The international fishing & aquaculture industry magazine

EDITORIAL & CONTENT

Editor: Jason Holland jholland@worldfishing.net

News Reporter: Rebecca Strong rstrong@mercatormedia.com

Regular Correspondents: Please contact our Correspondents at editor@worldfishing.net

Tim Oliver, Bonnie Waycott, Vladislav Vorotnikov

Quentin Bates, Terje Engø Eduardo Campos Lima, Eugene Gerden

Production

A

sustainable and efficient seafood industry is dependent on having all blue food producers be accountable for everything they produce

Full fish utilisation – a conversation that’s

With just a few months until the 5th Fish Waste for Profit conference gets underway in Reykjavik, Iceland, WF has grabbed an exclusive one-to-one interview with Dr Thor Sigfusson, Founder of Iceland Ocean Cluster Founder, event chair and champion of the 100% Fish movement.

Having recently informed our Special Report ‘By-Product Solutions: Cutting Waste and Maximising Value’ (January/February 2024) that approximately 10 million tonnes of by-products are wasted from targeted wild-capture fisheries alone, Sigfusson suggests in this issue that moving forward, a sustainable and efficient seafood industry is dependent on having all blue food producers be accountable for everything they produce.

He also insists that a wealth of benefits can stem from taking a holistic approach to full fish utilisation, including increased healthy nutrition, job creation, product innovation and value generation, and one of his overriding hopes is that companies and countries are sufficiently inspired to implement innovations that result in zerowaste across the seafood economy.

Since the publication of our By-Product Solutions Special Report, we’ve been informed of many more 100% fish-type initiatives, with ventures new and established finding innovative ways to use more of the raw materials available and to generate revenue from them.

In his interview, Sigfusson pointed to a growing list of start-ups that have successfully delivered new consumer products through the utilisation of fish by-products, and notes that there’s plenty more game-changing ideas likely to come to the fore. Like him, I’m looking forward to a very inspiring conference in September.

David Blake, Paul Dunnington production@mercatormedia.com

SALES & MARKETING t +44 1329 825335 f +44 1329 550192

Media Sales Manager: Hannah Bolland hbolland@worldfishing.net

Marketing marketing@mercatormedia.com

EXECUTIVE

Events Director:

Marianne Rasmussen-Coulling

Chief Executive: Andrew Webster awebster@mercatormedia.com

WF magazine is published bimonthly by Mercator Media Limited, Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD UK t +44 1329 825335 f +44 1329 550192 info@mercatormedia.com www.mercatormedia.com

Subscriptions

Subscriptions@mercatormedia.com

Register and subscribe at www.worldfishing.net

1 year’s digital subscription with online access £218.00

For Memberships and Corporate/multi-user subscriptions: corporatesubs@mercatormedia.com

Launched in 1952, World Fishing & Aquaculture is published by Mercator Media, a B2B media and events company specialising in international maritime industries, including marine business and technology, ports and terminals, and environmental strategies.

Through its publication and free access website (www.worldfishing. net), World Fishing & Aquaculture provides expert-written, in-depth coverage of the fisheries, aquaculture and processing sectors, with a strong focus on the emerging solutions, technologies and innovations that are shaping the broader seafood economy’s landscape.

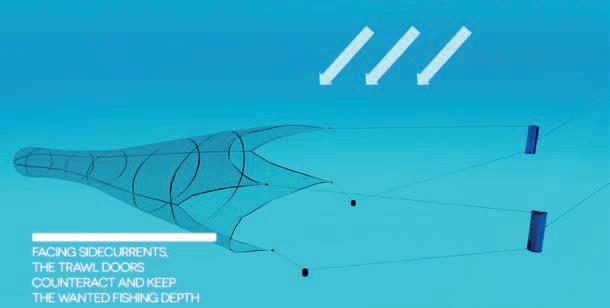

control SPREAD- control DEPTH - control RESISTANCE reduce CO2 EMISSIONS - reduce ENVIRONMENTAL IMPACT - reduce FUEL See video here: See brochure here:

Invest in our controllable trawl doors for unmatched versatility, allowing you to tailor them to your vessels requirements and fishing patterns. Experience eco-friendly, cost-effective fishing with reduced co2 emissions and quick setup adjustments, ensuring better profitability while minimizing environmental impact.

PISTONS & FOILS:

BATTERY & CHARGE STATION:

HYDROPHONES & INSTALLATION: SOFTWARE:

Thyborøn Skibssmedie A/S Sydhalevej 8, 7680 Thyborøn, Denmark

Tel. +45 97 83 19 22 sales@thyboron-trawldoor.dk www.thyboron-trawldoor.dk

The Our Ocean conference in Athens saw leaders unveil a series of commitments including establishing a marine protected area in Ghana by 2026 and an ambition by Guinea-Bissau to exceed the target of protecting 30% of the ocean by 2030.

Through the EU funded e-FishMed project, EFCA launched an exchange programme to enhance cooperation and to promote sharing of expertise and best practices in the fight against IUU fishing.

Therese Log Bergjord, CEO of aquaculture feed company Skretting is to leave the company after seven years. Bergjord will be succeeded on 1 June by Bastiaan van Tilburg, currently Managing Director for Trouw Nutrition Europe and Central Asia.

Norwegian football superstar Erling Braut Haaland has teamed up with Seafood from Norway in a 2.5-year collaboration. A separate deal has been struck with Norway’s national men’s and women’s teams.

Ministry of Oceans and Fisheries (MOF) has established the new “Plan for Further Enhancement for Working Conditions of Migrant Fishers on Distant Water Fishing Vessels”, which it developed in cooperation with NGOs Advocates for Public Interest Law (APIL) and Environmental Justice Foundation (EJF), and also the distant water fishing industry.

Announcing the plan, the government explained the characteristics of distant water fishing, with long-term fishing operations, make it difficult to conduct on-site inspections on working conditions and report human rights violations right away.

In December 2020, it prepared and implemented an improvement plan to strengthen the labour rights of migrant workers on distant water fishing vessels, which resulted in considerable improvements, including applying minimum wage standards and charging recruitment fees to vessel companies. However, civil society has continued to raise the need for further improvements in the working conditions of migrant fishers, criticising that human rights violations on distant water fishing vessel still remain.

In response, MOF, EJF, APIL and the distant water fishing industry have jointly established the new plan. This followed multiple meetings to update improvement of working conditions for migrant fishers of distant water fishing vessels.

Considering the characteristics of the distant water operation, the plan focuses on preventing possible human rights violations by imposing substantial sanctions on violators and strengthening victim protection. It also stops any deductions or the withholding of fishers’ wages under the pretext of savings or recruitment fees, MOL said.

Additionally, a comparative study on the wage standards and payment system between

Korea and other leading countries will be designed at the meeting of the Tripartite Council to promote upgraded conditions for the migrant fishers’ wages scheme including improved standards on wages and payment, and recognition of fishers’ career history and upgraded bonus. This meeting is scheduled for the second-half of 2024. There will also be an enforced port of call for tuna longliners during their sailing itinerary within one year of their initial departure for fishing operations.

With regards to periods of rest, employment contract provisions will include the entitlement for migrant fishers to have extra hours’ rest in return for their excessive work. Also, a survey will be conducted upon the crews’ disembarkation to establish whether they were rightly provided with their entitlements during their work and given a minimum of 10 rest hours per day (including six consecutive hours).

Substantial sanctions such as reduced quota will be imposed on violators.

Vessels suspicious of repeated violations of human rights protection will be blacklisted, resulting in random inspection conducted jointly by MOF and the NGOs. Also, consultations and cooperation with distant water industry

stakeholders will be sought for phased application of the C188, Work in Fishing Convention 2007 of the International Labour Organisation(ILO) to the related industry.

“This is an international best-practice and holds significant meaning as it is the first time that the government, NGOs, and the industry have jointly formulated a plan through communication. [The ministry] will closely monitor the implementation of the plan aimed at improving the working conditions of migrant fishers, and strengthening the protection of their rights, and will strive to ensure that all seafarers work in a safe environment without any discrimination,” Oceans and Fisheries Minister Kang DoHyung said.

“We view the government’s proactive engagement with stakeholders in formulating the plan as a positive trend, and we look forward to continued consultations to ensure active implementation of the Plan on the ground its tangible impact on enhancing human rights of migrant fishers.” said APIL CEO Jung Shinyoung and EJF CEO Steve Trent.

Both added that they anticipate continuous improvement on the matters that were not included in the plan this time around.

In the wake of new investigations uncovering forced labour in the seafood sector in India, China and North Korea, a leading industry group is urging supermarkets, restaurants, and other businesses to accelerate efforts to eradicate human and labour rights abuses from their supply chains.

To aid companies in initiating or expediting their efforts, the Conservation Alliance for Seafood Solutions has introduced a new set of guidelines, measures and resources to address the wellbeing of people and the planet.

The Guidance for Companies on Environmentally and Socially Responsible Seafood marks the first time that the 16-yearold alliance is calling on the industry to prioritise the “human factor” across its supply chains, including ensuring fair wages, safe and humane working conditions, and equitable opportunities for workers.

“The latest human and labour rights investigations confirm that the industry is facing a sea change,” said Ryan Bigelow, Project Director for the alliance. “While progress is being made, it’s clear that it’s time for the industry to meet this issue with the urgency it deserves. Prioritising human rights alongside conservation is not just the right thing to do; it’s the best thing companies can do to future-proof their businesses from consumer backlash and reputational damage.”

Bigelow insisted that companies of all sizes –from mass market retailers to

family-owned sushi restaurants – have the power to apply pressure on suppliers, spur reforms, and create new markets, models and supply chains that safeguard workers and the environment.

Founded in 2008, the alliance represents more than 150 seafood enterprises like Bumble Bee and Nestle Purina, NGOs, and environment and human rights experts across 30 countries. In North America, over 20 of the top 25 retailers, including Costco, Kroger, Target and Aldi have sustainable seafood partnerships with nonprofits within the alliance.

The alliance notes that as the world’s most widely traded food commodity, seafood involves complex supply chains – often passing through multiple intermediaries and countries before reaching the consumer – and as such, it’s especially vulnerable to exploitation since the majority of operations take place in remote, high-seas areas, far removed from regulatory oversight, or in

guidelines, measures and resources

countries like India and China where auditing firms have limited ability to effectively monitor supply chains.

It also highlighted that with forced labour generating an estimated US$ 236 billion in illegal profits annually – a sharp increase from $64 billion in 2014 – the European Union recently moved closer to joining the US in banning products made with forced labour.

The alliance’s guidance offers a toolkit and checklists for businesses that include a due diligence model companies can use to identify, assess and mitigate human rights and environmental risks in their operations and supply chains based on globally accepted frameworks. Additionally, it provides actionable resources for companies to inform their work and measure progress, including sustainable seafood

commitments made by dozens of companies like Aldi and Pepsico, along with 45 realworld examples demonstrating how businesses of various sizes and types across seafood supply chains, including retailers, restaurants, and fish co-ops, have successfully implemented steps to protect the ocean, people, and communities.

Bigelow said the guidance is critical to reaching the alliance’s 2030 goal whereby at least 75% of global seafood production should be environmentally responsible or make verifiable improvements, with safeguards in place to ensure social responsibility.

As of 2023, approximately 46% of the industry is progressing steadily. To achieve these goals, he stressed the importance of more companies beginning their efforts and those already committed embracing broader, more transparent processes.

The development of the guidance involved collaboration with a Working Group comprising leading industry experts, practitioners, and academics from organisations such as Fishwise, Seafood Watch and New England Seafoods.

whitefish

Denholm Seafoods, The Don Fishing Company and Seafood Ecosse have joined forces to establish Trinity Seafoods. The new business will focus on smaller-sized and underused sustainable stocks of whitefish such as haddock.

GSA names new CEO International, non-profit trade association Global Seafood Alliance has appointed Mike Kocsis as its new Chief Executive Officer. Long-time GSA leader Wally Stevens will assist in Kocsis’ transition into the role.

Products worth NOK 40.2 billion were exported by Norway in the first-quarter of this year, representing a fall of NOK 1.2 billion or 3%, compared with the corresponding period of 2023. This is the first value decrease in three years.

Strong progress has been made by tuna fisheries around the world to meet the Marine Stewardship Council Standard in the past 20 years, with 159 fisheries now engaged with the programme, or some 47% of the world’s wild tuna catch.

When it comes to seafood purchasing, consumers generally require some level of prompting to choose sustainable products and certification schemes can offer that motivation, according to new research from the Aquaculture Stewardship Council (ASC).

The farmed seafood certification programme has completed its most comprehensive consumer research to date, through an independent market research agency, interviewing more than 15,000 consumers in 14 countries about their perception and consumption of seafood.

Among its findings, of those consumers interviewed, 87% acknowledged that including fish and seafood in their daily shopping is quite important or very important, and that price is a top consideration for people when grocery shopping and notably when shopping for seafood.

Spain has the highest percentage of consumers who think including fish and seafood is important (92%) while the Netherlands and Japan have the lowest percentage, but still with strong agreement at 81%. More than half of Danish (52%) and US (51%) consumers think it is very important to include fish and seafood in their food shopping.

According to the survey, the main reasons consumers purchase seafood are because they enjoy eating it, and for its taste and health benefits. ASC said this indicates consumers are willing to prioritise food they enjoy in their budget, even when budgets are stretched.

With regards to sustainability, ASC learned that 83% of consumers are motivated to some degree to choose seafood with a sustainability label. Top considerations are that the product is safe and healthy for them and their families: free of antibiotics and chemicals (46%), comes from a healthy place with good water conditions (35%) and is safe to eat (30%). Social responsibility and worker

welfare are less important considerations.

Sustainability as a consideration when shopping for seafood is highest in northwest Europe, followed by south Europe and North America, with Asia lowest on the list. Italy has the highest percentage of consumers who choose sustainable products when there is a choice (82%) while Japan has the lowest (48%).

The survey shows that 67% of people are interested in buying more sustainable products, yet only 2% spontaneously think about sustainability when they are shopping for fish or seafood in the supermarket.

Clearly, consumers need a prompt in the supermarket to bring sustainability to the front of their minds,

ASC suggested, adding that certification scheme labels “can be the perfect prompt” in this situation. It advised that when asked about trustworthiness of sources of information, consumers trust independent certification schemes the most (21%) - more than environmental organisations, seafood brands, retail brands or other sources.

Additionally, its data showed that consumers associate certification logos with higher-quality fish/ seafood and safety, and that the highest awareness and importance of logos for consumers is in Germany and lowest in Japan

According to the research, ASC is the most recognised

farmed seafood label in all countries surveyed, scoring higher than other responsible farmed seafood programme labels. Awareness of the ASC label is highest in Germany and the Netherlands, followed by Sweden, the US and Canada, and is lowest in Japan. It also ascertained that ASC is the most trusted label for farmed seafood, with trust ratings ranging from around 70% in Spain and Italy to around 60% in most other countries.

ASC Senior Director –Markets and Communications Willem de Bruijn said the results from the survey revealed some interesting insights into how consumers shop for seafood and what informs their buying choices.

“The good news for the industry is that there is still strong demand for seafood because people enjoy eating it for its taste and health benefits and are willing to pay for it,” he said. “One of the most striking findings is that although twothirds of people say they are interested in buying more sustainable products, only 2% spontaneously think about sustainability when they are shopping for fish or seafood in the supermarket. This clearly demonstrates that consumers want to buy sustainable and responsible fish and seafood, but need an easy visual prompt in store, such as a certification label on pack, to remind and support them to consciously act on this desire.”

Longer ow route over the rope

Longer ow route over the rope

More speed = lower pressure

More speed = lower pressure

Shorter ow route under the rope

Less speed = more pressure

Quality is close to the heart of John Angus, Senior Sales Manager at Pelagia Shetland Ltd, and this dedication by him and the rest of the team to ensure best practice procedures in handling pelagic fish has resulted in discerning Japanese buyers now procuring mackerel on a regular basis from the processing facility

Combined mackerel exports from all Scottish processors to Japan have more than doubled in both volume and value between 2021 and 2022, underlining that this is a market with considerable potential for expansion.

Pelagia Shetland is playing its part in this growth and with landings of mackerel and herring into the processing facility set to increase over the coming years, the company will be looking to further develop the Japanese and other key markets.

“Maintaining the highest quality standards is key for us as we move forward, which is why we have invested in modern processing machinery and are embarking on constructing a major new coldstore facility, which will double our capacity,” Angus said.

Recent work by Lerwick Port Authority has reclaimed approximately 4,000 square metres of new industrial land at Arlanda East, adjacent to Pelagia Shetland’s factory, where the new coldstore will be built, with construction due to start later this year.

Maintaining the highest quality standards is key for us as we move forward

John Angus, Pelagia Shetland

The land reclamation part of the project received GBP 450,759 in grant from the UK Department for Environment Food & Rural Affairs (Defra) under round two of its UK Seafood Fund Infrastructure Scheme, with funding of over GBP 150,250 from the Port Authority.

“The great advantage here in Shetland is that we lie adjacent to some of the best mackerel and herring fishing grounds in the world, which means that boats only have to sail a short distance to land their catches,” Angus said. “This obviously makes economic sense for them, and from our perspective, it means that we are taking in the freshest and highest quality mackerel and herring. An added benefit is that because Lerwick is the closest fishing port to these rich grounds, there are less carbon emissions from the vessels landing to us.”

Paul Ratter, Quality Control Manager, oversees the quality and hygiene operation at the facility. Fish enter the factory from an adjacent landing quay at about -1.5°C, and great care is taken to move the fish quickly through the process to freeze as quickly as possible.

Quality and weight checks are continuously taken throughout the production to achieve a consistent product with as little variation as possible. Full traceability is demonstrated right back to where the fish were caught for each product. The fish are frozen whole and packed into 20kg cartons.

“It is an operation we take great pride in, and we have a fantastic team of people working here,” Ratter said.

As well as Japan, key markets for mackerel include other parts of the Far East and in eastern Europe, including Ukraine, Romania, and Bulgaria. The UK market is also important where most of the fish goes onward for secondary processing, including smoking and canning. To transport the frozen fish to export markets, reefer vessels berth at the quayside by the factory, for onward carriage to other distribution cold storage hubs in places such as Lithuania and the Netherlands.

Processing peaks

The main periods for handling mackerel catches from Scottish vessels are in the early part of the year in January and February, and then from the middle of October to the middle of November.

If a fishing access agreement is reached with Norway for UK waters, as happened last year, Norwegian boats land into the facility from the middle of September to early October.

For herring, the main landing period is August, and with there being a significant increase in the MSC-certified

North Sea herring quota for 2024, the coming season promises to be a busy one.

Most of the herring is filleted and mainly destined for markets in Germany and Poland. Herring roe is also produced, which is in strong demand in Japan, with the company having invested in specialised roe extraction equipment.

Pelagia Shetland employs around 35 people on a permanent basis, with the workforce doubling during peak landing periods. Traditionally, much of the extra labour required had been sourced from EU eastern European countries, but with the current challenges in accessing EU labour following Brexit, other avenues are being explored, including the successful hiring of peak period employees from Ghana and the Philippines.

The processing operation has come a long way since it was first founded as Shetland Catch in 1989 as a joint venture between the Lerwick Harbour Trust (now Lerwick Port Authority), the Shetland Fish Producers Organisation and Jaytee Seafoods. Over the period, increased automation has enhanced efficiency, and changes in the business structure led to Norwegian company Austevoll Seafoods becoming a shareholder. A series of company mergers in Norway in the years thereafter led to the formation of Pelagia, which has held a majority shareholding in Pelagia Shetland since 2016.

Green approach

The overall operation is complemented by the

nearby Pelagia Bressay factory, which processes the trimmings from processed mackerel and herring into high-grade fishmeal and oil. This ensures a highly efficient integrated operation, where all parts of the fish are utilised, ensuring environmentally responsible production.

According to Angus, sustainability and environmental protection are a key part of the ethos of Pelagia Shetland, which is why the investment of modern processing machinery and cold storage facilities is essential to ensure the lowest possible carbon footprint. Research has shown that Scottish caught mackerel is one of the lowest carbon footprint protein products around.

Ahead of the 5th Fish Waste for Profit conference in September, Iceland Ocean Cluster Founder Dr Thor Sigfusson tells WF that the 100% Fish movement is expanding its reach at great speed thanks to increased industry support and engagement, not least from the start-up community

WF: If you could sum up the 100% Fish initiative in a few sentences, what is it and why is it important?

Sigfusson: As I embarked on my journey with Icelandic fisheries, I encountered fishermen reminiscent of the trailblazers highlighted in “Good to Great” business literature – constantly striving to improve, particularly in maximising value from their side streams. Despite their 100% utilisation achievements, they remained humble. Their ethos inspired me to emulate their mindset and practices, especially given the stark contrast with the majority of fisheries globally, which waste between 30% to 60% of their harvest. This inefficiency not only squanders valuable resources but also contributes significantly to environmental degradation.

When meeting pioneers in seafood from different continents, you realise there are so many people in this industry who have the ambition to create value and jobs ‘‘

Motivated by the desire to instigate change, I envisioned a movement that would challenge the status quo: 100% Fish. This initiative encapsulates the ethical and environmental imperative of utilising every aspect of seafood production, whether from farmed or wild sources. By adopting a holistic approach to utilisation, we can unlock a wealth of benefits, including increased nutrition, job creation, product innovation, and value generation. Moreover, embracing the 100% Fish ethos aligns with Sustainable Development Goal 12, aiming to halve food waste by 2030. In essence, 100% Fish represents a compelling vision for a more sustainable and efficient seafood industry, one that resonates with both moral and practical considerations.

WF: What are the main short- and longer-term ambitions for 100% Fish?

Sigfusson: The ambition – or arguably the need – is to have all blue food producers accounting for 100% of everything they produce; wild-capture, farmed, shellfish, crustaceans, molluscs, everything. Shifting to 100% accountability is a useful step in the process toward the viability of 100% utilisation. Understanding operational changes, finding markets, supporting investment and entrepreneurs, creating new

products, all takes time and vision so, in the shorter term all systems moving to 100% accountability is an ambition, longer term: 100% utilisation. Producers will benefit from market support in this shift.

Our sense is that it will become a part of best-practice in time; for example, in MSC or in quota allocation, or in aquaculture licencing, BAP and ASC, which would accelerate progress. Our short-term plan also includes winning an Earthshot Prize for all those currently committed to 100% Fish around the world. The movement has been nominated, which is terrific.

WF: You have written a new book, also called ‘100% Fish’ – an extensive undertaking, with fantastic insights from the world of fish by-product utilisation. Is the hope that it inspires and accelerates further change in this space?

Sigfusson: My hope is that we can inspire and support countries and companies around the world in implementing their own 100% fish activities and fuelling the global entrepreneurial environment to see the establishment of exciting and creative seafood innovations that mean zerowaste for the world’s seafood. Tied in with improved global management and accountability of catch and oceans that have the health and resilience to sustain our future.

n Dr Thor Sigfusson, Founder of the Iceland Ocean Cluster and Chair of the 5th Fish Waste for Profit conference

WF: Researching and putting the book together, what initiatives and visions inspired you?

Sigfusson: When meeting pioneers in seafood from different continents, you realise there are so many people in this industry who have the ambition to create value and jobs. They are tackling different challenges, but their aim is to constantly to do better for their company, community and the environment.

WF: Iceland has been leading the way on this, particularly with innovation and entrepreneurship related to the utilisation of its whitefish. Can you outline some of the latest initiatives taking place in the country?

Sigfusson: In recent years, the fishing industry has seen unprecedented investment in innovative ventures, marking a significant shift. I see this surge in investment as unparalleled globally. I started the Ocean Cluster House with a support from the Port Authorities in Reykjavik and backing of seafood companies like Brim. Now, new spaces are being created in other parts of the country; Breið in west Iceland backed by Brim Seafood and Drift in north Iceland backed by Samherji. These activities exemplify the direct engagement of fishing corporations in the innovation sector. Such active involvement by influential companies is poised to become a pivotal force in reshaping innovation and the fishing industry in the foreseeable future. We need to inspire other large seafood companies to do the same in other parts of the world!

Fish Waste for Profit has been one of the cornerstones of 100% Fish and opened a great opportunity for 100% fish enthusiasts to meet and share ideas

WF: The innovation hasn’t stopped there. We’re also seeing several initiatives utilising fish by-products popping up around the world, which ones in particular have caught your eye?

Sigfusson: Multiple start-ups have been established with various products in the field of beauty and health, nutraceuticals (supplements), medicine, leather, omega-3, and enzymes to name few. Here we can name Kerecis, Nordlaks, Zymetech, Nordic Fish Leather, Marine Collagen and Ballstad to name just few. I am also a dedicated follower of some start-ups utilising crustacean shells, for instance Genis in Iceland and Marin skincare in the US. Our collaborations in 100% fish with the Great Lakes in the US, Namibia, the Pacific Islands and Korea to name few, have been very promising. For me, it is crucial to build the community of collaboration first and that has been very fruitful so far.

WF: Have you identified any new opportunities for utilising by-product materials that are ripe for progress?

Sigfusson: Icelandic R&D is observing both the eye liquid from the cod and perch, blood from whitefish and salmon. The Icelandic HPP Protein plant Ltd is also working on making fishmeal into pure protein. Every day is an innovation day here at the Iceland Ocean Cluster! Our latest start-up tenant in the Ocean Cluster House is Sea Growth. Their aim is to produce raw fish products from fish cells, so-called “ecological fish”.

WF: We’re seeing more and more interest in this space, but it’s likely there are many people and organisations that are not sure where to start. What advice would you give them?

Sigfusson: I believe we need to bring the start-up world into the picture; something that’s totally lacking in many countries. The bottom-up approach has been very lucrative in Iceland. The fishermen are contacted by start-ups and innovators and assist them by providing them with by-products and other support. Sometimes I feel that fishermen are sceptical that we all believe they can become pharmacists – developing high end pharmaceutical products from their products. We need rather to take it step by step; walk slowly up the value line, beginning with ideas regarding simple fishmeal production from side streams, then maybe up to some nutraceuticals etc.

WF: What can be done at industry, policy/regulatory, investor and research levels to ensure the 100% Fish message spreads fast and far enough?

Sigfusson: We have had difficulties in getting European regulators to accept some of our by-products for human consumption. We need to move some of the hurdles that are in the way of full utilisation. Sometimes, people are suggesting government should step in, full force and ban wasting of by-products. I believe we should allow the industry to develop further a 100% mindset rather than relying on government. Governments should support R&D and start-up accelerators.

WF: Where do consumers fit into this picture?

Sigfusson: Peter Handy, owner of Bristol Seafood in Maine, USA, says in my book: “One of the things I hear the seafood industry loves to say, and it’s always rubbed me the wrong way, is that we must educate the consumer. To me, that’s always just sounded arrogant. And I think what we should try to do is to be educated by the consumer. Rather than to tell them why they should eat what we make, why don’t we figure out why they’re not eating it.” I think this sums well up how we need to connect with consumers differently than we have so far.

WF: Last but not least, the 5th Fish Waste for Profit conference is taking place in Iceland this September as part of the IceFish 2024 programme. What are you most looking forward to about this year’s conference?

Sigfusson: Fish Waste for Profit has been one of the cornerstones of 100% Fish and opened a great opportunity for 100% fish enthusiasts to meet and share ideas. We are already receiving very interesting ideas and suggestions for topics that I believe will make the next conference a very dynamic event.

Spatial planning is key to establishing shellfish and seaweed farms in ports and benefitting local communities and environments, says a new study. Bonnie Waycott reports

Over the years, there has been much focus on the coexistence of offshore renewable energy and aquaculture, two rapidly growing industries that share a common resource: the ocean. Bringing these two industries together has the potential to generate economic, environmental, and social benefits, while addressing multiple challenges from food scarcity to climate change.

The same could be said for aquaculture and maritime ports. As ocean-based industries continue to expand, careful spatial planning is important to reconcile existing ocean uses and manage environmental impacts effectively. In January 2024, a team of marine spatial planning researchers from the NOAA National Centers for Coastal Ocean Science (NCCOS) and the Port of San Diego released a study on spatial planning methods for aquaculture siting.

The goal is to ask whether aquaculture can be accommodated within and around San Diego Bay, a highly trafficked maritime port, and determine the most suitable species and farming practices for the area.

“NOAA has been building programmes on spatial planning, siting and environmental modelling for aquaculture for the past 10 years,” Dr Ken Riley, science branch chief at the NOAA Fisheries Office of Aquaculture, told WF. “The first place to start with aquaculture development is real estate; how do you find the right location? Where is the best location a farm could be built, and the environment could sustain it?”

‘‘

We are in the midst of a major local food movement in San Diego and southern California and want to be better connected to our foodKen Riley, NOAA Fisheries

Riley continued: “We are in the midst of a major local food movement in San Diego and southern California and want to be better connected to our food. The ocean is the next opportunity to farm and produce food for southern California, and the state is already well known for its agriculture. It’s extremely exciting to see how much farming seafood in coastal areas will mean for California’s agriculture.”

Establishing partnerships

Using exclusion analyses and a multi-criteria decision analysis approach, Riley and his team identified specific areas suitable for shellfish and seaweed aquaculture, considering environmental conditions and compatibility constraints. One unique feature of the Port of San Diego, Riley said, lies in areas that could potentially support shellfish and seaweed farming. While working to identify opportunities to grow mussels or kelp in those areas, Riley and his team also focused on 16 to 17 local species

of shellfish and seaweed that grow well and are readily adapted to the environment surrounding the port.

“Starting with almost 50,000 acres, we first identified over 9,000 acres that offer promise for aquaculture development,” said Riley. “Our recommendation is that the port partner with local universities and the aquaculture sector to develop, observe and conduct pilot projects to validate the projected growth and performance of different species. Our aim was to identify areas that the port could use and help it decide where pilot activities could occur. Restoration is also a focal area. Abalone species, for example, are declining significantly and may benefit from restoration programmes.”

Having identified exclusion zones such as major shipping and navigation routes, mooring fields, areas for sailing, naval and maritime activities, potential sources of pollution and areas that would require major efforts to get aquaculture approved, a culture systems analysis was carried out. This involved investigating different species and culture system combinations to identify where different systems had potential for success and to gain a detailed understanding of the necessary environmental parameters with regards to culture, equipment and species combinations.

“This is the next step in spatial planning, because an exclusion analysis only reveals the areas where aquaculture could potentially succeed,” said Riley. “The greatest opportunities in and around the Port of San Diego are the farming of oysters and small-scale seaweed farming. Conversations began six to eight years ago at the port on developing the blue economy, with aquaculture and restoration a big part. We now have a follow-on study that looks at the ecosystem services and habitat considerations for aquaculture and restoration projects and how they could go ahead in certain areas, including a former site for marine debris that was restored through NOAA funding.”

are

As aquaculture continues to grow along the US Pacific coastline, the work by Riley and his team offers insights that extend beyond conflict avoidance. By identifying areas with potential for successful aquaculture development, the research supports the growth of sustainable aquaculture and other blue economy industries in and around the Port of San Diego, highlights how ecosystem services from shellfish and seaweed farming can benefit the area and sheds light on bigger issues such as climate change, rising sea levels and what these might mean.

Efforts are also being made to engage with public perceptions and misperceptions of aquaculture and better understand these by working with communities to grow the social acceptance of aquaculture. With plenty of national attention on work by San Diego to achieve its blue economy objectives, feedback has been positive, said Riley, who highlighted that his work is a positive example of marine spatial planning that can be replicated in other ports around the US.

While the study showcases how marine spatial planning can be a powerful tool for decision-making in the development of industries like aquaculture, Riley acknowledged that there are several steps to take to enable shellfish and seaweed farms to operate with minimal disruption in areas like ports.

“NOAA is conducting a number of studies in smart engineering, smart design and smart siting,” he said. “It’s also looking at rising sea levels and increased energy in particular environments, what this might mean and how to make sure that shellfish and seaweed farms are secure, for example anchoring and mooring for stable production systems and minimising biofouling to produce healthy shellfish.

“There are also permitting and regulatory considerations to go through, as well as environmental impact statements. Before establishing shellfish and seaweed farms in its jurisdictional waters, the port will have to work with the state of California and think about comprehensive environmental assessments.”

Riley and his team have demonstrated that even a busy port like the Port of San Diego can accommodate aquaculture, underlying the important role of spatial planning approaches

in economic development and environmental sustainability.

The port is now partnering with seaweed farm Sunken Seaweed, San Diego State University and Hubbs SeaWorld Research Institute to explore seaweed production in the port and the waters off California.

A pilot project is underway to better understand engineering, farming and harvesting, and the necessary economic business model for seaweed farming.

Land-based infrastructure at the port such as processing facilities, cold storage and shipping and transport logistics are also key parts of the work, along with workforce requirements and education and training to build that workforce.

“There is a realisation that there’s a gap in southern California, in which the area is not producing as much as other waters around the US,” said Riley. “We’ve worked for over a decade with the port of Ventura, a little further north of San Diego, with Los Angeles and the port of New Bedford, the largest commercial fishing port in the US. There is a lot of conversation with other ports, but our San Diego study was the first. It’s the seed that spawned the conversation, and we’re excited to see how things develop.”

Markus Lifenet ehf

Specialized in development and manufacturing of man overboard recovery systems. Most known for the Markusnet type MS and the variety of Markus Scramble-nets type SCN, Markus Emergency ladders type MEL2/SCN2 and Throw-line type RLC. www.Markusnet.com

MOB Boat Rescue-net

Light, quick fastening, takes little space, provides easy and fast method to place the casualty in the net, is soft but firm around the casualty, provides easy lift by one or two persons and is easy to repack after use

For upto 1,8 metre freeboard. Provides safe passage back on board at the side of the boat, can be pulled down from the water and it is made to go 1 metre into the water in lowered position.

Markusnet

For commercial and leisure. Lloyd´s Register EMEA type certified for ISO19898/2019

For all types of ships and boats. Ideal to carry on hikes near water.

Factory trawler Berlin NC-107 has joined the DFFU fleet, delivered by Norwegian shipbuilder Vard. The triple-rig trawler has capacity for processing both whitefish and shrimp onboard

Cuxhaven company Deutsche Fishfang Union opted for the Vard 8 03 design, developed by Vard’s Ålesund design team, and this is the latest in a series of trawlers delivered by the yard to operators in Norway and the Faroes Islands. The 84.4-metre newbuild has a beam of 16.7 metres and the hull was built at Vard’s Braila yard in Romania, and brought via a roundabout route – due to the uncertain situation in the Black Sea – to Brattvaag in Norway for outfitting.

“The delivery of Berlin NC 107 is pivotal for DFFU, and Vard has done an excellent job. Over the years, Vard has built several technologically advanced vessels, consistently meeting the highest standard with their craftsmanship and innovation,” stated DFFU Managing Directors Baldvin Thorsteinsson and Samuel Rodriguez.

“Berlin is equipped with advanced technical solutions from trusted partners. One significant change with this new vessel is its shrimp-catching and processing capabilities, enlarging the portfolio of products produced onboard. The production of whitefish has also been upgraded with new equipment, which increases options in production and expands our product range. The technology and equipment onboard will enable us to bring 100% of the catch to shore. This supports our goal of increased value creation at sea and directly aligns with our sustainability efforts.”

The heart of a fishing vessel of this kind is the processing deck, and Berlin has a factory deck outfitted by Optimar for a variety of production modes and to make full use of everything that comes on board as efficiently as possible.

The primary focus is on cod, haddock and saithe fillet production, with catches passing through the pair of Vélfag 500 heading machines to the Vélfag 525 and Breivik 290 filleting machines. The Marel waterjet portioning machine removes bones from fillets and is able to produce portions, loins, and tails to specifications as the market requires.

Packed fillets go to the bank of three automatic Optimar freezers, and frozen production passes to a freezing hotel where a robot collects cartons onto appropriate pallets before an elevator takes them to the refrigerated fishroom.

Production is designed with a high level of automation, with no human interaction needed for handling production once it leaves the freezers. The focus on automation throughout the production process minimises physically demanding tasks and the risk of accidents.

Alongside fillet production, a Sepamatic 6000 system processes heads and offal into mince for feed production and also processes backbones and offcuts into human consumption-grade mince. Ensilage tanks on board hold any remaining production waste so that nothing goes

n DFFU’s new factory trawler is skippered by Sigurdur Óli Kristjánsson and Teitur Björgvinsson

over the side with the exception of some bone material. Fish skins are graded out and frozen separately as these are used tp produce collagen for food supplements and cosmetics.

Also on Berlin’s factory deck is a full shrimp production line with a Style grader and two Connie cookers from Carsoe. Processed shrimp are passed through the individual quick freezing tunnels to produce a consumerready product.

Berlin’s deck is laid out with electric deck machinery from Seaonics, including four main trawl winches. This provides opportunities for triple-rig trawling, primarily when fishing for shrimp. Seaonics also delivered the eight sweepline winches at the head of the full-length trawl deck, a net drum mounted over the deck, three gilsons, an netsounder winch and smaller winches.

Cranes are a 3.75-tonne unit on the foredeck, and a pair of 8-tonne/7.5-metre deck cranes aft that have a working radius of 16 metres with a safe working load of 3.75 tonnes.

‘‘The delivery of Berlin NC 107 is

The main engine is a 5400kW Bergen B33:45L9, powering a 4-metre diameter controllable pitch propeller. The energy installation on board Berlin includes a 2500kW shaft generator, a 1785kW Caterpillar 3512 generator and a 640kW Scania CV DI16M 90M emergency generator. This is complemented by a 316kWh energy storage system that holds excess power generated by the permanent magnet motors on the trawl winches when shooting away the trawl gear. Energy from the batteries is released automatically to the vessel’s power network when required, such as when experiencing sudden load changes.

The main engine has modes that allow for optimised fuel consumption according to the required load at any given time. This is achieved by alternating RPM and VVT (variable valve timing) to achieve maximum fuel efficiency. While not a new concept, this represents a significant advance over past engine designs. In the past, larger engines meant higher minimum fuel consumption at the lowest load, and maximum fuel efficiency was fixed within a specific load range. This limitation meant the vessel was not operating within the optimal range at other load levels, posing a challenge for vessel operators who needed an engine robust enough for fishing operations yet efficient enough to minimise fuel consumption during transit.

For companies operating vessels that travel long distances between port and fishing grounds, achieving optimal fuel efficiency during these transfers and during fishing is crucial.

“There is growing pressure on the fishing industry to adopt environmentally friendly practices,” a DFFU representative commented. “This pressure stems not only from regulatory authorities and public opinion but also from our own commitment to sustainability. We strive to go beyond the basic requirements by implementing practical solutions across our fleet whenever possible and maintaining high maintenance standards. We also focus on educating our crew and fostering a company culture prioritising energy saving.”

In addition to a high-quality working environment and greater automation on board, with attention paid to ensuring healthy acoustics on the factory deck, Berlin has excellent crew accommodation, designed to maximise daylight levels.

The latest in a series of factory trawlers for the Russian Fishery Company has been delivered by Admiralty Shipyards in St Petersburg

The 108-metre LOA, 21-metre breadth Kapitan Martynov is the fourth in the Russian-built series of ST-192 factory trawlers designed to fish for Alaska pollock and herring in the Bering Sea and Sea of Okhotsk.

These trawlers are designed for a catch rate of around 60,000 tonnes annually, and the overall planning is to replace the company’s fleet of ageing Soviet-era tonnage with a smaller number of more efficient vessels with more economic running costs and lower emissions.

The factory deck onboard Kapitan Martynov has capacity to produce fillets, mince, surimi, fish oil and fishmeal, as well as having a canning plant for roe and other products. The freezing capacity for fillets is around 80 tonnes per day and there is also an 80-tonne/day surimi plant. The meal plant is capable of producing approximately 40 tonnes per day. The refrigerated fishroom space measures 5,620 cubic metres.

Kapitan Martynov follows new trawlers Kapitan Vdovichenko, Mekhanik Maslak and Mekhanik Sizov, all

Icelandic fishing, processing and aquaculture company Hraðfrystihúsið-Gunnvör has placed an order for a new factory freezer trawler to be built at Astilleros Ria de Vigo, the former Barreras shipyard which has been acquired by Astilleros Armón, enabling the yard to expand its activities in Vigo.

The delivery of the new vessel is scheduled for the second half of 2026, and it will replace the company’s current factory vessel, the 57-metre Júlíus Geirmundsson ÍS-270 which was built in Poland in 1989.

Hraðfrystihúsið-Gunnvör went back to Skipasýn for the design of the new factory trawler, as its Skipasýn-designed fresher trawler Páll Pálsson has performed extremely well since it was delivered to the company six years ago.

The new factory trawler will have dimensions of 67.1 metres overall with a 16-metre beam, and the same principles as went into Páll Pálsson’s design are applied to the newbuild, with a 3,600kW MAN main engine driving a slow-running, large-diameter propeller of not less than 5,000mm, to deliver a bollard pull of 76 tonnes. This is a combination that delivers economic performance, and energy economy is a key aspect of the overall design – as is crew comfort.

The working environment is also designed to ensure the best possible working conditions with minimal heavy lifting. The processing deck is to be outfitted with catches routed via the heading machines to RSW-cooled pounds before passing to the filleters or to vertical plate freezers. Filleted fish go to trimming stations before being packed

and frozen in an automated freezers system.

Frozen production is channelled to boxing and from there to a computer-controlled freezer hotel for automatic palletisation, wrapping and transfer via an elevator to the refrigerated fishroom. Technology to produce fish oil and side-stream products is part of the design.

Hraðfrystihúsið-Gunnvör operates two trawlers, shorebased production and a canning plant.

n New Júlíus Geirmundsson is a Skipasýn design. It features a slowrunning, largediameter propeller

Assurance and risk management

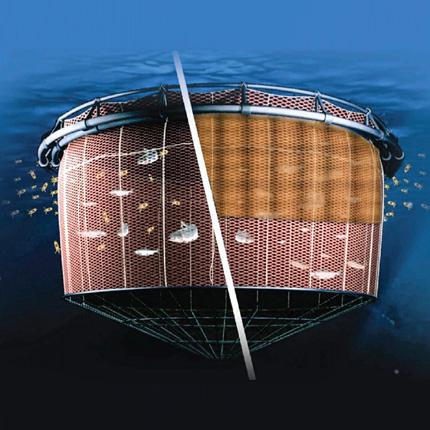

provider DNV and Ocean Sovereign have obtained French registration for the deployment of fish farming vessel Ocean Ark

Ocean Ark, a patented, advanced self-cleaning trimaran superstructure, was developed by Ocean Sovereign according to Marpol, Solas and IMO regulations. The vessel is designed with low density to operate in high offshore waters, drifting with the natural current and natural fish shoals. It is designed to ensure sufficient safety for the environment, fish and crew.

According to Ocean Sovereign, Ocean Ark’s mobility will help to ensure the health and welfare of the fish and ensure the fish are kept in their natural habitat.

DNV will support Ocean Sovereign with businesscritical challenges and innovations, designed to prevent fish escape and reduce risk of technical failure in operation. To achieve this, it will set up a regulatory framework to fulfil local requirements in alignment with the rules and standards of French authorities.

The project team advise that deploying Ocean Ark away from marine heatwaves, algae blooms and storms – “aquaculture’s three Achilles’ heels” – will increase fish welfare, produce higher quality protein, and increase world fish production without increasing pressures on fish stocks and coastal habitats.

“Offshore fish production is based on a combination

of two well-known concepts, fish farming and offshore technology, and therefore a cross-industry approach and know-how is needed,” Ocean Sovereign General Manager Zeyd Fassi Fehri said.

In addition to its high-quality standards and being Europe’s largest market for salmon, France also has one of the world’s largest maritime exclusive economic zones across the ocean.

Innovation | Industry insight | Knowledge sharing

visit: www.worldfishing.net/FWPCONFERENCE

contact: +44 1329 825335

email: info@icefishconference.com

DAY ONE – Thursday 19th September 2024

08:45 Coffee & Registration

09:15 Chairman’s Welcome

Thor Sigfusson, Founder and Chairman, Iceland Ocean Cluster

09:30 Gold Sponsor Welcome:

09:40 Keynote Address: Impactful partnerships for full utilization

The power of partnerships – how teaming up and collaborative relationships can accelerate full utilisation; what are the current available support systems for startups. Global collaborations that are making 100% fish impactful.

Alexandra Leeper PhD, Managing Director - International, Iceland Ocean Cluster

David Naftzger, Executive Director, Great Lakes St. Lawrence Governors & Premiers Namibian Ocean Cluster

10:20 Q&A

10:40 Coffee & Networking

Growing emerging opportunities linked closely to partnerships in the circular economy and opportunities that connect land and sea and cross sector - pharmaceuticals, nutraceuticals, feed, pet foods, biofuels, and fertilizers etc. Nutritional value of these new products where relevant for consumption/feeds.

11:10 Jónas Rúnar Viðarsson, Director of Business and Development, Matis

11:30 Rune Frostad, CEO, Pretio

12:10 Q&A

12:30 Lunch & Networking

SESSION 2: GOING FROM GREAT RESEARCH TO A PRODUCT ON THE MARKET Fireside chat, Mini-discussion session

Moderator: David Naftzger, Executive Director, Great Lakes St. Lawrence Governors & Premiers

14:00 Regal Springs*

14:20 Kerecis*

14:40 Runar G. Solstad, Senior Scientist Marine Biotechnology, Nofima

15:00 Q&A

15:20 Coffee and Networking

AI, digital technology, and applications in commercial fishing/aquaculture by-product production, trends in market demands and consumer needs. Automation and processing technologies.

15:40- Moderator: Thor Sigfusson

16:40 Anton Heiðar Þórólfsson, XR and Simulation Technology Manager, Marel

16:40 Q&A

17:00 Chairman’s Close

17:10 End of Conference Day 1

17:10-18:00 Networking and Drinks Reception

DAY TWO – Friday 20th September 2024

09:00 Coffee & Registration

09:30 Chairman’s Opening & Summary of Day 1 – Thor Sigfusson

Energising the industry for investment (what do investors want from start-ups), IPR (Intellectual Property Rights) opportunities/processes/assistance for start-ups, business models options.

10:45 Coffee & Networking

11:10 Mini – Pitch session and Panel Discussion from Session 4

12:20 Conference Wrap up – Thor Sigfusson

12:30 Lunch & Networking

14:00-16:00 Transfer to visit the Icelandic Fisheries Exhibition

Fee Includes

• Conference attendance 19-20 September 2024

• Full documentation in electronic format

• Lunch and refreshments on conference days

• Free time at Icelandic Fisheries Exhibition

Booking Online https://www.worldfishing.net// FWPBOOK or complete and fax the booking form below to +44 1329 550192. On receipt of your registration, you will be sent confirmation of your delegate place.

For further information on exhibiting, sponsoring, or attending the conference, contact the Events team on: +44 1329 825335 or info@icefishconference.com

Location

Grand Hotel, Reykjavik on 9-10 June 2022

Visit https://www.worldfishing.net//FWPBOOK to register

Please tick all that apply:

(Please copy this form for additional delegates)

Please register me for the Fish Waste for Profit Conference 2024

Time at Icelandic Fisheries Exhibition - No additional cost

Members of supporting associations will receive a 10% discount I am a member of

Family Name............................................................................................................. Country ....................................................................................................................

First Name Telephone

Title Mr/Mrs/Ms/Dr/Other Fax

Company Email

Job Title Signature

Company Address

Company VAT No.

HOW TO PAY *UK registered companies will be charged the std rate UK VAT, Icelandic Companies will be charged std Icelandic VAT

Bank Transfer: Mercator Media Ltd, HSBC Bank plc, GBP account, Sort Code: 40-21-03, Account number: 91894919

SWIFT/BIC8: HBUKGB4B BRANCH BIC11: HBUKGB4131C, IBAN: GB61 HBUK 4021 0391 8949 19

Bank Transfer: Mercator Media Ltd, HSBC Bank plc, EUR account, Sort Code: 40-12-76, Account number: 70235247

SWIFT/BIC8: HBUKGB4B BRANCH BIC11: HBUKGB41CM1 IBAN: GB35HBUK40127670235247

Bank Transfer: Mercator Media Ltd, ISK account, Landsbankinn, Personal ID (Kt.): 560307-9770, Account number: 0115-26-060307 (N.B This payment option is for Icelandic companies paying in ISK only) Standard Rate Icelandic VAT applies

NB: Prepayment is required in full for entry to the conference. Please fax form. Do not send by email as we Cancellations are not permitted, however substitutions are allowed. cannot guarantee the security of card information.

Credit/Debit Card: Complete the form with your card details

I have paid by bank transfer

Please charge my card (delete as appropriate) Mastercard/Visa/Amex Card Number Expiry Date

We look forward to welcoming you in September

The Icelandic Fisheries. Seafood & Aqua Exhibition hosts the latest developments from the industry showcasing new and innovative products and services, covering every aspect of the commercial fishing industry from catching and locating to processing and packaging, right through to marketing and distribution of the final product.

For more information about exhibiting, visiting or sponsoring, contact the events team

Visit: Icefish.is

Contact: +44 1329 825 335 or Email: info@icefish.is

A collaborative project between a group of partners to recycle nylon fishing and aquaculture gear could become an industry turning point, depending on the outcome of full-scale trials now in progress

Recycled fishing gear is not new, and a number of companies around the world are working with fishing and aquaculture gear to turn it into something useful instead of it becoming landfill – but there are a number of challenges associated with this, not least that there’s only so many times that the shredded material can be recycled, losing some of its strength and other qualities with each successive generation.

The Circular Fish Farming Nets (CFFN) project aims to recycle nylon using a different approach, which is predicted to maintain all of the strength and other qualities of virgin material – and it’s nominated for the Aquaculture Awards 2024.

The CFFN project is an exciting opportunity for Hampidjan Group to offer its customers a circular product with a major savings in carbon

Hampidjan ‘‘

The key to this recycling method that the CFFN project is exploring is the depolymerisation of end-oflife nylon, which has already been practiced for years by Aquafil, one of the project partners. This chemical process disassembles the polyamide back into a base oil that can be used to create new PA6 polymers.

Financed by the Norwegian Retailers Recycling Fund, the CFFN is a collaboration between Hampidjan Group, Nofir, Aquafil, Akva Group and Grieg Seafood and the aim is 100% recycled nylon as a one-to-one replacement for virgin nylon. Now about to enter testing at full scale for a normal cycle of usage, this has far-reaching implications for the fishing gear and aquaculture equipment sectors.

“This process creates a new feedstock for fibre production that is now being utilised for the first time in the production of fibres in the quality and strength that the aquaculture industry requires,” a Hampiðjan representative said, commenting that nylon is used heavily in aquaculture installations, purse seine fishing gears and heavy-duty codends for a variety of trawl gears.

Using this process has the potential to be transformative for the future sustainability of the aquaculture and fishing sector, and presents for the first time alternatives to disposal or processing via mechanical recycling.

“The CFFN project is an exciting opportunity for Hampidjan Group to offer its customers a circular product with a major savings in carbon emissions through the entire value chain of nylon. It will also be a guideline for what is possible in this sector through co-operation across the industry,” Hampiðjan states.

“Hampidjan Group will, in close cooperation with its subsidiaries Hampidjan Baltic, Vónin, and Mørenot, produce one full-sized aquaculture cage and as will Akva Group. Fibres and netting will be vigorously tested to demonstrate the ability of the recycled material to match the performance of ‘virgin’ nylon. The full cages will then be used at Grieg Seafood sites for a full normal cycle.”

Representatives of the companies participating in the CFFN project

The decision by David Lovie to rig his new trawler with a pair of Vónin’s Storm trawl doors when he took delivery of the 34-metre Endeavour V owed a lot to his uncle Mark Lovie’s success with these doors on Venture

That was back in 2020, and now Endeavour V is on its second set of 4.5-square-metre Storm trawl doors that have now been in use for more a while and show no signs of being near replacement yet.

“The Storm doors have proven to be powerful, highly durable and robust,” David Lovie said of the original set of doors that Endeavour V started out with. “Unlike our previous doors that required replacement every 12 months, we were able to use these for a remarkable 31 months before considering a replacement. In fact, the first minor maintenance we performed was after a substantial 24 months of use.”

His faith in Vónin has been taken a step further, and last year he went to the flume tank in Hirtshals to observe a variety of fishing gears – and immediately liked the look of the Zenith groundfish trawl. The outcome was an order a Zenith 572 trawl, which has met all of his expectations.

“The Zenith trawl and the Storm doors are a perfect match,” he said, commenting that the Zenith trawl meets the main requirement, as it fishes well, with excellent spread and headline height of eight metres, and it doesn’t do any harm that it’s light to tow.

This is a legacy of Vónin’s Fortis netting, formulated for a combination of high strength and stiffness, which provides the company’s designers with new options to scale down twine sizes in fishing gears, and took full advantage of the possibilities offered by Fortis netting as a starting point in

the Zenith design.

Although the Zenith design has fewer meshes in the fishing circle than comparable trawl gears, by optimising cutting rates and hanging ratios, Vónin’s designers have been able to produce a compact trawl that outstrips other gears in terms of headline height and horizontal spread, while maintaining steady ground contact.

“Everything Vónin has promised has met David’s expectations and when a client returns, it’s clear evidence that they’re happy with our gear,” said Vónin’s Jan Klein.

Thyborøn Trawldoor’s Icelandic agent Hampiðjan Ísland has confirmed an order for a pair of fully controllable doors for fishing company Gjögur, which operates pelagic vessel Hákon ThH-250

Gjögur’s new Hákon is under construction in Denmark and is due to be delivered in mid-2024, and will start fishing with a pair of 12 square metre, 4,700kg Type 42 doors. These are the first fully controllable pair of doors to be supplied to an Icelandic fishing vessel by Thyborøn, which has since 2017 been producing doors with foils that can be adjusted between tows using a hydraulic jack.

The arrival of Type 32, and more recently the Type 42 Bluestream doors, has introduced upgraded technology, including lithium batteries, servomotor control and a pair of transducers installed on the catching vessel’s hull. All this makes it possible to make the trawl doors fully controllable from the wheelhouse during fishing operations.

All of the hardware fitted to the trawl doors, as well as the software for the wheelhouse, has been developed by Thyborøn, with the exception of the batteries. These are lithium batteries with an endurance of up to 40 hours, even with the doors in constant use, before needing to be recharged.

Charging for two hours is enough to bring the batteries up to an 80% charge, and the full 100% charge takes roughly three hours.

The control system as a whole can be re-used when the doors come to be replaced. Today there are 12 fishing vessels using Thyborøn’s Type 32 doors and three fishing with Type 42 Bluestream doors, plus four more pairs are in production.

•

•

•

Shetland Fish Producers’ Organisation has bought a pair of the CatchCam gear-mounted cameras developed by SafetNet Technologies for use by member vessels, and these have already provided positive results

The CatchCams are rigged to the trawl gear, allowing recorded footage to be retrieved and when the gear is hauled, and for skippers to then make alterations to improve efficiency and to filter out by-catch, as well as reducing drag to minimise fuel consumption.

“Using the CatchCam meant you could see if your net was properly on the bottom, if the hoppers were hard down or bouncing along. If your net is light on the bottom, you are not going to be catching species like monkfish, and you are just wasting fuel. We were able to make adjustments to correct this,” reported Ellis Fullerton, skipper of Angelina LK-377.

‘‘

It’s great that the PO has invested in these, giving everybody in the fleet a chance to make their fishing more efficientemissions through the entire value chain of nylon

Ellis Fullerton, Angelina LK-377

“For me the best thing about using it was peace of mind. It answered a lot of questions that I have had for many years of fishing. There is nothing like seeing what goes on with your own eyes via the camera. It’s great that the PO has invested in these, giving everybody in the fleet a chance to make their fishing more efficient. It’s much needed as fuel is so expensive.”

Ian Shearer, who skippers Courageous LK-470, said that after some trial and error, he and his crew were able to make some alterations to their towing to improve their technique.

“We found them really good, easy to use, and would certainly like to have another go again in the future,” he said.

“Our fishing crews in Shetland are committed to sustainable and efficient fishing methods, and our investment in this technology will support them in understanding and adapting their fishing gear with even greater confidence than was previously possible,” SFPO chief executive Brian Isbister commented.

“Early uptake from our member vessels has been encouraging, and we’re confident that these CatchCams units will be an excellent tool in continuing to work towards the long-term aspirations that we in Shetland have for our fisheries, and our community.”

Shark monitoring and safety onboard among the potential new uses of recovered buoys.

Spanish technology company Satlink has launched the first programme for the reuse of smart buoys for tropical tuna fishing in the Atlantic Ocean with NGO Project Biodiversity of Cape Verde. The collaboration between the two entities is part of Project ReCon, the international initiative founded by the Spanish company and the Australian NGO Tangaroa Blue Foundation.

Dedicated to the conservation of marine ecosystems and the protection of protected species and habitats, Project Biodiversity joins the project with the aim of reconditioning these buoys to enhance shark monitoring, signal protected marine areas or promote on-board safety, among other potential uses.

Project ReCon is now present in nine countries and the three main oceans (Pacific, Indian and Atlantic). This project, launched by Satlink in 2022, has set up an international collaboration network between fishing companies around the world and local environmental organisations to recover, recondition and reuse these buoys for scientific and environmental purposes.

In addition to Cape Verde, ReCon in present in Australia, Papua New Guinea, Micronesia, USA (Palmyra), Marshall Islands, Cook Islands, Wallis and Futuna and New Caledonia.

The buoys incorporate echo sounders that detect the abundance of fish under the device, making them ideal for being reused in small-scale scientific studies, as well as marking and monitoring marine debris or preventing natural disasters.

Since starting in Australia with founding

n Rigged to a set of trawl or other fishing gear, the Catch Cam provides footage of the fishing gear in use, enabling crews to make adjustments to improve performance

partner Tangaroa Blue Foundation, Project ReCon has become an important fishing sustainability initiative, with the collaboration of other leading environmental organisations such as The Nature Conservancy (TNC) and The Pacific Community (SPC).

More than 100 vessels from 22 companies and organisations, such as Albacora, Echebastar, Inpesca, OPAGAC/AGAC, Sapmer, Bolton Food Group, Cape Fisheries, Caroline Fisheries Corporation, Trimarine, Oakcity Tuna Fishing Corporation, Hartswater, and US Pacific Tuna Group are participating in the project.

ReCon was recently awarded the Tuna Awards 2023, granted by AnfacoCecopesca and the Spanish Ministry of Agriculture, Fisheries and Food for its pioneering nature and its contribution to the fishing industry.

New innovations can steer fish farms towards more sustainable disease prevention, writes Bonnie

WaycottAs the fastest-growing food sector today, aquaculture has become a huge industry, with production accounting for over 50% of total global aquaculture and fisheries output. But as farmers densely pack offshore pens, ponds and tanks to meet the demand for aquatic food, contact between the fish increases, leading to increased disease transmission. Some deem these practices unsustainable and suggest they have a wider impact of spreading disease to already-vulnerable fisheries and negatively impacting the environment.

On a global scale, disease in aquaculture results in US$ 6 billion’s worth of losses each year, with significant challenges remaining despite advancements in vaccines and management practices. Meanwhile, the effects of antibiotics on humans and the environment continue to be a serious concern. As part of aquaculture’s growth and efforts to improve disease resistance and sustainable practices, companies and scientists are now proposing alternative concepts to control disease without resorting to chemicals or antibiotics.

In January 2024, scientists at the United States Department of Agriculture (USDA) announced the development of a green antibiotic alternative to treat the pathogen Streptococcus iniae in hybrid striped bass. S. iniae is the causative agent of streptococcosis, a prevalent disease that can bankrupt fish farms and put farmers at risk when handling infected fish.

‘‘

Aquaculture is increasingly seeking sustainable solutions for disease management beyond traditional antibiotics

Professor Daniel Nelson, University of Maryland

According to USDA figures, streptococcosis causes a worldwide economic loss of US$150 million each year.

“Losses from S. iniae specifically related to hybrid striped bass remain unknown, mostly because the species’ market is relatively new in aquaculture,” Professor Daniel Nelson of the Department of Veterinary Medicine at the University of Maryland told WF. “However, two of the largest hybrid striped bass start-ups in the US were permanently closed due to S. iniae outbreaks that occurred from interconnected RAS systems whereby the bacteria spread from tank to tank. As hybrid striped bass farming expands, we will closely monitor the incidence of S. iniae.”

Green alternatives

Together with Professor Nelson, the USDA team developed a novel antimicrobial protein and treatment regimen that

kills Streptococcus bacteria without leaving chemical residues in the environment. Known as ClyX-2, the protein is an endolysin; bacteriophage-derived enzymes that are typically active late in the bacteriophage infection cycle.

They rapidly cleave bonds that are essential for the stability of the bacterial cell wall. When applied directly to susceptible bacteria in a purified form, they can rapidly hydrolyse the bacterial cell wall, resulting in the osmotic lysis and death of the organism. They are not chemicals like antibiotics, Nelson said. Nor do they accumulate, leave behind a residue or enter the environment or food stream. Instead, they are simple proteins that break down into basic amino acids that are re-utilised by cellular pathways. As such, they are classified as a “green” alternative to traditional antibiotics.

“ClyX-2 is an engineered endolysin,” said Nelson. “It’s a chimera, in other words a fusion of two naturally occurring endolysins that we created in the laboratory. We’ve created dozens of such endolysins and ClyX-2 happens to be the best one at lysing S. iniae. Another exciting point about endolysins is that the species of fish you are treating does not matter because the endolysin only kills the Streptococcus bacteria without harming the fish or its natural flora.”

The USDA team administered S. iniae to hybrid striped bass by intraperitoneal injection to establish infections, followed by an intraperitoneal injection of ClyX-2 an hour later. The team found a 95% survival rate for the fish in the treatment groups compared to a 5% survival rate of fish in the untreated control groups. The results showed that the protein was statistically as effective at treating S. iniae as antibiotic treatments like carbenicillin (85% survival).

Although the injections were efficacious, it may not be economically feasible to hand inject each fish, says Nelson.

In the future, the team plans to look at treatments of tanks with ClyX-2, specifically a RAS system, to prevent infections from occurring in the first place.

“S. iniae also forms biofilms on water surfaces, including within RAS systems, and these biofilms can seed infections in fish as well as protect the bacteria from traditional antibiotics,” said Nelson. “In our future studies, we will look at the treatment of RAS systems with ClyX-2 to reduce S. iniae biofilms and prevent infection in commercially valuable farmed fish.”

Using control methods such as physical barriers, rather than relying exclusively on chemicals, contributes to better aquaculture practicesMarcos Jofré, Garware Technical Fibres Chile

Skirting the issue

Meanwhile in Chile, net and rope manufacturer Garware Technical Fibres has produced a preventive tool for salmon farms to delay the infestation of the Caligus parasite, one of the most serious parasites affecting salmon health and performance.

Known as the Garware Skirt X12, the new tool is a physical barrier that surrounds the perimeter of a cage’s centre with varied depths. It prevents the entry of the early stages of Caligus, promoting an adequate exchange of water and helping to maximise natural oxygenation.

“Resistance to chemical treatments, concern about the environmental effects of drugs and the search for more sustainable approaches have led to continuous research and development into strategies to control Caligus and other ectoparasites in aquaculture,” said Marcos Jofré, Business Associate at Garware Technical Fibres Chile. “Garware cloths in skirts have been successfully used as a mechanical barrier that delays and reduces sanitary baths in salmon farms worldwide.”

The Garware Skirt X12 is made from a three-dimensional fabric with an opening of 80 to 150 microns for Norway and a second generation of 60 to 100 microns for Chile, where the sea lice are smaller. It has high resistance to abrasion, is easy to install and clean, and is available with V2 technology, which delays biofouling. Keeping the skirt clean through low pressure cleaning in situ is key to preventing any reduction in water exchange between the

inside and outside of the cage.