04 08 16 22 24 26

LAWSUITS, I-9S AND OSHA: GRAPE INDUSTRY EMPLOYERS SHOULD PREPARE

PUBLISHER: Jason Scott

Email: jason@jcsmarketinginc.com

EDITOR: Taylor Chalstrom

Email: article@jcsmarketinginc.com

PRODUCTION: design@jcsmarketinginc.com

Phone: 559.352.4456

Fax: 559.472.3113

Web: www.grapeandwinemag.com

CONTRIBUTING WRITERS & INDUSTRY SUPPORT

Vicky Boyd

Contributing Writer

Catherine Merlo

Contributing Writer

Cecilia Parsons

Summaira Riaz Research Geneticist, USDA-ARS

Paul Schreiner Ph.D., Research Plant Physiologist, USDA-ARS

NO NEED FOR NEW RIGS

14 32

CONSISTENCY IN SAMPLING IS KEY TO BUILDING THE RIGHT FERTILIZER PROGRAM

MATING DISRUPTION AS PART OF A CONTROL STRATEGY FOR VINE MEALYBUG

ALTERNATIVE AND NEW WINE PACKAGING FORMATS SEIZE OPPORTUNITIES, TARGET NEW CONSUMERS IN A DOWN MARKET

FOLIAR FERTILIZATION OF GRAPEVINES: WHAT WE KNOW AND DON’T KNOW

CREATING A SUCCESSFUL WINEMAKER-VINEYARD MANAGER TEAM

PAST, PRESENT AND FUTURE OF THE USDA GRAPE BREEDING PROGRAM AT THE SAN JOAQUIN VALLEY AGRICULTURAL SCIENCES CENTER

Contributing Writer

Steve Pastis

Contributing Writer

UC COOPERATIVE EXTENSION ADVISORY BOARD

Surendra Dara Director, North Willamette Research and Extension Center

Kevin Day UCCE Pomology Farm Advisor, Tulare and Kings Counties

Elizabeth Fichtner UCCE Farm Advisor, Kings and Tulare Counties

Katherine Jarvis-Shean UCCE Orchard Systems Advisor, Sacramento, Solano and Yolo Counties

Steven Koike Tri-Cal Diagnostics

Jhalendra Rijal UCCE Integrated Pest Management Advisor, Stanislaus County

Mohammad Yaghmour UCCE Area Orchard Systems Advisor, Kern County

The articles, research, industry updates, company profiles, and advertisements in this publication are the professional opinions of writers and advertisers. Progressive Crop Consultant does not assume any responsibility for the opinions given in the publication.

For more than 20 years, attorney Anthony Raimondo has represented California’s agriculture industry in some of its toughest labor issues.

A partner with the Fresno-based Raimondo-Miller law firm, Raimondo specializes in helping agricultural employers handle labor relations and employment law both at the state and federal levels. His expertise runs the gamut from collective-bargaining negotiations, to defending against unfair labor practice, sexual harassment and discrimination claims, to representing clients in class-action lawsuits.

Raimondo recently told Grape & Wine he expects to see the pressure on compliance increase as the world returns to normalcy in COVID-19’s wake. “I want growers to be ahead of their game and prepared for the variety of things that are going to be thrown at them in what is a heavily regulated industry,” he said.

Raimondo is a frequent speaker at industry events and has been featured on the Valley PBS television series “American Grown: My Job Depends on Ag.”

Q. What are the biggest labor challenges facing California grape growers, processors and wineries? For a number of years now in Califor-

nia, the biggest challenge has been the same: a lot of wage and hour lawsuits involving representative action, like class-action and private attorney general act lawsuits. Those are high-exposure lawsuits that are expensive to defend. These types of cases generally involve very similar allegations of meal and lunch-break violations, rounding of time, accuracy of time records and minimum wage and overtime claims. They bring these claims usually with one or a few name representatives that are representing all the workers for a particular operation going back over a period of three to four years.

Q. How should agricultural employers handle that?

I have been encouraging growers to embrace technology. We still see a lot of agricultural operations using hand-kept time records out in the field. But we really need to use mobile applications and electronic time-keeping methods to more accurately record the time that employees are working as well when they take meal breaks. Technological solutions even can be used to reduce workers-comp claims out in the field by getting employees to record whether or not they’ve been injured. It’s vitally important for every employer to have a well-drafted arbitration agreement that employees receive in a language

they understand. These agreements can greatly reduce the cost and risk presented by these types of cases.

Q. What’s another management solution to help the industry with labor issues?

Management of work patterns in the field is really important, meaning they assure that meal breaks happen on the right schedule and on time. I do not recommend to my clients that they round time to the next 5, 10 or 15

minutes. That’s a very common practice that should be avoided. They should be reporting time electronically and paying to the minute.

Q. What about union representation and organizing?

Under the most significant change in the Agricultural Labor Relations Act in a very long time, unions no longer need to have elections to become certified as a bargaining representative of employees. Wine and table grapes particularly will be targeted for union organizing. Once unions get a majority of employees to sign authorization cards, which are just simple documents that say the signer wants union representation, the unions can force bargaining on employers, whereas secret ballot elections used to be required. They no longer are. The majority of authorization cards will be sufficient for a union to gain the right to represent farm workers.

Q. What can grape industry employers do about that?

Start the process of communicating with workers about union representation. Train employees and supervisors on what an authorization card is, what it really means to have a union, the fact that it costs workers money to have a union. Both management and employee training and orientation are going to be really important. In fact, our firm is already rolling out training modules for companies to develop a culture internally to remain free of union repre-

sentation, to orient their workers and know how to talk to workers, within the confines of the law, about the pros and cons of union representation.

Q. What’s your take on grievance processes for employers and employees?

It’s important for employers to have effective grievance processes so employees have the ability to raise and address grievances within a fair and transparent system internally and to have competitive wage and benefits packages. Those are the keys to remaining union-free. But also make sure workers understand what an authorization card is and how it binds them legally. Historically, unions have often misled workers. Workers shouldn’t sign something unless they know what it is or because they feel pressured to sign it. They have a right to make their own independent decision.

Q. What about immigration law compliance?

Employers must understand what their obligations are under immigration law. Internal training for employees who do the hiring is extremely important. Make sure personnel are effectively hired with adequate I-9 forms. If field supervisors and foremen are hiring people in the field, those folks need to be properly trained on how to complete the I-9 verification process.

Many agricultural employers are not aware that Section 1 of the I-9, which is the employee information, must be completed before the employee performs any

amount of work in the field. Then the document verification section, which verifies their identity and authorization to work in the U.S., has to be completed within three days of when they start work. Employers should internally and periodically audit their I-9s to make sure they’re completing that process correctly. Those I-9s create a very strong defense for the employer against any allegations of immigration violations. We regularly provide internal training and auditing for agricultural employers to strengthen immigration law compliance.

Q. What new laws have taken effect in 2023 that may not be well known in the grape industry?

A lot of growers are not aware of the expansion of the California Family Rights Act. That actually happened in 2021. Many growers are familiar with the federal Family Medical Leave Act, where employees can take up to 12 weeks of unpaid leave for a serious health condition or that of a family member. California’s similar law used to apply to employers of 50 or more employees. But it’s been expanded to employers of five or more employees. Even small employers now need to be aware of their employees’ right to protected leave.

Q. What’s happening with OSHA? Every grower should make sure they’ve been giving attention to their OSHA compliance. Just before the pandemic hit in 2020, OSHA hired a large number of new agents and investigators. We’re going to see a lot more OSHA inspections as state employees return from

remote work and the world goes back to normal. They’ve got a big backlog of activity they want to pursue. Similarly, we’ve been seeing increased inspections by the federal Department of Labor.

We’re also seeing more Employment Development Department audits for payroll tax compliance. These appear to be focusing on independent contrac-

tor issues under Assembly Bill 5. That changed the independent-contractor definition in California. They seem to be looking very closely to see if there have been folks classified as independent contractors paid under a 1099 who should have been paid under a W-2 as an employee, given the new definitions.

So, getting ready to be visited by these

state and federal agencies, and particular the EDD labor commissioner and Cal OSHA, is going to be something employers need to be ready for in agriculture.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

“…unions no longer need to have elections to become certified as a bargaining representative of employees. Wine and table grapes particularly will be targeted for union organizing.”

–Anthony Raimondo, Raimondo-Miller

Lodi-area Vineyard Manager Joe Valente admitted he was skeptical when he started working with Kingman Ag a few years ago on a prototype kit to convert a conventional tractor into an autonomous machine.

After navigating a few bumps and bugs, Valente is now a believer in the technology, having run a self-driving tractor for 1,200 to 1,400 hours mostly with a three-

point disk during the 2022 season.

“As long as your fields are GPSed, you can put it anywhere,” Valente said. “We’ve been pretty pleased with it and are in the process of getting a couple more.”

Kingman Ag isn’t the only company that has begun retrofitting conventional tractors to make them self-driving. Israel-based Bluewhite Robotics also

is working with growers of permanent crops in California with plans to expand into Washington this season, said Graham Thompson, Bluewhite director of business development. The firm’s U.S. operations are based in Fresno.

“Not only is the technology here but now there’s a willingness by the growers

Optimize irrigation and fertigation. Get ready for SGMA regulations and ESG reports with the only IoT & Plant-AI platform that helps you monitor, plan and automate every BEAT of your operation.

Optimize Irrigation and Fertigation: Save 25% of your water every year and avoid fertilizers wastage and soil contamination by irrigating according to real time tree/fruit demand and tracking tank level, soil and nutrients’ delivery

Full Hydraulic Monitoring: Peace of mind with Pond/tank-level, pumps, flow, in-field irrigation pressure (DU)

Pest and Disease: Save more with our hassle-free Suttera’s mating disruption aerosol and granular climate-monitoring (temperature and humidity)

More features and benefits:

Wind-machine Monitoring, NDVI maps, Frost monitoring, Combined soil moisture and tree-monitoring

Automation: Save labor and energy by automating your entire operation or just your pump

High-level Planning and Farm

Management: Budgeting, Planning, Work-order, sharing, tracking and reporting

Hassle-free 24/7 service and agronomic support

As crop prices drop while water, fertilizers, energy and labor prices increase, now is the time to switch to Phytech to maximize efficiency and ensure yields' potential.VICKY BOYD

to implement it,” he said. This is being spurred by labor availability as well as increasing costs.

By Farmers, For FarmersMore than four years ago, Kingman Ag Founder and CEO Connor Kingman partnered with Ted Sheely, a family farmer near Lemoore with winegrapes, pistachios and row crops, to develop an autonomous conversion kit.

One of the benefits of working with Sheely is they’re able to test prototypes under real-world situations and receive

four years in development before we released this to our first customers. We have the bugs worked out, and most importantly, this is safe.”

As a result, Kingman said he felt confident about moving forward with a commercial launch.

of high-powered computer programming that makes decisions and learns from repeated actions, helps guide the tractor.

The user can monitor tractor performance, including a live video feed, with a smartphone app or on an office computer. Should it encounter an animal, human or trellis askew, for example, the

upload a GPS map of their vineyard that includes boundaries and vineyard rows. This can be done quickly using an all-ter-

To comply with California Occupational Safety and Health Administration rules, Kingman Ag remotely supervises all tractor operations round-the-clock using cell connections. Should they see a problem, they can immediately stop the tractor.

When choosing a candidate tractor,

Kingman recommended one suitable for a variety of vineyard tasks because installing the kit takes time and it can’t just be popped on and off. He’s attached the kit to machines as small as 40 hp and as large as 275 hp.

“We’ve seen most growers use 100 to 125 hp, because you want to be able to use all the implements with the autonomous

system to get the most benefits from it,” Kingman said.

By simply flipping a toggle, much like a light switch, he said operators can go from autonomous mode to manual or vice versa.

Valente said they had the kit mounted on

ProBlad® Verde is a category-defining fungicide that delivers a paradigm shift in disease management and crop marketability. Its multi-site mode of action (MOA) quickly attacks all active life cycle stages of both fungal and bacterial pathogens, particularly powdery mildew and botrytis. And, ProBlad Verde leaves no residue, making it MRL exempt so you can maximize your competitive edge.

an 85- or 95-hp New Holland tractor that would allow them to disk or mow their vineyards.

“I think what’s enticing about this is you’re not out the initial cost of the tractor if you have a tractor that’s in reasonable shape,” he said.

Valente said they used it mostly in a large, remote vineyard near Thornton and had few problems with tractor operation and communication. They also hauled it to a vineyard near Linden to test reception, figuring it was an area with iffy cell service. But he said he was surprised that the tractor never lost communications.

Kingman said users can theoretically run a tractor 24-7 and only stop when they need to refuel or refill a spray tank. Based on an average speed of 4 mph, he said one tractor could work up to 80 acres per day.

One of their recent upgrades is increasing the tractor speed to 7 mph from 4.5 mph. This was an improvement growers requested for dusting sulfur application.

In the works are upgrades that would allow autonomous vine trimming as well as gondola pulling during harvest, Kingman said.

During harvest, the driverless tractor would run parallel to the mechanical grape harvester, catching fruit as it

dropped off the conveyor. When the grapes reached a certain level, the tractor would pull away to haul the load to a waiting trailer. Another autonomous tractor with a gondola would pull up behind the departing rig to begin receiving fruit, much like they currently do with human drivers.

Kingman Ag offers the conversion kits on an annual flat-rate lease arrangement, regardless of how many hours the tractor operates. The price includes kit installation, 24-7 monitoring, technical support and troubleshooting as well as any software and hardware upgrades.

Although every operation differs, Kingman said he figures a kit likely would be cost-effective for use on 500 or more acres.

Bluewhite is focused not only on grape vineyards but also on fruit and nut orchards. Graham describes their self-driving tractor market kit as “tractor agnostic,” meaning it can be installed on a variety of sizes and brands.

The kit interfaces with the tractor controls, including steering, three-point hitch and PTO drive. Multiple cameras and sensors, including LiDAR, detect objects and feed information into an onboard computer that uses artificial intelligence to make decisions. Bluewhite’s system operates independently from GPS or RTK since they are not always available when operating under the tree canopy.

Bluewhite introduces its technology to the growers in three phases. In Phase 1, company representatives survey the farm to determine whether it is suited to the technology. Then they digitally map the fields. Phase 1 also involves operating the tractor in the autonomous mode but with company representative at the controls. Phase 2 will train the grower to run the tractor but still with a person in the seat.

Phase 3 involves remote operations, which the company has not yet implemented in California because of Cal/ OSHA rules. But remote operation can be done using a smartphone or tablet.

“We’re certainly running tractors that way in Israel where our headquarters are, and we’re moving forward from Phase 1 to Phase 2 and starting to transfer operations to the growers themselves,” Graham said. “Phase 2 capability is there, and we’re also looking to move to the Washington market where the [Cal/ OSHA] regulations aren’t in place.”

So far, the company has logged more than 25,000 hours of tractor operations.

Graham said Bluewhite uses a subscription model that will include round-theclock service and technology updates. There is an initial fee to install the robotics on a tractor.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Apanel of viticulture experts featured at the Grape and Wine Show, held at the International Agri-Center in Tulare, Calif. on November 3, offered a variety of perspectives on vineyard nutrition. They all agreed, however, that the key to successful nutrition is consistent sampling and testing.

“You have to know what is happening in the vineyard to really make decisions in terms of purchasing fertilizers and applying fertilizers,” said Steve Vasquez, technical viticulturalist with Sun-Maid Growers, who moderated the session.

“Tissue sampling is the check that I use in season,” said Paul Crout, senior product manager and agronomist for Helena Agri-Enterprises. “I sample everything (soil, water and tissue) when I’m building a fertility program. I use tissues to check my work during the season.

“The key for me is keeping constant, using the same lab and using the same technology year over year, over year,” he continued. “You can use whatever you use, just use it consistently.”

Crout, who has sampled blades and petioles as well as used the same lab and same techniques for 18 years, looks for consistency before creating correlations between the tissues and numbers in the field. He also takes a lot of samples to get as much coverage as possible.

Jerel Kratt, CEO of Regenerative Crop Consulting, Inc., has been experimenting with sap testing for several years.

“Sap testing is extracting the actual sap within the leaf, and some labs will include the petiole,” explained Kratt. “That’s going to give you a different number and a different result than standard tissue testing.”

Kratt started by using a lab in Oregon that sent him “10-page reports with all these graphs, and my head was spinning.” He later used a lab in the Netherlands that many consider to be the originator of modern sap analysis, a technique originally developed in 1920 before new technologies and equipment were available. He described the shipping costs as “incredibly expensive,” and said that customs delays caused the nitrogen in the leaves to break down, making the test results meaningless. More recently, he started working with a lab in Michigan that maintains a database of critical values, which shows what the numbers should be and creates usable results.

Although his testing method is different, he agreed with Crout about the importance of using consistent testing methods and getting multiple samples for data that can be used in spreadsheets.

Larry Bettiga, viticulture farm advisor with UCCE in Monterey County, also agreed that the key is consistency. “Traditionally, we’ve done petioles in California. That works pretty well for most nutrients. Maybe the exception would be nitrogen, and that’s because we see a lot of variation.”

Bettiga also stressed the need to take a lot of samples, especially if you have a lot of variables. “It’s really consistency and where you take samples,” he said. “You have to make sure your samples reflect your management zones. Especially for nitrogen, it goes up and it goes down, so you need to be there the same time every year.”

“There’s different ways to look at the data,” said Tian Tian, Ph.D., viticulture farm advisor with UCCE in Kern County. “In this case, historical data is our friend. If you have similar timing and you stick with similar rows to decrease the variability caused by sampling error, and you have record for yield, how you fertilize, how you irrigate, all those will be a powerful tool and provide valuable information to guide fertilization.”

Tian described using rootstocks as “choosing a life companion for your friends.” She advised sampling them separately because there is a difference in the amounts of micronutrients such as magnesium and calcium.

“We plant rootstocks for pest situations, so that still is the first reason you should be planting a certain rootstock,” said Bettiga, who has conducted many rootstock trials. “A lot of what we do should be based on how those vines perform and what your production goals are, and if they meet it.

“Sap analysis was the one tool that actually spelled out the differences in

rootstocks more than any other tool I’ve seen, other than your visual eye,” said Kratt. “Salt is probably the number-one thing I was seeing show up differently in rootstock than the standard leaf testing would be.”

He also advised, “Absolutely without a doubt, always separate your rootstock blocks for sampling because I think it will tell you a lot more about what’s going on. Iron and magnesium are probably the two most common nutrients impacted by rootstock.”

“As a grower, a lot of times I’m at the mercy of the nursery and what’s available,” said Crout, “so a lot of time we don’t have the luxury of making those proper rootstock-scion selections.”

Crout has one vineyard with 14 different varieties and 20 different rootstock combinations, and another vineyard with 10 different varieties with one rootstock. As a result, he has had multiple rootstocks in his irrigation block and management zone.

“I’m handcuffed from a practical perspective to manage this in a realistic way that makes sense,” he said.

Crout said he includes dry applications in the fall and winter for his calcium- and magnesium-dominated soils. He uses compost, organic matter, calcium (gypsum or lime) and potassium.

“Typically, I vary the rate by block,” he said. “There’s some variable rate technology out there that allows us to vary the amount based on soil mapping.”

Kratt discussed the practices his company is currently developing, such as using sheep, cover crops, compost, biological inoculants and biostimuluants. He noted the increasing costs of current grape-growing methods.

“There’s no better time to look at other alternative methods to improve vine health and quality of your vine and your yield,” he said. “As far as best management practices, we really want to try to reduce these heavy, large slugs of nitrogen to the soil. I have definitely seen through the testing

I’ve done a large suppression of microbial activity with a large application of synthetic fertilizer.”

“I think it depends on whether you are dealing with a new planting or established planting,” said Bettiga. “There’s been some recent work on the Central Coast looking at the additions of either compost or biochar. If you can actually incorporate those in the row as you’re whipping and tilling those fields, especially in those less fertile soils, there’s some very dramatic improvements in vine growth and yield that more than compensate the cost of those materials.”

“When you’re putting your fertilizer program together, you really need to have a plan,” said Vasquez in his closing remarks. “Know what your goal is for that vineyard or block. Really understand what you’re trying to achieve there and some of the issues that may be brought by having that vineyard or block, such as irrigation. If you’ve got four rootstocks and one scion, you may have some challenges there.

“Understand your lab results,” he continued. “If you don’t understand what those results are telling you, find an expert and have them help you interpret those results. And it’s important to use the same lab and the same techniques to make sure that you’re getting a good analysis, and you’re making a good decision based on those lab results.”

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

By CECILIA PARSONS | Associate Editor

By CECILIA PARSONS | Associate Editor

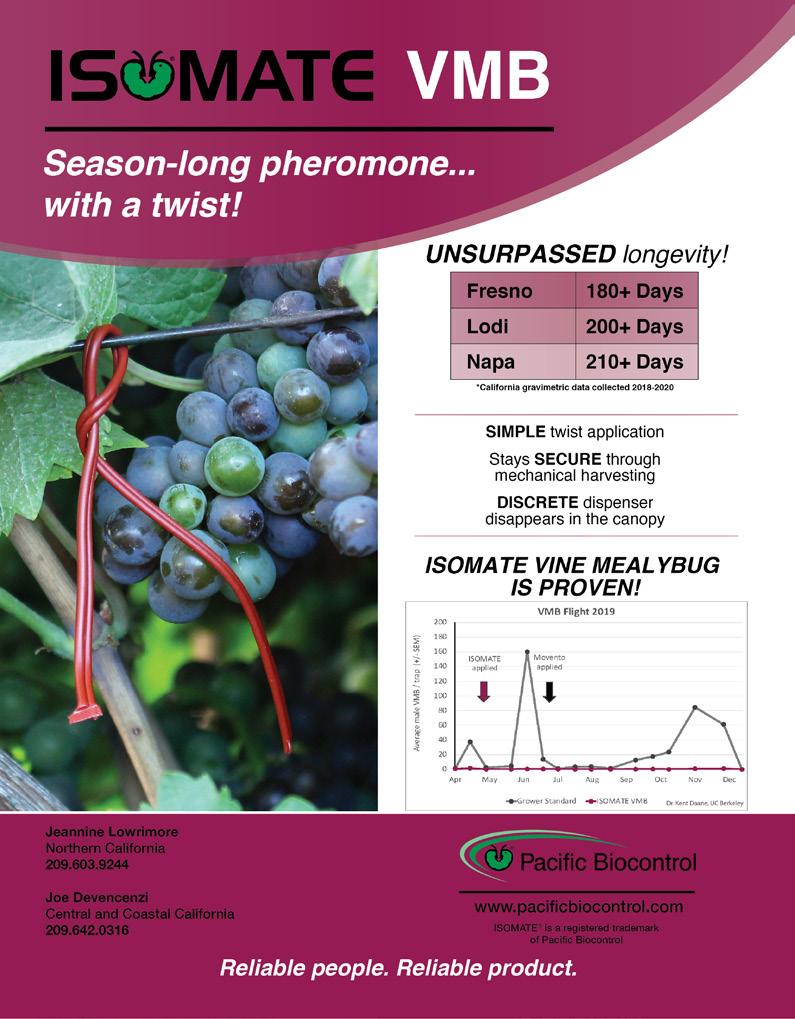

Considering the breadth of the California wine grape industry, when vine mealybug is tagged as being the most important insect pest, growers take that threat seriously.

Vine mealybug (VMB), Planococcus ficus, was brought into California on infested vineyard cuttings. This invasive pest is found throughout all California wine grape growing regions, with severity of infestation depending on regional climate conditions. When feeding on the sap of grapevines, VMB produces honeydew that contaminates grape clusters with black, sooty mold, degrading the value. A more serious impact is VMB is its ability to transmit grapevine leafroll associated viruses.

Control options for VMB are limited due to the phenology of this invasive pest. According to the UC Integrated Pest Management guidelines, VMB life stages can be present year-round in vineyards and multiple generations can be produced. Mating disruption can be used as an alternative or supplement chemical control. It is most effective when insecticides are used first to reduce VMB densities in the vineyard. Mating disruption as part of an ongoing control strategy can suppress VMB populations to lower levels.

Andrea Holeman, marketing manager for Suterra, said wine grape growers often do not realize the extent of their VMB infestation until they begin using pheromone lure traps in their vineyards to detect presence of this pest. The traps, yellow sticky cards with the female

pheromone, are placed in vineyards at bud swell and attract the males.

Pheromones a Viable Tool

Mating disruption has become a critical part of VMB control strategies in infested wine grape vineyards. Lodi

Wine Growers notes that a variety of chemical and biological controls have been developed to target VMB, but none are completely effective on their

‘Several field trials have shown the use of mating disruption to decrease mating success combined with carefully timed insecticide applications can control vine mealybug.’

Vine mealybug can destroy generations of success. Control your legacy with CheckMate® VMB. With over 10 years of proven resul ts, Suterra’s long-acting pheromones are the backbone in the fight against vine mealybug.

own. Several field trials have shown the use of mating disruption to decrease mating success combined with carefully timed insecticide applications can control VMB (lodigrowers.com/disruption-of-vine-mealybug-mating).

Winged adult male VMB locate and mate with wingless adult females due to the pheromone emitted by the female. The synthetic version of this pheromone is used for mating disruption as it overloads the vineyard environment, masking the female pheromone. This affects the male’s ability to fine females and mate. Growers have two options of pheromone delivery for mating disruption: the fluid spray form or the puffer dispenser.

Holeman said the fluid spray applications, often done in conjunction with

other foliar applications, begin in the spring, but timing varies with growing region or when new growth begins. She said growers will generally apply the early season pheromone, an encapsulated product, and then use the pheromone dispensers throughout the remainder of the season until harvest.

The application of the sprayable product should be made in the spring, generally May, just before male emergence or when male VMB are first detected in pheromone traps. The pheromone should be reapplied every 30 days for the period mating disruption is needed, generally through October. Applications can be made as a tank mix with most pesticides that are not EC formulations or contain oil. Applied by itself, only every other row needs to be sprayed. Holeman said the recommended application rate for the Suterra product ranges from 0.9 to 1.9 fl oz per acre with

a cost of $21 per acre per application at the lower rate. Depending on the timing and the population level of VMB in the vineyard, growers can spray once per season or the 30-day recommendation. The product can be applied with a standard spray rig.

The mating disruption dispensers are used at the rate of 250 per acre with one placed at every two to three vines. Holeman said the cost for the Suterra products is $113 per acre, and the dispensers operate throughout the growing season.

Holeman said growers will generally apply the fluid early season pheromone product and then use the pheromone dispensers throughout the remainder of the season until harvest.

The recommendation for the pheromone lures to determine VMB population

level is at least one trap for 20 acres. The traps only attract male adult VMB, not crawlers. One trap should be placed in the center of the vineyard and one where machinery typically enters, as this is where an infestation is likely to begin. Traps should be hung from the trellis wire where it will be in the vine canopy. Marking with flagging tape will help with locating the trap. Traps should be checked at least once every two weeks and replaced after one month of use.

Mating disruption can affect pheromone traps, and lower numbers should be expected in the traps when mating disruption dispensers or fluid sprays are used.

Correct identification of VMB is needed as other insect pests can be captured in the traps.

Vine mealybugs are small. Adult females are about one-eighth of an inch in length. They are segmented and whitish in color with powdery wax filaments. The adult males are smaller than the female, have wings and fly short distances to mate. There can be three to seven generations produced per year depending on the region.

In the north coast wine grape growing region during the winter, VMB nymphs can be found under the bark at the graft union, on trunk pruning wounds or below the base of spurs. In other regions, nymphs and adults are under the bark within developing buds and on roots.

In the spring, VMB becomes more visible in the vineyard as they move up the cordons and into the canopy. In the summer, VMB can be found on all parts of the vines and in fruit clusters.

Ants may transport VMB from the roots into the canopy where they tend VMB and feed on the honeydew produced by this pest. The honeydew serves as a substrate for black sooty mold. During

VMB feeding on plant parts, they can transmit grapevine leafroll-associated viruses that can cause vine collapse.

Suterra offers a monitoring guide for mating disruption and UCCE IPM guidelines are also a source of information on VMB.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Mating disruption can affect pheromone traps, and lower numbers should be expected in the traps when mating disruption dispensers or fluid sprays are used.

The Technology:

Through the use of minute electromagnetic fields (penergetic technology) stimulates biological systems. By working with nature, and without harming the environment such electromagnetic fields are able to stimulate agricultural processes (such as supporting biological activity, including plant growth); act as a (kind of) ‘virtual fence’ deterring unwanted wildlife (mainly deer and boar) from entering the treated property.

-For more information on the technology please visit www.penergeticsolutions.com or contact your penergetic rep.

Features of penergetic b WV (Wildlife deterrent)

SUITABLE FOR

wild boar control

From wildlife browsing PROTECTION

For Organic Farms

NON TOXIC / ODORLESS

for humans & animals

WITHOUT FENCING/ELECTRICITY

no capital cost

EFFECTIVE after precipitation

HELPS LIMIT SPREAD

of (potential) disease

“This is the only product I have tried that has provided 6 months of complete control from heavy deer pressure. Even trees that were previously damaged had a chance to rebound and have turned into productive trees.”*

Raymond Antonowich - General Manager - Rancho Esquon - Chico, CA

Last year we planted 3,000 new almond trees. In the first few weeks after planting, we lost 300 trees to deer. We used the penergetic deterrent and the deer damage literally stopped overnight. We have now used this product into the second year and have only had to apply once in the growing season. It’s like we put up a fence. We still have yet to see any signs of deer on the treated acreage, but see them on the untreated parts of our farm.”*

Matt Vernoga - Vernoga Orchards - Durham, CA

We are currently using penergetic b WV on three different vineyards on the coast. We definitely have seen success. It’s something our vineyard managers want to continue to use. It appears to be working better than any other tool we’ve had.”*

Joseph O’Gorman - PCA/Field Sales Rep - Wilbur Ellis - California

This product was sprayed directly over a high value cilantro crop, and since the application there has been no evidence of deer damage.”*

Michelle Armstrong-Zielinsky - Wilbur Ellis - Woodburn, OR

“We have resident deer always coming through the orchards and eating on the young replant trees. The first time we used this product, they just disappeared.”*

Shawn Conde - Conde Farms - Oakdale, CA

*Individual results may vary based on wildlife pressure and climate

Everyone in this room has heard the doom and the gloom of the industry, drinking down per capita,” said moderator Susan Owen at the beginning of a breakout session on alternative wine packaging at the Unified Wine and Grape Symposium held in Sacramento in January. “I’m not going to go down that route; I like to look at things as an opportunity. How can we take a potentially challenging situation and make it positive to our industry?”

Owen, director of sales at G3 Enterprises, a wine packaging company, reported that although Gen Z and millennials

account for 26% of the drinking population, they spend 50% of the total amount on premises.

“They want to be out,” she explained. “They want to be in restaurants, they want to be in bars. They want to drink wine, maybe at a music festival, maybe at a sporting event, maybe at an art hop. They want to be out. They’re also not drinking like those of us in this room drink, or maybe not like their parents or maybe not like their grandparents, maybe not around the dinner table with the traditional 750ml glass bottle. They’re looking for new ways to consume.”

Owen presented a survey result that found 19% of Gen Z drinkers are willing to embrace a new package format. “So, if we are looking at ways to bring people in, we already know that 19% are open to looking at maybe a crown cap bottle, a capsule-less wine bottle, a can, a single-serve package that they can put in their backpack on the way to the mountains, on a bike ride or to the beach,” she said.

“The wine industry has historically been White Anglo-Saxon Protestant,” she

continued. “It is our job to bring in new cultures, new races, new genders, new ages. Currently today, Hispanics and Blacks account for about 28% of legal drinking age, with a strong preference toward spirits and beer.

“There’s an opportunity to grab a bigger piece of the market share, to pull a drinker from a spirit or from beer,” she said.

She also noted that “90% of Gen X consumers are willing to spend an extra 10% for more sustainable products.”

Owen asked how the wine industry can take advantage of the new legal drinking age market to get them to choose wine over other options, such as seltzer, ready-to-drink spirits, hard cider, cocktails and beer.

“Let’s look at alternative and new packaging as a runway to reach new consumers,” she said. “Open your minds. We can’t continue what we’ve always done and expect different results.”

Owen addressed what she called “the elephant in the room.”

“Glass is good,” she said. “Nobody in the

room has the goal of saying anything negative or nefarious about packaging in glass bottles. Glass is a proven packaging material. We know it holds quality. We know it’s good for aging, but we have new people we’re trying to target. So, glass reaches a very large segment in the legal drinking age population, but we still have a big segment that we haven’t been able to penetrate.

“The idea is to look beyond the successes that we already have and find ways to succeed in an ever more increasingly difficult environment,” she said. “People have choices.”

Libby Enright, director of winery operations for McBride Sisters Wine Company, talked about the company’s SHE CAN and Black Girl Magic lines of canned wines.

“The [SHE CAN] brand is very unique,” said Enright. “It’s meant to help empower women in the wine industry as well as putting premium wine in a can.

“It was definitely targeting the younger generation looking for a more portable, all-occasion wine,” she said, adding that the design of the can is “something you want to keep looking at and touch and engage with.”

William Allen, proprietor and winemaker at Two Shepherds Winery, has experimented with different-sized bottles as well as “naked bottles.”

“One thing my tech background has taught me is you fail spectacularly 90% of the time and hit a home run 10%, so just keep trying,” he said.

During the pandemic, the company cancelled its bottling, so Allen “had time to play.” He used that time to launch a sparkling red wine in a can.

“Cans injected a new buying revenue stream from our existing customer base,” he said. “Also, I find them a little less panicky to ship during the summer. We can put them in the fridge. We can ship them out.”

He added that the chilled cans helped the company avoid its annual summer decline in wine sales in addition to reaching younger customers.

“Millennials have been our customer base,” he said. “We sell primarily in urban markets. We can’t get wine down to L.A. fast enough, also in New York, Seattle and other large markets.”

He also credited the use of creative labels as helping to increase sales.

Maddy Houghton, CFO at Archer Roose, said founder Marian Leitner-Waldman started her company “around a dining room table, looking for a way to experience a really nice, quality glass of wine in a sustainable format, in a single-serving format.”

This approach has opened doors for the company.

“We’re able to get our products in revenue streams that are not traditional to the wine industry,” Houghton said. “Transportation, for example. We’re able to get on planes. We’re not a heavy product so that saves on the airlines’ cost.

“We’re able to reach a demographic of consumers that doesn’t want to open a really expensive bottle of wine and feel

guilty about wasting it because they don’t want to drink the whole thing,” she added.

“We are big on experimentation and creativity” said Martha Stoumen, owner of Martha Stoumen Wines, which in addition to traditional wine packaging, produces wine in lightweight glass and packettes.

“In our portfolio, our lowest priced wine is currently around $30 a bottle,” she said. “A lot of our spending is in farming. We only work with organic grapes. So, we were trying to think of ways to have a lower entry-level product for folks.”

Stoumen said the company’s single-serving bottles attract people who want less alcohol, perhaps because of the time of day or type of gathering.

“The most powerful marketing is getting wine in a consumer’s hand,” she said. “We were a small business and could never sponsor events before, and events are where young people often are,” she said. “With our spritzer production, we’ve finally been able to start doing that. It’s definitely opened up new consumers to us.”

Allen reported an increase in online sales of the traditional-size bottles of Two Shepherds wine from people initially looking to order cans.

“We get conversion back and forth,” he said.

“The cans offer an entry-level trial to

The rise in popularity of canned wines is due to a level of convenience previously unseen by wine drinkers. The can allows the user to essentially take wine wherever they want, whether that be on a hike, to the beach, to a gathering, etc.

our other brands that are on nearby shelves,” said Enright, adding that the SHE CANS also attract customers to the McBride Sisters website.

“Once we get people to try our products, they keep coming back,” said Houghton. “It’s a behavioral thing.”

Recommendations and Concerns Houghton advised wine producers to maintain “a long partnership with wine grape growers” to maintain quality and consistency.

She also said that companies selling wine in alternative packaging don’t do enough to speak directly to their customers. She recommended that companies have an active social media presence.

Allen stressed the importance of wineries offering the same quality of wine in their cans as in their bottles.

“Labor is a huge thing when you’re thinking about alternative packaging,” Stoumen said, adding that new equipment is also a financial consideration.

Allen expressed concerns about the cost to distribute wine in containers that are lighter than traditional glass bottles.

“Distribution companies are saving money on distribution, but are charging the same,” he said.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

Fisk Biggar, co-owner of Graham + Fisk’s, a producer of canned wine, said he saw millennials starting to disassociate quality and packaging and realized that the wine industry had been slow to adapt to new methods because of tradition. This was in 2014.

Biggar recognized the success of canned wine from the company’s inception to present day. “At first, everyone told us no one would drink wine from a can; they don’t say that anymore,” he said.

Graham + Fisk’s offers five wine types in their cans: Rosé with Bubbles, White with Bubbles, Moscato with Bubbles, a Red Blend and a White Blend. “Rosé with Bubbles is our most popular, but all of them sell well,” Biggar said.

Biggar said that cans are not just more convenient than bottles, but also better vessels for wines that aren’t meant to be cellared and aged, which most wines aren’t intended to be. “Cans have a better seal so no oxygen can penetrate, and by nature they keep out UV light. These are the primary destabilizers of wine.

“There are also environmental benefits to cans. They weigh significantly less so the carbon footprint of the process is dramatically reduced, and most glass bottles are never recycled (even if you think they are). Not to mention something like 75% of all aluminum is still in circulation today,” he added.

Can size is also a convenience factor. Graham + Fisk’s offers 8.4 oz (250 mL) cans, which is about the equivalent of one traditional glass of wine. They also have a 12.6 oz can, or 375 mL, which is half of one traditional 750 mL wine bottle.

It can be agreed on by most that teamwork makes the dream work, especially when it comes to the business of winemaking.

At the Unified Wine and Grape Symposium in Sacramento, Calif. in January, winemakers and vineyard managers on a panel agreed that working together and communicating is key to achieving the best outcome when it comes to wine production. When those in the field are in sync with those in the tasting room, complications during the growing season and throughout the winemaking process can be reduced or eliminated.

The wine industry is naturally quite siloed, panelists said, due to the multiple different operations and departments that exist between growing grapes and making wine. Katie Madigan with St. Francis Winery and Vineyards said she’s seen a change over the last two decades with how teams in the industry work together, noting there’s been a shift away

from the silo to being more integrated.

“Now you’re seeing much more collaboration,” she said. “You have to meet early [in the season] and often.”

Winemakers and vineyard managers are starting to realize that the more each knows about each other’s happenings and commitments, the greater success the end product will see. The ideal level of communication is one that is yearround.

“It is just really important that it is a yearround relationship,” said Andy Erickson, winemaker at Favia Erickson Growers.

Communicating for the first time halfway through the season won’t do either side any good.

“Starting in May is tricky from a vineyard management perspective,” said Tim Rowe, vineyard manager at Domaine Carneros.

One common conflict the panelists see is how much fruit is wanted to be taken off the vine; the vineyard manager might have one idea about tonnage off the vine while the winemaker might have a different idea. Unmet expectations, Erickson said, are always a sticky point when one party expects a certain amount to be taken off and the other wants something else. This is where the ‘year-round’ aspect plays into communication. Starting the season off with a plan laying out specific numbers for specific blocks/ fields is crucial.

“A farm plan helps to build trust off the bat between winemakers and winegrowers,” said Blake Wood, director of vineyard operations at Constellation Brands, Inc. “Discussions around the plan form the basis of trust.”

“Color-coating times and tonnages [on a plan] really helps,” said Chris Louton, winemaker at St. Francis Winery and Vineyards.

“We don’t know what Mother Nature is going to throw at us, so we have to be on the same page with our expectations all the time,” Madigan said.

The notion echoed most often by the panelists was the importance of getting out in the field and facilitating the winemaker-vineyard manager relationship. This again goes back to separating from the wine industry silo, and while it can be a challenge at times, it’s an important part overcoming challenges on the road to being a successful winery with successful growers.

“When you’re on a ranch together, you know the problems are going to be taken care of,” said Tony Bugica, Atlas Vineyard Management’s director of farming and business development, noting team members should understand why a vine is being leafed or why a wine is being tasted. “Make sure everyone knows why things happen in the field and the winery.”

Rowe spends his time as a vineyard manager both in the field and the winery by choice, joining blending sessions for different wines to “dovetail” management strategies and techniques while also taking winemakers into the field so they can see what he’s doing. “Break that silo and help them understand opportunities and challenges to bridge any communication gaps.”

“It’s much better to go into June and July with things going as expected rather than having missed things,” Madigan said.

“It’s so critical for the winemakers to be out in the vineyard,” said Remi Cohen, CEO of Domaine Carneros. “If you go out in the end of the season and you don’t know what’s happening, that can cause tension. By the time you get to harvest, everyone is too stressed, and most of the work in the vineyard has already been done.”

Cohen started an internal mentorship program at Domaine Carneros to aid in winemaker-vineyard manager

relations. Anyone can apply and will be paired up with an individual on the management team.

“We were trying to create these cross-department opportunities, especially for people who are just starting out in their career,” she said.

Domaine Carneros also holds monthly meetings that are bilingual to bring all vineyard management staff into the fold of winery culture.

Dialogue in the field even goes as far back as having the owner of a vineyard themselves out and being more involved in management decisions, according to Kirk Venge, owner of Venge Vineyards and Croix Estate. While a big challenge, he said, this is important because it ultimately affects the wineries the vineyard owners are growing for.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

By PAUL SCHREINER | Ph.D., Research Plant Physiologist, USDA-ARS

By PAUL SCHREINER | Ph.D., Research Plant Physiologist, USDA-ARS

Applying fertilizers or plant nutrients to foliage has a long history, and there is an extensive number of papers published on the subject. However, it may surprise some to learn that we still do not fully understand how nutrients applied to the foliage cross the leaf cuticle and enter the cytoplasm of plant cells where they can be used in metabolism. The cuticle is the main barrier to absorption of foliar applied nutrients.

All aerial plant parts, including leaves and berries, are covered by a complex

structure (a little like our own skin) known as the cuticle. The plant cuticle limits or regulates the transport of water and other substances between the plant and the environment, in addition to protecting plant cells from UV light and discouraging or sensing pests or pathogens. The cuticle is a hydrophobic layer formed just outside the cellulose cell wall that is composed mainly of the cutin polymer (a polyester) with waxes both embedded in it and covering its surface. However, numerous other chemical constituents beyond the scope of this discussion are also present in the cuticle and alter its properties with

respect to the transport of any compound across this barrier. While there is still much debate about how different compounds (including plant nutrients) cross the cuticle, two major pathways of transport are known: the non-polar pathway or waxy pathway, and the polar pathway or aqueous pathway.

Compounds that are soluble in oil or an organic solvent, such as some herbicides or even smoke-related phenols, cross the cuticle easily through the waxy pathway because they are basically soluble in it. However, most plant nutrients are polar compounds or ions that are water-soluble, and transport of these substances relies on the aqueous pathway. This aqueous pathway exists because of ‘aqueous pores’ that occur within the waxy cuticle. While these pores are known to exist based on indirect evidence, they have yet to be seen. Aqueous pores in the cuticle become more open or connected as the relative humidity in the air increases. Therefore, transport of foliar-applied nutrient ions is much greater at higher humidity, and spraying foliar nutrients early in the day when humidity is still high is more effective than at midday or in the afternoon when humidity drops. Higher humidity also translates to a longer time that the spray droplets remain wet, thus keeping ions in solution longer, which also facilitates greater transport across the cuticle. Humidity also affects what is known as the point of deliquescence (POD) for different ions, which is the level of humidity needed for a given ion to attract water vapor and remain in solution on a given surface. POD varies for different nutrients, but higher humidity levels increase the chance that POD will be exceeded.

Another property of nutrients or ions related to aqueous pores and transport through them is known as the hydrated ion radius, which is the molecular size of the given ion and those water molecules tightly adhered to it when dissolved in water (Table 1, see page 25). Many macronutrient ions have a larger hydrated radius when compared to micronutrient ions. A smaller hydrated radius allows for greater transport through aqueous pores estimated from various studies to have a diameter of

about 0.3 to 2.0 nanometers. This is one reason that foliar application of micronutrients is more effective than foliar application of macronutrients. However, one must also consider that micronutrients are needed in much, much lower quantities to be in a healthy range. Indeed, it would be difficult, if not impossible, to supply enough nutrients for most macronutrients like N through the foliage alone.

Table 1 shows that the hydrated radius for boric acid is actually on par with the macronutrients. Yet, we know that boric acid and other sources of boron (e.g., Solubor) are used very effectively to alleviate B deficiency in grapevines. This is because uncharged molecules cross the cuticle far easier than charged ions. While it is still not entirely clear, some foliar nutrition experts think that relatively small molecules that are uncharged, such as boric acid and urea, cross the cuticle via the waxy pathway. Indeed, water molecules appear to be transported to some extent via the waxy pathway, allowing some plants to take up significant water directly through their leaves.

Cuticles on the upper surface of leaves (known as the adaxial surface) are generally thicker than the corresponding cuticle on the leaf bottom surface (abaxial surface). When nutrients were applied separately to upper versus lower leaf surfaces, more transport occurred across the bottom side of the leaf, up to four times more. Another practical consideration to increase nutrient absorption is to ensure that sprays are well deposited on the underside of leaves by having good airflow during spraying. This could mean increasing fan speed.

Another consideration important for nutrient transfer is the contact angle of the spray droplets that land on plant surfaces. This property is mostly dictated by cuticle properties, particularly the waxes on the outer surface, and by the physio-chemical properties of the spray solution. Different plant species, different tissues (leaves vs fruits) and even different ages of the tissues along with the prevailing environmental condi-

tions affect cuticle properties that alter contact angles. Spray adjuvants or surfactants can also reduce the contact angle (i.e., help spread out the droplets) and increase transport across the cuticle. Numerous studies using isolated cuticles have shown the importance of spray adjuvants to increase foliar absorption of nutrients. In addition, adjuvants can delay the drying time of droplets and keep the nutrient in solution longer, allowing for greater uptake. It should be noted that there are also cases where the naked nutrients alone (without spray adjuvants) were absorbed just as effectively as when applied with an adjuvant.

What about chelates? This area gets a lot of marketing attention, but due to the proprietary nature of many chelates sold, it is often difficult to untangle advertising from evidence that specific chelates actually improve foliar uptake. While there are cases where chelates have proven more effective than nutrient ions alone, there are also cases where they have not.

Finally, another factor still unresolved regarding foliar uptake of nutrients is the role of stomates and other structures on the external surface of leaves, such as trichomes (leaf hairs) and specialized cells above veins.

Recent findings show that stomates can play a clear role in facilitating uptake of nutrients. For example, in a series of experiments with bean leaves where stomates were manipulated to be open or closed, uptake of nitrogen from urea, ammonium or nitrate was two times higher when the stomates were open. It should be noted that uptake via stomates does not just flow through the open stomatal pore; it is still a diffusion process along the edges of the stomatal guard cells that is more apparent when the pore is open. Additionally, recent studies using some new-age microscopic imaging methods showed that the base of trichomes was a key area for the uptake of foliar zinc in sunflower leaves, and other specific cell

types directly above major veins was the primary uptake site of foliar phosphorus in barley leaves.

It is worth noting that much of what we know regarding cuticular transport of plant nutrients was derived from studies using isolated plant cuticles (enzymatically isolated from leaves.) Such a model system has its drawbacks, and artifacts can occur. For example, some studies comparing isolated cuticles to intact leaves did not yield consistent results for transport. This is why real-world studies with natural plant canopies under production conditions are needed to provide practical data on efficacy of foliar fertilizers. Numerous other factors not discussed here can also influence the success of foliar fertilization, which makes generalized recommendations difficult.

My lab has conducted a number of foliar nutrient trials, and I will briefly share some of our findings. We have conducted three different trials using foliar urea-N for the specific purpose of boosting fruit or must YAN levels. Two experiments were conducted in Pinot noir and one in Chardonnay. These trials have shown that foliar urea is an effective tool to boost YAN (Table 2), and it has the advantage over soil-applied N in that canopy growth is not increased (a clear benefit for improving YAN in high-vigor sites.)

We also conducted a P trial years ago at two Pinot noir vineyards in the Willamette Valley. P was applied in three foliar sprays at a moderate dose, and leaf blade and petiole P status was improved at only one of the two sites. The increase in leaf blade P concentration at one site at veraison was only about 12%, and I concluded there was little benefit to spraying vines with foliar P (data not shown).

Currently, as part of the High-Resolution Vineyard Nutrition Management (highresvineyardnutrition.com/project),

we are testing a foliar potassium treatment along with two rates of soil-applied K to correct a low K Pinot noir vineyard, and we are assessing two rates of foliar magnesium to correct a low Mg Pinot noir vineyard.

In the K trial, we are comparing a foliar K product (K-Metalosate, Albion Labs, Layton, Utah) at the highest label rate using three sprays per year (total = 3.3 pounds K/acre) with fairly high doses of soil K (K 2SO4) at either 188 or 369 pounds K/acre applied in spring. Results from year 1 of this trial showed no increase in leaf or petiole K status at bloom or veraison, nor any impacts of K on growth or yield as well as must sugars, pH or TA. However, K levels in dormant-season canes (pruning wood samples) were slightly improved by all three K treatments compared to the no-K control. In year 2, leaf and petiole K status at bloom was increased in the soil K treatments, more so by the high rate, but not in the foliar K vines. Veraison leaf and petiole nutrients and pruning wood nutrients have yet to be analyzed for year 2, but similar to last year, no effects on growth or yield as well as must sugars, pH or TA were apparent due to K treatments (data not shown).

In the Mg trial, we are testing foliar sprays using MgSO4 (Epsom salt) because an earlier trial my lab conducted in the Willamette Valley with soil-applied MgSO4 at a high rate was unsuccessful. We are comparing foliar sprays of MgSO4 at 10 or 20 pounds/acre using three sprays (supplying a total of 3 or 6 pounds Mg/acre). The high rate of Mg

increased leaf blade Mg levels at veraison in year 1 but did not alter petiole Mg levels as we found before. Both the low and high rates of foliar Mg reduced the number of leaves with Mg deficiency symptoms by more than 75% around harvest time in both years (Figure 1, see page 24). However, Mg applications did not affect growth or yield as well as must sugars, pH or TA thus far.

In conclusion, foliar feeding of plant nutrients has its place in vineyard management, and certain foliar nutrients are effective in improving nutritional health of grapevines. This is especially true for micronutrients, notably B and zinc. Of the macronutrients, both Mg and urea-N have been effective in alleviating Mg deficiency or in boosting must YAN levels. Foliar applications of P and K have proven less effective so far. Caution is warranted when considering the myriad of foliar products that are being marketed to you as grape growers, and this is because we still have much to learn about how and when foliar-applied nutrients will be effective. A key question you should ask yourself when considering foliar nutrition is whether you have a deficiency or other problem that needs to be fixed. This is where money spent on tissue sampling for nutrients and tracking vine nutrient status over years will pay for itself in the long run. Prophylactic use of foliar fertilizers, except perhaps for B, is generally not a good idea.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com

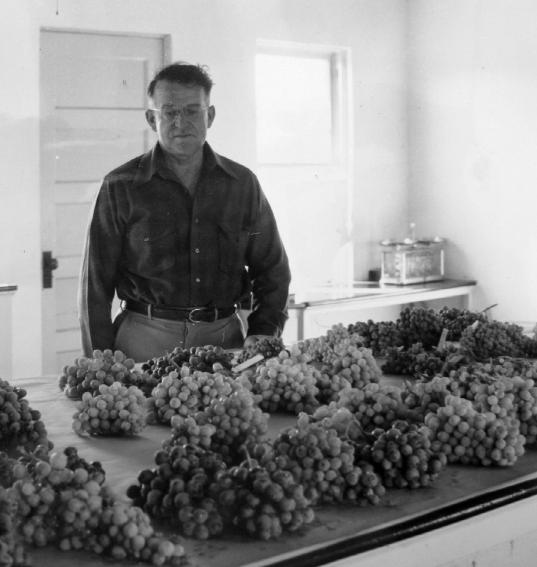

The history of grape research in the Central Valley dates back to 1916 with a modest program at the U.S Horticultural Field Station in Fresno, Calif. At that time, it was under the Bureau of Plant Industry program and was a USDA experimental vineyard, more famously known as Peach Avenue Station. The Station started with 20 acres of land that were donated by California grape growers. The first head of the Station was Elmer Snyder, who served until 1954. In earlier time, the main objectives of the station was production of table grapes and seedless grapes with Vitis vinifera background, new rootstocks with rootknot nematode resistance (Meloidogne spp.) and some work on special wine types. The first controlled cross was made in 1923, and by 1951 a total of 45,726 seedlings were grown from 399

crosses and 112 self- and open-pollinations of varieties and seedlings. It did not take very long for the table grape breeding program to release new varieties like Cardinal, Calmeria and Blackrose. The variety Cardinal resulted from a cross made in 1939 between Flame Tokay and Alphonse Lavallee. It was introduced in 1946 to the public, and by 1951 it was planted in San Joaquin, Coachella and Imperial valleys of California as well as parts of Arizona. Calmeria and Blackrose were introduced in 1950 and 1951, respectively. Dr. Snyder was an expert on table grapes and had intimate knowledge of the history of vineyards in the San Joaquin Valley and could tell which varieties were grown in vineyards simply by driving down the road. Among his peers, he was nicknamed ‘Elmer the Great Emasculator.’

Dr. Jonnie Weinberger joined the program in 1954 and more emphasis was put on breeding stone fruits.

Dr. Horace Loomis was more focused on grape breeding. The research of this duo was very productive over the years in terms of developing new varieties of both grapes and tree fruit with extended season, extended marketing time with better cooling and storage methods, and improved packaging. Dr. Weinberger retired in 1975 with a legacy of releasing over 35 peach, nectarine, plum, apricot, table grape and raisin grape varieties. Two of his selections, Flame seedless (table grape) and Fiesta (raisin grape), are still grown in many parts of the Central Valley. Dr. David Ramming joined the program in 1975 and shifted the focus

USDA grape breeding program identified disease resistance for grapevine powdery mildew in wild relatives of grapes and used traditional crosses to bring resistance in the new varieties.

of the program back to grape breeding. During his time, progress was made to streamline the laboratory technique of embryo rescue that allowed using two seedless grape plants as parents to develop new seedless offspring. This technique has significantly shortened the time required for development of new table grape and raisin grape cultivars.

The raisin variety DOVine (dry on vine) was the first release that resulted from the hybridization of two seedless grapes using embryo rescue techniques. DOVine resulted from a cross of 79-101 and Fresno Seedless made in 1983. 79-101 is a blue seedless grape of unknown parentage; Fresno Seedless is a sibling of Flame Seedless and resulted from the cross of Cardinal and Thompson Seedless; Red Malaga and Tifafihi Ahmer; and Muscat of Alexandria and Thompson Seedless. Dr. Ramming was instrumental in developing over 40 varieties of table grapes, raisin grapes, peaches, apricots and other stone fruits; 15 of his table grape varieties represent more than half of table grape production in California. The raisin grape industry was revolutionized by release of DOVine and Selma Pete that could be dried on the vine by cane cutting, and mechanical harvesting could be implied. The Sunpreme, a newly released variety (2015) by the breeding program, offers further im-

The schematic steps to develop new seedless grape variety. Grape flower emasculations to make controlled crosses start in March/April depending on the temperature; cooler weather prolongs the season. After pollination, flower clusters are bagged to prevent other pollen to contaminate the cross. Young berries are harvested in June and surface sterilized, and up to 25 ovules/immature seeds are cultured on the media with plant hormones and nutrients to grow the embryo inside the ovules. Two months later, ovules are cut open, and each embryo is placed in culture test tubes on a gel-like bed of nutrients. In about two to three weeks, embryos germinate to form a small seedling plant that is transferred to the soil and nurtured in controlled environmental chambers. They are transitioned from low light to high light intensity and moved to the greenhouse to get ready for the planting in the soil in the spring season.

provement to the raisin industry. The fruit of Sunpreme dry naturally on the vine and becomes raisin; no cane cutting is required.

The program at Avenue Peach Station also benefitted from the contributions by Dr. David Cain on grape rootstock breeding between 1979 and 1981.

In 1981, the California Table Grape Commission began a decades-long partnership with the breeding program that continues today.

In late 80s, land was purchased to devel-

op the San Joaquin Valley Agricultural Sciences Center at Parlier. By fall 2000, the main building was complete and in 2001, some operations of the fruit breeding program moved to the current location in Parlier, Calif. However, field location of the breeding program stayed at California State University, Fresno till 2004. Dr. Ramming continued his breeding work with a focus on disease resistance for grape powdery mildew and Pierce’s disease.

Grape powdery mildew is a fungal disease that attacks all growing plant parts, and if not controlled can cause complete crop loss. The USDA grape breeding program identified disease resistance in wild relatives of grapes and used

traditional crosses to bring resistance in the new varieties. DNA-based genetic markers are also used to identify and select seedlings that will retain desired traits of resistance. Dr. Craig Ledbetter led grape breeding efforts in addition to his successful Prunus breeding program at the Center upon Dr. Ramming’s retirement in 2013. Dr. Rachel Naegele contributed to the grape breeding program between 2015 and 2021. Until his retirement in 2022, Dr. Ledbetter’s leadership enabled multiple grape showings per season in partnership with the California Table Grape Commission. His ingenuity allowed the program to persevere during the COVID-19 pandemic. Dr. Summaira Riaz joined the program from UC Davis in 2022 as a research geneticist in the Crop Diseases, Pests and Genetics Research Unit (CDPGRU) at the Center to continue the tradition of impactful table and raisin grape breeding.

Pierce’s disease is a devastating disease caused by the bacterium Xylella fastidiosa (Xf) that is spread by different types of leafhoppers (glassy-winged sharpshooter (GWSS); blue green sharpshooter). GWSS is a serious threat to California vineyards because of its faster mobility and longer flight distances into vineyards. There is no cure upon infection; plants die within two to five years. Disease control is based entirely on preventing infection by controlling the vectors. New grape varieties with natural resistance to the disease are the only sustainable solution. Warmer winters will increase the incidence of Pierce’s disease because of increased vector activity and less cold weather curing of grapevines.

Following on a century of achievements by giants in grape breeding with the program, Dr. Riaz is poised to benefit from previous collective efforts to develop and introduce new cultivars of seedless table grape and raisin varieties that are high-yielding with improved fruit quality and consumer appeal and require less cultural practices. It is also essential to develop varieties that are better adapted to climate change. Advanced molecular approaches will be applied to research on disease resistance. Dr. Riaz’s experience is an asset that will benefit the program into the next century using innovative research tools like access to resistant germplasm, knowledge of genetic resources and hands-on experience with modern genomic tools to put the breeding program on the fast track. The conditions are ripe for a bright future of grape breeding at the Center given the collaborative nature of research by USDA-ARS and its partnership with stakeholders representing the California table and raisin grape industries that continue to deliver grape varieties with traits popular among consumers.

Comments about this article? We want to hear from you. Feel free to email us at article@jcsmarketinginc.com