5 minute read

The Blueprint for Better Lighting

What Are Photometrics and Why Are They Needed?

By Sarah Fox

Cover Photo: When a photometric calculation is not run for an auto dealership, and theft is an issue. Photo credit: Sarah Fox

There is a certain amount of excitement you feel with designing lighting for a new project, ensuring the fixtures create the right aesthetics and give the space the right feeling. It can also be a daunting task calculating the right light levels, angles, and distributions.

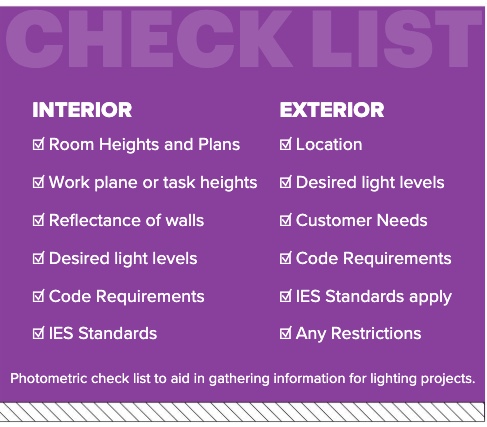

This is where photometrics enter the process. Knowing what they are and how to use them separates good lighting projects from great ones.

WHAT ARE PHOTOMETRICS?

Photometrics are the study of the measurement of light and how light works with surfaces to meet the requirements of a space or project. Each luminaire is tested to create an IES file which contains information on how the light from the fixture behaves.

These files, in conjunction with computer programs like AGi32 or Visual, validate that the luminaire will function as designed for the space and situation. These calculations confirm the type and quantity, and ensure the lighting layout will meet the requirements or governing standards.

Layouts can be completed by lighting designers, technical specialists, or knowledgeable professionals. Reputable lighting manufacturers, like LSI Industries, will provide the IES files to verify the lights will function as intended, and calculations are run for each project.

HOW TO USE PHOTOMETRICS?

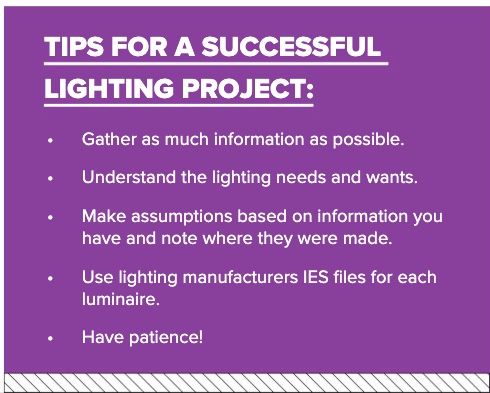

When starting a photometric calculation, information should be gathered about the site and space. For basic interior lighting projects, information from architectural drawings with room heights provides room-specific information and allows the calculations to be modeled on top of these drawings.

Knowing the materials and colors (light reflectance values or LRVs) within the room is critical. Without that information, the final results might be much different that what is calculated.

A standard assumption of 80/50/20 is acceptable, which says that the ceiling is 80% reflective, the walls are 50%, and the floor is 20% reflective, or rather dark.

However, this is not always a safe assumption, and it is best to get the actual data when possible. As an example, an indoor tennis facility was calculated using 80/50/20. The real LRVs, measured onsite, were 50/50/20. The light levels were 15% lower than the onsite calculation, which did not meet the US Tennis Association nor the IES Sports lighting recommended light levels.

Having the right data at the start allows for a more accurate calculation and the right lighting for the space.

Next, confirm what the desired light levels for the tasks will be in each space. The customer might also have brand standards that must be followed, or there might be a governing body that has specifics you need to follow.

IES has various Recommended Practices (RPs) to aid in specific tasks, types, and needs. These are great to utilize as they provide standard light levels, so spaces are illuminated effectively without too much wasted light. Gather the above information so each interior space type can be modeled and then calculated using the luminaire IES files.

For exterior or site lighting projects, the location of the site is crucial. Sometimes only an address is available, but a drawing, like a site plan, would be the best.

A site plan is a detailed drawing of a specific property that includes information on what is existing, dimensions of the site, and proposed structures, which is a tremendous help to develop a lighting layout. This provides the site constraints for the specific property that will aid in the layout, which will inform the desired light levels based on the tasks being performed and any customer or code requirements.

Some jurisdictions have limits on pole heights, light trespass or spill light, color temperature, or DarkSky compliance. These can affect the luminaire selection and design of the site lighting. Remember, the goal is to have the right luminaire with the right light level and distribution to properly illuminate the site.

So why does all this upfront work matter? Photometrics prove that appropriate light levels have been met based on the information input. Lighting or technical designers create a photometric plan that is not just a document, but a roadmap to a well-lit, efficient, and compliant facility that aligns with the strategic goals of the business or residential community it serves.

Lighting manufacturers should invest in their applications team. This investment demonstrates that they can provide accurate calculations which create trust with their clients. The manufacturers know their own products and how they function best.

Lighting design is like a game of Tetris, trying to find the right product to fit the unique ‘hole’ or issue. Like Ben Franklin said, “An ounce of prevention is worth a pound of cure.” Be proactive upfront.

If no photometric calculations are made, there might be follow-up site visits to add lights, reconfigure, or redesign, which means more time and money to amend any issue. If the lighting is not addressed, the site or space might not be safe, and unplanned additions might be needed.