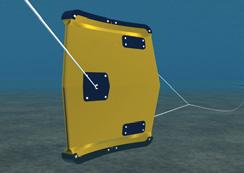

Lightweight data cable, designed specifically for data transfer from headline sonar to bridge.

• Lifts up during towing

• Pulls headline up and increases trawl opening

• Proven lifetime over 5 years

• Flies over trawl doors during turning

• Improved signal quality

• No need for regular reconnecting

• Doesn‘t rust

• No lubrication needed

• In use on over 100 trawlers today

After switching to Dynlce Data

- no one has gone back to steel cable!

Our cutting edge technology provides co-axial data transfer cable with central copper conductor and screen enclosed in a DynIce Dux rope.

JASON HOLLAND | Editor | jholland@worldfishing.net

Have you seen it? By “it”, I mean “Ocean” – the new Sir David Attenborough feature length documentary showcasing the world and life underwater and some of the biggest challenges facing our seas today. Launched to coincide with the great man’s 99th birthday, the film debuted ahead of World Ocean Day, June’s United Nations Ocean Conference 2025 in Nice, France, and midway through the United Nations Decade of Ocean Science for Sustainable Development (2021-2030).

The international fishing & aquaculture industry magazine

EDITORIAL & CONTENT

Editor: Jason Holland jholland@worldfishing.net

News Reporter: Rebecca Strong rstrong@mercatormedia.com

Regular Correspondents: Please contact our Correspondents at editor@worldfishing.net

Tim Oliver, Bonnie Waycott, Vladislav Vorotnikov

Quentin Bates, Terje Engø Eduardo Campos Lima, Eugene Gerden

Production

David Blake, Paul Dunnington production@mercatormedia.com

SALES & MARKETING t +44 1329 825335 f +44 1329 550192

Media Sales Manager: Hannah Bolland hbolland@worldfishing.net

Marketing marketing@mercatormedia.com

If it hasn’t happened already, get ready for impassioned conversations about the destructive nature of bottom trawling, with Attenborough comparing it to “bulldozing a rainforest”

Visually stunning – tick, inspirational – tick, thought-provoking – tick. Ocean delivers all that and more besides. But what it also does is critique commercial fishing, with a particular focus on the environmental and social impacts of destructive industrial trawling. And gauging by the initial reactions of some of my fellow cinemagoers, it’s likely to trigger a wave of varied, but largely appalled responses from the general public and consumers, with seafood –wild-caught and farmed – in the direct firing line.

If it hasn’t happened already, get ready for impassioned conversations about the damaging nature of bottom trawling, with Attenborough comparing it to “bulldozing a rainforest”; the high rates of by-catch; the overexploitation of krill in Antarctic waters, which is threatening the food supply of penguins, whales etc; an end to what he calls “modern colonialism at sea”, where fleets from affluent nations deplete fish stocks in developing regions, and the importance of marine protected areas.

Ocean does conclude on a hopeful note, with Attenborough emphasising that seas possess a remarkable capacity for recovery if given the chance. As such, he’s urging global leaders to honour commitments, such as the pledge to protect 30% of the world’s oceans by 2030, highlighting that proactive measures can lead to significant positive change. Notwithstanding, was there ever a more appropriate time for proactive industry storytelling?

EXECUTIVE

Events Director: Sally Wattam

Chief Executive: Andrew Webster awebster@mercatormedia.com

WF magazine is published bimonthly by Mercator Media Limited, Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD UK t +44 1329 825335 f +44 1329 550192 info@mercatormedia.com www.mercatormedia.com

Subscriptions

Subscriptions@mercatormedia.com

Register and subscribe at www.worldfishing.net

Single user: Full online access plus bi-monthly digital issues £246.00

For Memberships and Corporate/multi-user subscriptions: corporatesubs@mercatormedia.com

Launched in 1952, World Fishing & Aquaculture is published by Mercator Media, a B2B media and events company specialising in international maritime industries, including marine business and technology, ports and terminals, and environmental strategies. Through its publication and free access website (www.worldfishing. net), World Fishing & Aquaculture provides expert-written, in-depth coverage of the fisheries, aquaculture and processing sectors, with a strong focus on the emerging solutions, technologies and innovations that are shaping the broader seafood economy’s landscape.

The Scottish Ocean Cluster has secured the support of almost 60 cross-sector organisations. The initiative aims to drive up to three times more value from existing marine resources through innovative biotech applications, new product development and zero-waste practices.

Alaska’s pollock fishermen wrapped the 2025 A season with the Alaska Pollock Fishery Alliance reporting strong harvests, low by-catch rates, and tangible benefits for coastal communities.

Ireland’s seafood economy grew to €1.24 billion in GDP terms in 2024, up 4% yearon-year, driven by a 9% rise in exports, an 11% increase in landings to Irish ports and stronger domestic sales.

Formed through the merger of Intership, Aquaship and FSV Group, Trident Aqua Services brings together over 60 aquaculture vessels and 1,000 employees across seven countries.

Thorsteinn Már Baldvinsson is vacating the role after serving in the position since 1983 when the Icelandic company was founded.

EU fishing vessels will continue to have access to UK waters through to 2038 as part of the package of new deals agreed at the first-ever EU-UK summit.

With the 12-year fishing agreement getting some criticism from the UK sector, Prime Minister Sir Keir Starmer defended the new arrangements, saying they provide long-term certainty for fishing fleets, as the old deal necessitated annual negotiations on fishing access. He also insisted fisheries would be better off, pointing to the Sanitary and Phytosanitary (SPS) agreement with the EU.

“We’ve reached a deal today on fish, protecting our access, rights and fishing areas with no increase in the amount that EU vessels can catch in British waters,” he said. “Our fishing industry will also benefit from the new SPS agreement which slashes costs and red tape for our exports into the European market.

Starmer said the new agreement would make it easier for fishermen to sell their catch to Europe.

“It is incredibly important for fish, because over 70% of our seafood goes into the European market. So, for the first time

under this arrangement, our fishing communities are able to sell more easily into the European market.”

In a later statement, he said: “Selling iconic Scottish products like salmon – the UK’s biggest food export – has become needlessly difficult. Red tape meant a GBP 75 million drop in exports to the EU from 2019-2023.

“So, this agreement will tear down those barriers to trade, making it much easier to sell fantastic Scottish goods to EU markets.”

Alongside the EU access agreement, UK government has also launched a new GBP 360 million Fishing and Coastal Growth Fund, aimed at modernising the country’s fishing fleet, enhancing workforce skills, and revitalising coastal communities to boost tourism.

The fund will invest in new technology and equipment, deliver new training and skills to back the next generation of fishers and promote the seafood sector to export produce across the world. Under new plans to be set out soon by the government, coastal communities will receive a cash boost for new community facilities, better

transport links and investment in apprenticeships.

Proposals would see offshore wind farms required to invest into coastal communities benefiting for families, businesses and local community groups across the country.

The All Party Parliamentary Group (APPG) on Fisheries confirmed it is to meet to scrutinise all aspects of the UKEU deal on fisheries. The APPG has been collating priorities for future UK-EU fishing arrangements since January, ahead of next year’s expiration of the Trade and Cooperation Agreement’s (TCA) adjustment period on fisheries.

It said it will look at the details of the new agreements and their implications for the long-term sustainability of the UK’s fishing communities and fisheries, alongside the wider seafood sector. As part of this, it will be scrutinising the SPS deal be pressing for details of supports to industry in the face of any agreed arrangements, including relating to the Fishing and Coastal Growth Fund.

A new executive order signed by US President Donald Trump wants to bring the American seafood industry back to life. Amongst other things, the order, titled “Restoring American Seafood Competitiveness”, places high tariffs on imported seafood and calls for a review of existing federal regulations that industry leaders say have limited the growth of domestic fisheries.

In the order, Trump states that while most American fish stocks are healthy and have viable markets, seafood is one of the most heavily regulated sectors in the United States, with “federal overregulation” restricting fishermen from productively harvesting American seafood including through restrictive catch limits. In addition to this, he highlights that fishing grounds have been sold off to foreign offshore wind companies, that the fisheries data is “inaccurate and outdated”, and there has been a delay in the adoption of modern technology.

“The United States should be the world’s dominant seafood leader. But in addition to overregulation, unfair trade

practices have put our seafood markets at a competitive disadvantage. Nearly 90% of seafood on our shelves is now imported, and the seafood trade deficit stands at over $20 billion. The erosion of American seafood competitiveness at the hands of unfair foreign trade practices must end,” Trump said.

He continued: “The United States must address unfair trade practices, eliminate unsafe imports, level the unfair playing field that has benefited foreign fishing companies, promote ethical sourcing, reduce regulatory burdens and ensure the integrity of the seafood supply chain.”

To usher in “a new era of seafood policy, the President said the Secretary of Commerce, in consultation with the Secretary of Health and Human Services and with input from the US fishing industry, shall immediately consider suspending, revising or rescinding regulations that “overly burden” America’s commercial fishing, aquaculture and fish processing industries at the fishery-specific level.

The Secretary of Commerce

has been tasked with identifying the most heavily overregulated fisheries requiring action and take appropriate action to reduce the regulatory burden on them, in cooperation with the Regional Fishery Management Councils, interagency partners, and through public-private partnerships.

Furthermore, in consultation with the Secretary of Agriculture, the Secretary of Commerce shall develop and implement an America First Seafood Strategy to promote production, marketing, sale and export of United States fishery and aquaculture products and strengthen domestic processing capacity.

This programme shall accelerate the Department of Agriculture’s efforts to educate American consumers about the health benefits of seafood and increase seafood purchases in nutrition programmes, Trump’s order states.

n The US President’s executive order highlights that almost 90% of the seafood on US shelves is now imported, and the country’s seafood trade deficit now stands at over $20 billion

The People’s Republic of China, the world’s largest capture fisheries producer, has become the 108th State to join the FAO Agreement on Port State Measures to Prevent, Deter and Eliminate Illegal, Unreported and Unregulated Fishing.

Norwegian Minister of Fisheries and the Oceans Marianne Sivertsen Næss has unveiled a new white paper titled “Future aquaculture – sustainable growth and food for the world”, which outlines steps the government will take to ensure the aquaculture industry can continue to create value and contribute to local coastal communities.

Eugenio Piñeiro Soler has been named Assistant Administrator for NOAA Fisheries. In the role, Piñeiro Soler will oversee the federal agency responsible for managing marine fisheries and conserving protected marine species.

The Scottish salmon farm has launched the new Loch Duart Standard, a bespoke assessment process designed to reflect the unique way it raises its salmon from Scottish broodstock, in small-scale, low-density pens, and using a natural, welfare-led approach to farming.

Vičiūnai Group of Lithuania and Kalaneuvos Oy of Finland won the top prizes in the 2025 Seafood Excellence Global Awards at Seafood Expo Global, taking Best Retail Product and Best HORECA Product, respectively.

ICFA’s new nutrition toolkit

The International Coalition of Fisheries Associations is set to launch a Seafood Nutrition Toolkit that will provide resources for its members to communicate the nutritional benefits of seafood around the globe.

South Korea has opened its first land-based Atlantic salmon farm. Developed by GS Engineering & Construction and operated by its subsidiary Eco Aquafarm, the facility is located at Pukyong National University’s Fisheries Science Institute in Gijang-gun, Busan.

Certified Seafood

International has launched a new global eco-certification programme aimed at improving transparency, access and credibility in the certification of wild-capture seafood.

Australia’s southern bluefin tuna longline and minorline fisheries have joined the purse-seine in being certified to the Marine Stewardship Council standard.

Amid strong concerns about human rights violations within the seafood sector, a new study highlights the challenges of establishing enforceable labour standards for migrant workers in the tuna processing industry around the world and also explores how the seafood industry is working to improve labour conditions and tackle human rights violations.

The analysis, titled “A study into the implementation of responsible recruitment practices and the Employer Pays Principle (EPP) in the global tuna processing sector”, was co-launched at a Seafood Expo Global (SEG) 2025 event in Barcelona, hosted by the Seafood Ethics Action Alliance (SEA Alliance).

Delivered by Impactt, the document and its recommendations aim to identify ways to encourage responsible recruitment practices in the tuna shorebased processing sector, to provide mechanisms for improving labour standards for migrant workers.

At the event, chaired by Julia Black, Group Ethics and Social Sustainability Senior Manager at Hilton Foods and chair of the SEA Alliance, and Georgia Worrall, Head of SEA Alliance, outlined how the group of 39 leading UK retailers and seafood businesses, along with a consortium of seafood groups: the British Retail Consortium, Food Network for Ethical Trade, Global Tuna Alliance and the Seafood Business for Ocean Stewardship, sought to respond to industry concerns by commissioning the independent study.

The authors of the study, David Rousseau and Priyanka Kanani, Principal Consultants at Impactt, outlined how the findings highlight both the challenges in establishing enforceable labour standards for migrant workers in tuna processing around the world and explore how the seafood industry is working to improve labour conditions and tackle human rights violations.

With a focus on five countries Maldives, Mauritius, the Philippines, Seychelles and Thailand – the study centres on migrant labour used in tuna processing, building a picture of practices in each country by reviewing regulatory frameworks and conducting interviews and surveys. Key findings include:

• A lack of sufficient commercial or regulatory pressure or incentives for actors to commit suitable resources for full implementation

• Challenges for industry associations to establish enforceable standards or commitments around responsible recruitment

• Complexities in seafood supply chains increase the risks, as well as hindering buyers from achieving sufficient oversight and leverage to encourage suppliers to adopt responsible recruitment practices

• Challenges in understanding the “true” cost of recruitment It also suggests the following opportunities:

• Industry associations to act as convenors to facilitate dialogue, foster collaboration, and collective engagement to address responsible recruitment

• Buyers to provide incentives for suppliers to implement employer pays principles, support capacity building and embed responsible recruitment principles into their procurement practices

• Suppliers to collaborate with buyers to estimate fair recruitment costs, streamline supply chains, partner with zero-fee recruitment agencies, enforce contractual safeguards, and actively monitor recruitment practices

• All groups to increase information sharing to increase transparency into supplier recruitment practices

“SEA Alliance members are actively seeking a deeper understanding of the issues arising in recruitment in the tuna sector and practical actions that can be taken towards resolving them. The study highlights the urgent need for coordinated action between industry associations, governments, and the private sector to eliminate recruitment issues and increase fair treatment of all workers,” Worrall said.

The Aquaculture Stewardship Council (ASC) has launched its new certification standard for farmed seafood. Aligning 12 species into one global standard, ASC said its new Farm Standard brings greater consistency to requirements across all species standards.

“Sustainability is no longer a trend; it’s the undeniable future, unfolding now. With the population estimated to reach 10 billion by 2050, and with wild-caught fisheries at capacity, the importance of seafood farming will continue to grow – the environmental and social impacts of our industry must be addressed. That is why ASC is driven to accelerate that transformation, not least by championing farms and feed mills that are making change,” ASC CEO Chris Ninnes said.

According to ASC Director of Standards and Science Michiel Fransen, the standard,

which is built on the four pillars of fish, farm, people and planet, empowers producers to meet regulatory and market demands, enhance farming practices and fish health, prioritise worker and community wellbeing, and protects biodiversity.

The standard was unveiled at the Seafood Expo Global 2025 in Barcelona, Spain.

Speaking at the launch event, Global Salmon Initiative (GSI) CEO Sophie Ryan, described the new standard as “ambitious yet practical”.

She said: “We see the standard playing a critical role in guiding our sustainability journey but also being a key marker to our stakeholders of our responsible practices. It is ambitious in its scope and its requirements – continuing to demonstrate its leadership in assessing impact across a holistic spectrum of impacts. Yet it is practical in that it follows a risk-based approach

to focus on topics where there is the highest risk and reduce the administrative and cost burden where there is low risk. This is something that is key if we are to focus efforts where it is really needed and not overburden to limit progress.”

ASC is implementing a two-year transition period to provide the time companies need to adapt their practices to fully implement the new standard. Existing ASC species standards will remain operational during this time.

Significant technological advancements have already boosted industry efficiency, sustainability and profitability, writes Jason Holland

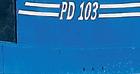

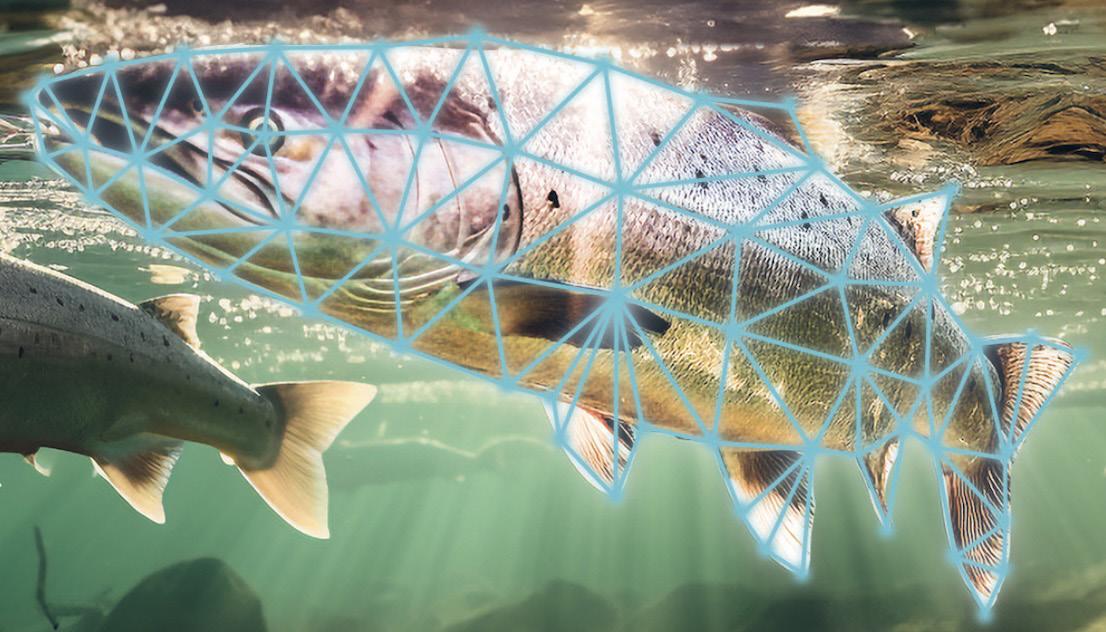

There’s been a rapid adoption of artificial intelligence – or AI – in the aquaculture space in the past two years, with validation and significant advancements in these technologies replacing manual processes and enhancing efficiency, sustainability and profitability, particularly in the salmon and shrimp farming sectors.

In using AI to replace previously manual processes, its functions in aquaculture differ from its general application where it tends to take a digital process, augments it and makes it super-efficient, Aquabyte AS Founder & CEO Steve Tucker told the recent Blue Food Innovation Summit in London.

“Very simply, if you’re counting lice on fish, measuring weight or biomass, looking at the welfare of fish, the behaviour of fish, or you’re trying to feed them more efficiently, or if you want to know about maturation, you’re now using technology to do it, and it’s become super important to do that, because the farming technology as well as the actual physical infrastructure of farming has changed a whole bunch,” Tucker said.

“If you look at the Norwegian market for salmon, for example, a great many pens are now submerged so you can’t even see the fish. You need technology to look at them. They’re in a different environment now than they used to be. So, you need to understand exactly how the

‘‘

This is making a difference, and it’s part of how I think farming has changed

Steve Tucker, Aquabyte

fish are performing, how they’re feeding and how they’re growing... But you’re not going to buy products, solutions or features like the ones we provide, unless we’re also enhancing the efficiency, unless we’re saving costs for the farmers, or we’re increasing the yields.”

Companies like Norway-based Aquabyte are building revenue for fish farmers, but at the same time, they’re improving sustainability and helping producers to overcome the environmental challenges that they all face, Tucker said.

“For us, we’ve seen a really fast adoption over the past 12 or 18 months, where farmers globally (not just salmon farmers) have now accepted the real benefits of using the sort of predictive data and analytics that companies like ours provide. I think we’ve almost become part of the operational daily workflow. This is AI in action. This is making a difference, and it’s part of how I think farming has changed.”

n AI helps producers understand exactly how their fish are performing and facilitates financial benefits too

Progress was slow at the beginning, but as more features have been added and the adoption has incrementally increased, now technology developers and providers are being more creative with the application of AI into aquaculture systems and looking at further possibilities and opportunities, asserted Tidal’s Global Director Kira Smiley, Global Director of Tidal, a Google spinout company that develops AI-powered solutions for the industry, including a platform that monitors environmental factors like temperature and oxygen levels, and also interprets fish behaviours.

“A positive feedback loop has allowed for more and more adoption, and as we’ve had a few years where we’ve been able to very rigorously validate this technology in many different conditions and in many different areas, farmers are starting to feel much more confident and comfortable with these types of technologies – they’re now willing to really scale up and increase. They’re taking this into everyday commercial use and adopting it in ways that many of their weekly decisions are made using these insights,” Smiley said.

Nevertheless, many farmers, including ones Kampi works with, have developed a taste for innovation and trying new things, Sokalsky said.

The company’s own AI-based mobile application, also called Kampi, was launched last year with the aim of enhancing the management of shrimp farms.

“We are an operating system. First, at the farms, we use AI to understand all the inputs of what they’re using – from feed to their costs. Our solver models will tell them, based on past cycles, the variables that stood out that either gave an uptick in performance or a decrease in performance. It helps them to very quickly do hypothesis testing of new equipment, new feeds or new feed inputs, or different ways of farming.”

She continued: “Having better precision around your information and an ability to link what is happening to profitability allows you to take those decisions much more quickly.

“It’s a long cycle for these sorts of decisions to happen. But I think once farmers get comfortable with having more precise information, the innovation loops get shorter and shorter – so helping them to innovate faster and achieve better profitability.”

n Farming technologies and the physical infrastructure of aquaculture have changed dramatically, heard this year’s Blue Food Innovation Summit

I think once farmers get comfortable with having more precise information, the innovation loops get shorter and shorter

Katie Sokalsky, Kampi ‘‘

Kampi CEO Katie Sokalsky told the summit there’s been a significant uptick in the adoption of new tech among shrimp producers in the last five years. This, she said, was fuelled by early innovators, who initially invested in hardware –mainly smart feeders – and through long cycles of trustbuilding, where producers found the technology helped them to be more performant, so the realisation came that the old way of doing things could be improved upon.

“It has opened up that mindset. Shrimp is a huge industry, but we sometimes forget how nascent it is. Shrimp has really only been farmed in the last 30 years at scale, and so we’re undergoing this technical revolution, but we’re really only at the early, first chapters of what that looks like.”

There are important considerations to be made when looking at the adoption of such technologies, including a fast evolution of the ocean environments that are home to many aquaculture production systems, and also quickly evolving and adapting biology, Smiley said, adding that to adapt to all of these shifting dynamics, farmers also need to adapt in terms of the methods they use.

n Mathew Zimola,

Founder

& CEO of ReelData AI, a venture-backed company that provides a suite of AI and automation products for landbased fish farming

“There are many different tools, but at the end of the day, you need to know if these new tools work. And you need to see how that impacts their growth, their health and the final outcome of the harvests. That’s the beauty of having these types of technologies that provide real-time insights. And they will be important throughout the whole process, because no matter what new technologies and new methods of farming are implemented, you’ll need to see what the results are.

“Monitoring, in this sense, becomes critical. It allows and enables really fast iteration compared to what was possible in the past, with small samples or waiting an entire growth cycle to see what the food-to-feed conversion ratio was. I think that’s making it a really permanent thread into the future of aquaculture,” she said.

Taking on assistive technology at the earliest stage helps the total production of the industry – in its entirety

Mathew Zimola, ReelData AI

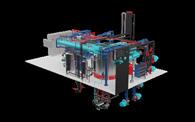

Meanwhile, the ReelData AI suite which is tailored to providing operational data and automation for land-based farms has brought some major improvements within the recirculating aquaculture systems (RAS) sector, confirmed its Founder & CEO Mathew Zimola, who confirmed the company has been getting deeper into the smolt and postsmolt space, due to it becoming “a really important trend” in Norway’s salmon industry.

ReelData was founded in 2019, and it has gone from having just five clients in its first five years to having its technology in some 25 different facilities today. These range from 50-gram fish to full harvest RAS and flowthrough systems.

“What we’ve seen with the smolt and post-smolt producers is a trend where the industry is growing bigger and bigger fish before they move it out to the ocean. And with assistive technologies – especially AI – that can feed fish, one of the big things farmers were looking at was reducing the feed conversion ratio, which increases the numbers on their financials. But one of the big things we’ve

seen is that assistive feeding technology really increases the growth rate of fish. [Farmers] are able to grow fish faster, get them out to the sea faster, and now the idea is they can flip production cycles faster. In a sense, taking on assistive technology at the earliest stage helps the total production of the industry – in its entirety, which is great.”

According to Zimola, integrating AI-based solutions into RAS presents an opportunity to get into the environmental parameters of the water system that fish are being raised in.

“The ocean-based side of the industry has to deal with environments, but in the land-based industry, you actually get to create the environment. It provides a neat industry where you can take a lot more control over systems and continuously push boundaries on health and welfare, and also the growth optimisation of these facilities. I think it’ll take a little bit of time to get there, but that’s our vision: getting more and more into this massive amount of data that comes from these facilities that you can actually use to create a change in that facility and in the environment of the fish,” he said.

Moving forward, and crucially for the aquaculture industry as a whole, AI-based technologies provide scope to navigate what’s a very tough regulatory landscape, the conference heard.

Smiley acknowledged that with evolving conditions and lice pressure, for example, on salmon becoming so intense, there’s more scrutiny surrounding fish production. But, she said, having tools that allow producers to track how effective or ineffective different treatment methods are, or being able to markedly see an improvement over time will not only create internal benefits to allow companies to find the right solutions, they’ll also give opportunities for greater transparency.

“That, in some ways, can cause pressure, but then when you can show real measured improvement, and you can demonstrate that you are actually doing very well through the efforts that you’re taking, then it’s proof, and it allows for digital storytelling – to show that everything you are doing in fact supports sustainable aquaculture.

“I think AI can help be a tool for sharing truths and stories, and that will be important for changing some of the stigma that exists against aquaculture, because it’s truly a big opportunity for sustainable protein compared to so many other animal proteins,” she said.

n AI Smart Feeding – ReelData’s fullyautomated system accurately identifies real time population appetite and adjusts feed levels accordingly

TEMPERATURE ADAPTED FEEDSTM

10 years of supplying and optimising seasonal feeds!

Electronic monitoring can be a tool for continual improvement, compliance verification and more in Taiwan, writes Bonnie Waycott

The lack of insight into activities on industrial fishing vessels, particularly those operating in distant waters, poses significant challenges in global fisheries management. Indeed, one of the biggest obstacles to sustainably managing global fisheries is the lack of on-the-water data. The Nature Conservancy estimates that one in every five fish caught comes from illegal, unreported, and unregulated (IUU) fishing, while the vast majority of industrial fishing activities are often left unchecked for compliance with fishery regulations if there are no monitoring systems on board vessels. This results in an uneven playing field for the many lawabiding fisheries around the globe.

Taiwan represents a significant proportion of the world’s distant water fleet, harvesting highly valuable commercial fish such as tuna that are vital to global food systems. Taiwan also owns one of the largest distant water fishing fleets in the world (China, Taiwan, Japan, South Korea and Spain account for around 90% of distant water fishing activity worldwide.)

However, Taiwanese fisheries face an array of challenges from by-catch, interactions with Endangered, Threatened and Protected (ETP) species, and IUU fishing practices, according to Ho-Tu Chiang, Taiwan Program Manager who leads the development and implementation of Fishery Improvement Projects (FIPs) and other on-thewater sustainability initiatives in Taiwan for international NPO Ocean Outcomes.

If people are willing to break down the wall and work together, taking advantage of collaboration, then a lot of amazing sustainable work can be achieved

Ho-Tu Chiang, Ocean Outcomes ‘‘

Chiang and his team are working with fishery managers and market leaders to introduce electronic monitoring systems (EMS) – onboard video cameras, GPS and sensors – on Taiwanese tuna longliners in order to expand the availability and accuracy of fisheries data by monitoring and verifying fishing activities. Work is taking place in Donggang, home to one of Taiwan’s largest fishing harbours.

“The biggest challenge in generating uptake of EMS in the Taiwanese fishing industry is that people are unwilling to work with areas that they are unfamiliar with,” Chiang told WF. “The wall of defence is quite high. Those in the industry are busy, and don’t have enough time to understand the various issues that are occurring between different groups when it comes to fisheries. Meanwhile, IUU fishing practices and underreporting catches are also serious concerns. This results in many negative impacts, such as reduced sustainability of fish stocks, and threatens the livelihoods of those dependent on marine resources.”

Through a partnership with local seafood traders, such as Fue Shin Fishery Ltd (FSF), Chen-Hung Seafood

Frozen (CHSF), Lungsoon Ocean Group/Da Yang Seafood, and local universities, EM providers, and the Fisheries Agency of Taiwan, Chiang and his team are installing EMS on Taiwanese vessels as part of FIPs between Ocean Outcomes and their local seafood companies.

The FIPs have mandates to enhance the transparency of fishing operations, generate and provide better fisheries data to managers, and increase observer coverage. EMS will assist the vessels involved in FIPs to gather species data (catch data) and accelerate local capacity for the development of electronic monitoring. Ultimately, the aim is to help Taiwanese seafood companies achieve Marine Stewardship Council certification.

n Ocean Outcomes is working with the industry to introduce EMS on Taiwanese tuna longliners in order to expand the availability and accuracy of fisheries data

EMS represents a potentially cost-efficient solution that can enhance the availability and accuracy of fisheries data, said Chiang. However, in Taiwan’s case, it is drawing attention for another reason.

“In Taiwan, human observers onboard vessels are not hired by the vessel captain or the fishing industry but assigned by the government,” said Chiang. “The situation also changes every year. One year a vessel may have an observer, but the following year it might not. This only gives Taiwanese vessels an observer coverage of around five to 10%. However, under the Marine Stewardship Council’s updated requirements, vessels must have at least 30% coverage in order to be certified. In Taiwan, this number is currently impossible to achieve, which is why vessels that are interested in certification need to look at other ways, such as EMS.”

In addition to addressing some of the key obstacles in achieving sustainable fisheries management, EMS can help to reduce by-catch and support crew welfare. It can also provide the means to mitigate any conservation and compliance issues that put tuna stocks, ocean ecosystems and tuna supply chains at risk.

By recording images of fishing operations, it offers views of critical vessel areas such as gear deployment and retrieval, catch aboard, sorting, processing and storage, while third party reviewers can analyse the footage to determine primary species, ETP species, by-catch and more. It can also offer greater certainty that products are sourced in compliance with government or company commitments and requirements.

The idea is that EMS is an independent data source, separate from fishermen’s logbooks, that can potentially be used to replace or compliment the use of human observers, said Chiang. Local EM providers are also involved in Ocean Outcomes’s work, with a focus on vessel management plans, or installation plans, to determine how many cameras a vessel requires and where they can be installed.

Having installed the necessary components, the data and footage are then transported to the cloud before analysis to determine species and bycatch data, fishing effort, the occurrence of any marine debris, and more.

However, despite the growing interest in advancing EMS in Taiwan, progress has been hindered by various challenges, most notably the ability of flag states and fishery managers to incorporate electronic monitoring into a national policy

and regulatory framework, an underlying factor for enabling electronic monitoring to scale in Taiwan. There is also a significant lack of knowledge and experience of electronic monitoring.

“Most fishermen have never used or experienced EMS,” said Chiang. “They don’t know how to define the data, the type of devices that they need on their vessels, and how to clearly communicate their needs with EM providers and other resources. Cost is also a challenge, and this circles back to the lack of experience. Fishermen don’t understand EMS, so it’s difficult to negotiate costs. It’s a huge issue that Taiwan doesn’t have a comprehensive electronic monitoring policy and regulatory framework. Standardising, mandating and implementing EMS is difficult without such a framework. Without such guidance from government managers, fishing vessels and owners can find themselves dead in the water when pursuing EMS.”

Nevertheless, those who are involved in Ocean Outcomes’s work are beginning to understand the advantages of EMS –better data, easier compliance with international standards, and even market and brand recognition. The ability of EMS to collect variable and valuable data is extremely good for the Taiwanese fishing industry in terms of obtaining essential information, said Chiang.

The key is to work to build confidence in the application of the technology and the use of data, and explain to fishermen the benefits of EMS in order to encourage broader adoption and uptake. Towards this end, Ocean Outcomes is working with EM providers and stakeholders to provide hands-on training on the use, maintenance and repair of EMS, while also supporting efforts to establish a Taiwanese regulatory framework for electronic monitoring.

This work is playing a key role in the journey to increasing transparency in Taiwanese tuna longliners.

“If people are willing to break down the wall and work together, taking advantage of collaboration, then a lot of amazing sustainable work can be achieved,” said Chiang. “It’s all about communication, collaboration and building trust. This year, we hope to be able to support industry players to become familiar with electronic monitoring and feel comfortable using it. We also want to support them in talking to stakeholders, markets, and the government about what they need, and involve local Taiwanese research teams, companies or organisations that work with electronic monitoring in terms of data reviewing and storage. We believe that EMS provides significant opportunity and potential, and hope to include many more stakeholders in our work.”

The industry is being challenged to make sustainable products more convenient, affordable and appealing to the buying public, writes Jason Holland

Not only are young consumers less likely to choose seafood over other food groups, it’s also been ascertained that as a demographic they are moving out of the seafood category faster than any other consumer group. This unwelcome trend was recognised at the 2025 Seafood Futures Forum, held at this year’s Seafood Expo Global in Barcelona, hosted by the Marine Stewardship Council (MSC), which heard it’s not a dislike of seafood that’s putting them off in their droves, instead, the departures are being driven by a lack of confidence in both the selection and preparation of products, together with an overwhelming amount of alternative purchasing options.

“Every single day we’re presented with choose this versus this. You go to a grocery store, there’s new products every time, and making decisions on how you’re sourcing and what you’re feeding yourself or doing for yourself has become much more challenging,” Chef, content creator and MSC ambassador Charlotte Langley said.

“I would also say it’s a category or sector that’s harder to feel confident in the kitchen with. You know, if you’re

looking at a tuna steak, it has a high value that you spend money on. You put your dollars in that product, but if you mess it up, make a mistake, overcook it or forget about it at the back of the fridge, you are not going to be as keen to go back for that product again.”

Establishing confidence and engaging consumers is an increasingly important part of the strategy for UK fish supplier New England Seafood International (NESI), owned by Sealaska, a for-profit Alaskan Native Corporation.

“Our brands do a good job of that,” NESI Head of Marketing Lisa Cowell told the forum. She gave the example of “Fish said Fred”, launched five years ago and named after the company’s founder Fred Stroyan with the intention to take the risk and confusion out of buying fish.

“Fish Said Fred is all about wrapping our arms around consumers, showing them how quick and easy it is to cook with seafood,” Cowell said. “We also work with influencers, chefs, and we do a lot through social media. We also work closely with retailers, bringing those stories to life at the fixture with recipe cards, things like that, to inspire consumers.”

Younger consumers are also being influenced in their decision-making by sustainability issues and are widely seen as being more environmentally-aware when it comes to buying products. Indeed, recent analysis from global insight consultancy GlobeScan and the MSC determined these demographics are most likely to take action to protect the ocean with 27% of 18-to-24-year-olds and 22% of 25-to-34-year-olds reducing their seafood consumption for this reason.

The survey of over 27,000 people across 23 countries also found that 9% of 18-to-24-year-olds and 6% of 25-34-yearolds have stopped eating seafood altogether, while over 70% of people in both age groups said they are prepared to do more for ocean protection. Furthermore, 33% of 18-to34-year-olds were found to be eating less fish compared to two years ago, with just 12% eating more. Meanwhile, 39% from this age group are eating more vegetables, and 21% are eating more plant-based alternatives.

MSC also conducts regular surveys across some 20 markets, with part of the questioning tasked with ascertaining what could drive more seafood consumption. MSC Chief Communications Officer Ishbel Matheson said what comes through loud and clear in these findings is that for younger consumers, environmental issues and sustainability are important contributors. However, the studies also confirm these factors sit well behind cost and affordability, particularly in the current economic climate.

Sustainability is not the biggest draw at this time, Langley said, but added that the onus is on the producers of seafood products to create items that incorporate affordability and cost together with sustainable sourcing, transparency, traceability etc. so that consumers can just take them off the shelf and consume them without any misgivings.

In Germany, cost is again the biggest driver of seafood sales, but among all consumer groups – especially Gen Z – sustainability features strongly among the biggest fears and interests, said Julius Palm, Deputy Managing Director at followfood, a German-based company that has grown from start up to a midsized brand through a combination of holistic sustainability and creative marketing. It’s also found that while there’s a lot of interest in being more sustainable with natural resources in Germany and many other countries, there’s still a sizeable gap between good purchasing intentions and what consumers actually buy, Palm said.

As a result, the seafood category isn’t meeting its potential, he suggested. “I think the mission should be to fill this gap and to realise that there is a cost issue.”

Awareness campaigns such as “Check Your Cans”, developed by Langley and MSC and recently launched in Australia to urge consumers to take a closer look at the canned tuna they’re buying to ensure they are living up to any environmental claims that they make, and also the so-called “Dolphingate” campaign of five years ago, led by followfood, which saw a fake baby dolphin eaten by an influencer have been successful in raising awareness and promoting sustainable seafood, heard the forum. It was also highlighted that younger consumers look to get their information about brands and products in a completely different way, with platforms such as Tiktok proving especially popular.

To capitalise on these, Langley has created an advisory youth board of people aged 25 and under. “They’re excited about sustainability. They’re talking about messaging. They’re guiding my decisions based on what they see and feel and how they want to interact with the medium of material. It’s actually very helpful,” she said. Followfood has taken a similar approach, and the way these campaigns are executed is very different from traditional marketing methods, Palm said.

“It’s fast. It’s cheap. Trends on Tiktok start today and they end the day after tomorrow, so you have to be quick in your actions. Our content looks totally different on Tiktok than it looks on Instagram, and that’s a challenge. But we are successful. For the last two years, we were the most successful food brand on Tiktok, and we’re not the biggest food brand in Germany.

“Others try to copy the things they did on other platforms, and it doesn’t work at all, and they don’t reach younger generations,” he added.

Convenience on-trend

From a product perspective, to have the best chance of retaining younger consumers, seafood producers should embrace the convenient cuisine trend, with quick, easy-tomake, delicious choices, suggested Langley.

Convenience is key, Palm agreed. “It’s one of the mega trends. Every year, it’s the new trend, and it stays for the year, so the convenience level rises and rises and rises.”

Health also offers significant scope for growing the seafood category, he said.

“Especially after Covid, we’ve seen a change of perception, where saving the world as a consumer is too complex and too overwhelming for a lot of people and so the motives have changed in the direction of ‘what’s in it for me,’ – more egoistic motives than altruistic world community motives. And so, sustainability issues are reaching more towards health, personal health and individual health content. In Germany, we see it a lot that health issues are get much more reach than classic ecological sustainability issues.”

favourite canned tuna has been sourced from

Built for the Orion Fishing Company, Argos Berbés was delivered by the Nodosa yard in Marín for the first Falklands squid season of this year

Handed over just a few weeks after the completion of Prion for the Petrel Fishing Company, which also starting fishing this season, newbuild Argos Berbés has an 85-metre overall length and a 14-metre beam. It has been designed with an inverted bow to provide optimal seakeeping qualities.

Argos Berbés doesn’t represent the first time owners Orion Fishing Company has gone to Nodosa. In 2018, it took delivery of the 75-metre Argos Cies to operate on the same Falklands fishing grounds.

Orion Fishing Company is a joint-venture between the Vigo-based Grupo Pereira and Argos Group in the Falkland Islands, and in her speech at the new trawler’s delivery ceremony, Argos Group’s Sheila Stewart highlighted the solid relationship with Pereira, which goes back more than 30 years.

Pereira was represented by its president José Enrique Pereira Molares, whose sister Ana took the role of the new vessel’s godmother, cracking the traditional bottle against the hull plates to send Argos Berbés down the slipway.

“We are proud to continue investing with our partners at Argos Group in the renewal of our fleet and in a fishing area with such an important target species for us as the Patagonian squid. A model fishing area for sustainability and responsible fishing,” José Enrique Pereira said.

Technologically advanced

Nodosa’s commercial director José Ramón Regueira commented that the new vessel “is at the forefront in every aspect”.

“It is an honour to design and build such technologically advanced and environmentally friendly vessels on a fully customised basis for shipowners who understand that quality and sustainability are the way forward, and where Nodosa is fully involved,” he said.

Argos Berbés has accommodation for 74 persons and its 4640kW Wärtsilä 8L32 engine provides a 15.50-knot steaming speed.

Its full package of electric deck equipment, including the main trawl winches, net drum, sweepline winches and associated equipment was delivered by Naust Marine.

The cranes are from Guerra and the wheelhouse has been outfitted with largely Furuno and Simrad electronics.

The processing deck systems have been supplied by Vigo company Josmar, which also delivered the catchhandling systems for Prion and for Hadassa Bay, which was built by Astilleros Ría de Vigo, both of which are also joining the loligo fishery for the first time this season.

The refrigerated fishroom has a 2,442-cubic-metre capacity and the processing deck freezers have a throughput capacity of 120 tonnes per 24 hours. These use ammonia as their refrigeration agent.

7 – 9 October 2025

Kobe, Japan

As the Association celebrates its seventieth anniversary, IAPH looks forward to welcoming you to Japan and the city of Kobe, where its roots can be found. Following the symbolic idea of establishing world peace through world trade, and world trade through world ports, this 70th annual meeting at the #IAPH2025 World Ports Conference will reunite global port leaders with their counterparts from policy makers, financial institutions, ship and cargo owners, and service providers, delivering a forum for networking, knowledge sharing and debate.

To secure your delegate place or further information on attending/sponsoring contact the events team:

visit: worldportsconference.com contact: +44 1329 825335 or email: wpc@mercatormedia.com #IAPH2025

Built for Faroese fishing company Framherji, Høgaberg has joined the long series of pelagic vessels delivered by the Karstensen yard. Skipper Høgni Hansen took the new purser-trawler to start on blue whiting before making a first call in the Faroe Islands

Høgaberg is the Karstensen’s own design, fine-tuned in co-operation with the owners, with the build completed at the yard in Skagen on a hull fabricated in Gdansk by the yard’s Polish subsidiary. Operating company Framherji also has pelagic vessel Fagraberg, as well as freezer trawler Akraberg and longliners Stapin and Jógvan 1

Designed as a pelagic trawler with capacity to switch to purse seining for specific fisheries, Høgaberg has an 87.8-metre overall length with a moulded breadth of 16.6 metres. Carrying capacity is 3,470 cubic metres in 15 RSW tanks, chilled by a triple 1300kW PTG FrioNordica RSW system. C-Flow supplied the vacuum system.

The focus is on optimising catch handling and storage, while keeping fuel consumption as efficient as possible – while also providing an exceptionally high standard of crew accommodation. Noise levels are minimised by placing accommodation areas as far as practical from the propeller. During sea trials noise levels proved to be well below the required and recommended levels.

In a departure from the usual configuration, Høgaberg has twin main engines. These are twin 3600kW Bergen Diesel B33:45L6P units driving a 4500mm diameter Kongsberg KaMeWa CPP111A1 propeller via a Flender GVL-1400 reduction gearbox.

The energy system on has 2300 kW Cummins AvK shaft generators mounted in the front end of each of the main engines. Additional electrical power is sourced from the Caterpillar auxiliaries, a 940kWe C32 and a 565kWe C18. These are backed up by an 1100kWh Corvus Orca battery pack.

The power layout onboard is designed for the main engines to be the primary energy sources for both propulsion and the deck systems, with the shaft generators engaged while hauling. This works on the premise that when full power is needed for the winches, there is a reduced load on the propulsion system.

Its electrical power system is fitted for sliding frequency (60-50 Hz), by means of frequency converters for 400/440 V and UPS clean power static supply/converter for 230 V. This allows the main engine and propeller to be run at 17% lower revolutions that would otherwise be possible.

Høgaberg’s owners opted for a deck layout with electric trawl and auxiliary winches from Evotec. The 118-tonne trawl winches are controlled by a Scantrol system. The trawl layout has a pair of 147-tonne net drums in a waterfall configuration, aligned with a hydraulic stern gate with hydraulic operated guide pins. There is a 69-tonne tail-end

winch, a 20-tonne end-wire winch and a pair of netsounder winches mounted on the aft gallows.

Evotec also supplied the 40-tonne main and 15-tonne auxiliary purse winches, while the purse seine layout has been supplied by SeaQuest Systems, starting with a 40-tonne nethauler. The gear is routed back to the recessed net bin on the port side via the netstacker crane, plus there’s a floatline stacker and a telescopic leadline stacker.

An additional net crane on the aft gallows provides reach over any part of the aft deck.

The 4t/18m foredeck crane and the 3.5t/13m fish pump crane are also from SeaQuest, as are the three 20-inch electric fish pumps and the cable and hose reels.

Høgaberg’s wheelhouse is outfitted with electronics from Furuno, Simrad systems supplied by Radioservice and a Marport installation supplied by Vikmar.

The Furuno Smart Bridge System is at the centre of the wheelhouse array, with four 55-inch North Invent displays facing the two Nor-Sap 1600 skipper chairs. This allows the wheelhouse team to configure preferred sets of displays depending on the job in hand. In addition, there are a further 34 displays placed around the wheelhouse.

The heavyweight fishfinders are the 15-25kHz lowfrequency FSV-25S, and 180kHz high-frequency FSV-75 sonars from Furuno, plus a 25kHz Simrad ST94 sonar, and the Simrad FS-70 trawl sonar. The sounders are Furuno FCV-38 and FCV-1900 units, complemented by a Simrad ES38 and a Simrad SN90 box scanner.

The current indicator is a Furuno CI68 and Marport supplied a full package of trawl sensors.

In addition to the Tecdis T-2128 system, the plotters are a pair of MaxSea Time Zero units. Radars, AIS, GPS and GPS compasses are all Furuno equipment, and the gyro compass and autopilot are from Simrad.

The Sat-TV, GMDSS A4 comms installation and the VHF sets are all from Sailor and the satellite communications are

Hvide Sande Shipyard in Denmark has been contracted to build an innovative fishing vessel for Canadian fishing company Clearwater Seafoods

Clearwater’s 40.9-metre newbuild, designed by Norwegian naval architect Skisteknisk, will fish for lobster in North Atlantic waters.

An innovative design arranges gear handling operations around a moonpool, providing a safe and stable mode of operation to retrieve fishing gear, making the job both easier and safer for the crew by moving the process of hauling lobster traps from an exposed deck to a sheltered space inside the vessel.

Development of this new design has been completed in close collaboration with Clearwater staff, with the focus on safe operation, as well as efficiency and sustainable fishing.

The shipyard in Hvide Sande will take delivery of the hull by mid-2026, and work on outfitting the boat will then begin, with the new vessel due for delivery in spring 2027.

Clearwater’s new lobster catcher is designed to have accommodation for a crew of up to 19 and will be equipped with three RSW tanks to keep the catch alive onboard and in peak condition.

It is seen as a key order for the Hvide Sande Shipyard, which continues to expand its international presence by taking on innovative and specialised construction projects.

Unlock

Following its acquisition of a 75.1% stake in Indian rope and netting producer Kohinoor, the fishing gear company is streamlining its production around new these newly available opportunities

The initial steps of relocating machinery and production from Lithuania have already begun, Hampiðjan said. The first rope machine is already en route, with another awaiting shipment.

As the peak season for aquaculture cage production and related materials winds down in late summer, four knotless net weaving looms will be moved from Norway to Kohinoor. At the same time, specialised sewing machines and other equipment will be transferred from Poland and Lithuania to India.

Fine-tuning efficiency also entails relocating braiding machines and super rope production from Mørenot’s factory in Hildre in Norway, to the super rope division of Hampiðjan Baltic, where installation is underway. This optimisation aims to take advantage of lower labour costs and better utilisation of equipment that was underused in Norway.

At Mørenot Denmark, staffing has been reduced from 12 to five, with further reductions expected by yearend when only two international sales managers will remain. Operations previously located in Denmark will be transferred to Norway.

“These developments mark an exciting period ahead, as India becomes a centre for expansion and production relocation – particularly of aquaculture cages – from Norway, Poland, and Lithuania. These changes bring significant efficiency gains due to India’s more favourable operating environment,” a Hampiðjan spokesperson said.

These developments mark an exciting period ahead, as India becomes a centre for expansion and production relocation

Hampidjan

Efforts are currently in progress to acquire land in India for further development, with construction planned to begin this spring and the first phase expected to be completed in the new year.

Authorities have pledged 12 hectares of land in the Auric industrial zone, about 20 kilometres east of Aurangabad – a city of approximately 1.7 million inhabitants. The site allows for construction of 60–70,000 square metres and is fully equipped with infrastructure, including electricity, water, internet, sewage systems and paved roads with dual lanes in both directions, with a connection to the Mumbai highway close by.

Kohinoor is one of India’s largest manufacturers of nets and ropes, with an annual production of around 14,300 tonnes. The company employs just over 700 people and has three operational sites – two net and rope factories in Selu and a net workshop in Jalna. The company also maintains an office in Aurangabad.

n Following the acquisition of the majority stake in Kohinoor, the Hampiðjan Group has approximately 2,700 staff on its payrolls

A flexible grid tested onboard Norwegian pelagic trawler Cetus looks promising after being tried out for two trips on Norway pout

The development work behind the flexible grid has been conducyed by Egersund Trål and the Institute of Marine Research in a project partly funded by the Fisheries and Aquaculture Industry Research Funding (FHS) and the Directorate of Fisheries in Norway.

According to a report published by FHF, the flexible grid is effective in filtering out unwanted bycatches and it could have applications in other fisheries.

“There are some challenges to handling the steel grid that we are required to use. It is easily damaged when we spool the trawl on board. It is heavy and is simply difficult to handle. With this flexible excluder, the work is much easier, and the by-catch is filtered out unharmed,” said Helge Olav Vikshåland, owner of Cetus

The two trial trips with the flexible grid have followed tank testing ashore.

“We have a double rig, so we were able to work both a regular trawl and the test gear at the same time. That way we got a reference trawl so we could compare the catching operations,” he said, commenting that this excluder design could be effective for other fisheries.

“Unwanted by-catch is a challenge in many fisheries, so this is probably a method that can be further developed for other fisheries as well,” Vikshåland said.

Whitefish is a problem for the Norway pout fishery, and if the by-catch exceeds acceptable levels, there is a possibility that fishing grounds can be closed. The matter is now with the Directorate of Fisheries, which has the authority to decide whether or not to allow the use of this new selection device.

A variety of technologies, including Hampiðjan’s DynIce Data cable and the Star Oddi Fish Scanner, were brought together earlier this year to provide a new look at assessing stock, tested for the first time alongside acoustic sampling during one of the winter capelin surveys

The FishScanner is a plastic ring placed ahead of a trawl’s codend, with twin wide-angle stereo cameras mounted inside the ring. These produce 3D images of the subject, which makes it possible to measure the length of the fish observed, regardless of its distance from the lens.

During the current testing phase onboard research vessel Árni Friðriksson, red light was used, which has less impact on capelin behaviour.

Hampiðjan DynIce Data cable enables image data to be streamed in real time for processing. This real-time analysis saves time in data collection, but also to trains a neural network (AI) to automatically identify and measure the capelin. By using this device alongside echo sounder measurements, the accuracy of the analysis can be improved.

The first results of the test were promising and suggest that the technology could lead to more accurate echo sounder measurements by seeing what is entering the trawl at each location and depth and what the composition of the catch in real-time is in terms of age or species.

This initiative demonstrates how cooperation between research institutions and high-tech companies can lead to innovations that improve both research and commercial fisheries. With further development, implementing this technology in commercial fishing is expected to be

possible in the near future, which will further enhance the knowledge of the biological characteristics of the ocean while also improving the accuracy of fishing and saving time and energy.

The FishScanner was developed by StarOddi and the Marine and Freshwater Research Institute in collaboration with Hampiðjan. It was funded by the Rannís Technology Development Fund.

The whelk fishery is second only to scallops for the Normandy fleet – and a number of gaps remain in the knowledge relating to this important fishery pursued by around 130 fishing vessels in the region

Following the success of the EMFAF-funded Mecanor2 programme that examined fisheries for both whelks and crustaceans, the Normandy Fisheries Committee is continuing the work with the CCLIMBUP programme, also supported by EMFAF and in collaboration with a number of research institutes.

“The CCLIMBUP programme aims to better understand the effect of climate change on whelks, track the status of the resource and get to examine the economic health of fishing companies that target whelks,” a Normandy Fisheries Committee representative commented. “This work aims to support this fishery, despite the many uncertainties that affect on the resource.”

The work of the Mecanor2 programme was to analyse pot fisheries in Eastern Channel and North Sea waters, not least as a number of Hauts-de-France gillnetters have switched to fishing with pots. Without an accurate assessment of stocks of whelks and crustaceans, this left the industry with concerns about the state of these stocks.

In 2022 and 2023 Mecanor2 worked with the Normandy and Hauts-de-France fisheries committees, and researchers at Ifremer, SMEL and the University of Caen to monitor four Eastern Channel and North Sea areas using self-sampling methods and analysis of landed catches.

Results indicated that whelk stocks in the Bay of Seine were overexploited that SeineMaritime stocks were close to overexploitation. It concluded that part of landings consists of immature individuals, affecting the renewal of the stock. Recommendations were to increase the minimum landing size, to close the fishery for one day each week or to establish closure periods and fallow areas.

Mecanor2 also concluded that in the North Cotentin area crab stocks were considered overfished and lobster stocks were close to overexploitation, while spider crab stocks are increasing due to environmental changes and the fact that this species is not heavily targeted due to a limited market.

A new IT solution in Portugal, Greece and Cyprus could help aquaculture make informed decisions quickly and optimise fish feeding and production planning, writes Bonnie Waycott

Over the years, information technology (IT) solutions have become crucial for aquaculture, offering benefits across all aspects of production, management and sustainability. Because the sector is also significantly diversified, with a range of activities underpinning species, feed production systems, disease, and new business structures, it must continue innovating to produce more seafood and meet the demands of the global population. By embracing new technologies, such as IT solutions, aquaculture can become more productive and sustainable, improving efficiency and optimising operations through data-driven decision making.

SPAROS, a Portuguese small/midsize firm that offers new products and tailored nutritional solutions for aquaculture, is a firm believer in the potential of IT solutions, in particular digital nutritional tools. In 2023, the company formed a consortium known as The OptiFeeSH consortium with cloud-based data management and data analytics firm Blue Analytics, i2s (Integrated Information Systems)/ aquaManager, which specialises in software technology, data analytics, sensors and data loggers for aquaculture, and Portuguese land-based flatfish producer Flatlantic.

The goal of the consortium is to develop a solution for optimal fish feeding and production.

Tailored feeding strategies not only support healthier fish development but also enhance overall production efficiency and environmental sustainability

Alexis Glaropoulos, i2s/aquaManager

“Our focus is biological and nutrition modelling-based solutions for the aquaculture sector,” Ana Nobre, product manager at SPAROS, told WF. “We recognised the challenge for fish farmers in having to use lots of different types of software, and thought it would be interesting to work closely with i2s and explore together the synergies between the SPAROS digital nutrition expertise and their aquaManager fish farming systems, which are available for farms worldwide.

“We began talking about joining forces and decided to start with applying fish growth models to create custom specific feeding rate (SFR) and feed conversion ratio (FCR) plans. Now, the consortium has combined its expertise on fish nutritional modelling, data analysis and predictive tools, fish production management systems, and industrial R&D to develop a platform that enables farmers to embrace

a more scientific, data-driven approach to feeding and production management.”

Following the consolidation of the aquaculture management software space over the last decade, nonintegrated tools targeting precision farming are currently booming, the consortium explained. These are based on technologies such as underwater cameras, echo sounders, sensors and image processing algorithms for specific monitoring. However, a practical solution for on-farm feed use optimisation is non-existent in the global market.

Productivity in aquaculture is heavily influenced by feed and feeding practices, but despite their importance, significant gaps persist in feeding management across many aquaculture systems, said Alexis Glaropoulos, Consultant at i2s/aquaManager. Feeding decisions are still largely based on subjective visual assessments, he said, such as the speed of feed consumption, surface activity of the fish, and occasional gut content analysis. These methods often lead to manual, reactive adjustments in feeding rates, which can be inconsistent and inefficient. However, recent advances in aquaculture technology offer promising solutions.

“Automated feeding systems, real-time monitoring tools, and data-drive models make it possible to optimise feeding strategies, simulate ideal production

a platform that enables fish farmers to embrace a more scientific, datadriven approach to feeding and production management

scenarios, and significantly reduce feed waste, ultimately enhancing productivity and environmental performance,” said Glaropoulos.

“Production plans, such as SFR and FCR tables, are finetuned based on a trial-and-error approach,” said Nobre. “However, our solution, OptiFeeSH, enables farmers to create tailored feeding production plans. It will help them greatly in making daily feeding decisions, and help managers with long-term production planning.”

OptiFeeSH is an innovative cloud-based application. It draws on the consortium experts’ knowledge and experience and enables farmers to create optimal production plans, closely monitor their implementation, identify any deviations, and adjust the plans as needed to meet production targets. It estimates fish feed requirements based on site-specific growth targets and feeds used.

Users can create multiple plans that meet their farms’ target growth and choose the optimal one according to their criteria: faster growth, minimum FCR, maximum profit or a compromised solution. These tailored plans help avoid overfeeding, fine-tune FCRs, and detect underfeeding early, providing a solid basis for daily feeding decisions. To date, OptiFeeSH is available for seabass, seabream and tilapia.

“The strength of this tool is that it creates sound feeding tables that can be implemented in the field with confidence,” said Rui Amaral, production controller at Flatlantic. “This will provide more trust in daily feeding recommendations and hopefully prevent some of the fluctuations in fish appetite while maintaining steady growth.”

The solution is being developed based on the main expertise of each international partner in the consortium: SPAROS will share its knowledge and skills on fish nutrition and developing nutritional modelling tools for the fish farming industry. Blue Analytics will contribute its expertise in developing data analysis and predictive tools, especially with regard to data mining and machine learning techniques, and in developing cloud-based solutions. i2s/aquaManager will offer knowledge in fish production management systems, developing software solutions and its experience in commercialising this type of solution as SaaS (software as a service). Finally, Flatlantic will bring its expertise on fish production and industrial R&D.

“Our solution is a powerful tool designed to optimise fish feeding and production management in aquaculture by generating optimal FCRs and SFRs based on fish biology, nutritional requirements, and the targets of fish producers,” said Angeliki Sagia, Consultant at i2s/aquaManager. “Our team is committed to technologically advanced, userfriendly solutions that help to improve feed efficiency, growth performance, and sustainability in aquaculture.”

“We expect to help fish farms not only to increase profit, but also in other ways, for example, by improving water quality through feed waste reduction, and adapting to the market through optimised harvesting plans,” said Nobre. “Perhaps the biggest challenge during the system’s development has been working to guarantee simplicity at the interface while hiding the complexity at the back-end, and ensure that only minimal inputs are required for farmers to create the OptiFeeSH production plans and benchmark with their own production data. In other words, to ensure that we build something that can be used in a straightforward way by farmers, and encompass the required complexity of nutritional and biological processes to estimate feed requirements and optimised production plans.”

Aquaculture faces increasing pressure to improve feed management due to rising global demand for seafood and the need for sustainable practices, including better feed efficiency, alternative protein sources, and disease

prevention. In this sense, the demand and need for better feed management in aquaculture is high. Feed typically represents the largest single operational expense in aquaculture, often 50 to 70% of total production costs depending on the species and production system, said Glaropoulos.

Optimising feed isn’t just about cost-cutting; it’s also about improving efficiency, reducing waste and minimising environmental impact.

Alongside significant progress in fish genetics, the implementation of optimal feeding regimes has become increasingly vital in modern aquaculture. As selective breeding and genetic enhancement improve growth rates, disease resistance, and FCR, it is equally important to ensure that feeding practices are aligned with the physiological needs of these improved stocks, said Glaropoulos.

“In both land-based and sea-based systems, tailored feeding strategies not only support healthier fish development but also enhance overall production efficiency and environmental sustainability,” he said. “By optimising feed composition, frequency, and delivery methods, aquaculture can reduce waste, lower costs, and minimise the ecological footprint of fish farming. Together, genetic advancements and precision feeding form a powerful synergy, driving the future of sustainable aquaculture forward.”

Looking ahead, future research will focus on quantifying the improvements that OptiFeeSH production plans may bring to fish farms, based on the results of ongoing pilots, and expanding the solution to include more species, such as Atlantic salmon.

“This decision-making tool is a unique offer for aquaculture farmers to optimise feeding strategies and production plans based on a sound nutritional approach,” said Kostas Seferis, Director of Blue Analytics and Group CEO of aquaManager Group.

“The OptiFeeSH project will empower fish farms to make their business more profitable, environmentallyfriendly and fish-friendly,” added Luis Conceição, Co-CEO at SPAROS.

n OptiFeeSH’s seabass and seabream trials have led to the creation of feeding tables that can be confidently implemented in the field

Amid food security concerns, the industry is being urged to do much more to ensure it can meet the world’s growing food demands, writes Jason Holland

While aquaculture is widely recognised as being crucial to global food security, the recent Blue Food Innovation Summit heard the industry needs to do much more to ensure it can meet the world’s growing food demands and provide much of the estimated 25 million tonnes of additional seafood that will be required as soon as 2030.

Setting the scene at the London-based conference, Erik Giercksky, Head of Sustainable Ocean Business at the UN Global Compact, stressed that food security was the “number one, most pressing issue” for all G20 governments, the United Nations and the FAO.

“There are only three things that can really address this: aquaculture, aquaculture and aquaculture,” he said. “We have depleted land resources too much, and the wild catch is at its limits and might only slightly be improved. But aquaculture has massive potential if we get it right.”

In this regard, Giercksky pointed to salmon farming for inspiration, which he said delivers a fantastic product but is still quite limited in volume terms when it comes to feeding the world population. Nevertheless, it’s essential that knowledge and technology is transferred from the “silicon fjords” of Norway and Chile to other blue food production sectors, he said.

“I think a crucial point for this industry to really grow is to have a trickle down of this knowledge and investments into other parts of the world.”

From the salmon sector, Cermaq Global CEO Steven Rafferty told the conference that 80% of global production continues to come from just two countries – Norway and Chile, and that the overall growth has been “very limited” over the past four-to-five years.

“It is growing more this year, but we have struggled as an industry to really expand,” Rafferty said.

One of the things we’re able to do is transfer knowledge, technology development, knowhow on starting up an industry, and that’s the biggest challenge facing the growth of aquaculture

Steven Rafferty, Cermaq

Part of the reason for this, he explained, is down to climate changes, including higher water temperatures. “In fact, most of the production countries today are the same as they were 20 years ago, maybe with the exception of Iceland that is growing quite strongly.”

Farming salmon is very capital-intensive, and the reason that producers are able to do it is the profit margins on production have been quite high over the past 10to-15 years, Rafferty said, adding that this has allowed companies to reinvest on a large scale.

“The dilemma we now face is the traditional ways of producing salmon are coming under more pressure, and we need much more innovation, new technologies to grow salmon within more challenging conditions. We can produce salmon on land. We can produce salmon in types of closed containment systems in the sea, but these are extremely expensive and they’re new innovations, so it’s taking time to scale up, and that’s really why we’ve not seen too much development. But we’re very confident that we’ll keep on going. There’s a lot of new technologies coming, and lots of new innovation.”

and demand, but similar innovations are desperately needed in other sectors