11 minute read

Picking the Right Label Solution for Your Package

Picking the Right Label Solution for Your Brand

The next stop in our label journey is the importance of selecting a label solution. There are multiple label solutions to pick from when launching a new product. Do you know which one is right for your brand? We offer a breadth of label solutions to choose from. Various factors can come into play when deciding, but don’t worry, our team of label experts are here to help you pick the right one for your brand to succeed!

Cut & Stack

Labels (C&SL)

Cut & stack labels are a cost-effective solution for high volumes. They offer a variety of substrates and embellishments.

The name of this label leaves little to the imagination. It is printed on large sheets or rolls. Afterwards, the labels are cut into the correct shape. These labels are highly recommended for high-volume products: low material costs and total applied costs provide an effective solution. Cut & stack is designed for efficient application during the packaging process. The minimal waste makes this an eco-friendly label. In addition, we also offer a sustainable variant: the paper label. It’s possible to print your design on a wide variety of substrates, including paper (metallized and holographic), film (metallized and opaque), and eco grades. To enhance the label design, there’s a comprehensive range of embellishments including foil stamping, embossing, striking metallics, stunning varnish effects, and intricate shapes.

Key Features

• Cost effective on high-volume products • Efficient application • Substrates: paper, film and eco-grade

Printing Capabilities

• Rotogravure • Flexography • Lithography • Digital

Pressure Sensitive Labels (PSL)

Pressure sensitive labels can be used on almost any type of material and can be custom-made to fit any shape and size.

Pressure sensitive labeling is the perfect balance of cost efficiency and premium brand appeal that produces sharp, bright colors in a wide variety of applications. They are very similar to stickers, requiring pressure to form a bond between the adhesive and the product. The self-adhesive characteristics of these labels mean that no water, solvent or heat is required for the label to adhere to the product. Pressure sensitive labels are not only easily applied, but can also be easily removed simply by peeling off the label from the container. They can be used on almost any material from glass bottles, to plastic, to metal auto parts. Pressure Sensitive labels are easy to use, look great, and contain all the important information you need.

Key Features

• Offer a high-efficiency, glue-free labeling option • Available in transparent, white or metallized film and in a variety of paper substrates • Suitable for PET, glass and aluminum containers • High speed label application provides greater efficiency • Excellent print quality in up to 11 colors • Unidirectional and returnable material options

Printing Capabilities

• Rotogravure • Flexography • Digital

Autoland, a Polish family operated company with over 30 years of experience in producing high quality car care products and automotive fluid, is 100 percent committed to sustainability, with facts to prove it.

Sustainability first

Autoland uses 100 percent recyclable PET bottles filled with ingredients that are at least 95.5 percent biodegradable for their NATURAL car care cleaning product line. They want to minimize the negative footprint on the environment, with a commitment of putting the natural environment first. They were only missing one thing to achieve a 100 percent, fully recycling package – a recyclable label.

A sustainable match

Autoland searched for a label provider with the same amount of passion and dedication that they have towards sustainability. They were introduced to MCC and our sustainability vision. At MCC, we CARE about a better tomorrow, today. CARE stands for Collaborate, Act, Resolve and Engage. We continuously strive for sustainable development that provides shared value and helps build a brighter future for all. With visions and goals aligned, it was time to create a sustainable label solution for Autoland.

Digital and sustainable label

MCC utilized their digital printing capabilities to provide a digital pressure sensitive label printed on PET material. The PET material allows for the label to be 100 percent recyclable. They now have a 100 percent, fully recyclable packaging for their car care product line, solidifying their commitment and vision on sustainability.

“I love working with the MCC team. They deliver professional customer care through whole process.

From designing, choosing the printing method to optimum delivery date. Great cooperation with the whole MCC team.”

Damian Halej, Head of Marketing at Autoland

Heat Transfer Labels (HTL)

Achieve a ‘no-label’ look with heat transfer labels.

Heat transfer labels enhance brand packaging to create a visually appealing and highly-functional product.

Heat transfer provides a seamless, aesthetic, ‘no-label’ look while offering virtual 360-degree application. This technology can be applied to a variety of containers in different shapes and sizes (from two ounces to five gallons) with extremely accurate label placement. Heat transfer affords greater adhesion and durability – even in high-moisture environments. These labels are fully recyclable without removing them from the container. They are also squeeze and product resistant, lightfast and have a high degree of ink opacity.

Key Features Printing Capabilities

• No-label look • 360 degree application • Fully recyclable • Greater adhesion and durability • Rotogravure • Flexography • Digital

Want to learn more about HTL? We have an entire Whitepaper that will help increase shelf appeal and optimize production processes! Click here to download it now.

Offering Full Scope of HTL Capabilities for KOST USA

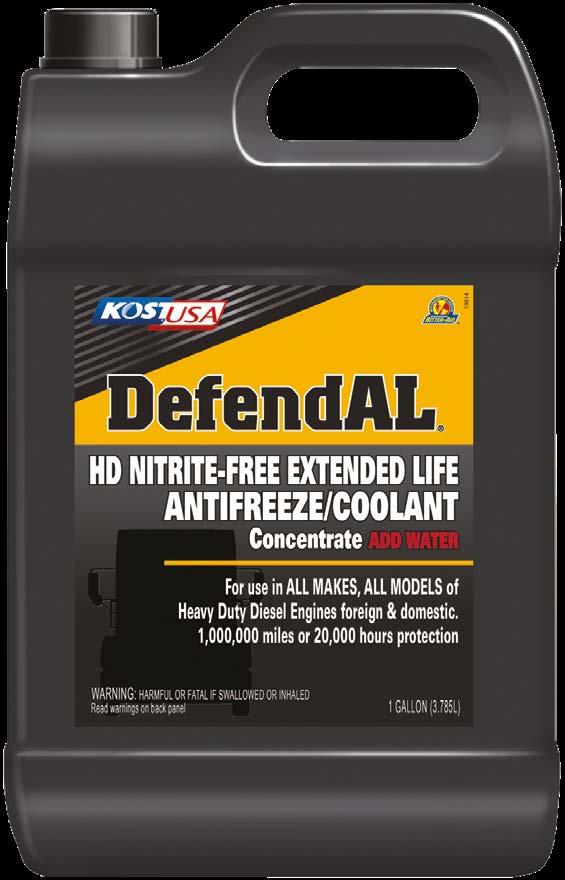

KOST USA, Inc. is the largest familyowned manufacturer, supplier and marketer of antifreeze and functional fluids in the United States. They were previously using another label solution for their DefendAL® branded antifreeze/ coolant line but challenged MCC to find a new label solution that met their business goals.

Late stage differentiation

Through extensive knowledge sharing sessions with KOST, our label experts determined heat transfer labels (HTL) is the right label solution for their DefendAL® bottle. HTL is a cost-effective solution that prints superior quality, high color labels onto branded bottles. HTL allows for late stage differentiation in their manufacturing process. They now fill their bottles in-line and manage both the color of the bottle and the label at the same time without having to carry dedicated finished goods inventory.

One company, all the solutions

KOST can now lower their inventory costs by utilizing MCC as their turnkey label solutions provider. We provide them with our full service of capabilities, technical support and expertise for their DefendAL® branded antifreeze/coolant line. There is a huge benefit in providing them with one company to go to for their label needs. We collaborated with them from the beginning, developing a comprehensive supply chain strategy that led to delivering a national brand onto retail shelves. We have every aspect of their packaging covered, exceeding their expectations along the way.

In-Mold Labels (IML)

Decorate your plastic containers with strong, hygienic labels that showcase high-resolution images.

We offer in-mold labels for injection molding, blow molding and thermoforming. They provide superior graphic reproduction and are 100% recyclable. Our customers consistently find that in-mold labeling is a cost-effective solution for decorating plastic containers. It removes the need for post-mold labeling, eliminating costly bottlenecks in production and requiring less manufacturing floor space. In-mold labels work well in either injection mold, blow mold or thermoforming applications, providing the ultimate ‘no-label’ look even on unique container shapes. These labels provide superior graphic reproduction, with a high degree of product security because of the lack of delamination. In-mold film labels are 100% regrindable and recyclable, which is increasingly important considering today’s level of environmental awareness. They also allow for quick design changeovers.

Key Features Printing Capabilities

• Maximum print quality • Environmentally friendly • Quick design changeovers • Strong and hygienic • Wide range of look & feel options • Rotogravure • Flexography • Lithography • Digital

Want to learn more about IML? We have an entire Whitepaper that will help your products stand out on the shelf! Click here to download it now.

A Bright New Era for Exterior Paint

When it comes to making high-end paint stand out from the rest, high-quality packaging is a must. When the German Lebanese Co. for Industry (GLC), a leading manufacturer of paint products in Africa and the Middle East, was designing their new line of Storm Shield exterior paints they worked with MCC Verstraete on a packaging solution that effortlessly lets customers know the paint in the pail is the best in the business. Metallic IML elegantly captures attention with a stylish and sophisticated finish that’s a direct reflection of the product inside.

The hunt for the perfect packaging

The collaboration between MCC Verstraete and GLC was initiated during Storm Shield’s early development stages. IML comes with multiple advantages compared to other types of labels, such as direct print and self-adhesive options. The benefits go above and beyond appearance. IML is a solution that’s flexible: when it’s time to update the label design, this can be done quickly and easily, with many options for creating the right look and feel. They make labeling a breeze using a one-step process that bypasses any need to manufacture pails and labels separately. And the results are difficult to copy - a factor that’s paramount in the paint world due to the proliferation of counterfeiting.

Standing out on the shelf

To create the optimal labels for Storm Shield, MCC Verstraete and GLC customized an exclusive design using Metallic IML Foil, Matte + Spot HighGloss, creating a first-class finish that shows elegance. Metallic IML captures attention on any shelf. The customer immediately recognizes a superior, highend product. Metallic IML preserves the look and feel of a metallic paint can, with the bonus of being less expensive. It gives the paint pail an exquisite shine and adds an element of modernity and class that is perfect for the Storm Shield range.

Lighting up the marketplace

Storm Shield is truly a giant leap forward in the quality customers can expect from exterior paint. And thanks to GLC’s collaboration with MCC Verstraete and the innovative technology of Metallic IML, this revolutionary range is destined to make the industry take notice.

“To market our high-end Storm Shield range, we needed packaging that represents the quality and durability of the paint inside. IML was the obvious choice for creating an innovative and exclusive design, and

Metallic IML in particular provides unique and eye-catching options.”

Shrink Sleeve Labels (SSL)

Discover unlimited branding opportunities with shrink sleeve’s 360-degree coverage

Shrink sleeve technology optimizes the printable label area with 360-degree graphics, while accommodating extreme container contour. This flexibility is applicable to virtually any shape or size container on a variety of films.

Shrink sleeve labels are the fastest growing label technology for many different reasons. This solution allows you to have a 360-degree display of your beautiful graphics and text. This in turn gives your products maximum marketing exposure and aesthetic impact. Once the film comes in contact with heat, the label shrinks and tightly conforms to the shape of the container. Shrink sleeve labels can accommodate extreme container contour. This flexibility is applicable to virtually any shape or size container on a variety of films.

Both UV flexography and rotogravure printing can be utilized, providing photo quality images. Many different eye-catching label innovations can be implemented with shrink sleeves to gain stopping power at shelf. Shrink sleeves are not only beautiful, but also provide functional benefits such as: excellent scuff resistance, easy detection of tamper evidence, and consumerconvenient multi-pack presentation.

Key Features

• 360-degree graphics • Tamper evidence • Multi-packs • Scuff resistance • Great solution for unique shaped containers

Printing Capabilities

• Rotogravure • Flexography • Digital

Creativity and Shrink Sleeves Support WD-40® Brand’s Bike Line

WD-40 Brand’s iconic blue and yellow can with a red cap is recognized in factories, workshops and homes across the globe — but the brand offers so much more.

The challenge

Through its line of WD-40 Specialist® products, the company brings to market more than 20 specialized, high-performance solutions including a line of bike products designed for everyone from amateur cyclists to leading athletes in road and off-road racing. When the company changed its bottle for the bike line from opaque to clear plastic, it offered a challenge to MCC: create a shrink wrap label that mimics the appearance of the metallic silver used for the entire line of WD-40 Specialist products. This is where MCC’s expertise came in.

The result

Since shrink sleeve material isn’t available in silver, MCC had to get creative. MCC’s technical experts utilized metalouire specialty inks to replicate the desired look. The new labels bring brand continuity for users by connecting the bike line to the iconic brand trusted for almost 70 years. By doing so, the new labels will reinforce a strong brand presence at retail and digital shelves.

“The original WD-40 Multi-Use Product formula was created in 1953 when scientists set their sights on a challenging mission: helping rockets get into space. Today, that spirit of perseverance and innovation live on as we solve new problems and help things run smoothly. MCC was able to embody that spirit through creative problem solving for the label redesign and the end result is a label that reinforces the

WD-40 Brand and makes the product easy to identify for end users.”

Erin Bala, Director of Brand Management and Innovation at WD-40 Company