4 minute read

Overcoming Challenges with Smart Label Solutions

Here are some of the current challenges we see companies are facing today in the Healthcare industry. Learn how our smart label technologies can help solve some of your problems!

Challenge 1: Traceability of Consumable Medical Devices

In recent years the US has spent nearly 200 billion dollars on medical and health research which created thousands of new products that needed to be administered by the health care system. While at the same time, mass tort litigation is now a growing concern for medical device companies. Now these companies are looking for ways to manage risk while providing the best new technology to fight diseases.

Smart labels create a trail

Smart labeling is one avenue medical device manufacturers can use to ensure both the highest quality care and mitigate risk at the same time. A great example would be connecting a device consumable to a smart device. The system is set up to have a unique identification placed on the consumable using one of the smart label technologies. It also includes the means to read the identification in the smart device. The smart label information could be a traceable serial number, may include a lot number and expiry or even device settings such as temperature and flow rate.

When the consumable is introduced, it can read the label, authenticating the consumable and can associate that specific consumable with a patient, health care worker, facility and even set the delivery parameters correctly. Multiple versions of smart labels can be used for this ranging from a simple 2D barcode to a UHF tag (for longer range readings) to a near field HF tag (for security and more data). Advantages of these systems include simplified training, traceable lots, safeguards against use after expiry and a digital trail of verifiable events.

Dave Uland, Smart Label Expert at MCC

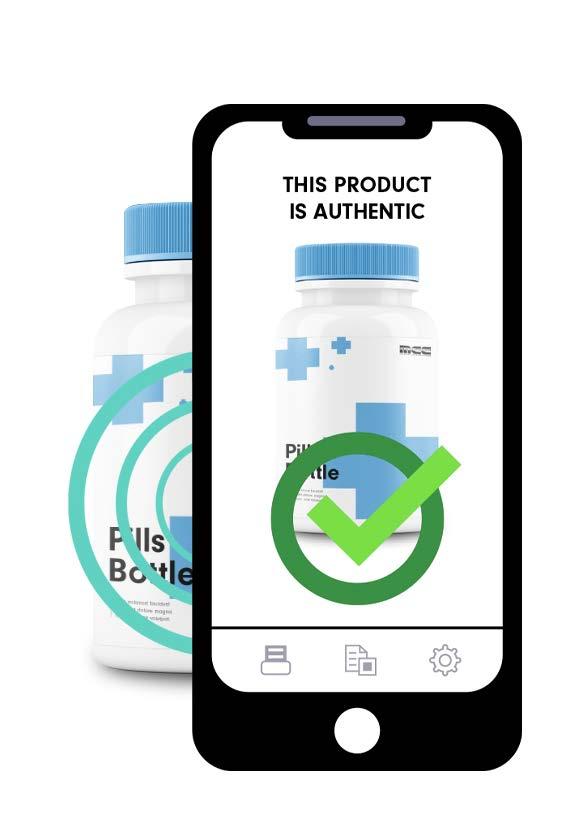

Challenge 2: Inventory and Expiration Management of Consigned Material

Many consumable medical devices are sold on a consignment basis through health care providers. Virtually all these implants have an expiry date which may vary by jurisdiction and are tracked by lot numbers. The lot number can be used to pull devices if a problem is found with another device from that lot. During medical procedures when these implants are needed, it’s difficult to find the right one because the packaging looks the same. The medical staff must also search for one that isn’t expired. This can take a lot time. In addition, these devices are very expensive and because of that can be returned to the manufacturer after expiry to be remanufactured and reconsigned.

Identify and authenticate with UHF tags

Smart labels can help with these issues. UHF tags are helpful in identifying and authenticating what is or isn’t useful in the storeroom. Typically, a system is comprised of a smart label on the product, a handheld UHF reader or fixed reader in the storeroom and software to store the location and status of the consigned inventory. This status can be read by the manufacturer’s rep, the health care provider or both if standard encodings are used. In addition, the manufacturer can use the same smart label to speed up reception and processing of returned goods.

To be effective in this application, the UHF tag must be suitable for the required read range on the package. This is often complicated by metalized heat seal bags in the package or neighboring package. It can be overcome by optimizing the placement and performance characteristics of the tag.

Challenge 3: Controlling Delivery of Pharma Consumables

Hospitals and clinics are busy places in a ‘normal’ world, but the pandemic has demonstrated the need to simplify and automate processes for health care workers. Smart labels can enable simplified, yet secure automation of consumable delivery, while also adding a layer of safety for the product.

Monitoring the supply chain

You can embed a UHF tag in the label on a reagent or pharma container and mount a reader inside the smart storage unit. The health care worker can access the smart storage unit through their hospital badge and remove the products they need. The reader can automatically detect what is removed and assign it to that health care worker. The smart storage unit can also monitor for expired product or storage conditions like temperature and humidity. It will alert health care providers notifying them of the products associated so they are not used inadvertently.

Contact our smart label experts today for more information! marketing@mcclabel.com