4 minute read

Start-Up Program

from November 2021

by MilkProducer

By Tamara Botting CONTRIBUTOR

While funding from Dairy Farmers of Ontario’s (DFO) Start-Up Program was a huge help, the truly invaluable component was the advice, knowledge and guidance offered through the program’s facilitators as his family’s farm entered a new venture, says Scott Walker, manager of Walker Farms Inc., just east of Alymer, Ont.

“We had this idea to process bottle all our milk in one location. We were playing with the idea for five or six years,” Walker says.

He says when the North American Free Trade Agreement (NAFTA) was replaced by the Canada-United States-Mexico Agreement (CUSMA), there were a lot of questions about what the industry might look like down the road.

This became the turning point for the farm.

Continued on page 18

WALKER FARMS INC., just east of Alymer, Ont., recently opened an on-site processing plant to bottle its milk. This project was done with help from Dairy Farmers of Ontario’s Start-Up Program.

Photo courtesy of Walker Farm Inc.

Only the best will do!

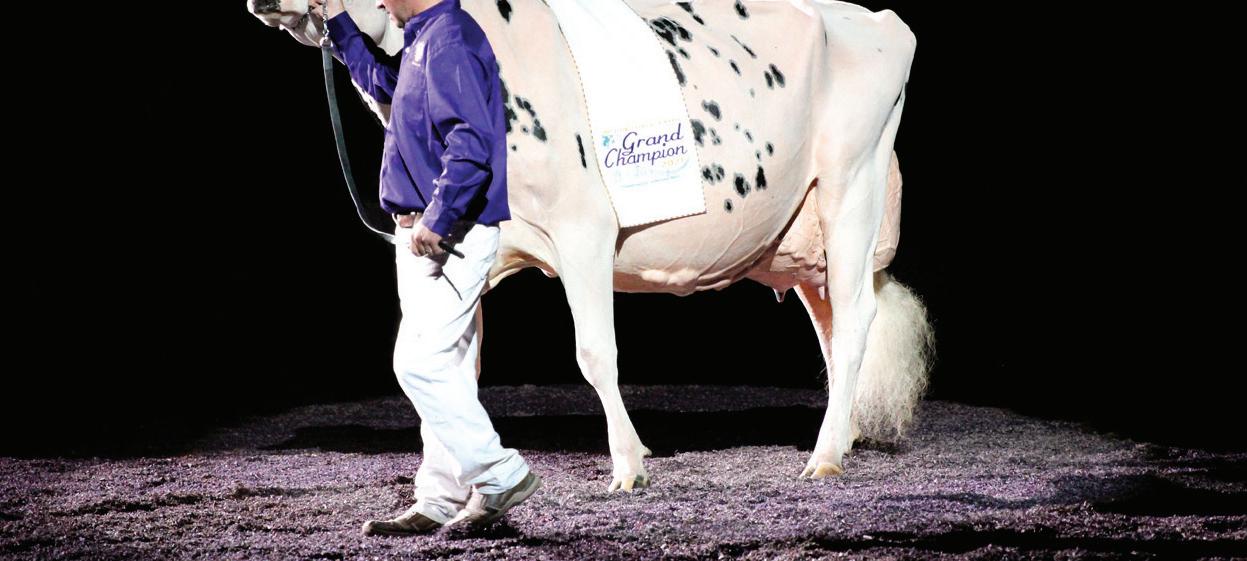

Shakira reigned supreme!

Honored to be the #1 udder product, Choice of Champions for over 10 years!

“We believe in Udder Comfort™ and are using it over 10 years for our show cows and our fresh cows to bring the quality and texture to the udder,” says Ysabel Jacobs of Ferme Jacobs, Cap-Santé,

Quebec. They apply Udder Comfort lotion daily at shows and to all fresh udders after each milking for 3 days after calving.

Ysabel’s husband Tyler Doiron led Erbacres Snapple Shakira

EX-97-CAN to 2021 World Dairy Expo Supreme Champion in

October. Shakira is owned by Ferme Jacobs, Ty-D Holsteins,

Theraulaz, Ferme Antelimarck and Jacobs family members.

Ferme Jacobs was premier breeder for the 7th time!

1.888.773.7153 1.613.652.9086 uddercomfort.com

Call to locate a distributor near you.

For external application to the udder only, after milking, as an essential component of udder management. Always wash and dry teats thoroughly before milking.

FROM LEFT are Jon, Scott and John Walker from Walker Farms. The family recently opened an on-site processing plant to bottle their milk.

Photo courtesy of Walker Farm Inc.

WALKER FARMS offers several varieties of fluid milk bottled on site. Operations manager Scott Walker says they hope to expand their product line to include drinkable yogurt.

Photo courtesy of Walker Farm Inc.

DFO’s Start-Up Program helps Walker Farms launch on-farm processing,

cont’d from page 16

“We’re going to have to start taking our destiny by our own hands,” Walker says.

That was about 3.5 years ago. When they decided they wanted to build a processing plant on-site, DFO was one of the first entities they reached out to.

“There’s a lot of grant programs for dairy processing, but almost all of them were for existing plants. There was nothing for new plants trying to establish themselves,” Walker says.

Except, of course, for DFO’s Start-Up Program.

Walker says while it was great to get some funding assistance, “The biggest thing was resources— people to talk to and people to bounce ideas off of.”

Through the program, they were able to get help with tasks, such as finding the right lab equipment and connecting with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA).

While building the plant took a bit longer than originally anticipated—the COVID-19 pandemic contributed in part to the delay—the Walkers are now producing several varieties of fluid milk, including one per cent, whole milk and chocolate milk.

In August, they processed about 35,000 litres themselves. Meanwhile, the dairy farm produces about 50,000 litres of milk per day.

Along with expanding their fluid milk operations, Walker says they are also looking to develop a drinkable yogurt.

“Our plant is set up for that, so we don’t have to bring any more equipment in,” he says.

While the farm’s time in the Start-Up Program is now drawing to a close, Walker is hopeful they’ll be able to be a part of DFO’s Scale-Up Program.

“If they’ll offer it to us, we’ll take the help,” he says with a chuckle.

Tamara Botting

ARE YOU PROTECTING YOUR HERD?

The DairyTrace Story

Crisis Affects Everyone Animal traceability helps protect your herd in the event of a crisis. It‘s essential to your livelihood and the economic health of the Canadian dairy industry. DairyTrace strengthens the industries reputation and competitive advantage for quality dairy products at home and around the world. Safeguard Your Business Effective traceability includes animal identification and movement reporting. With timely, accurate and relevant traceback information, you can count on DairyTrace to protect your herd and address food safety issues to reduce unfavourable fallout.

Beyond Milk By knowing where animals come from and where they reside, consumers and suppliers alike can feel confident in their food supply chain of animal products.

Read our full story at dairytrace.ca/ sustainability/advantages/

Get Started

Visit DairyTrace.ca, set-up your DairyTrace account and get started.

Free, Easy On-line Access

Report from the DairyTrace portal, mobile app, or from select on-farm software.

One-Stop Tag Shop

Choose from three styles of dual tag sets or the DairyTrace WHITE single button RFID tag.

We’re Here to Help

DairyTrace supports you in meeting proAction® livestock identification and traceability requirements.