6 minute read

Pipe Bursting

Horizontal Directional Drilling, Slip Lining or Pipe Bursting 3 Optional Solutions to Traditional Open-Cut Trench Construction

Joel Ogle, Underground Solutions

Advertisement

More and more, municipalities are encountering ever increasing challenges in the upkeep and maintenance of their water/ wastewater systems. Initially, the usual question is, “How are we going to pay for this?” But as a municipality digs deeper into the project, they encounter issue after issue. In the past, if a municipality needed to expand or rehabilitate their water/ wastewater pipelines, they would contact the property owners where their pipe is located, with a usual utility easement, notifying them of the upcoming maintenance or pipeline replacement, and then dig up the pipe and replace it. With improvements in water/wastewater system design, this isn’t always just replacing pipelines. It may require a need to reorganize the lines to provide for better system hydraulics or system flow, redundancy, or the elimination of dead-end lines. Today, systems don’t just throw pipe in the ground. There is usually consideration given to reducing power consumption, water disinfection, retention time, and residual level in water lines. Flow capacities in wastewater lines and dry and wet weather conditions in sewer force mains are also considered. When this impacts property owners and other utilities, things can get messy, costly, and just downright impossible with previously used installation methods. An increasing number of smaller utilities are having to deal with these issues. What Grandpa could accomplish with his word and a handshake just doesn’t work anymore. Keeping this in mind, you need to ask the following questions: • Are you replacing an old line, or is this new construction or system expansion?

Are you looking to increase your line capacity?

Do you have adjacent utilities to deal with?

Do you have right-of-way issues?

Once you have these answers, you can consider several options for installing your new lines. Traditionally, open cut trench construction was the go-to, but today an increasing number of alternative methods are proving more cost effective, as well as being “socially” economical with less impact on the community. Awareness of how your project impacts your community is worth actual money saved from not having to address the concerns of business owners, residents, and possibly other utilities, before, during, and after the project is complete. The issues that typically arise primarily deal with the impact on traffic flow, business accessibility, use of public spaces and safety concerns of the citizens of your community.

Below are three alternative methods to open cut trench construction that can save you money and lessen the impact your project has on your community. These three methods will save money by reducing or removing the need for: replacement of asphalt or concrete streets and underlayment; sidewalk replacement; disturbing other utilities.

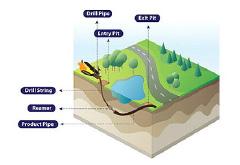

Horizontal Directional Drilling

Horizontal directional drilling, also known as directional boring, is a trenchless technology for installing pipe underground without impacting the area above the borehole. It is typically a shallow arc or crescent borehole in which a pipeline, conduit, or cables are pulled through once the borehole is completed. Although typically a shallow arc, directional boring can also navigate turns during the boring process. This is especially important in urban boring situations where existing buried infrastructure such as sewer, water and tunnels must be avoided.

This trenchless technology is effective for crossings of creeks, streams, rivers, roads, highways, and railroads. To simply break it down into stages:

Pilot Hole - The first stage consists of drilling a small diameter pilot hole.

Pre-Reaming - The second step is to pre-ream the pilot hole and enlarge it to a size sufficient to safely install the product lines. Pipe Pullback - The final step is the pullback of the pipe within the pre-reamed hole.

Materials commonly used for this trenchless technology: Fused PVC, Fused HDPE, Restrained Joint PVC, Ductile Iron, Steel

Slip Lining

Slip lining is completed by installing a smaller, carrier pipe into a larger host pipe, grouting the annular space between the two pipes and sealing the ends. Slip lining is one of the oldest methods of trenchless installation.

Typical Materials used: CIPP (cast in place pipe), Fused PVC, Fused HDPE

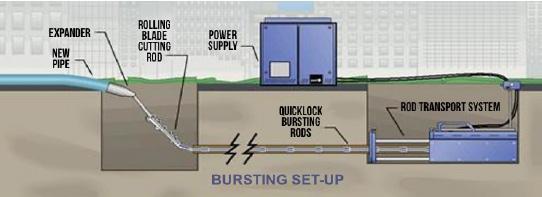

Pipe Bursting

Pipe bursting is a trenchless method of replacing buried pipelines (such as sewer or water pipes) without the need for a traditional construction trench. “Insertion and Reception pits” replace the trench needed by conventional pipe-laying.

(continued on page 48)

Fused HDPE, Fused PVC, Restrained Joint PVC

While more than one of these technologies may be viable for your water/wastewater project, each has its specific advantages. All aspects should be considered during project planning. It is a good idea to assign values to each of the technologies and of the materials to best assess the true costs. Sometimes contractors can overlook the value and trade-offs with each of these methods and materials, so it is important for municipalities to educate themselves on the technologies in order to evaluate them in terms of what best fits their needs. Ultimately, municipalities need to make sure they get what they want in the end: a system with longevity and serviceability built into every project.

Here is a list of just some of the municipalities within the state that are using these alternative pipe installation and replacement methods: Boone PWSD #9 - HDD for creek, highway and interstate City of Peculiar - HDD - Water Main crossings. (Water) City of Independence - HDD - Force Main Howard County Regional Water - HDD - Water Mains City of Sedalia - HDD - Water Main St. Charles PWSD #2 - HDD for Force Main replacement City of Jefferson City - HDD & Pipe Bursting- Force Main City of Ashland- HDD - Water main replacement City of Bowling Green - HDD - Casing City of Hannibal- HDD - Water main replacement Boone County #1 - HDD - Water Main Clarence Cannon Wholesale Water Commission - HDD - City of Sullivan - Slip Lining - Water Main

Force Main City of Kirkwood - HDD - Water Main Platte PWSD #4 - HDD - Water Mains City of New Florence - HDD - Water Main City of Louisiana - HDD - Water Mains City of Columbia - HDD - Water Mains (Interstate Crossing) CPWSD #1 - HDD - Casing City of Lee’s Summit - Pipe Bursting MSD - HDD - Force Main MSD - Slip Lining - Force Main City of St. Louis - Slip Lining - Water Main City of Kansas City - HDD - Water Main

A SUPERIOR WEBSITE FOR YOUR TOWN OR WATER SYSTEM IS NOW EASY & AFFORDABLE! Municipal Impact and Rural Water Impact provide beautiful, mobile-friendly websites for towns and Water Systems – all at a very affordable price. Kick back while we do all the work and setup, then make updates yourself anytime you want.

Secure hosting and unlimited support are included, too.

You’ll never hire an expensive web designer again!

For pricing and information, visit us online at www.municipalimpact.com or www.ruralwaterimpact.com Or call us today at 1.800.551.4815.