, mineral solubility in the soil-water solution is also reduced as soil temperatures decline.

Evapotranspiration is the primary

ContinuedonPage30

Sales and Marketing Representative, Agro-K

Maximizing nutrient uptake and energy conversion of vines begins at budbreak and leads to larger,

28 Grape & Wine Magazine January 2023

higher-quality crops (all photos by S. Jacobs.)

SCIENCE-DRIVEN™ NUTRIENT APPLICATIONS

Provide Optimum Nutrition for Maximum Yield

You’ve heard the phrase, “Work smarter, not harder.” This applies to crop nutrition as well. By developing a nutrient input program that is based on the plants’ physiologic needs at each key growth stage, you can save money, avoid wasted inputs and labor, and get the best quality and yield from your vineyard.

5Rs

A science-based nutritional program follows the “5 Rs of Crop Nutrition”:

Many growers might assume that a water-run fertilizer application in the spring is the answer, but a science-driven approach proves differently. Soils are cold in the spring; roots grow slowly, and undeveloped leaves are not transpiring and drawing nutrients up into the plant. Meeting the needs of young tissues following budbreak is most effectively accompolished through timely foliar nutrient application in the short post-harvest window the season prior. Why a foliar application? Because the right foliar formulation is absorbed quickly and the nutients are easily translocated for storage while leaves are still functioning.

This same science-based approach should be used to determine nutritional needs and how to meet them at every crop stage, from budbreak through pre-bloom, bud differentiation, set and berry development, post-veraison and post-harvest.

The Right Formulation and Mix

- Right nutrient

- Right time

- Right form

- Right mix

- Right location

For example, grapes have specific nutritional needs at key development milestones, such as bud break in early spring. What is the best place and time to apply the nutrients needed to support spring leaf and root growth.

Nutrient inputs come in many different forms, and it is important to understand the advantages and disadvantages of each. Cost, of course, is important. But make sure your money goes to a product that is in the right formulation for the plant and will provide the best quality and return on investment. Some formulations, such as sugar complexes, are easily and quickly absorbed through the leaves with little expenditure of resources by the plant. Others might take more energy from the plant because of the chemical processes required to convert them to plant-usable forms.

Understanding nutrient interactions is important. For example, phosphorus and calcium are antagonistic to each other, and efficacy is reduced if applied together. On the other hand, synergies exist between other nutrients, improving application performance.

The experts at Agro-K have a deep understanding of the science of plant nutrition. They can use that knowledge to help you develop a cost-effective nutritional program that gives your grapes what they need for high-quality yield and the best return on your investment.

January 2023 www.grapeandwinemag.com 29 agro-k.com

ContinuedfromPage28

mechanism for the movement of nutrients between the soil and the plant. When air temperatures decrease, so does the amount of moisture a given volume of air can hold as does the rate that the air can cause evaporation. Coupled with the small surface area of new growth, very low levels of evapotranspiration result.

The classical thought that soil nutrient stores alone can support optimal plant growth and development early on is

brought into doubt, and other fertility decisions need to be considered. Other non-evapotranspirational mechanisms exist within the plant to mobilize and move stored nutrients but should be viewed purely as supplemental.

Right Place in the Plant

Just as important as what nutrient to apply and when to apply it is identifying the most efficient or appropriate place in the plant for the application. As addressed above, early spring conditions result in the soil being a poor nutrient source with low delivery efficiency. Yet,

nearly all nutrients found in or used by the plant over a growing season were sourced from the soil via the roots. So then why is “Right place in the plant” a core principle? When nutrient demand timing and nutrient delivery limitations meet, the end goal of maximizing economic yield focuses less on ‘where is the nutrient found?’ and more on ‘where are the nutrients needed and what is the best way to deliver them?’ Hint: The answer isn’t always via soil application.

For most nutrients, what is found in or applied to the soil meets the volume requirements of the plant, but often soil conditions during the demand period or interactions with other nutrients limit their availability. Even in soils with perfect nutrient conditions, periods still exist where only foliar nutrient applications can meet the limited window of nutrient demand. Post-budbreak is such a time and pre-bloom, bud differentiation, set and berry development, post-veraison and postharvest periods all see benefits from timely foliar applications. During these periods, foliar nutrient applications can achieve results that the soil cannot deliver. And to go a step further, foliarly applied nutrients can uniquely alter nutrient ratios or balances within the plant in ways that cannot be achieved economically, or potentially at all, through the soil.

A combination of both foliar and soil-based applications for most nutrients will be necessary to meet the quantities and timing required for high-level production.

A combination of both foliar and soil-based applications for most nutrients will be necessary to meet the quantities and timing required for high-level production.

30 Grape & Wine Magazine January 2023

Plant nutrient demands fluctuate over the season, and nutrient-to-nutrient ratios shift subsequently.

However, just as the soil cannot deliver all nutrients at the right time, the volume of macronutrients needed cannot be delivered solely through foliar feeding. In the end, some combination of both foliar and soil-based applications for most nutrients will be necessary to meet the quantities and timing required for high-level production.

Right Form(ulation)

The soil and leaf environments to which nutrients are applied are extremely harsh, albeit in almost opposite ways. This article will not go into specifics, but generally, foliar applications dry quickly, are exposed to comparatively high oxygen concentrations and wide-ranging temperatures, and are bombarded with solar radiation. The soil, on the other hand, is very chemically and physically active at the molecular scale and is teaming with life that needs many of the nutrients for its life cycle that our plants require.

Nutrient products are available as various compounds that can be organized roughly into four formulation groups: insoluble salts, soluble salts, chelates and complexes. Ideal use scenarios can generally be defined for each formulation group, and nutrient stability and uptake performance rely heavily upon where (right place) they are applied.

The main points to understand are 1.) there is no “magic bullet” formulation possessing very high performance as a nutrient delivery vehicle in both soil and

foliar applications; and 2.) something else is always competing with the plant to acquire applied nutrients or acting against the formulation of the nutrient, decreasing its availability to the plant.

Insoluble salts: carbonates, oxides, hydroxides

Nearly or completely insoluble in aqueous solutions but micronize well. Foliarly, they coat tissues like paint and are highly effective reflectors/blockers of sunlight. As such, they are often used to prevent sunburn or sunscald of plant tissues. Foliar nutrient delivery performance is very poor. Slow conversion to plant-available forms in the soil results in poor performance.

Soluble salts: sulfates, nitrates, acetates, chlorides

Soil applications usually perform very poorly, but low cost can offset the inefficiency. Foliar performance is poor as uptake is slow, and excess accumulation of the companion anions (SO4, NO3, C2H3O2 , Cl) elicit stress responses in the plant or are otherwise problematic

Chelates: EDTA, EDDHA, EDDHSA, citric acid, amino acids

Synthetic, EDTA-type and similar are generally large, highly water-soluble materials that perform exceptionally well in soil applications. They are toxic to plants and soil organisms, however, and can solubilize heavy metals in the soil, causing accumulation in plant tissues. They are not great foliars.

Conversely, citric and amino acid based chelates perform well when applied foliarly and are less toxic. Stability is an issue in soil applications compared to EDTA-type chelates.

Complexes: dextrose-lactose, mannitol, glucoheptonate, lignosulfonate

Poor performers in soil applications, these naturally derived materials make average to exceptional foliar delivery vehicles. Molecular weight and size of

the complex affects performance. The complexing compounds of some offer carbon skeletons that are easily assimilated by the plant once the nutrient is removed.

Right Nutrient/Nutrient Mix

While not always grouped together, the right nutrient and the right nutrient mix are closely related. Plant nutrient demands fluctuate over the season, and nutrient-to-nutrient ratios shift subsequently. Nutrient-to-nutrient inhibitions, synergies, antagonisms and stimulations exist and must be accounted for as not all nutrients work well together in the plant at the same time.

In our budbreak to pre-bloom vineyard, demand for all nutrients except potassium are high, and calcium and phosphorus are both needed early on. But Ca and P antagonize each other, decreasing application and assimilation efficiency. So, which do we apply? If we assess the right time and right place components, foliar application of Ca makes sense since it moves exclusively with the transpiration stream and as is needed in the leaves to initiate cell division and develop cell walls. P on the other hand provides the energy needed for cell division and other growth functions to occur. Under ideal circumstances, we could apply P foliarly today and Ca foliarly in three to seven days and see the greatest benefit. Practicality doesn’t often allow for this type of application situation, and in our attempts to reduce the number of passes through the field, we must apply both simultaneously.

Tie-ups and antagonisms in real-world agriculture are inevitable and will occur in the spray tank and in the plant. But synergies and gains in efficiency and yield will occur from a little time, effort and application of the Five Rs into your nutritional program.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

‘

’

January 2023 www.grapeandwinemag.com 31

…something else is always compet- ing with the plant to acquire applied nutrients or acting against formulationthe of the nutrient, decreasing its availability to the plant.

Pocket Gophers in the Vineyard Prepare your management tools now before these rodents multiply.

By TAYLOR CHALSTROM | Editor

Pocket gophers stay active yearround wreaking havoc in vineyards and other irrigated land, but they can be particularly menacing in late winter or early spring when their breeding activity peaks. Thus, it’s crucial to think about management strategies now before it’s too late and populations are out of control.

Pocket gophers are rarely seen aboveground so calculating exact number of rodents in the vineyard can be difficult, but their burrow system is what gives them away. Under their obvious fan-shaped soil mounds over tunnel openings are typically hundreds of square feet of main tunnels with lateral branches.

In terms of damage, pocket gophers feed off vine taproots or belowground bark on vine trunks, killing young vines or reducing vigor on old ones if feeding is extensive enough. They also damage subsurface drip irrigation. According to UCCE Wildlife Specialist Roger Baldwin at the recent Grape and Wine meeting in November 2022, gopher mounds themselves can also kill vines, create weed seed beds and are a physical hazard in the vineyard.

Pocket gopher management, like most other forms of pest management, utilizes an integrated approach with different tools and strategies. “Mixing and matching these tools is generally going

to give you a better result than if you were to rely on just one,” Baldwin said.

Currently available options for pocket gopher management include biocontrol, habitat modification, baiting, burrow fumigation and trapping. Repellent is one other option that may become more efficacious in the coming years.

Biocontrol with Barn Owls

Biocontrol is becoming more and more popular as an option for pest control today as chemical options continue to dwindle. In the case of pocket gophers, the barn owl, a predatory raptor species, will hunt them when present in the owl’s

feeding territory; however, Baldwin said that barn owls are not a particularly territorial species.

While barn owls have been efficacious for control of other rodent types, results are inconclusive for pocket gophers. In vineyards, barn owl boxes can be erected to create a home for the owls to live in and breed.

“[Recent studies] have shown potential to reduce pocket gophers in a particular area, so that part is somewhat encouraging,” Baldwin said. “However, we do have to keep in mind that even if they provide some reduction in gophers,

32 Grape & Wine Magazine January 2023

According to UCCE Wildlife Specialist Roger Baldwin, gopher mounds can kill vines, create weed seed beds and are a physical hazard in the vineyard (all photos by R. Baldwin.)

they’re certainly not going to eliminate gophers.

“That’s their food resource; if they eliminate it, they’ll have nothing to feed on.

“If you want to include them as part of an IPM program, I think that’s okay, that’s a good strategy, but I wouldn’t rely on them as your sole tool.”

Habitat Modification

Altering the desirable area for a particular species is the basis of habitat

modification, Baldwin said, and pocket gophers utilize in-row cover and weeds as food sources.

In grape growing areas where gopher populations are high, it might be beneficial to remove cover crops and control weeds in order to reduce food for gophers. “It’s important to remember these nitrogen-fixing plants are good food sources for gophers and other rodents,” Baldwin said. “If you can shift away from some of these nitrogen-fixing plants to grasses that are less desir-

able, then that can potentially limit the densities of gophers that you get in a particular area.

Many vineyards utilize nitrogen-fixing cover crops as they provide multiple benefits to plant and soil health in the long term, so removing them to control gophers could be a detriment in certain situations, thus Baldwin noted it can

ContinuedonPage34

Research conducted by Baldwin and others revealed that between 56% and 68% efficacy could be achieved for gophers across various soil conditions using carbon monoxide machines.

–

" January 2023 www.grapeandwinemag.com 33

The depth of the drip tape is usually at the perfect level for gophers, so they come through and chew quite extensively on this drip tape. This creates situations like substantial flooding which leads to all kinds of issues.

Roger Baldwin, UCCE

be a balancing act of which benefit outweighs which negative more in a given vineyard.

Important to note is not just modifying the food source but also the burrows themselves for gopher management. Once gophers are controlled, their burrows remain, and new populations can spring up fast if they are allowed to use existing burrows to establish. Baldwin recommended deep ripping to remove burrow systems.

Repellents

In general, according to Baldwin, repellants have not worked well for controlling rodents in field or orchard settings, noting that often repellents require periodic reapplication in order to maintain efficacy, which can be costly and laborious.

One possible application for rodent control using repellents is reducing damage to surface drip irrigation (SDI) from pocket gophers. SDI has become a popular irrigation option throughout the state, but Baldwin said that gopher damage is one of the biggest hurdles for greater implementation.

“The depth of the drip tape is usually at the perfect level for gophers, so they come through and chew quite extensively on this drip tape,” he said. “This creates situations like substantial flooding which leads to all kinds of issues.”

Baldwin said that he and researchers have begun to look at the potential of running a repellent through the water during an irrigation event to move gophers out of a particular area. A product called Protec-T (active ingredient is methyl mercaptan) became registered in California within the last two years.

“We’ve just begun to look at the efficacy of this. What we’ve seen so far is a 41% reduction in gopher numbers. It’s not getting rid of gophers, but it is reducing the number in the field.”

Baldwin said that they haven’t studied this method enough to determine whether damage is reduced on SDI, but he believes that the possibility of damage reduction is promising.

“We haven’t had a chance to do it yet, but we need to measure the number of strikes on drip tape. That’s the most important thing that we need to measure right now,” he said.

Burrow Fumigation and Trapping

In the last few years, California has legalized carbon monoxide machines, sometimes referred to as pressurized exhaust