Building Better Connections

Viega presses forward with cutting-edge manufacturing + training center in Mantua

As the seasons change, so do the risks to your roof. After a long winter, it’s essential to ensure your roof is in top shape before spring storms roll in. A Spring Roof Inspection can save you from costly repairs and headaches down the road. Call today to schedule your Free Roof Inspection and Discover the Diamond Difference.

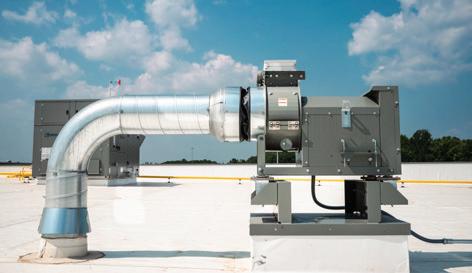

Smarter Air Starts Up Here

• Smart controls

• Application-driven design

• Inverter-driven efficiency

• Quality construction

ACP On Site keeps your systems efficient, reliable, and ready when it matters most, because consistent performance isn’t a luxury, it’s a need.

Start up & Commissioning Services include:

• Equipment Testing to verify proper operation

• Performance Verification against design intent

• System Optimization for long-term efficiency

Start-up & Commissioning

Bringing new HVAC equipment online and verifying proper operation per manufacturer specifications.

Maintenance Team Training

Teaching in-house staff how to inspect, clean, and maintain equipment for optimal performance.

Adjustments & Calibrations

Fine-tuning equipment settings, sensors, or control systems to ensure accurate and reliable operation across all components.

Issue Troubleshooting

Diagnosing irregular fan speeds, airflow imbalances, or equipment alarms on-site.

Fans (Supply, Exhaust, Recirculation)

Louvers & Dampers

info@propertiesmag.com www.propertiesmag.com

EDITOR-IN-CHIEF

Mark Watt mwatt@propertiesmag.com 216.251.2655

OFFICE MANAGER

Lisa Larissey llarissey@propertiesmag.com 440.429.6153

CONTRIBUTING WRITERS

Doug Bardwell, Scott Esterly, Dan Holland, Christopher Johnston, Alec Pacella

MEDIA CONSULTANTS

Matt Lehnert mlehnert@propertiesmag.com 216.251.6753

Larry Overbey loverbey@propertiesmag.com 216.251.6649

OWNER

Real Estate Publishing Corporation

Jeff Johnson, CEO jeff.johnson@rejournals.com

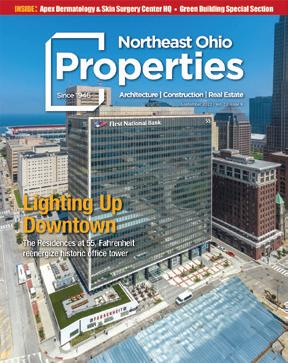

Cover photo: Viega Seminar Center and Manufacturing Plant, by Harry Dempsey

FEATURES

9 Building on the Brand AVID Architects’ Fairlawn HQ reflects a refreshed identity built on decades of trust

17 Building Better Connections

Viega presses forward with cutting-edge seminar center + manufacturing plant in Mantua

39 Rolling Forward

Kenda Tire/Martin Wheel invests in its future with production, warehouse + office facility

48 Special Section: Building Products + Maintenance

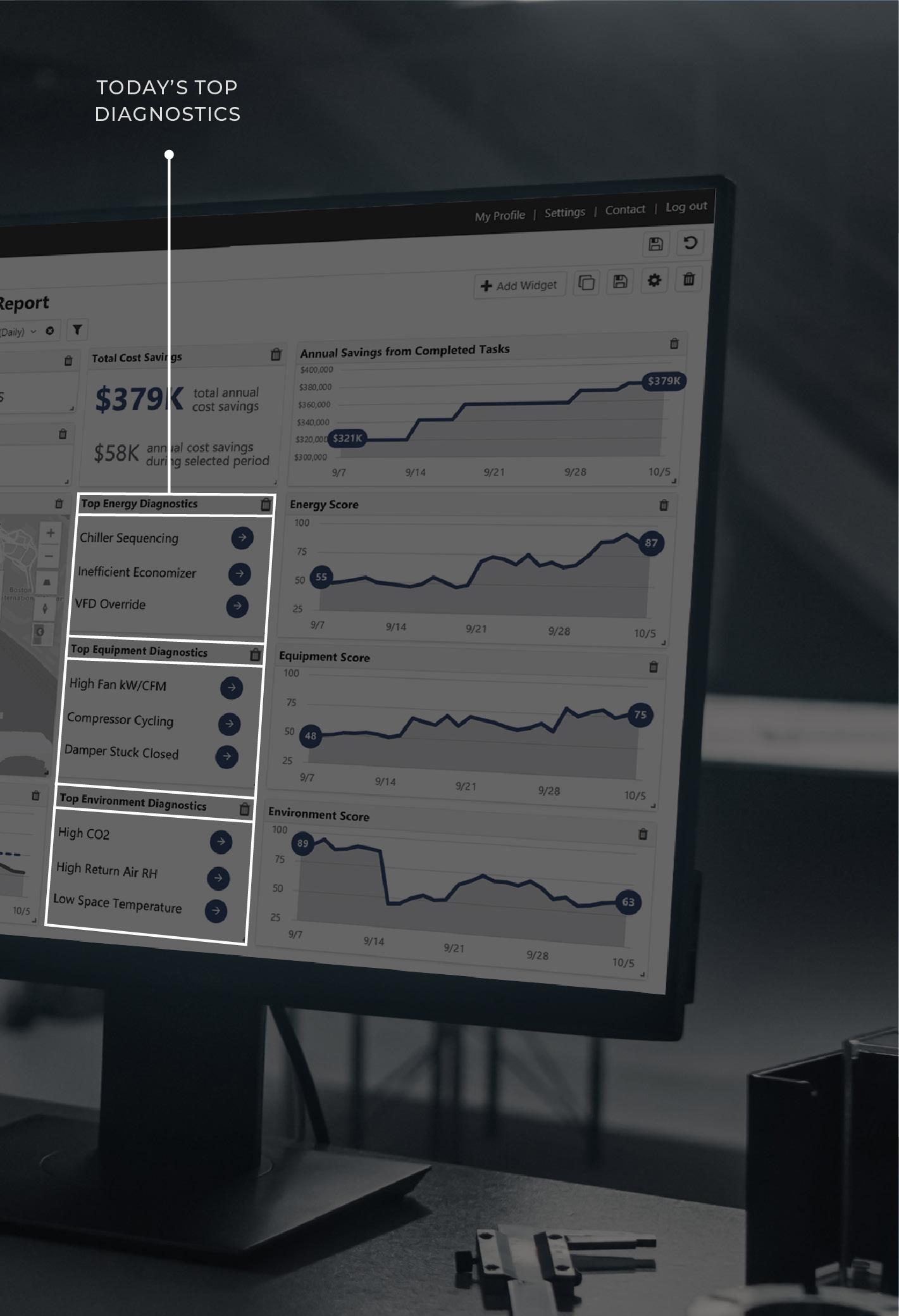

48 How AI Is Transforming Building Fault Detection: Harnessing technology to bring clarity, speed + action to facility operations

52 Cold Snap, Big Trouble: Proactive steps to prevent pipe freeze-ups & avoid costly mid-winter shutdowns

54 Smarter Surveillance: Modern PoE + IP-based video security systems streamline integration + risk reduction

58 Cleaning for Health: Preventative carpet care cuts allergens, boosts IAQ + improves employee well-being

60 Legal Perspectives: Issues Arising from Sole Source Projects 64 Vantage Point: Building in the Now – Construction in 2025 & Beyond

DEPARTMENTS

Photo by Jason Julian Smalcer @ Liza Sue Productions

PROPERTIES PEOPLE

1 Daniel Last (KeyBank Community Development), Kenneth Kalynchuk (PMC), Amy Haney (DLR Group) and Rosemary Mudry (Cleveland Public Market Corporation)

2 Behind-the scenes

3 Daniel Last (KeyBank Community Development)

West Side Market Tour

Recently, the Northern Ohio chapter of Institute of Real Estate Management (IREM) hosted an evening celebrating Cleveland’s historic West Side Market, which is poised for a $70 million renovation. The event included a behindthe-scenes tour and a panel discussion at Great Lakes Brewing Company where leaders shared details of the project.

The Akron chapter of American Institute of Architects (AIA Akron) recently hosted its biennial Design Awards Celebration at Akron’s Canal Park. The event began with tour of the ballpark, followed by its awards program to highlight top regional work. (See full story, pg. 32.) During the celebration, the association held its annual meeting and voted in the 2026 board of directors.

1 Kent State University students and AIAS members Alex Frisina, Aiden VanDussen, Melanie Burns and Allison Kollar

2 Elizabeth Nicklas and Matthew Schwarz (Peninsula Architects)

3 Regan Everhard (Hasenstab Architects Inc.)

4 Dan Herstine and Dennis Check (Hasenstab Architects Inc.)

5 Deanne Schopfer, Jennifer Snyder, Tamisha Davis-Lawson and Aaron Rodebaugh (GPD Group)

6 Lead juror Barry Yocum (Archimania) and student winner Aiden VanDussen

Trade Show

BOMA Northeast Ohio held its annual Vertical Trade Show recently at the Holiday Inn South Cleveland in Independence. The Halloweenthemed event, “Step into the Web of Industry Connections,” featured a keynote presentation by Brian Cappelli (GBX Group) during lunch, followed by an exhibitor showcase and a spirited happy hour.

1 Sondra Turek (BOMA Northeast Ohio) and Steve Dimino (BOMA International)

2 Nick Riley (Key Center, Millennia), Michael Wallenstein (Neptune Plumbing & Heating) and Alan Hazzard (Westfield)

3 Kevin Ballish (NAI Pleasant Valley) and Adam Miller (Usource Energy Partners)

4 Jessica Brown (BOMA Northeast Ohio) and Dave Ellison (H&M Landscaping, Inc.)

5 Victor Scarpelli (JTL Construction), Cassie Brown (Midwest Installation Group) and Mike Pierce (JTL Construction)

6 Miguel Villa (St. Moritz Building Services) and Erich Landis (USource Energy)

The Future Is Under Construction

With our new headquarters complete, AVID Architects is primed for a transformative year ahead.

For more than 50 years we’ve supported clients in healthcare, multifamily, industrial, adaptive reuse, and other commercial sectors with a design process built to maximize investment and deliver long-term value. Our in-house MEP Engineering team streamlines coordination and improves execution — redefining what it means to design with efficiency and build with confidence.

Discover our work at AVIDtransforms.com

DESIGN / DRAW / ENGINEER

Photo by Jason Julian Smalcer

@ Liza Sue Productions

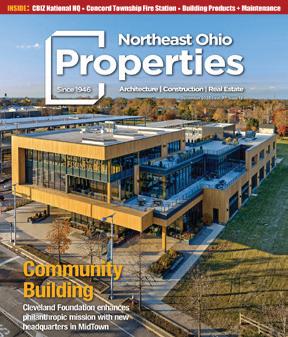

Building on the Brand

AVID Architects’ Fairlawn HQ reflects a refreshed identity built on decades of trust

Story by Scott Esterly | Photos by Jason Julian Smalcer (Liza Sue Productions) & Scott Esterly

When AVID Architects opened the doors to its new 15,000-square-foot headquarters in Fairlawn in September 2025, it marked much more than a change of address. The building, along with the new name on the sign, represents a deliberate evolution for the firm formerly known as MPG Architects. After more than five decades of steady growth, the leadership team saw an opportunity to create a space and a brand that reflected who they had become and where they were headed.

The decision to design and build their own facility was both practical and symbolic. “We took a leap of faith to build our own building and create what we want, knowing it was the right decision to catapult this firm forward,” says President Randy Parsons. “It’s an investment in our people and in the future.”

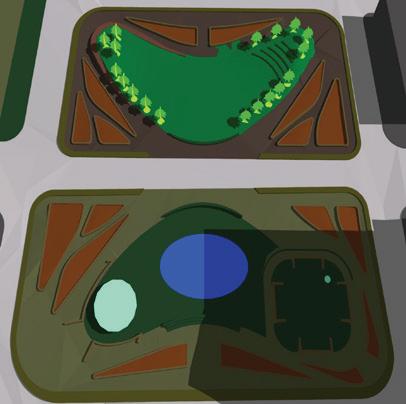

That investment began in 2019, when the firm started searching for land that could support a purposebuilt office to accommodate its expanding team, now totaling 34 employees. The site they found was unconventional: a 2.75-acre parcel that had once been a city-owned stormwater retention pond. Working closely with the City of Fairlawn, the team partnered on the pond’s relocation and development of an engineered site capable of supporting the new headquarters.

With an overall project cost of about $5.25 million, the headquarters was built to evolve, shaped by the

“We took a leap of faith to build our own building and create what we want, knowing it

was the right decision to catapult this firm forward.”

Randy Parsons AVID Architects

needs of a collaborative team and a vision for steady, lasting growth. For Parsons and his colleagues, the building and the brand change are two sides of the same story. Both speak to continuity and collective ownership, a move away from individual names

toward a shared identity that could endure for generations.

From Reinbolt to AVID

The story of AVID Architects stretches back more than 50 years to a small office in the center of Copley Township. Founded in 1972 by architect James J. Reinbolt, the practice grew through successive names: R.E.M. Architects (for Reinbolt, Evans and Mann), then Mann Architects, later MPG Architects (for Mann, Parsons and Gray) and today AVID Architects. Each chapter reflected a generational handoff and a growing network of long-term clients across the region.

“When I started with the company, we were seven or eight people. Today we are 34,” says Parsons. “Our growth is not forced. It is all organic. When you

Photo by Scott Esterly

do a good job for a repeat client, they tell others, and those people become repeat clients too.”

The firm’s structure has long been a strength. By housing both architectural design and mechanical, electrical and plumbing engineering in one office, AVID gives clients a coordinated process from start to finish.

Turning a pond into possibility

Despite the firm’s expanding reach, Fairlawn has remained its home base since 2006. Parsons says the city’s accessibility, business-friendly environment and long-standing partnership made it the right place to invest in a new headquarters.

Few office projects begin with a leap of faith quite like this, however. The City of Fairlawn needed to relocate a stormwater retention pond as part of its long-term infrastructure plan. When the opportunity arose, AVID’s leadership took on a tremendous challenge.

“How many people are lined up outside the door waiting to buy a pond to put a building on? No one,” says Parsons.

Working with former Fairlawn Mayor Bill Roth and city officials, AVID reached an agreement that benefited both sides. The city gained the ability to relocate the pond to an adjacent parcel, which is visible

Photo by Jason Julian Smalcer

OPEN-OFFICE PODS Sunlight fills the collaborative work pods, which are designed to support teamwork and allow quick access to flexible meeting rooms and client presentation spaces.

from the new parking lot, and AVID secured a prime site in a growing business district. The partnership was strengthened by a shared commitment to making the project workable from an engineering standpoint.

“It was an engineered fill site,” Parsons explains. “The city was responsible for the groundwork, and we knew what had to happen to make it viable.”

To help offset the cost of moving the pond and preparing the land, the city created a tax increment financing (TIF) district, a program that directs future property tax revenue toward public infrastructure improvements.

“The TIF strictly goes to the city,” says Parsons. “We didn’t ask for any special treatment because we knew we were fortunate just to be in this position.”

Timeline + team

After several years of planning and design work, the project came to life with design development beginning in late 2023, groundbreaking in October 2024 and move-in by September 2025.

The firm handled every part of the process in-house. AVID Architects served as owner, architect and construction manager, with project manager

Tailane Moore as job captain, architectural director Justin Fye overseeing design and longtime collaborator Brian Booth serving as construction superintendent and project manager.

Moore notes that the project was truly a firm-wide effort. “Everyone in the com-

“Everyone in the company –architecture, engineering and administration – contributed. We wanted the new building to reflect how we actually work together.”

Tailane Moore

AVID Architects

pany – architecture, engineering and administration – contributed,” she says. “We wanted the new building to reflect how we actually work together.”

From fill to foundation

Turning a former retention pond into a buildable site required patience and precision in both the process and the partnership with the City of Fairlawn. After the pond was moved in 2023, the

city began hauling in clean fill material gathered from nearby municipal projects, including the new Copley Safety Center (see full story in Northeast Ohio Properties, July 2025 issue, available at www.propertiesmag.com).

“Timing is sometimes your best friend,” says Booth. “Copley had extra material from their projects, and we were the beneficiaries.”

The site presented significant grading challenges, with a roughly nine-foot elevation difference toward the back of the property. Truckload after truckload of compacted soil slowly transformed the land into solid ground. “We just kept trucking in dirt until it met the grade elevation need,” says Parsons.

Each layer of soil was compacted in six- to eight-inch lifts, reaching a bearing capacity of four thousand pounds, which is double the strength of standard soil.

“We bought a piece of land that’s better than what is typically found in nature. 2,000 pounds bearing capacity is the assumed code minimum in this region for a building to stand on,” explains Parsons. “We achieved 4,000 pounds bearing capacity by engineering it.”

With the site prepared, AVID selected a pre-engineered metal build-

Photo by Scott Esterly

Team +

Team

SIGNATURE ANGLES Although guests may not immediately notice it, the interior’s angular lines draw inspiration from AVID Architects’ logo, subliminally weaving the firm’s brand into the building’s design.

ing system for its balance of flexibility, efficiency and long-term adaptability.

The design incorporated long-span structural beams that created 65-foot open spaces without interior columns, while the frame was up-sized and reinforced where needed to support rooftop HVAC systems and parapet walls, all of which are rare features for this construction type.

“It is a pre-engineered metal building, but we elevated it into an architectural showcase,” says Parsons. “We wanted the benefits of a pre-engineered structure but designed it to look and perform like a custom building.”

While the team contended with unpredictable weather and material delays, construction continued to progress thanks to strong coordination between the city, contractors and AVID’s in-house project team.

Collaboration + serendipity

The design of AVID Architects’ new headquarters began much like any of the firm’s projects – with conversations.

“We started with five or six of us in a room with nothing but imagery and ideas,” says Fye. “It was truly collaborative from the beginning.”

The concept grew from the inside out, as Fye describes it, with every space programmed around how employees work. Through early feedback, the design team learned what components of the old space weren’t supporting employees adequately, and that insight shaped nearly every design decision. It also set the direction for a layout that responded to the site as much as to the people inside it.

“The L-shaped plan was all about maximizing our views of the protected wetlands, something no one can ever build on,” he adds.

The building’s one-and-a-half-story height provided generous volume and natural light while still maintaining a human scale. Materials were chosen with texture and longevity in mind, blending the warmth of wood-look aluminum siding with the strength of brick and metal panels, all tied

by Scott Esterly

Photos

DYNAMIC WORK SPACES The firm’s new headquarters offers a variety of work settings, from private offices (top) to openoffice cubicle pods (middle), alongside versatile meeting rooms (bottom).

together by broad glazing that draws the landscape into view.

Inside, polished concrete defines the space, while cabinetry and quartz add light, and carpeted areas create a softer feel where needed.

Serendipitously, an unexpected harmony emerged between the firm’s rebrand and the building’s geometry. The angular forms of AVID’s new logo echo in the building’s walls and interior lines, creating a subtle visual link with the firm’s visual identity.

Built by and for the industry

Every phase of construction reflected the relationships AVID Architects has built over decades in the field. Many of the collaborators were long-time partners from client work, which brought an immediate sense of trust and shared expectations.

Booth describes the process as uniquely direct. “Normally I’m running between architect and owner,” he says. “This time, the person asking the question was also the one giving the answer. It kept everything moving.”

That trust carried through from early coordination to the smallest of on-site adjustments – such as when a cabinetry run met the backside of an angled wall. The team discovered the clash during installation. Because of where the wall sections are cut in the drawings, the conflict went unrecognized until they were in the field. To resolve it, they pulled the casework forward and modified the upper cabinets. This fix preserved the design intent.

“If I didn’t tell you that story, you’d never know the difference,” says Parsons. Reflecting on the experience, he adds, “Sitting in the owner’s seat changes how you see things. You understand what clients go through.”

A building for people

From the moment visitors step inside AVID Architects’ new headquarters, it becomes clear the building was designed around its people. Every aspect supports how the firm collaborates. Architects and engineers work together in shared,

Photos by Jason Julian Smalcer

open-office cubicle workspaces that the firm refers to as “pods,” with nearby rooms that adapt to everything from quick team huddles to private calls and full client presentations. Each setting was tailored through direct staff feedback.

“We talked to everyone, from our office administrator to our engineers, to design spaces that worked for their processes,” says Moore.

Amenities reinforce the same philosophy. A spacious break room connects to a covered outdoor patio of more than 2,500 square feet through a folding glass wall, creating a seamless indoor-outdoor gathering space. Just a short walk away is a fitness center, as well as a golf simulator and mothers’ wellness room.

A central beverage station keeps coffee and refreshments within easy reach, while a reconfigured reception and plot room reflect the direct staff input on workflow and comfort.

Natural beauty was central to the design. From the inside, the landscape outside feels close. Broad glass walls open the pods and break room to the surrounding wetlands, while the L-shaped plan frames those views at every turn. Even walking between

offices, employees and visitors catch flashes of sky and trees. Outside, the covered patio extends the workplace into the open air, blurring the boundary between building and nature.

That precision extends into other areas of the final design. Structural

“It was a unique experience being both the client and the architect. You see the process from both sides, and it gives you a renewed appreciation for what clients experience.”

Randy Parsons AVID Architects

cross-bracing, visible in the attached three-bay garage and the break room, doubles as an architectural feature, adding rhythm and strength to the open span. Interior lighting offers flexible, brightness controls used throughout the office, with exterior illumination that can change colors. Even the garage floor received an

epoxy finish, reflecting the same care given to the public spaces.

Designed to grow

The new headquarters was built with the future in mind. “We set this building as far west and north as we could to leave room for future growth to the east,” says Parsons.

Looking back on the project, he adds that designing their own headquarters offered a rare perspective. “It was a unique experience being both the client and the architect,” he says. “You see the process from both sides, and it gives you a renewed appreciation for what clients experience.”

“We experienced the same questions, the same decisions and the same challenges our clients face every day,” says Fye.

That firsthand understanding reinforced the same long-view that guided the firm’s rebrand. AVID was created to stand beyond any single generation of leadership, a foundation for both the present and the future.

“We wanted a name and a place that outlasts all of us,” Parsons says, “and I’m proud to say I think we’ve accomplished that.”

by Scott Esterly

COMMUNAL COMFORT The spacious break room connects seamlessly to the outdoor patio through a folding glass wall, offering a flexible space for meals, meetings or casual gatherings.

Photo

Your 1st Choice in Design/Build & Industrial Steel Fabrication

◆ Engineering/design of structural & miscellaneous steel

◆ Experiened project management dedicated to project execution & delivery

◆ Production processes using the latest technology/automation in engineering, drafting, fabrication & shipping

◆ Transportation of fabricated material utilizing company-owned & operated fleet of tractors & trailers

◆ Erection of structural & miscellaneous steel

◆ Project support from inception to completion of project

◆ Certified fabrication of structural & miscellaneous steel per AISC & CWB Standards

◆ American Institute of Steel Construction Safety Award Recipient 2015 & 2016 PROUD PARTNER WITH

Building Better Connections

Viega presses forward with cutting-edge seminar center + manufacturing plant in Mantua

By Doug Bardwell | Photos by Harry Dempsey & Doug Bardwell

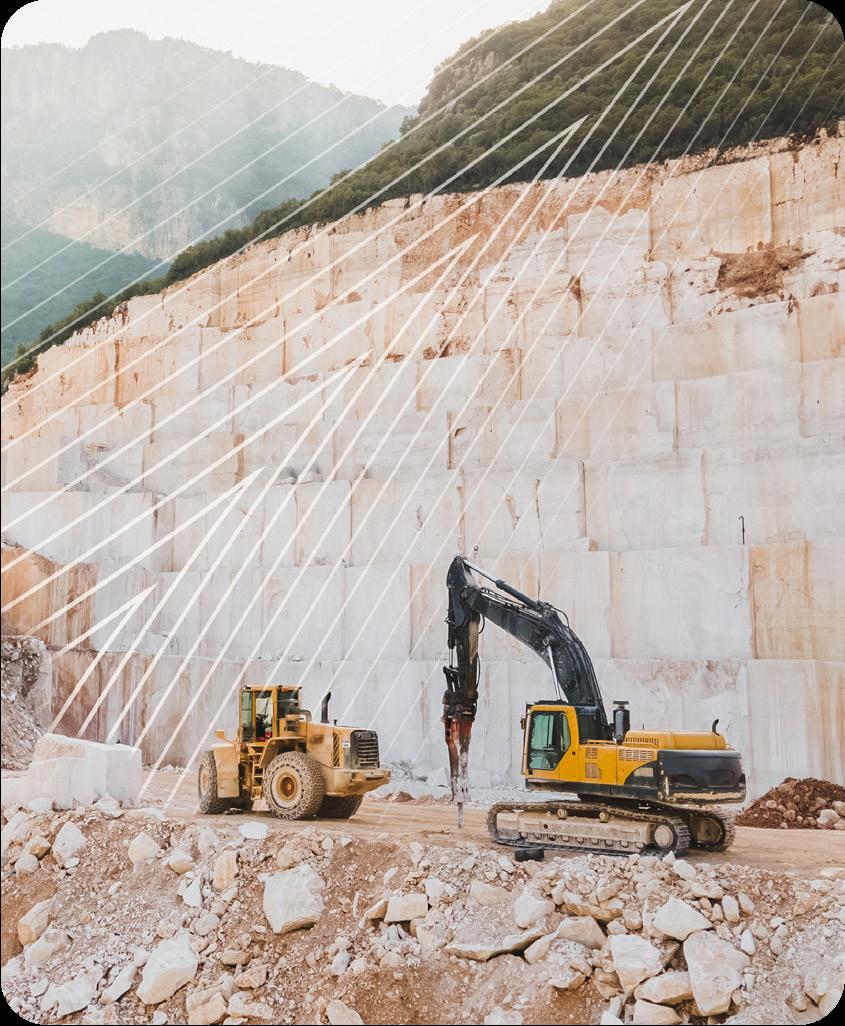

The Viega Seminar Center and Manufacturing Plant at 4400 Beck Rd. in Mantua, is a 244,000-squarefoot facility valued at $200 million. As the newer of Viega’s two U.S. manufacturing facilities, it was built to grow distribution eastward from their original plant in McPherson, Kansas.

With quick highway access to Ohio Turnpike Exit 193, Viega is well-positioned to serve customers throughout the eastern United States and Canada.

Drawn to the Buckeye State

Viega is a family-owned German company that was founded in Attendorn, Germany, 126 years ago,” explains Emily Pajek, Viega’s plant director. “The Viegeners started the company by building beer taps, and it grew into plumbing fittings. We came to the U.S. in 1999, building our first manufacturing plant in Kansas, and this is the second one. The company is still a family-owned business today.

a mechanical press fit, using a power tool to make the connection.”

Pajek explains that Viega also produces plastics and various types of metal

“Viega has had separate seminar centers across the country and a manufacturing plant, but we’ve never combined them before now. So, this was a very unique opportunity for Viega to have customers come in, not only to get trained on our products but also to see how we make them.”

“What makes Viega different is that we make a metal press-fit technology, so it’s not a traditional pipe joining method like welding, threading or soldering. There’s no heat involved. It’s actually

The technology was used across Europe for years before being introduced to the United States in 1999. In 2008, Viega opened its first manufacturing and distribution center, the 450,000-square-foot Kansas facility, followed by two additional buildings and expansions, bringing the total on campus to 1 million square feet.

Emily Pajek Viega

fittings, along with many other products worldwide, but press-fit technology remains the main focus for this seminar center and plant in Mantua.

The company projects a period of rapid growth over the next five to 10 years and expects the Mantua facility to employ between 400 and 500 people. With a focus on customers in major eastern cities, they aim to better serve this region of the country.

Viega agreed to acquire an 80-acre parcel within Geis Development’s 470-acre Turnpike Commerce Park, providing plenty of space for their initial plant and room to expand as demand grows. Pajek explains that many reasons

Photo by Harry Dempsey

influenced Viega’s decision to choose this location for their first expansion.

“It came down to a decision between locating in Pennsylvania or Ohio,” recalls Pajek, “but there was a night and day difference in dealing with the governmental bodies in these two states. Portage County really wanted us here, and offered substantial tax benefits. The property was priced right, and the location was immediately off the highway. Lastly, being a manufacturing hub, there was a wealth of skilled labor. Early on, it became an easy decision to locate here.”

After a competitive RFP process, Geis Construction was awarded a construction contract in the summer of 2023.

A client with clear priorities

For architectural design services, Viega turned to TESSERE.

“We actually started working with Viega in 2006,” states Jeff Weiford, executive vice-president of TESSERE, “including the design of all million square feet in McPherson. Initially, we thought it was going to be very similar to the McPherson plant, which consists of multiple independent facilities. Our first thought was a campus-type project similar to that one. And then, through the course of conceptual design, working with Viega, this project came about.”

As Weiford explains, the new building was specifically sited so that it can be easily expanded to the east and the west,

where it could eventually total 1 million square feet under roof in one building.

“The difference on this project is they wanted to focus more on the customer experience at this location,” explains Weiford. “Their main seminar/customer experience center is at their headquarters in Broomfield, Colorado. And, they wanted to have that sense here in Ohio, as they place a great deal of importance on educating their clients and contractors. This facility was designed to reproduce that experience here in Northeast Ohio.”

“Viega has had separate seminar centers across the country,” adds Pajek, “and a manufacturing plant, but we’ve never combined them before now. So, this was a very unique opportunity for Viega to have customers come in, not only to get trained on our products but also to see how we make them.”

While working with Viega’s executive committee, the requirement was for a unique facility – one that both Viega employees and customers would genuinely enjoy.

The one-inch insulated glass curtain wall at the front of the building allows plenty of natural light and extends into the production area. Viega selected a Kingspan Quadcore Optimo Series, a three-inch-thick horizontal insulated metal wall panel system, different from the one currently used in McPherson, adding even more architectural appeal. Given the location in Northeast Ohio, they wanted a long-lasting solution.

STRATEGIC SITE Viega chose Mantua for its second U.S. manufacturing plant due to excellent highway access, tax incentives and strong local support. The facility strengthens distribution to the eastern U.S. and Canada and positions the company for major growth.

Photo by Doug Bardwell

Since Viega has a storied 125-plus-year history, the building materials it typically selects are very durable, including features like auger cast piles, thick flooring and a 30-year roof warranty.

“The design also offers ultimate flexibility, allowing machines to be moved around in the production hall easily without having to demolish floors or foundations,” Weiford says. “This flexibility is important given their longstanding manufacturing history.”

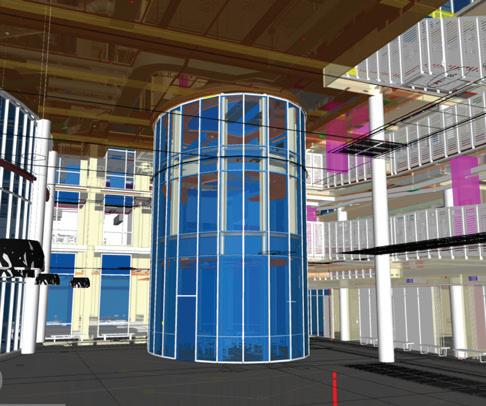

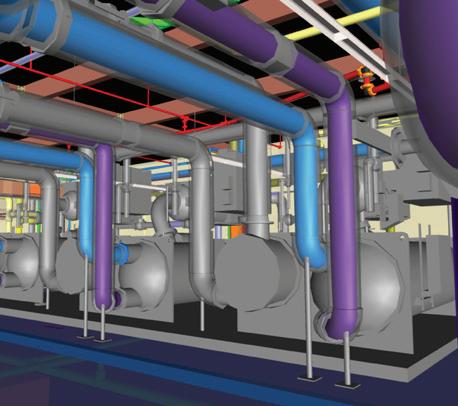

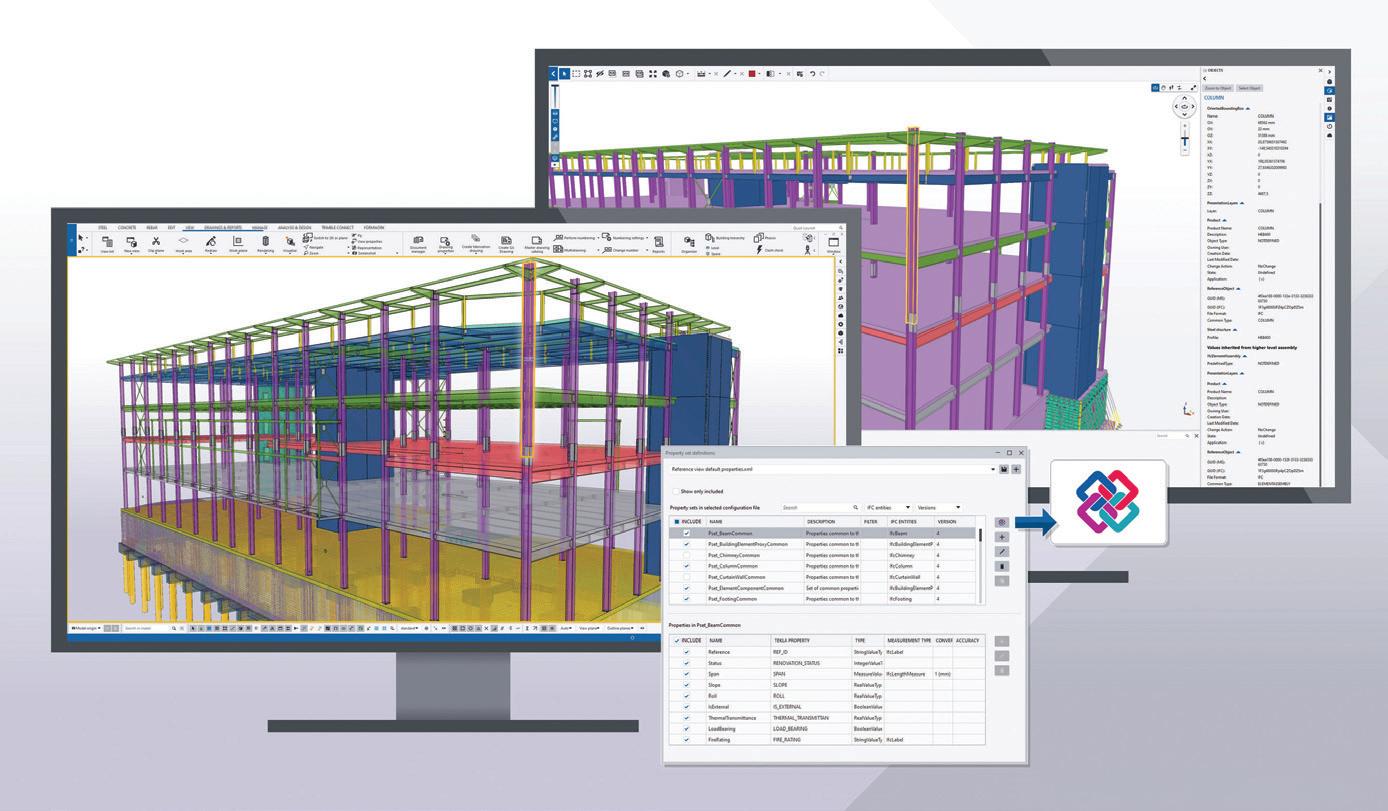

Viega strongly supports using BIM (building information modeling) for building design, and it proved to be a clear advantage on this project as well.

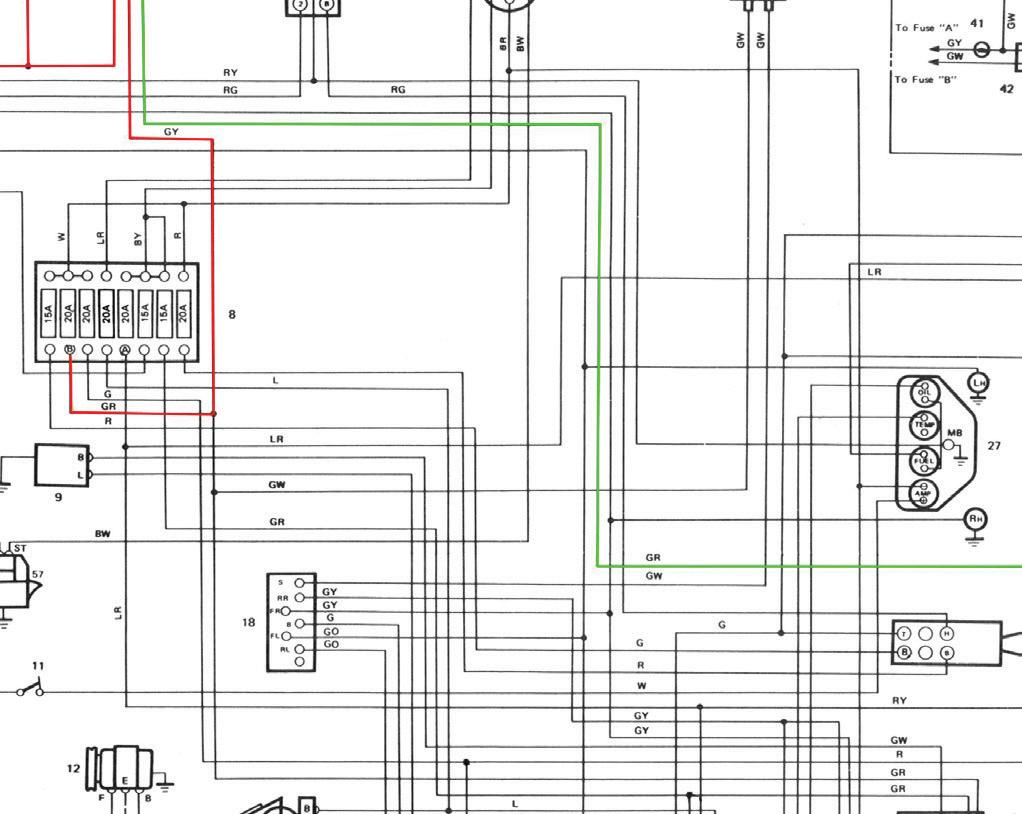

“Making sure, from an interference standpoint, that everything was coordinated, BIM was a very useful tool,” explains Kevin Hartfelder, senior project manager with Geis Construction.

“When it came to fire suppression, plumbing, process piping and HVAC, those were modeled to pick up any

PROUD ARCHITECTURAL DESIGN PARTNER OF THE VIEGA SEMINAR CENTER &

PLANT

interferences and identify them prior to happening in the field.”

“We held weekly BIM coordination meetings,” says Hartfelder. “Those meetings then led to the creation of install drawings and submittals, which were reviewed with the architect and officially approved. After that, we proceeded with fabrication and installation.”

“We drew this project in a full Revit environment,” Weiford adds, “and so, we were able to model the facility, add

CUSTOMER-CENTRIC CAMPUS Combining a seminar center with live manufacturing, the 244,000-square-foot facility uniquely allows customers to train and observe production in one location.

Photo by Harry Dempsey

CONCRETE PAVING DUCTILCRETE EXCAVATION UTILITY WORK

SOUND DECISION Instead of a sound-masking system, acoustics were achieved through perforated metal decking, insulated office assemblies, floating ceiling clouds and sound-absorbing light-fixture elements.

walls, furniture and more as part of the schematic design through Construction Documents (CDs) review. Then, rather than doing a page turn at each milestone, we walked the client through our model, which is very helpful for explaining what the project will look like before any construction starts.”

Challenges met, standards raised

Master planning was completed in late 2022, with schematics finished by early 2023. CDs were created in packages, starting with the earthwork and grading package, followed by the foundation package, and then the remaining drawings.

When asked about first thoughts after reviewing the plans and specifications for this project, Hartfelder says he was impressed by the high level of quality the owners requested.

“The biggest thing I remember was that this would be a very detailoriented project, driven by what the owner wanted,” says Hartfelder. “While we usually go through many pricing exercises, it was clear that Viega was only interested in premium products and materials for this project, but required working very closely with the Viega team to stay under budget.

“We love taking on large manufacturing projects, and even more, we love working with customers who have a clear vision and direction. They weren’t interested in cutting corners. They had a carbon initiative to make the building all electric, and they were committed to having the building achieve LEED Gold certification.”

The first challenge on the project came early. “By the time we got our

“While we usually go through many pricing exercises, it was clear that Viega was only interested in premium products and materials for this project, but required working very closely with the Viega team to stay under budget”

Kevin Hartfelder Geis Construction

approvals and were ready to go with Portage County, we weren’t moving dirt until December,” says Hartfelder. “So, that was a challenge through the wintertime, but through soil conditioning and stabilization, we weren’t letting Mother Nature stop us.”

Geis provided the owners with options for conventional footers, geo piers and auger cast piles.

“Prior to becoming the Turnpike Commerce Center, this area was a potato field,” explains Hartfelder. “The area was quite sandy. Viega builds its facilities on auger cast piles, so we drilled and installed auger cast piles to bedrock approximately 20 to 25 feet down before placing the 12-inch-thick, double-layer reinforced slab throughout.”

To create a fully carbon-neutral building, extensive attention was given to the R-value of the exterior envelope. Highly insulated wall panels were selected along with excellent roof insulation. Solar was considered, but the payback period was too long to be feasible at present.

Roofing consists of a fully adhered 80 mil white TPO membrane over DensGlass sheathing. The underside of the assembly features a perforated metal deck with acoustic insulation, which performs very well in the office area.

The team deliberately avoided installing a sound-masking system and instead chose creative sound-absorbing materials on light fixtures, floating ceiling clouds and specific wall surfaces. Full-height demising walls separate each office area

Photo by Harry Dempsey

Shalersville,

SKILLS IN SESSION Classrooms (top) and hands-on workshops (middle) anchor the training wing, while a nearby gathering area gives visitors and trainees a comfortable place to meet, relax and continue conversations (bottom).

from the next, preventing sound transmission between them.

For HVAC, as an all-electric building, there are multiple rooftop units over the production and office areas, with radiant fin tubes along the curtain wall for supplemental heat.

Viega uses chillers as part of the manufacturing process, including aircooled chillers mounted on the roof. Since air compressors and chillers are essential to production, Viega specified a high level of redundancy, just in case.

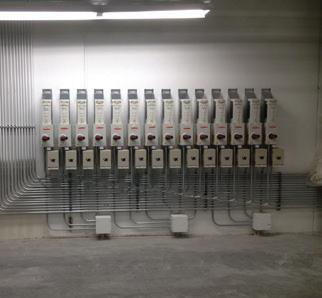

All the electric rooms are at full capacity, as all the necessary electrical equipment for more than a dozen production lines is already installed

“[Viega wasn’t] interested in cutting corners. They had a carbon initiative to make the building all electric,

and they were committed to having the building achieve LEED Gold certification.”

Kevin Hartfelder Geis Construction

and ready. They are currently drawing power from the existing grid in the area, but plans are already in place to install their own substation.

Viega produces a line of components specifically for radiant heat, so the sidewalks in front of the plant are all equipped for snow melting.

A campus for learning + making

Parking for employees and guests is on the north side of the building, facing Beck Road. Wayfinding is simple, as the main entrance is underneath a large canopy with four custom-designed column covers, which are made to resemble carbon steel pipes and giant Viega metal press fittings.

As you enter the glass-walled lobby, the reception desk is outlined with what looks like a section of oversized copper pipe. An acoustical wood ceiling floats overhead.

by

Photos

Harry Dempsey

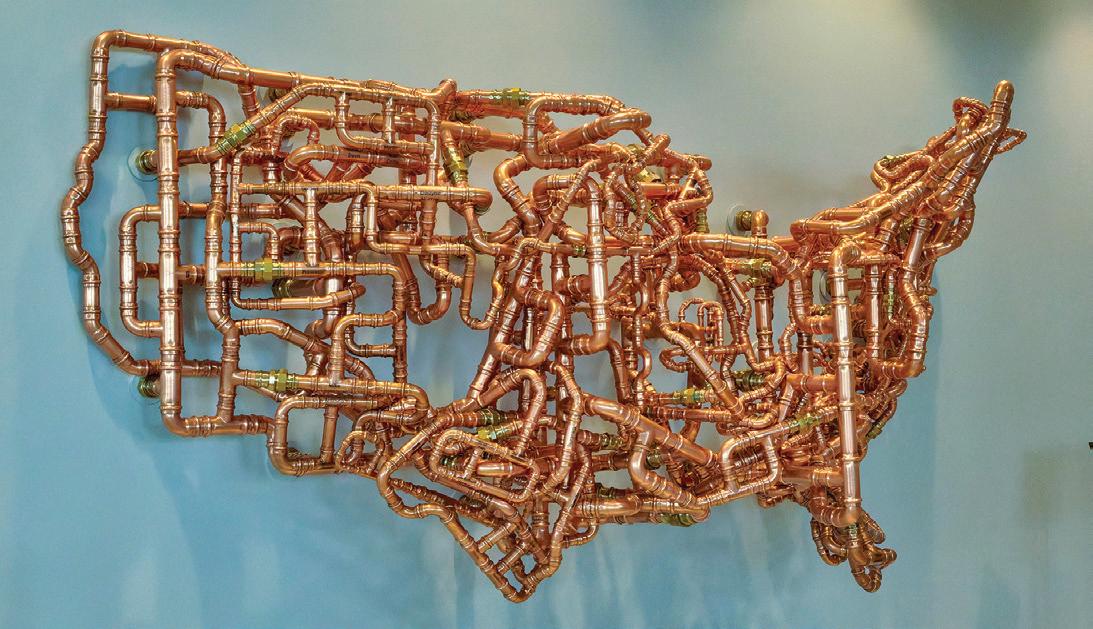

To the right is a large piece of custom sculpture by renowned artist Michael Murphy, who was born in nearby Youngstown. Murphy used hundreds of pieces of copper pipe and Viega fittings to create a threedimensional artwork that appears to change as you walk past it. From the left, you can clearly see the outline of

the United States, while standing centered on the sculpture, you can easily read “Viega.” Moving to the right, the outline of the State of Ohio comes into view. Truly remarkable.

From there, down a wide serpentine corridor done in Viega’s signature yellow and black, full-size displays of Viega products line both walls, guiding visitors to

the canteen at the end. The displays serve as teaching tools, helping groups understand the extensive range of Viega’s 15,000 products.

On the north side of the corridor are two large seminar classrooms, one of which can be divided into two smaller rooms.

“The majority of our educational effort is honestly teaching the tradesmen how to effectively use our product and install it,” says Pajek. “We also dedicate time to training large customers and industry professionals so they are aware and knowledgeable about the product and how it can specifically benefit large projects.”

On the south side of the corridor, there are two workshops where students can get hands-on experience using the power tools that connect the Viega fittings to various types of piping.

A bright, welcoming canteen area is located outside the workshops and provides a variety of refreshments and drinks.

Up on the mezzanine level is a row of private offices that overlook the bright, north-lit open office area and the production floor on the opposite side. In the northwest corner, a large, impressive Board Room features a long table with seating for 18.

COPPER CRAFTSMANSHIP Anchoring the lobby is a striking sculpture, crafted from hundreds of copper pipes and Viega fittings, that transforms as visitors move around it, revealing the outline of the state of Ohio (left), the U.S. (top right) and the company’s name (bottom right).

Photos by Doug Bardwell

ELEVATED EXPERIENCE A secured enclosed catwalk offers architectural visibility into the production floor, enabling tours while maintaining safety and acoustic control.

The east end of the floor is another gathering area with a kitchenette and access to the outdoor seating deck. The deck is above the canopy over the downstairs entry door and is furnished with a table and chairs for outdoor breaks.

The railing around the deck features a unique, custom design, mimicking the shapes of plumbing tees, elbows and straight pipes.

Separate small rooms are available off the kitchenette for an employee health office, a meditation room and a mother’s room.

Doors also provide access from here to a fabulous, enclosed catwalk that extends well into the production area on the first floor. From there, tours can be conducted safely and quietly, while guests enjoy a great view of the activity below.

Areas to check include the water treatment plant in the southwest corner and the stock room, where a two-story-high Modula Lift storage rack rotates 100 trays of parts, allowing you to query the inventory on a touchpad, and to select the drawer you need with a touch of a button.

On the manufacturing floor, two production lines are already installed and

running. The third line is currently being installed. The fourth is scheduled for June, and the fifth in November next year. Installation will continue until they have nine lines in the main bay of the building. In the other bay, plans include adding four Mega-Press lines, which will then fill the building.

“As part of our manufacturing process, we have to wash and polish the

“[We] dedicate time to training large customers and industry professionals so they are aware and knowledgeable about the product and how it can specifically benefit large projects.”

Emily Pajek Viega

fittings,” explains Pajek. “That uses a lot of water, so we installed a water treatment process that is a closed loop to recycle all that water, which is very unique. That way we’re not discharging any water into the environment.”

“And I would say that from a LEED standpoint, their water recycling use led

to a huge advantage in getting LEED Gold certification,” adds Weiford.

Finishing a high-performance build

With a demanding schedule, everything came together smoothly. Before the building was even set for completion, Viega employees began working on-site in a trailer parked out back. Twenty employees coordinated equipment installations and made arrangements, sometimes collaborating with German machine builders as various components arrived on site.

“Looking back, I remember that one of the early requirements for this project was to have a space ready for the first piece of equipment 14 months after we started breaking ground,” recalls Hartfelder, “and not just any space, but fully conditioned space, with power and an epoxy floor. This was all before substantial completion, which was scheduled for June 2025, four months later.”

By July 1, 2025, Viega shipped its first complete order.

“At the end of the day,” Hartfelder says, “I think I’m most proud of the entire Geis team which brought another project in safe, under budget and ahead of schedule.”

Photo by Doug Bardwell

The PCPA Welcomes

FINANCIAL STRATEGIES

Six of One

The origin of phrases has always intrigued me. One of the earliest phrases that I can remember comes from my mom, who frequently would say “six of one, half dozen of the other.” It took me a while to realize that this meant that there was really no difference between two alternatives.

This month, we are going to dig into two hot topics that have recently emerged as a result of the passage of the One Big Beautiful Bill Act (OBBBA) earlier in the year – bonus depreciation and Section 179 expenses. While it may seem like there is no difference between the two, simple concepts often get very complex when we enter the tax world. To have a deeper understanding of these forms of depreciation, read on.

Before we jump into a complicated discussion, let’s start with a brief review of what the concept of depreciation means. Most of us are familiar with this concept in the context of a car. Suppose I buy a brand-new Honda Accord for $40,000. Six months later, that car will be worth something less than $40,000. And over the following months and years, this loss in value will gradually continue. This isn’t because I’m a bad driver or that I don’t take care of the car. Rather, the car

is subject to wear and tear. And suppose five years later, a completely redesigned Honda Accord is introduced. Now, in addition to wear and tear, there is also a loss of value as a result of economic obsolescence – my 2025 Accord barge is no longer state-of-the-art in comparison to this rocket ship 2030 Accord. This is also how the IRS views depreciation of real estate. The improvements immediately starts to lose value once the asset is placed into service as a result of wear and tear as well as economic obsolescence. As a result, the IRS allows the owner of that real estate to offset the income it produces each year against the amount of loss they believe that asset has incurred. This is a true shelter, as the amount of depreciation really isn’t costing the owner anything. But the income that it generates each year will be reduced by this non-cash expense come tax time.

ALEC J. PACELLA

Bonus depreciation and Section 179 expenses allow the owner to recognize even greater amounts of depreciation by recognizing certain items not gradually over their useful life but rather at 100% in the year they are placed into service. The end result of either concept is similar, as the owner can receive a shelter that is dramatically greater if using either of these concepts. But there are several nuances to be aware of that are specific to each.

Section 179 allows the taxpayer to deduct the cost of certain types of assets as an expense in that tax year. Suppose that I upgrade my building by installing a new roof. Traditionally, this expense would be capitalized (not recognized as an expense for that particular year) and the cost would be spread over its useful life – 39 years if considered non-residential and 27.5 years if considered residential. However, this type of improvement would likely fall under Section 179, which would allow me to expense the entire cost in the tax year it was placed into service. This concept has been applicable for real property since 2010, but the OBBBA increased the maximum annual expense limit from $1.22 million to $2.5 million.

Bonus deprecation allows the taxpayer to deduct a percentage of the cost for qualifying business property. It has been around since 2002 and, under the Affordable Care Act of 2017, was following a schedule that would have seen 2026 as the final year, with 20% of the asset’s cost subject to being immediately recognized. The OBBBA restored this to the full 100% deduction starting in the 2025 tax year. Suppose that I bought $500,000 worth of office furniture this year. I would be able to recognize the full amount of depreciation for this tax year. And that 100% is not just for 2025 but rather indefinitely.

You may be thinking that bonus depreciation and Section 179 expenses are six of one, half a dozen of the other. And while both have a similar impact of increasing the amount of shelter for the taxpayer, there are some key differences, as follows.

Bonus depreciation can reduce your taxable income below zero, but Section 179 cannot. If you want to reduce taxable income to something less than zero, which results in a taxable loss, bonus depreciation is your only option.

What I C @ PVC

BREAKING THE BARRIER Last month, a 10,000-square-foot warehouse built in 1989 on Hub Parkway in Valley View sold for $1 million. While there was nothing splashy about the building, the location, the buyer or the seller, the fact that the pricing for warehouse buildings has crossed the $100 psf mark is notable. –AP

Section 179 expenses can be more specific, with the taxpayer indicating application to specific assets. Bonus deprecation is much broader and applies to the entire asset classes and not just

Bonus depreciation can reduce your taxable income below zero, but Section 179 cannot. If you want to reduce taxable income to something less than zero, which results in a taxable loss, bonus depreciation is your only option.

specific improvements. Also, bonus depreciation is automatically applied to eligible assets. If you do not want it applied, you must opt out and, again, it’s all or nothing as the taxpayer cannot pick and choose between which specific assets they want to be included and which they want to be excluded.

Bonus depreciation can include new as well as used tangible property, so long

as its new to the business. It can also now be applied to a new classification of property called a Qualified Production Property (QPP). For a property to qualify as QPP, it has to be nonresidential located in the U.S.; construction must have begun after January 19, 2025 and before 2029; the original use of the property must begin with the taxpayer; the taxpayer must make the election to treat this property as QPP; and the property must be used by the taxpayer as an integral part of a qualified production activity, such as manufacturing, production or refining. Portions that are occupied by office, sales, research, etc. are excluded.

My mom’s favorite phrase is generally credited to a British naval officer, Ralph Clark. Upon crashing and sinking his ship in 1790, he wrote the famous phrase in his journal, comparing the actions of his ship’s sailors to be no better but no worse than the actions of convicts. While the comparison of bonus depreciation and Section 179 expenses is much less dramatic, having a good understanding of the benefits of each can result in much smoother sailing come tax time.

Alec Pacella, CCIM, president at NAI Pleasant Valley, can be reached by phone at 216-4550925 or by email at apacella@naipvc.com. You can connect with him at www.linkedin.com/in/ alecpacellaccim or subscribe to his youtube channel; What I C at PVC.

ACAR CORNER

Issues in the real estate industry

Evolving Trends in Residential Remodeling

Home remodeling is surging, and more homeowners may be calling on their real estate agent for help. Agents who answer the call are finding they can play a role as an ally to clients who are embarking on a renovation.

Remodeling has been surging over the last few years as more homeowners opt to stay in their homes longer and leverage their equity for renovation projects that help them age in place. Also, the average age of U.S. homes is about 40 years old, so many homeowners are looking to update their property. Homebuyers also may be purchasing a home with the intent of remodeling, and about 8% of homeowners say they were motivated to remodel in order to sell, according to research from remodeling site Houzz.

“A real estate professional absolutely can help clients with remodeling,” says Angie Hicks, co-founder of the home services site Angi, formerly known as Angie’s List. “I always like to say, ‘You want to keep up with the Joneses, but you don’t want to beat the Joneses.’ If you have three bathrooms when everyone else has two, you won’t be getting the return on that. In thinking of the resale on your house, a real estate agent is going to be a great person to talk to.”

Also, agents view so many homes that they know what works, what doesn’t and the materials they see the most frequently, Hicks adds.

Here’s how real estate agents can play a part in the remodeling boom.

Recommendations matter

Real estate agents should consider expanding their network of home service providers and contractors. Their clients may need them. They should have a list of vetted, licensed plumbers and electricians, as well as painters, carpenters and project managers. After all, 33% of homeowners identified “finding the right service providers” as the biggest challenge in a home remodel, according to research from Houzz.

“A real estate professional may not be the pro who is going to do the work, but they can help them find a pro,” says Marine Sargsyan, staff economist at Houzz.

Talk resale value

It’s easy to get distracted by fancy finishes and materials and lose sight of what matters most to a remodeling budget. But as the National Association of Realtors’ Remodeling Impact Report shows, it’s not always the biggest or most expensive project that nabs the highest return at resale. For example, refinishing

DREW GAEBELEIN

hardwood flooring could offer the biggest bang for your remodeling buck, with an estimated $3,400 in upfront expenses but a potential $5,000 cost recovery at resale, according to NAR’s report.

Agents can share data for comparable homes in the neighborhood to help their clients gauge what features competing homes offer. They can also share industry data about which renovation trends result in the highest ROI so clients can make more informed choices.

NAR’s report identifies the following top interior projects for cost recovery at resale:

1. Hardwood flooring refinish: 147% of value recovered at resale

2. New wood flooring: 118%

3. Insulation upgrade: 100%

4. Basement conversion to living area: 86%

5. Closet renovation: 83%

6. Attic conversion to living area: 75%

7. Complete kitchen renovation: 75%

8. Bathroom renovation: 71%

9. Kitchen upgrade: 67%

10. Add new bathroom: 63%

11. Add new primary bedroom suite: 56%

The report showed the following cost recovery at resale for exterior projects:

1. Roofing: 100% of value recovered at resale

2. Garage door: 100%

3. Fiber cement siding: 86%

4. Vinyl siding: 82%

5. Vinyl windows: 67%

6. Wood windows: 63%

7. Steel front door: 63%

8. Fiber glass front door: 60%

Know the remodeling trends

Homeowners frequently ask agents which design choices are most popular in today’s market. Data from Houzz reveals that kitchens, bathrooms and outdoor spaces continue to lead renovation activity.

In the kitchen, cabinet upgrades remain a top priority. Shaker-style doors and brushed nickel hardware dominate, though many homeowners are incorporating accent or glass-front cabinets to break up traditional layouts. White cabinetry remains the

most common choice, but warm wood tones and two-tone designs – such as white uppers paired with blue or wood-tone lowers – are gaining traction. Engineered quartz continues to

It’s not always the biggest or most expensive project that nabs the highest return at resale. For example, refinishing hardwood flooring could offer the biggest bang for your remodeling buck, with an estimated $3,400 in upfront expenses but a potential $5,000 cost recovery at resale, according to a NAR report.

be the preferred countertop material for its durability and low maintenance, while transitional design styles and extended ceramic or porcelain backsplashes remain in vogue.

Bathroom remodels mirror many of these trends, with shaker cabinetry still popular but wood finishes now edging out white. Quartz countertops are the top selection, and large-format tiles

are increasingly used on shower walls. Freestanding bathtubs are becoming less essential as homeowners prioritize spacious showers, custom lighting and accent walls that bring color and texture into the space.

Outdoor improvements are also on the rise. Homeowners are investing in new decks, shade structures and outdoor kitchens equipped with grills, refrigerators and sinks. Many are upgrading lighting, irrigation and security systems to create multifunctional spaces that extend living areas beyond the home’s walls. White and gray remain the leading exterior colors, while metal roofing continues to gain popularity for its modern appearance and longevity.

These remodeling trends reflect homeowners’ desire to balance functionality with personal style, an insight real estate professionals can use to guide clients toward updates that enhance both comfort and resale appeal.

This article was reprinted with from the NAR website and submitted by Drew Gaebelein (Keller Williams Living), who is 2025 president of Akron Cleveland Association of REALTORS.

BILLBOARD

News about people, products, places & plans

AIA

Akron Awards Honor Regional Design Excellence

AIA Akron recognized nine projects and practitioners for design excellence at its 2025 Design Awards Celebration, held recently at Canal Park in Akron. The biennial program highlights work that demonstrates innovation, technical execution and meaningful contributions to the region’s built environment. Recipients represented a range of project types and scales.

Prime AE Group earned a Citation Award for the newly completed Patterson Park Community Center in Akron. Hasenstab Architects received two Citation Awards: one for its newly completed Pugliese STEM Academy in Steubenville and another for its interior design at Crafted Artisan Meadery in Mogadore. Peninsula Architects was also recognized with a Citation Award for The Urban Barn in Valley City. Sol Harris/Day Architecture was honored with a Merit Award for the Plain Township Amphitheater. Hasenstab Architects’ Brian Miner earned the program’s Photography Award for his “Fort Jefferson Nightscape Exterior.” In the student category, Aidan D. VanDussen received a Merit Award for his “Tidal Frame” project. Conor McDonald Creative was recognized with a Make Project Citation Award for its Hippo Coffee Table, and GPD Group earned the People’s Choice Award for its work at Cloverleaf Middle School/High School in Westfield Township.

AIA Akron’s full awards program and 2025 Annual Report are available at www.aiaakron.org.

Hahn Loeser Partners Named to National Leadership Roles

Hahn Loeser & Parks LLP recently announced it has appointed partners Aaron S. Evenchik and Tara J. Rose to new national leadership roles within the firm. Evenchik

will serve as national co-chair of the firm’s Construction Law Group alongside Rob Remington, while Rose will join Evenchik as national co-chair of its Real Estate Practice Group.

Evenchik has been with Hahn Loeser since 2017,

representing clients in transactional and litigation matters across construction, real estate and zoning law. His work has been recognized by Chambers USA and Best Lawyers, including as 2025 “Cleveland Lawyer of the Year.” Under his guidance,

Hahn Loeser’s Construction Law Group has consistently ranked among the nation’s Top 50 firms in Construction Executive magazine for six consecutive years. Rose joined Hahn Loeser in 2020, became a partner in 2023, and was later elevated to Ohio real estate co-chair. She advises clients on real estate transactions, leasing, acquisitions, dispositions, construction contracts, easements and litigation, including construction defects, land use and zoning, and eminent domain matters. She has been recognized by Best Lawyers Ones

Photo

Aaron Evenchik

Crafted Artisan Meadery

to Watch

and Ohio Super Lawyers Rising Stars.

Kent State Students Capture Peterson Prize

A team from Kent State University’s John Elliot Center for Architecture &

Environmental Design captured first place in the 2025 Charles E. Peterson Prize for their measured drawings of the Jagger House at Hale Farm and Village in Everett, Ohio. The national competition recognizes excellence in documenting historic American architecture.

Nearly 20 students collaborated to record the 19th-century farmhouse’s craftsmanship and character through detailed fieldwork and precise drafting. Their comprehensive drawings will join the Library of Congress’s Historic American Buildings Survey collection, preserving the home’s architectural legacy. The project was led by instructor Emily Steiner Little, AIA.

“Receiving the Peterson Prize is an incredible honor,” says Aiden Heichel, now an architectural designer at AVID Architects. “This experience reminded me that documentation is both a technical skill and an act of stewardship, connecting the craft of the past with the creativity of the

present and the future of our built environment.”

NAIOP Announces Awards of Excellence Call for Entries

NAIOP Northern Ohio recently announced a call for entries for its Annual Awards of Excellence. To submit a

OH LIC #21927

Tara Rose

Charles E. Peterson Prize recipients

Mike Hicks President

nomination, complete the Intent to Enter form online at www.naiopnorthernohio.com.

Official entry forms will be sent to applicants in mid-January.

The annual awards recognize outstanding achievements in commercial real estate in several categories, including Broker; Construction, New Ground-Up; Construction, Exterior or Interior Renovation; Design, Architectural; Design, Interior; Design of Renovation, Exterior; Rising Star; Developer; Development; and Landscape Architecture/Infrastructure, Land Development.

The Transaction of the Year category returns but has been revised to include any lease, purchase or sale transaction in Northeast Ohio where the nominee was instrumental

in the project’s completion through advisory services, brokerage or financing.

New this year is an award for Transaction of the Year (Out of Market), focused on transactions located outside of Northeast Ohio.

For additional information, contact the NAIOP office at naiop@wherryassoc.com.

AIA Cleveland Names Executive Director

The Cleveland chapter of American Institute of Architects (AIA Cleveland) recently announced it has named Ann Davis as its new executive director.

Davis brings more than two decades of experience in strategic operations,

News about people, products, places & plans

stakeholder engagement and community outreach. She most recently served as chief of staff at Newmark Commercial Real Estate’s Cleveland office. Her prior leadership roles include Saint Martin de Porres High School and University

Circle Inc. She has also held positions at Cleveland Clinic, Parker Hannifin and Rockwell Automation.

Davis is a licensed real estate salesperson in Ohio and holds a Bachelor of Arts in Communications from John Carroll University. She recently co-chaired the Urban Land Institute Cleveland Women’s Leadership Initiative. She will be based in the AIA Cleveland office, and members and community partners are welcome to visit the office to meet her and use the space for meetings.

WHAT’S NEW?

For complimentary coverage in Billboard, send company news & project information to billboard@propertiesmag.com. P

Ann Davis

Commercial real estate happenings

What Leadership Looks Like in CRE Today

As I complete my term as president of NAIOP Northern Ohio, I find myself reflecting not only on the year we’ve had as an organization, but also on the broader lessons I’ve learned about leadership in today’s commercial real estate landscape.

The challenges facing our industry right now have tested every participant in the market. But they have also revealed something powerful: leadership in CRE today is less about authority and more about adaptability, collaboration and clarity of purpose.

This past year reinforced for me that leadership begins with listening. Our membership represents a remarkably diverse cross-section of the industry –developers, owners, brokers, architects, engineers, lenders, lawyers, contractors and countless specialists whose work forms the backbone of commercial real estate. Each group experienced the past year differently. By listening carefully, we were able to design programming, educational sessions and advocacy priorities that addressed the real issues facing our members. In a market as complex as this one, no single perspective is enough; effective

leadership comes from making space for many voices.

Another lesson from this year is that collaboration is no longer optional. Projects today are more complicated than ever, often requiring public-private partnerships, creative incentive strategies, sophisticated underwriting tools and broader community engagement. As president, I saw firsthand how much our members rely on one another to navigate this complexity. NAIOP’s role as a convener – bringing the right people together at the right time – has never been more important. Leadership means not just participating in those conversations, but creating the environment where they happen. NAIOP truly stands out in this regard.

I also gained a renewed appreciation for the value of transparency and honesty in leadership. With so much uncertainty in the market, it can be

JUSTIN EDDY

tempting to sugarcoat challenges or overstate short-term optimism. But the most productive discussions we had this year – whether with members, public officials or industry partners – were those grounded in realistic assessments of the market. Leadership means acknowledging difficulty, then focusing the conversation on solutions. That mindset helped guide our educational programming, our committee work and our advocacy efforts, which tackled the key legislative initiatives paramount to the success of our industry and our members.

Perhaps the most inspiring lesson of this year was the reminder that leadership is a team sport. Our chapter accomplished an extraordinary amount in 2025. We strengthened our legislative presence, expanded our Developing Leaders programming, delivered high-value educational content, executed perhaps the most successful Awards of Excellence we’ve ever had, and supported members through a turbulent market cycle. None of that happened because of one person. It happened because our volunteers, committee chairs, board members, sponsors and event partners invested their time and expertise. Serving as president gave me a front-row seat to the generosity and dedication that define NAIOP.

One area where this collaborative leadership was particularly evident is in our advocacy work. Public policy touches every corner of commercial real estate, and this year we continued to reinforce NAIOP’s position as the voice of the industry in Washington, Columbus and at the local level. Our members demonstrated that good advocacy is simply good leadership – showing up, participating in the dialogue and offering practical, real-world insights that help shape better outcomes.

Leadership also means investing in the future, and this year underscored the importance of developing the next generation of professionals. Our Developing Leaders program continues to thrive, providing mentorship, education and community to emerging talent in the industry. Their energy and perspective are essential to our chapter’s long-term strength. They are not just the future of our industry – they are shaping it right now.

As I step out of the role of president, my greatest takeaway is that leadership in commercial real estate today is fundamentally about connection: connecting disciplines, connecting generations and connecting market realities with long-term vision. Our chapter is stronger when we are learning from one another, supporting one another and elevating the collective work of the industry. I am grateful for the opportunity to have served and even more grateful for the people who made this year so meaningful.

Commercial real estate will continue to evolve, and the challenges we face will require thoughtful, engaged leadership at every level. But if the past year taught me anything, it is that our region has the people, the creativity and the collaborative spirit required to meet the moment. I look forward to seeing how NAIOP continues to lead the way.

Justin J. Eddy is a partner with Tucker Ellis LLP (www.tuckerellis.com) and outgoing president of NAIOP Northern Ohio. Visit NAIOP Northern Ohio online at www.naiopnorthernohio.com.

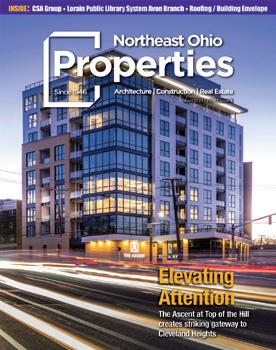

Rolling Forward

Kenda Tire/Martin Wheel invests in its future with production, warehouse + office facility

By Dan Holland | Photos by Mark Watt & Red Tail Aerial Imaging

As a fixture of Summit and Portage counties’ manufacturing community since 1946, Martin Wheel – a subsidiary of Kenda Tire – opened its new 197,500-square-foot manufacturing and office facility within Brimfield’s Maplecrest Business Park in November.

The company, which currently operates a 130,000-square-foot facility located at 342 West Ave. in Tallmadge, manufactures and ships specialty wheels for use in lawn and garden, industrial, trailer and towing, power sports and other applications.

Kenda Tire, with its world headquarters located in Taiwan, operates three additional divisions in the U.S. –Monitor Tire & Wheel in Cartersville, Georgia, as well as Dextar Wheels and American Tire & Wheel, both located in Elkhart, Indiana. The company’s U.S. headquarters and research center in Reynoldsburg, Ohio operates the company’s passenger and light truck division. Additionally, they also operated a research and development facility in Green, Ohio.

Custom-made products

The company manufactures wheels ranging in size from four inches up to

16 inches in diameter, with select orders custom-painted in-house for a number of original equipment manufacturers (OEM) and retail outlets.

“We supply Menards, Rural King and Northern Tool, just to name a few,“ says Jeff Hixson, vice president and general manager for Kenda USA/Martin Wheel, who joined the company two years ago. “We supply a lot of retail and OEMs, including John Deere and MTD. We do some OEM, some retail and some distribution. We do a full circle of different supply points.”

Kenda imports rubber tires from overseas that are then heated and fit onto various-sized wheels prior to being shipped out to customers.

“We make the wheels and bring in the tires and couple them together on a mounting line,” Hixson explains. “We have ovens where we heat the small tires – as they come from Vietnam or Taiwan bundled, smashed down and tied

together – and they have to be brought back to their normal size.”

“We run them through a line where they are heated, and then we can mount them on the wheel we build,” he continues. “We can also paint wheels – we can paint them John Deere yellow, SCAG orange or Cub Cadet yellow – through our powder coat line, by which we can paint various OEM wheels and the color associated with those OEMs. Then we palletize and shrink-wrap everything and ship them out.”

The new plant, which will allow for direct shipments versus a “container-only” model, contains ample acreage should the company’s additional divisions decide to build expansion facilities at the site.

“This was the first building that was built, as far as new construction, and with the knowledge that there will be a second and third phase,” says Hixson. “The passenger and light truck industry has always been, what

Photo by Red Tail Aerial Imaging

we call in our business, a containeronly program.”

According to Hixson, customers of Kenda in the passenger and light truck industry have had to buy direct containers, as the company previously did not have ample warehouse space to stock all products onsite.

“This could ultimately turn into warehouse space for other divisions outside of Martin, like our passenger and light truck line, or our power sports, which is ATV and UTV off the road products,”

says Hixson. “To really get to the next level in the passenger and light truck industry, you have to have available warehouse space, so that customers can buy out of your warehouse rather than just buying 42-foot containers.”

Addressing a need

Company executives began researching avenues for expansion in 2019, including the possibility of adding onto its existing Tallmadge facility. The company discovered that it was

somewhat “land-locked” at its original location, however.

“They wanted to expand their Tallmadge location two years ago,” explains Jeff Stevenson, vice president of business development for Campbell Construction, which served as the design/ build team on the project. “We drew up plans for an addition, but it didn’t make sense, as they would then be landlocked with no space for future expansion.”

Stevenson made the company aware of an available 38-acre site in Brimfield

Proud Sitework Contractor for KENDA/MARTIN WHEEL MANUFACTURING PLANT

FLOORING FINISH Polished concrete floors in the warehouse employ a Green Umbrella System, providing durability, a glossy sheen and resistance to curling and stains.

Photo by Mark Watt

Township, which is directly across from a 63,000-square-foot Hamrick Packaging Systems facility, designed and built by Campbell Construction, that opened in early 2023 (See Northeast Ohio Properties, February 2023 issue, available at www.propertiesmag.com).

Built on the site of the former Maplecrest Golf Course and just west of the I-76 interchange along Tallmadge Road, the industrial park is part of a Joint Economic Development District created in 2003 through an agreement between the City of Tallmadge and Brimfield Township.

“They began looking ahead for future expansion in a location in which they could grow down the road, rather than just a one-and-done expansion,” Stevenson continues. “So, that was when we started looking at properties, and we knew this was available, since we built Hamrick Packaging right across the road, and we’ve done work for DeHoff, as the industrial park was developed jointly by DeHoff Development and Lemmon and Lemmon.”

“And, that’s how they came to settle on this location,” Stevenson continues. “There was tax abatement available and the availability of property to build on. So, now they have the ability to triple in size if needed on this site.”

Martin Wheel had added onto their original facility multiple times over the years, explains Hixson. “They’ve done 16 additions to that facility, so there are 64

Photo by Mark Watt

ENVISIONING GROWTH Situated on a 38-acre site in Brimfield’s Maplecrest Business Park, the new 197,500-square-foot facility combines manufacturing, warehouse and office spaces. The location provides ample space for expansion and logistical access near I-76.

corners on that building,” he says. “The last addition was in our warehouse area, and that allows us to stack three stack racks high.

“But with having 64 corners, there are people who work there who may not see each other for an entire week, as they’re at different elevations and going down stairs and around corners,” he continues. “I call it a ‘honeycomb cave’ to do business out of it. We also only have seven operable loading docks there.”

Groundbreaking for the new facility took place in October 2023, with substantial completion and owner occupancy achieved in June 2025. Full operations, with all equipment moved in, are expected to commence in late 2025.

“We’re in the process of finalizing all the drawings for the warehouse area,” explains Hixson. “Campbell’s architect is helping us gather all of that together, submit that to the Portage County Building Department, get a sign-off there and get the permits to finalize the paint line. Then, we will bring in and start the electrical hookups to all of the equipment, hopefully by the end of the year.”

Notably, the plant is the first new greenfield facility built by Kenda Tire in the U.S.

Interior layout

The structure is divided between a 180,000-square-foot Butler pre-engineered manufacturing/warehouse section, which

consists of 4.1 acres under-roof, and a 13,000-square-foot, one-level front office suite. The warehouse area also includes 4,500 square feet of space spread between four mezzanine areas with concrete floors.

Visitors entering the L-shaped front office building will pass through a covered entryway and encounter a main vestibule area. Situated along the main

“[Kenda] began looking ahead for future expansion in a location in which they could grow down the road, rather than just a one-and-done expansion... Now they have the ability to triple in size if needed on this site.”

Jeff Stevenson Campbell Construction

corridor is a row of private offices, which feature interior corridor windows and glass-front doors, while rows of office cubicles sit to the rear. The office suite, which includes two conference rooms, a lunchroom, an employee locker room and restrooms, also features large windows along the rear wall that offer views into the warehouse/manufacturing area.

A walled outdoor patio, with access from the office suite, is situated along the south wall.

The vast manufacturing/warehouse portion of the facility features a tire

warehouse area and a trucker’s lounge with restrooms, receiving office, technical group office and shipping office. The structure contains 21 bays, with each featuring a locking safety component that anchors a truck to the physical dock when in use.

Equipment in the warehouse/manufacturing area includes robotic welding machines, mounting machines, a powder-coat paint line and compressors.

Exteriors

Office suite exterior walls consist of light-toned CMU split-face block with a red horizontal row near the roofline, which incorporates Kenda’s company colors. The office suite features tinted, Low-E glass aluminum tube exterior windows.

An 88-inch-high CMU split-face block abuse wall surrounds the entire pre-engineered warehouse building. Metal panel walls extend upward, with clerestory windows located within the upper reaches of the walls.

The industrial park is “all-inclusive,” Stevenson notes. “When you look for a site, you want one that is flat, level with no trees on it, and here the all-inclusive part of it is that it has onsite retention basins,” says Stevenson. “So, for anyone who builds here, rather than each company having to put in its own retention basin, [the development company] put in a master detention basin. When DeHoff Development decided to put this back

by

Photo

Red Tail Aerial

Imaging

FLEXIBLE + FUNCTIONAL With multiple meeting spaces (top), private offices (middle) and open cubicles (bottom), the layout encourages productivity and collaboration.

here, they put in a master detention basin for the entire industrial park.”

The site also includes new, lighted paved asphalt parking areas and extensive landscaping.

Building systems

The front office suite was conventionally built, using CMU, bar joist and a metal deck with a TPO roofing membrane atop.

The steel frame warehouse/manufacturing building spans 400 by 450 feet, rising to a height of 30 feet with a single peak in the Butler MR-24 standing-seam metal roof. Due to the wide span, the ceiling structure incorporates specialty truss purlins.

“Butler calls it a ‘landmark building’ that uses truss purlins rather than roof purlins,” explains Stevenson. “A roof

“It was great working with Martin Wheel. We appreciated the opportunity to help them to locate, and stay in the area in Portage County and the Tallmadge-Brimfield Joint Economic Development District.”

Brad Ehrhart Portage Development Board

purlin is a Z-shaped purlin, and those can only go up to about 40 feet or so, but you can get wider spans with this. It looks like a bar joist, but it’s not. It’s a proprietary Butler product.”

The warehouse building features WMP-50 insulation, with 9.5 inches of insulation in the ceiling and four inches in walls, while office suite insulation consists of R-30 in the ceilings and R-13 in the walls.

The warehouse features a polished concrete floor that utilizes a Green Umbrella System, an integral concrete curing process that gives the floor a protective and glossy sheen.

“It’s a system for curing the concrete that reduces curl and hardens the face,” explains Hixson. “The finished product

Photos by Mark Watt

The PCPA Wel

EMPLOYEE AMENITIES The lunchroom (top) provides a bright, welcoming space for employees to recharge, conveniently located next to the locker room for easy access before and after shifts (bottom).

is a burnished, sheer look that protects it from stains but is not slippery at all.”

Facility HVAC needs are served by four Cambridge Units mounted high on the walls of the warehouse area. The office suite features a split system with condenser units situated on the ground.

Challenges

One unique challenge faced on the project? In late summer 2024, a tornado passed through the industrial park and blew down one of the concrete masonry front office walls that had just been erected.

“The wall was braced with two-byfours, but it still blew it right over,” says Stevenson. “But it didn’t slow construction, as we had other aspects of the building going on. It may have delayed it slightly, but we were able to recover quickly from that.”

Financing incentives

According to Brad Ehrhart, president of Portage Development Board, a combination of local incentives helped bring Martin Wheel to the site.

“We used the Portage County Port Authority to provide the sales tax as savings for material use in the building construction,” says Ehrhart. “And, we worked with the township school district and county for a 60%, 10-year tax abatement for the project.”

“It was great working with Martin Wheel,” he adds. “We appreciated the opportunity to help them to locate, and stay in the area in Portage County and the Tallmadge-Brimfield Joint Economic Development District.”

A winning team

Thanks to the efforts of all involved, a second major building project was completed in the new industrial park, with tax revenues benefitting both Tallmadge and Brimfield Township.