5 minute read

Replacing Equipment and Improving Energy Efficiency

Mark Klaus, MRWA Energy Efficiency Circuit Rider

Advertisement

If your first thought is, “How much extra will that cost?” this article is for you!

Missouri Rural Water Association personnel recently performed energy calculations for a lagoon aeration project at Cleveland, Missouri. The city of Cleveland is a Cass county community with an estimated population of 660 persons. Special thanks to city of Cleveland representatives: Public Works Director, Mike Gregory; Water Superintendent, Randy Maynard; Public Works Assistant, Doug Neller; Board member, Ray Morgan; and City Administrative Professionals, Ms. Dana and Ms. Tasneam. Your dedicated teamwork is appreciated.

The city’s wastewater collection system has three lift stations with treatment provided at a two-cell lagoon. The primary lagoon cell utilized six “splash style” aerators which were equipped with 7.5 horsepower motors. Three of the six aerators were operated at a time, utilizing a zig-zag pattern to provide mixing. Two of the aerator motors expired, requiring replacement. Of the two, the second motor terminated service toward the end of 2019.

Cleveland representatives proactively reviewed various replacement options for the expired aeration units. Various manufacturer representatives viewed the facility, answering questions and providing formal prices. A spreadsheet was developed, listing parameters for aerator replacement which included equipment pricing, energy use, yearly maintenance requirements/costs, local availability of parts, and if in-house maintenance was possible. This completed document was provided to the city council along with the preferred choice. The city council approved the purchase of the aerator with the highest energy savings. The estimated energy savings will provide a fast payback on this investment. The following table notes the number of motors, total horsepower, and estimated energy savings for the various options.

After a delay associated with the COVID-19 pandemic, the new lagoon aeration unit was delivered and installed at the Cleveland wastewater lagoon on May 4, 2020. City personnel assisted the equipment manufacturer during the installation process. The five horsepower, C and H Systems Gen-Aer unit was custom built for the Cleveland lagoon. The unit was upsized, providing additional aeration capacity. Within a few minutes of startup water circulation was noticeable. Two days later, I received a

phone call from the Cleveland Public Works Administrator noting water circulation and aeration bubbles traveling through half of the lagoon.

Prior to delivery, city personnel removed the two inoperable aeration units. Additionally, employees restructured cross ties, bracing cables, and existing electrical lines to the remaining four aeration units. A new electrical line was installed from the main breaker to the proposed aeration location. Needless to say, a lot of prep work was performed prior to installation.

Two weeks after installation, a follow-up phone call with the Cleveland Water Superintendent noted elevated dissolved oxygen levels and water circulation in the primary lagoon cell.

Did you ask, “How much more will it cost?” The answer: More than a duplicate replacement of the prior equipment. However, the energy savings will quickly pay for the entire project. The continued savings will prove beneficial over the extended use of the equipment. When repairing or replacing equipment, taking energy consumption into account and a comprehensive approach yields the best results. Always look at the big picture. MRWA Energy Efficiency is here to assist you in reviewing your options.

MRWA Circuit Rider Billy Everett and Wastewater Technician Donald Jones provided additional assistance concerning engineering activities performed for the city of Cleveland. Their experience and common sense approach proved helpful while saving the city large sums of money.

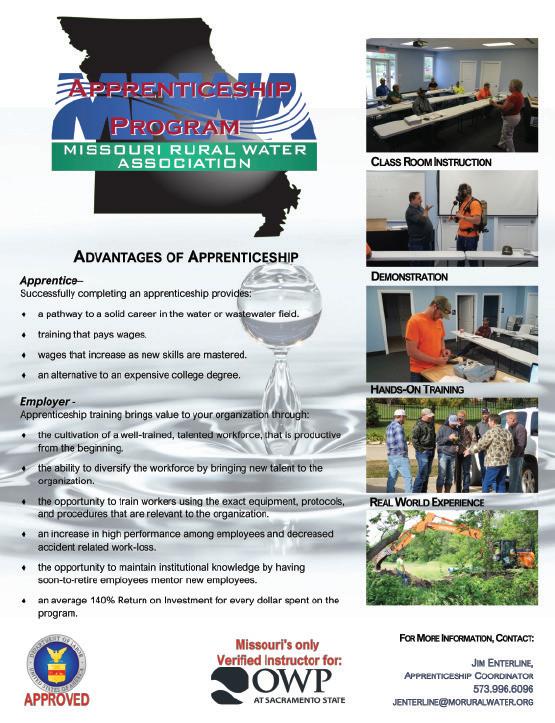

Your Missouri Rural Water Association system membership is a valuable tool. Please utilize all that we do: water, wastewater, and energy efficiency circuit riders, administrative professionals, source water protection, apprenticeship program, leak detection, training and conferences.

We work for you, our members. For more information on all that MRWA has to offer, visit our website: www.moruralwater.org.

Equipment That Works for Your Community.

KX040 — Standard Tail Swing Excavators • Turbocharged Kubota Diesel Engine — 40.4 HP* • Kubota Original ECO PLUS ® Prioritizes Fuel Economy • Superior Cabin with A/C and Deluxe Suspension Seat Available

SVL95-2 — Compact Track Loaders • Turbocharged Kubota Diesel Engine — 96.4 HP* • Standard 2-Speed Travel, Auxiliary Hydraulics & High Ground Clearance • Spacious Cab with Premium High-Back, Full-Suspension Seat

ZD1000 Series — Zero Turn Mowers • Powerful Kubota Diesel Engines — 19.3–21.6 HP* • All-New 48", 54" or 60" Kubota ProDeck with Aerodynamic

Cutting System (ACS) • Up to 22% Improved Fuel Efficiency

BX Series — Sub-Compact Tractors • Powerful Kubota Diesel Engines — 18–25.5 HP* • Available Performance-Matched Attachments & Implements • New Easy-Over Mid-Mount Mower Deck** —

Available in 54" or 60" Deck

Explore Kubota’s full line of quality mowers, tractors, utility vehicles, construction equipment and more. Visit www.MissouriKubotaDealers.com to find a dealer near you!

kubota.com

*For complete warranty, safety and product information, consult your local Kubota dealer and the product operator’s manual. Power (HP/KW) and other specifications are based on various standards or recommended practices. **Available on BX2370 and BX2670 models only. Kubota Tractor Corporation Markets a Full Line of Tractors and Construction Equipment Through a Nationwide Network of Over 1,000 Authorized Dealers. Optional equipment may be shown.