8

Merida INTERNAL BLOCKSYSTEM A SMALL BUT VERY EFFECTIVE ELEMENT FOR OPTIMAL FRAME PROTECTION

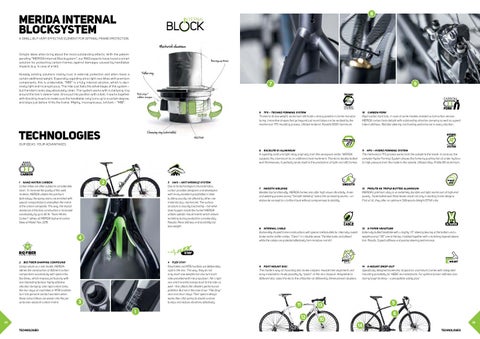

Simple ideas often bring about the most outstanding effects: With the patentpending “MERIDA Internal Blocksystem”, our R&D experts have found a smart solution for protecting carbon frames against damages caused by handlebar impacts (e.g. in case of a fall). Already existing solutions mainly trust in external protection and often mean a certain additional weight. Especially regarding ultra-light race bikes with premium components, this is undesirable. “MIB” is a fully internal solution, which is decisively light and inconspicuous. The rider just feels the advantages of the system – but the bike’s looks stay absolutely clean. The system works with a clamping ring around the fork’s steerer tube. Once put into position with a bolt, it works together with blocking inserts to make sure the handlebar only turns up to a certain degree, and stops just before it hits the frame. Mighty, inconspicuous, brilliant – “MIB“.

7

9

5 TFS – Techno Forming System Thanks to its low weight, aluminium still holds a strong position in frame manufacturing. Innovative shapes that go beyond just round tubes can be realized by the mechanical TFS moulding process. Utilized material: Racelite 6061 aluminium.

10 Carbon Fork Rigid carbon front fork, in case of some models realized as full-carbon version. MERIDA carbon forks delight with outstanding vibration damping as well as superb lateral stiffness. Reliable steering and braking performance in every situation.

6 Racelite 61 Aluminium A superbly solid and light alloy originally from the aerospace sector. MERIDA subjects this aluminium to an additional heat treatment. Thanks to double-butted wall thicknesses, it perfectly lends itself to the production of light and stiff frames.

11 HFS – Hydro Forming System The mechanical TFS process works from the outside to the inside. In contrast, the complex Hydro Forming System shapes the frame by pushing hot oil under hydraulic high pressure from the inside to the outside. Utilized alloy: Prolite 66 aluminium.

7 Smooth Welding Besides top functionality, MERIDA frames also offer high visual attractivity. A second welding process during “Smooth Welding” evens the connecting seams – an elaborate concept for a brilliant look without compromises to stability.

12 Prolite 66 Triple Butted Aluminium MERIDA’s premium alloy is an extremely durable and light aluminium of high-end quality. Triple-butted wall thicknesses result not only in exciting frame designs: First of all, they offer an optimum Stiffness-to-Weight (STW) ratio.

8 Internal Cable Elaborately shaped frame constructions with special inlets/outlets for internally routed brake and/or shifter cables. “Clean” in a double sense: The bike looks uncluttered while the cables are protected effectively from moisture and dirt.

13 X-Taper Headtube Externally butted headtube with a mighty 1.5” steering bearing at the bottom and a weight-saving 1 1/8” one at the top; installed together with a matching tapered steerer fork. Results: Superb stiffness and precise steering performance.

9 Post Mount Disc The modern way of mounting disc brake calipers. Hassle-free alignment and easy installation made possibly by “posts” at the rear dropout. Adaptable to different disc sizes thanks to the utilization of differently dimensioned adapters.

14 K-Mount Drop-Out Specifically designed brake-disc dropout for aluminium frames with integrated mounting possibility for HEBIE rear kickstands. For optimal torsion stiffness also during tough braking – a perceptible safety plus!

Technologies OUR IDEAS. YOUR ADVANTAGES.

2

1 Nano Matrix Carbon Carbon bikes are often subject to considerable strain. To increase the quality of the used material, MERIDA utilizes this premium technology: the epoxy resins are enriched with special nanoparticles to strengthen the matrix of the carbon composite. This way, the impact resistance of the final construction is increased successfully by up to 40 %. “Nano-Matrix Carbon” refines all MERIDA high-end carbon bikes of Model Year 2015.

3 AWS – Anti Wrinkle System Due to its technological characteristics, carbon provides designers and developers with many excellent possibilities in bike building usually not offered by other raw materials (e.g. aluminium). The surface structure is visually fascinating – but what does happen inside the frame? MERIDA utilizes specific mould inserts which reduce wrinkling during production considerably. Results: More stiffness and durability but less weight.

4

2 Bio Fiber Damping Compound Using nature as a role model, MERIDA refines the construction of different carbon components successfully with special bio flax fibres, which impress particularly with one interesting feature: highly effective vibration damping. Like rigid carbon forks, the rear stays of road bikes or MTB hardtails turn into genuine comfort wonders when these natural fibres are woven into the per se torsion-resistant carbon matrix.

4 Flex Stay Road bikes and MTB hardtails are deliberately rigid in the rear. This way, they do not only reach low weights but also turn each rider-provided watt into propulsion. Yet a rigid rear end transmits bumps back to the rider as well – this affects the athlete’s performance potential. But not in the case of our “Flex Stay” seat and chain stays: Their special design works like a flat spring to absorb surface bumps and reduce vibrations effectively.

3 1

22

11 12

5

13

6 10

23

14 Technologies

Technologies