5 minute read

Safety First

from Wavelength #74

SAFETY FIRST! from the SQE Department

Message from the DPA: Safety starts with communication

Advertisement

New Health & Safety Campaign

Dear seafarers, The pandemic that came into our lives during 2020 has created change and raised concerns for not only our own health, but also for the health of our colleagues and our loved ones. However, our concerns are not only about health issues. The economic impact of these unprecedented events will be felt for some time to come. Under the circumstances, being resilient will help us to adapt. Enhance your resilience by talking openly, something that seems more essential now than ever. Ask yourself and your colleagues: How is life onboard for you and the team? What is morale like on board? Are you receiving enough information and support regarding the COVID19 pandemic? Are you getting the necessary provisions?

Elli Moretti Is there anything more the shore team can do to support you and your team’s wellbeing? Do you have enough PPE to keep the crew safe and healthy? Have you had any difficulties with visitors complying with our procedures to keep the vessel a safe place to live and work? Do you feel our people are still 'switched on' to the possibility of accidents and incidents? Do you feel their safety vigilance and reporting is strong? While serving on board during these weird times I urge you more than ever to discuss issues amongst yourselves and convey your opinions to head office without any hesitation. Talk to, listen to and learn from each other; RESET safety! I wish you safe voyages and a safe return home.

Elli Moretti

Over the past few years, the Shipping Industry has considered the process of collecting and circulating Best Practices to be a vital tool for continuously improving Company Safety Culture. Thus, our Company has recently launched a Health & Safety campaign on the topic of Safety Best Practices in common areas of Risk Assessment across the Fleet. The purpose of this campaign is to identify areas for improvement and to increase Safety Awareness on this important issue and thus ensure the Continuous Improvement of Safety Onboard. Masters are asked to inform and motivate their Officers and Crew on how to report best practices with cases from their daily routine on which safe practices can be improved. Even though this is a voluntary effort, crews should be vigilant in reporting any practices that may enhance crew safety & welfare, improve onboard living standards, or provide environmental protection that could also be adopted by other fleet vessels. The goal is to receive ONE Best Practice from each vessel per month. With this practice, we will gradually collect a large pool of safety ideas that can be implemented across the Fleet and meet relevant Shipping Industry requirements. All Best Practices will be recorded at Head Office and will be evaluated by the corresponding Office Staff. The ones that are considered to be the most beneficial will be circulated to the Fleet. Where appropriate, best practices will also be incorporated into our Company SMS. Finally, we wish to reward this voluntary effort every 6 months as follows: • The Top 5 Best Practices will be published in our

Wavelength Safety Bulletin by nominal recognition. • The whole crew of the vessel with the BEST of the Top

Best Practices will also be awarded free internet or calling cards as a token of appreciation / recognition of their efforts in this Campaign.

Hong Kong Marine Department (MARDEP) shared lessons from an incident onboard a Hong Kong-flagged container ship Lessons learned: Fitter crushed to death by exhaust valve

The incident When the vessel was anchored at Western Anchorage No.3 in Hong Kong, the crew transferred some spare main engine exhaust valves on the aft deck to the engine room with a monorail hoist through a skylight hatch, and then moved them to a designated position with an engine room overhead crane. At that time, a fitter was working alone under the skylight hatch. The fitter temporarily lowered an exhaust valve on a removable floor plate (RFP) and released it from the hook of the monorail hoist. Soon after the release of the hook, the exhaust valve toppled and crushed the fitter on the left side of his abdomen, resulting in his death. Probable cause The investigation identified that the main contributory factor to this incident was the overloading of the RFP by the exhaust valve as it could not support the 3-tonne weight of the exhaust valve. As a result of the overloading, the RFP deformed and the exhaust valve toppled, crushing the fitter to death. Safety issues The investigation also identified the following safety issues: •The crew should have worked as a group rather than leaving one crew member to handle the exhaust valve transfer operation alone. •During the toolbox talk, there was neither any discussion nor risk assessment made regarding the operation necessary for the receipt of heavy machinery parts. Lessons learned 1. Senior ship officers should carry out proper risk assessment and/or a toolbox talk to all crew members concerned in order to identify any potential safety hazards and implement appropriate safety measures to eliminate the risk of dangers when handling heavy machinery parts. 2. Ship crews should maintain good housekeeping of the engine room in accordance with the “Code of Safe Working Practice for Merchant Seafarers”, i.e. floor plates or gratings should be properly secured.

TRUST:

TEN Really Useful Safety Tips

FAIL SAFELY!

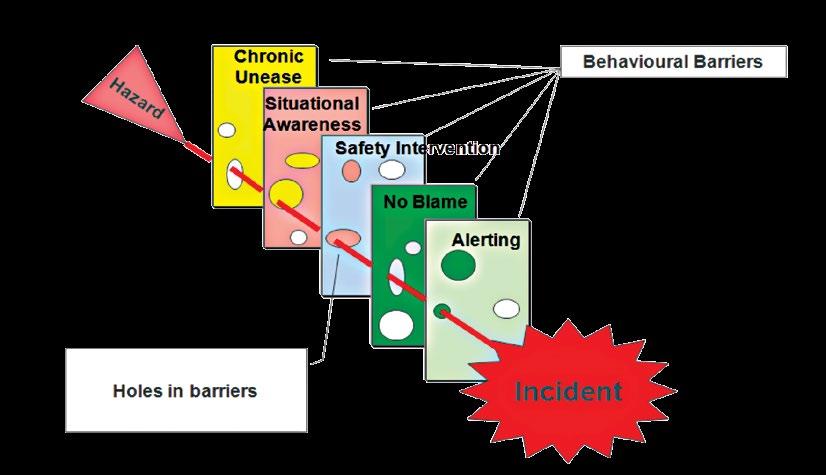

When an undesirable event doesn’t result in harm because barriers were in place and worked as intended

1. Consider failing safely in toolbox talk discussions.

2. For each task, ask what can go wrong and seriously injure the people involved. 3. For each task, ask if everyone is wearing full protection. 4. For each task, ask if everyone feels comfortable enough to speak up. Find out! 5. For each task ask: When mistakes are made, what will keep you safe? 6. But is that enough? If it is not enough, what else is needed? Can the job be done a different way? 7. In your team, YOU know how the work is actually done and YOU have the best solutions.

8. Prepare for the unexpected! 9. Keep your Behavioural Barriers STRONG! (the sketch of these barriers apply on every occasion, and that is why it is repeated in most of our “Safety First” sections of Wavelength) 10. Mistakes should not be life changing. Mistakes will happen BUT when we do make mistakes, no one should get hurt! That is what it means to fail safely!

Keep your Behavioural Barriers STRONG!

When all your barriers don’t work properly at the same time... the holes line up... then the hazard passes through and results in an incident!