Mark Tool was established in 1954. We quickly earned an excellent reputation providing downhole-cutting tool service.

In 1969, the company became Mark Tool & Rubber Co, Inc. with the application of rubber coating blast joints and SplashTRON® pipeline coating. The company became the leader in splash zone protection because it took a comprehensive approach to developing the ultimate pipeline coating products for its customers in the oil, gas, and petrochemical industries.

The Mark Tool’s vision is to have a strong commitment to selling quality products while delivering outstanding customer service. This vision allowed us to continually expand the company’s reach with innovative technology, knowledgeable personnel, and excellent service.

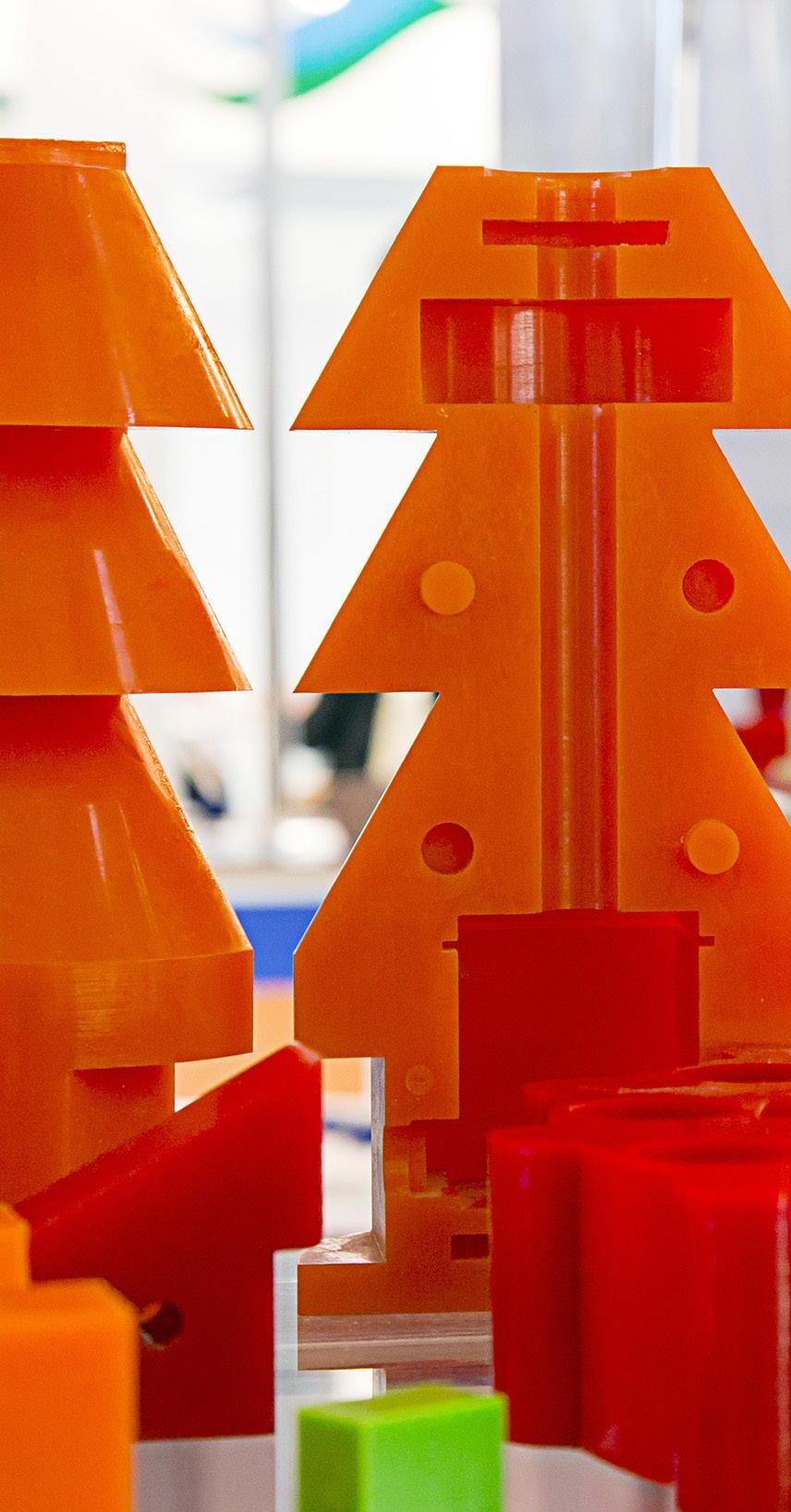

Today, Mark Tool & Rubber Co, Inc. is still a familyowned and operated business. We have expanded into related industrial and manufacture products like custom molded rubber products, rubber rollers, and cast urethane products, which are popular products for the oil and gas industry.

Mark Tool & Rubber is the leader in splash zone protection and a leading manufacturer of cast urethane and rubber tools for offshore and marine applications. Specialty products include rubber rollers, polyurethane rollers, pipe spacers, tensioner pads, SplashTRON® Pipeline Coatings, and other custom molded rubber products.

Mark Tool has been in business since 1954 and has proudly serviced the Gulf with the best in rubber and molded urethane products.

Use the contact information below to reach us or request a quote at www.marktool.com today!

Every pipeline system is susceptible to corrosion. Even a brand-new system can show signs of destructive wear in as little as two years after installation. Therefore, using a high-quality coating is crucial.

SplashTRON® pipeline coating prevents biofouling, provides quick and durable protection against corrosion and other stuctural threats, and can last for over 30 years.

The tough, yet flexible, SplashTRON® is uniformly bonded to the metal surface that will be exposed in the splash zone in thicknesses of 1/4″, 1/2″, 3/4″, and 1″. It resists impact damage, features exceptional weatherability, requires no routine maintenance, has excellent insulating properties (thermal and electrical), and can be used at temperatures from -45°F to 200°F.

• Platform structural members (diagonals and legs)

• Risers

• Riser clamp linings

• J-tubes

• Bends

• Pipe field Joints

• Spools

Common applications of this product include pipeline coatings, platform structural members (legs and diagonals), conventional risers, pipelines pulled through J-tubes, conductors, and the lining of riser clamps. Mark Tool has coated offshore platforms with SplashTRON® for two decades.

The tough, long-lasting elastomer is applied to structural members exposed to the splash zone during fabrication. It provides complete protection against the erosive action of abrasive-laden seawater, the harsh attack of ozone and ultraviolet rays, incidental impact from boats and floating debris, and the effect of sea life which builds upon all offshore installations.

An important feature of SplashTRON® in pipeline coating application is the fact that it is completely and permanently bonded to the metal surface, and because it is flexible, it won’t crack or disbond as the members bend, expand, and contract. This product can be expected to protect against corrosion for the life of the platform. SplashTRON® has proven its effectiveness in the Gulf of Mexico and other offshore areas around the world for more than 30 years. It is used by the leading producers of oil and gas, and most transmission companies.

ThermoTRON 350® is a high temperature, wet insulation coating that can be used to protext subsea tiebacks, flow lines, pipelines and more. It can insulate up to 350°F without bending, cracking or disbonding as your pipe bends.

This coating is strategically made using three critical layers:

• Corrosion-resistant layer

• Bonding agent layer

• Elastomeric insulation later

In January 2016, Mark Tool and Elite Elastomers of Ohio LLC entered into a joint venture focused on the research, development, and end-use application for complete, elastomeric, subsea hightemperature thermal insulation systems that could be installed via three methods: J-Lay, S-Lay, and Reel-Lay.

TWO TYPES:

• ThermoTRON 350®

• ThermoTRON XT®

350®:

• Insulation System for Flow-lines

• Insulation System for Production Risers

• Insulation System for Hull piping

• Insulation System for Tie-backs

• Insulation System for Spool

350®:

1. The first layer is a corrosion coating that provides the pipe surface (the pipe is first steel grit blasted) with a film that is highly resistant to chemical attack and to cathodic disbondment.

2. The second layer consists of a bonding agent that works as a bonding layer between the top coat and the first layer of corrosion coating.

3. The third layer consists of extruded ThermoTRON 350™ 1” thick depending on the service conditions (the thickness could vary). The function of the third layer is to provide the system with excellent thermal insulation properties and both anticorrosive and mechanical protection.

PRODUCTS:

Ruber Rollers

Rubber Surfacing

Vulcanized Rubber Clamps

Tensioner Pads

Because such a broad range of industries use rubber, thousands of specific and unique rubber parts are required in order to make machines or processes function.

Whether needed in the form of large rubber rollers for factory conveyors or petroleum pipeline, or in the form of the tiniest rubber o ring for the smallest of pipes, a wide variety of industries regularly seek custom molded rubber products to fit individualized needs.

Mark Tool Company, Inc. can manufacture just about any size and type of rubber roller. Whether you’re looking for agriculture rollers, industrial rollers, or even pipeline rollers, we can supply and satisfy your rubber roller needs.

02

Rubber surfacing offers an array of benefits for outdoor and indoor playgrounds, around pools, livestock trailers, and much more.

03

Mark Tool & Rubber has been vulcanizing riser clamps for the oil & gas industry with SplashTRON® for over 40 years. Mark Tool & Rubber also can fabricate riser clamps to customer specification or drawings.

04

We can manufacture almost any size and type of tensioner pad to meet or exceed customer specification. Long-lasting and durable, Mark Tool Co., Inc. keeps tension pads in stock for immediate shipment, based on customer demands for volume and usage.

Mark Tool Company, Inc. can manufacture just about any size and type of rubber roller. Whether you’re looking for agriculture rollers, industrial rollers, or even pipeline rollers, we can supply and satisfy your rubber roller needs.

Rollers can be produced out of a variety of rubbers based on specific customer needs and rubber applications. Long lasting and durable, Mark Tool will keep customers’ rollers in stock for immediate shipment based on customer demands for volume & usage.

CUSTOMIZABLE, COST-EFFECTIVE, DURABLE PRODUCTS FOR A VARIETY OF INDUSTRIAL APPLICATIONS

We can produce many different types of rollers and products including:

Conveyor Rollers

Rubber Pipeline Rollers

Roller Reconditioning

Industrial Rollers

Rubber surfacing offers an array of benefits for outdoor and indoor playgrounds, around pools, livestock trailers, and much more.

These benefits range from aesthetics and tactile appeal, to durability, safety, and more; making it the premier choice over other options like loose fill and colored concrete. Its many benefits also offset any cost variables due to the longevity and lifespan of the product.

We offer a “One Stop Shop” for all your rubber surfacing needs. We provide high-quality colored EPDMs, buffings, high-tech polymer resin binders, and rubberized mulch for a wide variety of agriculture, commercial, and residential environments.

Mark Tool & Rubber has been vulcanizing riser clamps for the oil & gas industry with SplashTRON® for over 40 years. Vulcanization refers to a specific curing process of a rubber product involving high heat and the addition of sulfur or other equivalent curatives. It is a chemical process in which polymer molecules are linked to other polymer molecules by atomic bridges composed of sulfur atoms or carbon to carbon bonds.

The end result is that the springy rubber molecules become cross-linked to a greater or lesser extent. This makes the bulk material harder, much more durable, and also more resistant to chemical attack. Mark Tool & Rubber also can fabricate riser clamps to customer specification or drawings.

CUSTOMIZABLE, COSTEFFECTIVE, DURABLE PRODUCTS

Mark Tool Co., Inc. has provided tensioner pads to the major lay barge operation for years. We can manufacture almost any size and type of tensioner pad to meet or exceed customer specification. Long-lasting and durable, Mark Tool Co., Inc. keeps tension pads in stock for immediate shipment, based on customer demands for volume and usage.

Our range of high quality rubber parts and components includes rollers, tension pads, and a wide variety of custom molded rubber products. We have the capabilities and resources to take our customers’ designs and create precise molds that are then utilized to create high quality parts through compression molding, injection molding, or extruding. Regardless of what type of rubber components you require, chances are that Mark Tool & Rubber Company can meet your unique needs.

PRODUCTS:

Urethane Forklift Pads

Polyurethane Rollers

Ureguard Pipeline Supports

Urethane Pipe Spacers

UreGuard Towline Protectors

Other Custom Products

SAVE TIME AND MONEY ON COSTLY REPAIRS BY HELPING EXTEND THE LIFE OF YOUR EQUIPMENT.

Prevent damage to packages and skids from sharp edges of fork truck forks with blunt end Fork Blade Protectors. Hide unsightly scratches and gouges on your forks as well. Constructed from lightweight 100% Polyurethane material. Simply slide over forks. Held in place with a clevis pin and cotter pin.

Mark Tool’s custom molded polyurethane forklift pads will prevent scratches or scuffs guaranteed to protect Fusion Bonded Epoxy (FBE) coated pipe or any other coated substrates. This will save you time and money on costly repairs.

Our forklift pads are fabricated steel sleeves and then coated with high quality, custom molded polyurethane, engineered to stand up against extreme abuse and environmental conditions.

We can make pads many different sizes & styles to fit the customer’s needs. We can also strip worn out polyurethane off steel pads and recoat pads to new. This can be done many times over the years.

HIGHER, MORE RELIABLE PERFORMANCE FROM A MATERIAL THAT STRONGLY RESISTS ABRASION, HARSH CHEMICALS, ACIDS, AND SOLVENTS

All of our polyurethane rollers are made from the highest quality polymers available. We can make hundreds of shapes and sizes of rollers, including (but not limited to):

• Hourglass Polyurethane Rollers (or V Polyurethane Rollers)

• Conveyor Belt Polyurethane Rollers

• Pipe Conveyor Polyurethane Rollers

• Sheave Rollers

• Paper Mill Rollers

• Polyurethane Pipeline Rollers

Rollers can be made of many different thicknesses, sizes, colors, and hardness from shore 10A to 80D.

The next time you are thinking of discarding those old, used, worn-out polyurethane rollers, think again! Give Mark Tool a call or email us and let us see if we can rebuild your old parts and save you some money by putting them in our burn-off oven, cleaning them, and re-coating them.

In addition to polyurethane pipeline rollers, Mark Tool also offers rubber pipeline rollers and pipe spacers (see page 25-26).

OUR PIPELINE SUPPROTS CAN BE REMOVED WITHOUT PICKING THE PIPELINE UP FOR MAINTENANCE OR PAINTING

The corrosion-related cost to the transmission pipeline industry is approximately $5.4 to $8.6 billion annually. One of the most common corrosion problems on a pipeline is where pipe supports interface with the pipe.

Mark Tool & Rubber Co, Inc. working together with pipe line Corrosion Technician has come up with the ultimate design for Pipeline Support System.

Our UreGuard Pipeline Supports are made of a durable castable polyurethane 90D durometer and can be adjusted to multiple sizes of pipe. The biggest advantage of our system is that it can be removed from the pipeline without picking the pipeline up for maintenance painting.

Polyurethane is the ultimate workhorse.

Whether used as a spray, foam, a flexible, spongey elastomer, or a solid that is as hard and tough (almost) as any diamond, polyurethane’s versatility means it can be molded into components of any size, shape, and hardness.

The oil and gas industry demands a lot from its tools, including customization in the design-build phase and ongoing reliability in the field. Polyurethane parts stand up to any punishment thrown at them, and new ones can be quickly machined as needs change or evolve.

Urethane pipe spacers and casing spacers are placed around pipelines in underground and subsea applications. They make a perfect case study to illustrate what we’re talking about.

Put simply, these humble components keep pipes carrying oil and gas a specific distance apart. Outside of the oil and gas industry, they’re used to hold water, sewage, and electric pipelines in place. They also prevent damage to pipes and casing as they’re being stored in pipe yards or transported to the field. Pipelines protected by casing also use spacers to separate and isolate the carrier pipeline from the casing.

Pipes maybe made of steel, concrete, PVC, polyethylene, or plastic. Pipe spacers can be formed from various types of rubber and plastics, including polyurethane, polyethylene, PVC, carbon steel, and stainless steel. Along with the product the pipe carries and the environment surrounding the pipeline, the pipe’s material will determine what kind of spacers are appropriate.

Polyurethane, however, is our material of choice for the harsh environment of the oil and gas industry. When other materials often crack, break, tear, swell, abrade, and deteriorate, polyurethane can stand the test of time. Metallic and plastic spacers are vulnerable to problems that can slow down operations and, ultimately, lose revenue.

Polyurethane pipe spacers can be easily formed to your precise specifications because they are castable. Complicated design and engineering are usually required to adjust metallic pipe spacers, while urethane-based materials are easily formed into exact dimensions from simple silicone molds.

OUR UREGUARD TOWLINE PROTECTORS ARE CUSTOM MADE TO FIT ANY SIZE CABLE OR ROPE

Commercial towing vessels depend on towlines, also known as hawsers. They also depend on Mark Tool to keep those lines protected from chafing and from the harmful effects of seawater.

Whether used for offshore oil and gas operations, dead-ship towing or salvage, the towing hawser is the key element in the tugtow connection.

Hawsers used for conventional tugs are essentially a thick cable of wire rope. The condition of these lines is critical; they must be inspected on a regular basis, lubricated regularly, and shielded against excessive wear.

UreGuard towline protectors are made of two halves bolted together with high-grade, noncorrosive bolts for easy installation. The tapered ends of the Mark Tool towline protectors act as bearings to prevent premature line parting and lost tows.

A tug master should always know the condition of his tug, towing hooks, and fittings. Steel towlines and ropes should have a safe working load at least two to three times the bollard pull of the tug. Ancillary equipment, including wire towage protectors and thimbles, should be regularly inspected.

Regular towline inspection means looking for signs of ultraviolet or chemical degradation, worn or fused strands, overstretched sections, and kinking.

It also means having the sleeves and protectors you need for your main and secondary towlines. Mark Tool towline protectors are available in lengths of 5-10 feet or can be manufactured to your specifications. We’ll be happy to custom-build them to fit any size cable or rope.

Mark Tool produces custom rubber and urethane products used in a broad range of industry applications including farm equipment, the oil & gas industry, valves, electrical distribution, railroad, heavy truck, and a variety of automotive applications.

Given your design, Mark Tool can offer to manufacture your product by fabricating a custom mold. After analyzing your product, its dimensions, material, and anticipated volumes, we can then cast your parts out of a wide range of polyurethane products.

At Mark Tool & Rubber, we understand the importance of performance and product demand; therefore, when the customer came to us looking for a new supplier that could consistently deliver a high-quality product on time, we got to work and began developing a product that would satisfy their needs. With the creativity of our engineering team and the hard work of our technical team, we delivered a top-notch scooter wheel that we have since produced thousands of for our loyal customer.

The process:

The manufacturing process of our customized scooter wheels involves 4-steps. The first step is surface preparation, where the aluminum hubs are blasted and coated with a bonding agent. Next, the hubs are placed in the molds, and the polyurethane is poured. After the material has hardened, the part is removed from the mold and set on the rack to be cured in our oven. Once the part is cured, we machine the exposed side to give the wheels an appealing finish. Lastly, the finished product is checked by our quality control team, then packaged up and ready to be shipped out.

Mark Tool takes pride in the fact that we have the capability of meeting the needs of companies of all sizes and markets. Our customer list includes small business operations to the major oil & gas companies.

The polyurethane protective pads were developed when Offshore Energy came to us looking for an answer to a problem they had recently encountered. As a result, our team at Mark Tool started brainstorming and created the ideal solution for safeguarding your valuable equipment and products. Whether you need to protect delicate glass surfaces, furniture, or heavy machinery, our customized pads are up to the task.

At Mark Tool & Rubber, our team always goes the extra mile, ensuring complete customer satisfaction. This job was no different; being a turnkey job, we designed and fabricated the polyurethane pads, blasted, and painted all the equipment, then delivered them to their location. The services that went into this job are all done daily at Mark Tool, guaranteeing we can make your idea become a reality.

Our gap fillers were designed to bridge and fill gaps where needed. Our team at Mark Tool engineered this product to minimize the risk of injuries and provide exceptional slip resistance. The textured surface provides optimal traction, even in wet or oily environments. In addition, the gap fillers’ chemical resistance ensures longevity, minimizing maintenance and replacement costs.

Look into our platform gap fillers for any of your dangerous voids that require a safe and viable solution.

Mark Machining (a division of Mark Tool Co., Inc.) specializes in elastomeric roller machining & grinding, mold & die fabricating, and parts manufacturing for the worldwide oil and gas industry. Our modern facility is equipped with the most up-to-date equipment available to supply your machining needs. Total capabilities include CNC machining, sawing CNC plasma cutting, and weld fabrication, allowing us to give excellent service at competitive prices.

Superior equipment, qualified people, and the desire to be the leader in the machining and repair industry give us the combination we need to serve your industry in the most efficient manner available. With over 40,000 square feet of manufacturing area, Mark Machining can strip, cast, cure, and machine new or refurbished rollers and any related accessories. We also offer production machining services which include, but are not limited to turning, milling, drilling, tapping, and grinding.

Our highly skilled staff has nearly a half century of experience in the resurfacing of coated rollers and will be glad to help you select the proper coating for your roller application. These expert craftsmen bring you the highest quality parts, shipped on-time, and for a fair price. In addition to meeting regular lead-time requirements, we will do all that is possible to meet any expedited delivery requirements you may have.

For all rubber, polyurethane, machining and custom part needs, depend on Mark Tool & Rubber. Since 1954, we have earned our reputation for producing the highest quality cast urethane and rubber tools of all kinds for the offshore and marine industries.