ENDORSED BY SAPMA, SAPSDA, SAVAMA AND VAMCOSA

MAR/APR 2024

MEMBER OF THE BILFINGER GROUP OF COMPANIES

Dewatering leader offers growing range of pumping solutions

At Xylem we are 100% about water, including delivering transformative solutions across the entire water cycle. We are pioneering our approach through 360 Performance solutions, delivering source-to-tap support, products, engineering expertise, and more for real value, efficiency, and lasting performance. Let’s Solve Water is more than a slogan, it is our mission! Discover 360 Performance, the cornerstone for a sustainable water future.

Presenting the Lowara e-IXP smart pump, designed according to ISO 2858 and 5199 standards to be the 360 Performance solution for industrial and multi-storey building applications due to its ability to be energy efficient, reliable and easy to maintain. At its core lies the ability to provide real-time data, empowering users with unparalleled insights into the system and efficiency. With proactive alerts, the e-IXP takes a 360 Performance approach to maintenance, ensuring timely interventions to prevent potential issues before they escalate.

e-IXP Centrifugal Pump

STANDARDIZATION MATCHES INNOVATION

SMART RELIABLE ENERGY EFFICIENT

Find out how we can solve water together.

Vesconite Hilube wear rings included

The Busch Group is one of the world’s largest manufacturers of

Next-gen slurrysucker for silt-challenged water areas powered by Toyo 26 VALVES

The curtain goes up on IVS 2024, the fifth edition of the Industrial Valve

Paltech appointed as Meson Group

Invincible Valves, +27 (0) 11 822 1777, enquiries@invalve.co.za, www.invalve.co.za

Pipes, Pumps & Valves Africa

Managing Editor: Surita Marx

Tel: +27 (0) 87 700 9834

Cell: +27 (0) 83 281 5761

Email: info@pumpsandvalves.co.za

Web: www.pumpsandvalves.co.za

Sales: sales@pumpsandvalves.co.za

Production Manager: Xane Roestroff

CONTENT Pipes, Pumps and Valves Africa - Mar/Apr 2024 3 Disclaimer: Opinions in this Publication are those of the authors and do not necessarily reflect those of this publication, its editorial board, its editor or its Publishers SAPMA or VAMCOSA The mention of specific products in articles and advertisements does not imply that they are endorsed or recommended by this Publication or its publishers in preference to others of a similar nature, which are not mentioned or advertised. Reliance on any information contained in this journal is at your own risk. While every effort is made to ensure the accuracy of editorial board makes no representations or warranties, express or implied, as to the correctness or suitability contained and/or the products advertised in this publication. The Publisher shall not be liable for any damages or loss, howsoever arising, incurred by readers of this publication or any other person/s. The Publisher disclaims all responsibility and liability for any damages, includes pure economic loss and any consequential damages, resulting from the use of services or products advertised in this publication. Readers of this publication indemnify and hold harmless the publisher, its officers, employees, and servants for any demand action, application or other proceedings made by any third party and arising out or in connection with the use of any services and/or products or the reliance on any information contained in this publication. Advertisers Amandla Pumps 35 Aumanat 21 Bauma China IBC Billfinger OFC BMG 39 Busch Vacuum 25 DFC 17 EMV Africa 13 Industrial Vale Summit 42 Integrated Pump Technology 7 Invincible Valves OBC KSB 11 Machine Tool Africa 27 Marechal Electric Africa 33 Monitor Pumps & Systems 19 PH Industrie Hydraulik 9 Ragon 37 Valve Hospital 15 Vesconite Bearings 45 Xylem IFC COVER STORY Bilfinger Intervalve Africa has set its sights on Southern Africa 4 PUMPS

in European OEM’s NSF61-accredited pump series 6 Dewatering leader offers growing range of pumping solutions 7 PAH series® (Prime Aire Plus) 8 New

battery-powered hydraulic pump performance

usability 10 Sulzer

controller

performance of

pumping stations 12

Tsurumi brings smart solutions for wastewater management at Craft Brewers 2024 14 Electrically operated

solutions improve fluid handling productivity 16 Energy savings begin with the pump 18 Amandla Pumps commitment to quality, reliability and service 22

vacuum pumps 24

Enerpac XC2-series redefines

and

launches

for optimized

wastewater

Lifecycle approach with OEM parts for sustainable pumping solutions 13

diaphragm pumping

Summit 28

Distributor

South Africa

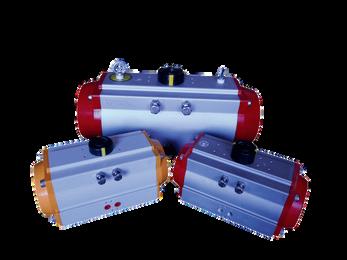

parts of Africa 30 WATER Taking the pressure out of water pressure measurement 32 Creating a culture that protects water creates business success 34 Steps to climate proof your brewery 36 INDUSTRY NEWS The key role of hose couplings and clamps 38 PRODUCTS & SERVICES The world’s latest state-of-the-art mechanical actuator 42 BUYERS GUIDE 43

in

and

On

the cover

Bilfinger Intervalve Africa has set its sights on Southern Africa

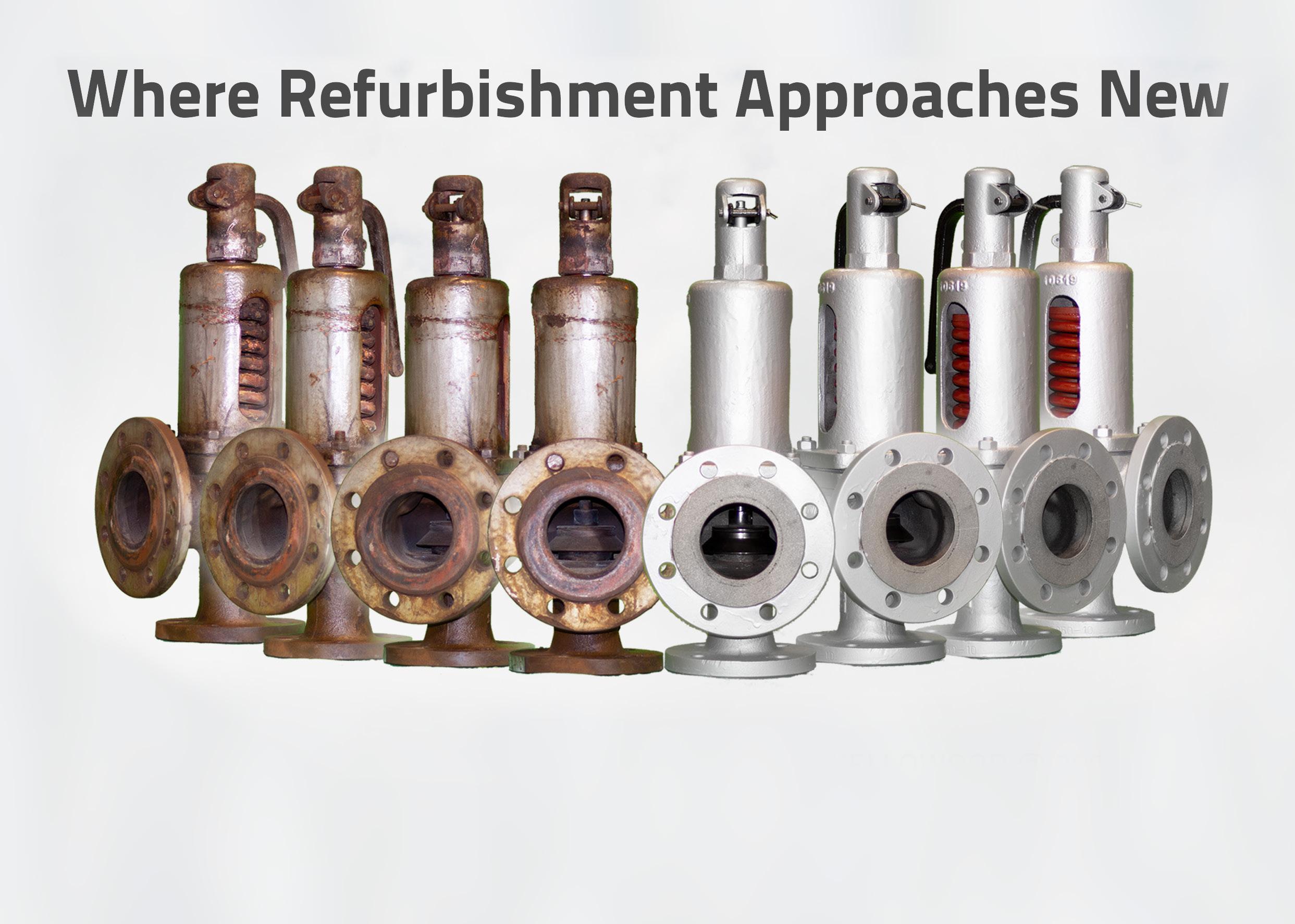

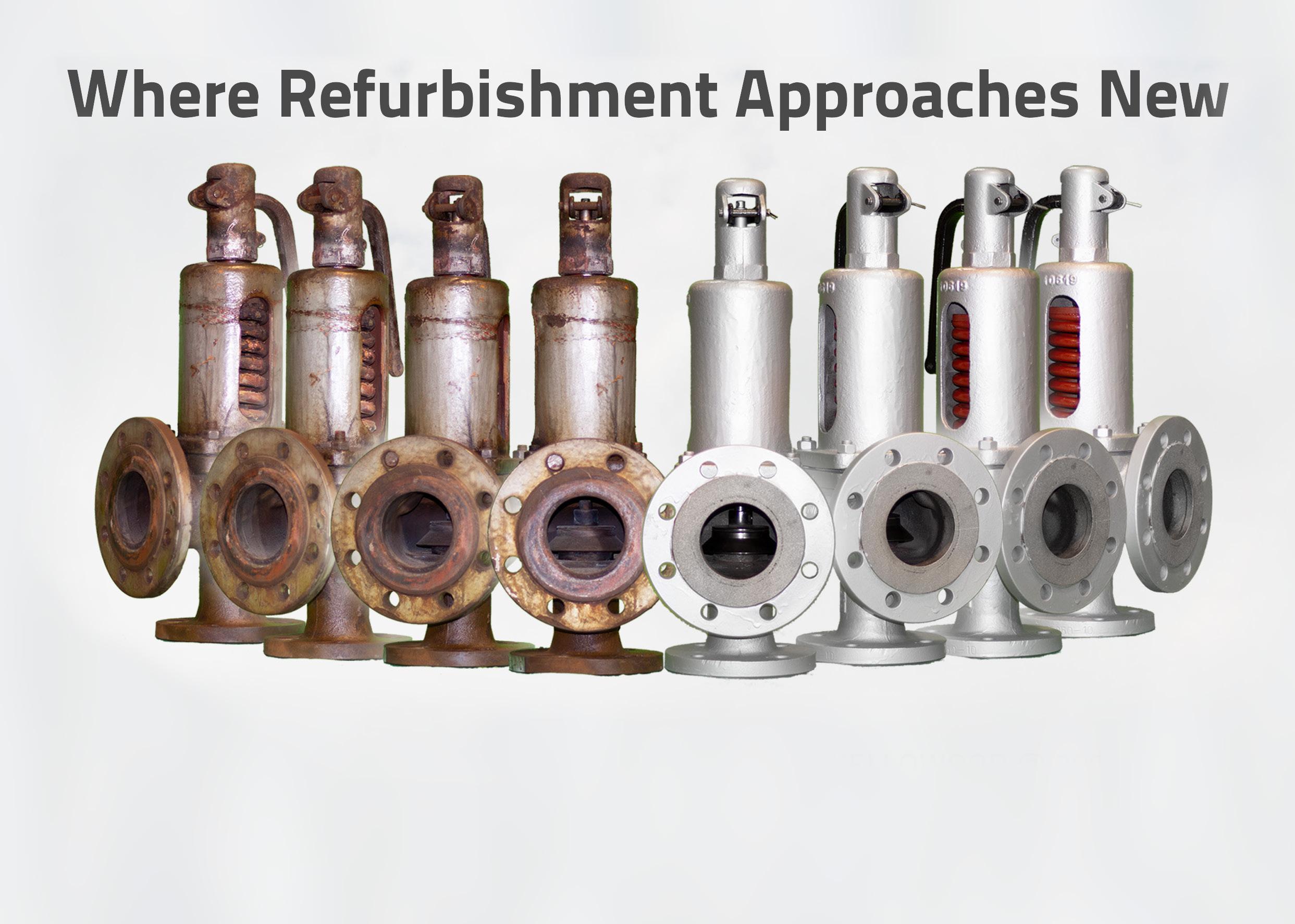

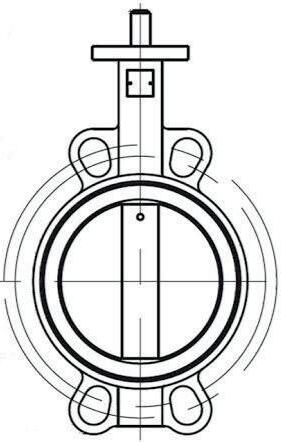

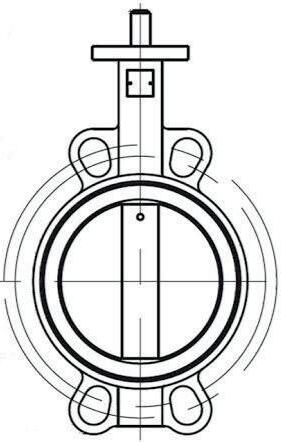

Bilfinger Intervalve Africa has set its sights on Southern Africa, marking a significant regional expansion programme. With a steadfast commitment to excellence and innovation, the industrial solutions provider is well positioned to enhance its presence across diverse sectors. Pipes, Pumps & Valves Africa spoke with Raj Hurrilaal, the company’s Sales Manager, to learn more.

Expansion in today’s dynamic business environment is a necessity. It represents more than mere geographic reach; expansion efforts signify a strategic commitment to innovation, resilience, and seizing untapped opportunities.

“We’ve identified substantial opportunities across diverse regional sectors and are confident in our ability to deliver value. As we venture into new markets and expand our presence across Africa, we’re diversifying our revenue streams and sharpening our competitive edge,” says Hurrilaal.

Established in 1971, Bilfinger Intervalve Africa has been a trusted valves supplier and related services to the power generation industry. With a sprawling 2000 square-meter workshop in Bethal, Mpumalanga, the company has been instrumental in providing top-tier products and services to major industrial plants spanning the length and breadth of the country.

“We are known for our work in the power sector, particularly for the products and services we supply to coal-fired power stations countrywide,” Hurrilaal says when asked about Bilfinger Intervalve’s specialization. “Our strategic decision to broaden our footprint stems from our success in this domain, fueling our confidence in our capabilities to excel further and innovate” he adds.

Quality assurance

The company prides itself on its unwavering commitment to compliance with all safety regulations, ensuring that stringent standards are met and upheld at every turn. With

a dedication to safety protocols, Bilfinger Intervalve Africa ensures the well-being of its workforce and the integrity of its operations, setting a benchmark for excellence in the industry.

“We firmly believe that accidents are preventable,” emphasises Hurrilaal. “Achieving this goal calls for strict adherence to safety regulations by every team member. That’s why we’re committed to investing in comprehensive training programmes, ensuring our staff stay well-informed about the latest knowledge and skills.

Our workshop undergoes annual audits to uphold international standards and ensure that all processes are meticulously executed. According to Hurrilaal, the company operates a documented quality assurance programme based on ISO 9001:2015. “We have a quality control plan (QCP) in place that stipulates and documents the logical sequence of operations and quality control, referencing controlling documentation, verification of conformance and quality record reference.”

This is further supported by the complete backup support offered by the Bilfinger SE group and its facilities.

Top-notch facilities

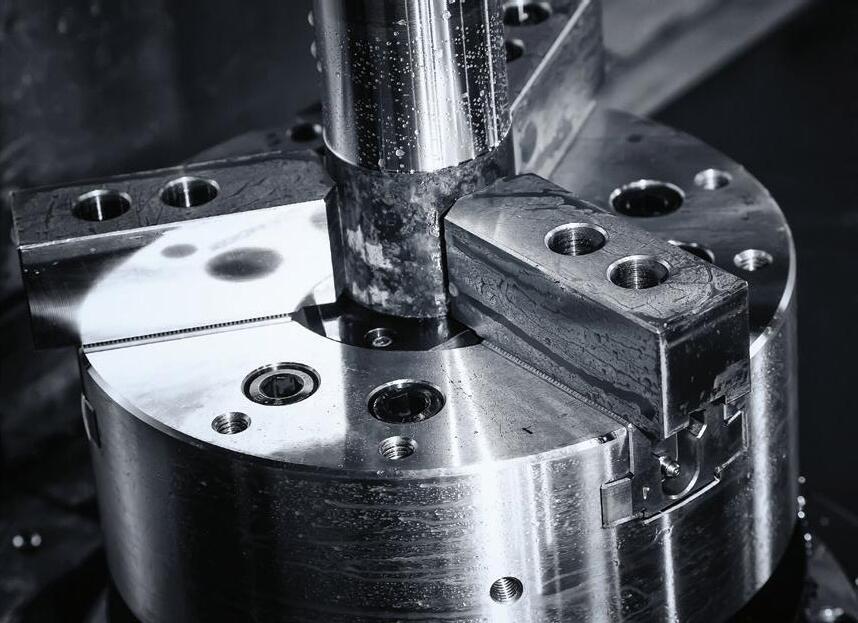

Hurrilaal highlights that ongoing investment in facilities remains a cornerstone of Bilfinger Intervalve Africa’s capabilities. “Beyond just having the essential equipment, our workshop is dedicated to continuously enhancing our capabilities by expanding our range of machines and introducing cutting-edge technology,” he affirms.

4 Pipes, Pumps and Valves Africa - Mar/Apr 2024 COVER STORY

Furthermore, the company can deliver its comprehensive services directly to the field. “With our mobile workshops, operational even in the most remote areas, we can refurbish valves on-site without the need to transport them to our Bethal facility,” explains Hurrilaal. “This minimises disruption for our clients and ensures quicker turnaround times for refurbishments, reducing downtime significantly. By bringing our services directly to the operations instead of removing valves from the site, we provide a more cost-efficient solution, delivering enhanced value to our clients.”

intervalve

Expanding these workshops and services to be available across multiple countries including the likes of Namibia, Botswana and Zimbabwe will boost the company’s offering extensively. “In today’s fast-paced business landscape, time is of the essence,” emphasises Hurrilaal.

“Our services are comprehensive, and our machinery is adaptable to any valve. With all the necessary certifications in place, we ensure the quality performance required for the refurbishment of valves right on site. This streamlined approach saves valuable time and guarantees that our clients receive quality service wherever they operate.”

Among its specialist mobile equipment is the Orbit 24 flat lapping and polishing machines, designed for high precision and fine finishing of faces. These cutting-edge machines are pivotal in ensuring top-tier quality and accuracy in refurbishment, delivering impeccable results even in challenging on-site conditions.

“The field service,” says Hurrilaal, “holds immense value, particularly in time-sensitive sectors where downtime is critical. Our unique ability to conduct most refurbishment work on-site, without transporting valves to workshops for overhauls and repairs, significantly minimises downtime and operational disruptions for our clients.”

Adding value

As distributors of a diverse array of products, Bilfinger Intervalve Africa holds the distinction of being an approved OEM local repairer and service provider throughout Southern Africa.

“With our highly experienced team readily available, we offer expert assistance in the application, selection, and specification of valve installations. Moreover, our dedicated after-sales teams are accessible 24/7, providing on-site or workshop assistance whenever needed.” This commitment to comprehensive support underscores the company’s dedication to ensuring optimal performance and client satisfaction throughout the lifecycle of its products.

“We are all about building solid relationships with our clients, ensuring we meet their needs and add value to their operations. In the valve business, honesty and transparency are key for success, and we’re committed to delivering just that,” concludes Hurrilaal.

Bilfinger Intervalve Africa, +27 (0) 17 624 5000, sales.intervalve@bilfinger.com, www.intervalve.bilfinger.com

Pipes, Pumps and Valves Africa - Mar/Apr 2024 5

Vesconite Hilube wear rings included in European OEM’s NSF61-accredited pump series

Vesconite Hilube NSF61-approved wear rings will be featured in an NSF61-approved submersible pump series developed by a well-known European original equipment manufacturer (OEM).

The pump company confirmed that the pump series had been certified as NSF61 compliant.

The quality assurance manager at the European pump OEM expressed satisfaction with the recent approval, stating, “We are glad to announce that our pumps received NSF61 approval last week.”

The NSF/ANSI 61 accreditation, “Drinking Water System Components – Health Effects”, is a highly-regarded US national standard that sets stringent health-effects requirements for chemical contaminants and impurities. The accreditation ensures that products, components, and materials used in drinking water systems meet the highest standards for protecting public health.

Production of the pump series is set to commence, and the product will hit the market in early 2024, said the pump company’s quality assurance manager.

As part of this launch, orders will be placed for Vesconite Hilube wear rings, he noted.

Vesconite Bearings, the global provider of no-swell wearresistant Vesconite Hilube wear rings and bearings to the pump industry, has been in discussion with the European OEM since 2016 when the first sample products were sent for evaluation and testing.

The engagement continued with additional samples sent in

subsequent intervals.

In October 2023, as part of the developing supplier relationship, it was announced that the pump series, incorporating Vesconite Hilube wear-resistant wear rings, had received NSF61 approval. As part of the launch of multiple submersible pumps, approximately 10 differentsized Vesconite wear rings are expected to be ordered.

The European pump company anticipates that the NSF61 pump accreditation will enhance its global exports.

This accreditation is not only a mandatory requirement for all drinking water pumps in the United States but also serves as a recognised quality indicator in various international markets.

Vesconite Bearings is proud to be a contributor to this innovative and accredited pump series, providing a reliable and NSF61-approved solution that aligns with the highest standards in the industry. Vesconite Bearings looks forward to continuing its successful collaboration with the European OEM and contributing to the advancement of water system technologies worldwide.

Vesconite Bearings, +27 (0) 11 616 1111, vesconite@veconite.com, www.vesconite.com

6 Pipes, Pumps and Valves Africa - Mar/Apr 2024 PUMPS

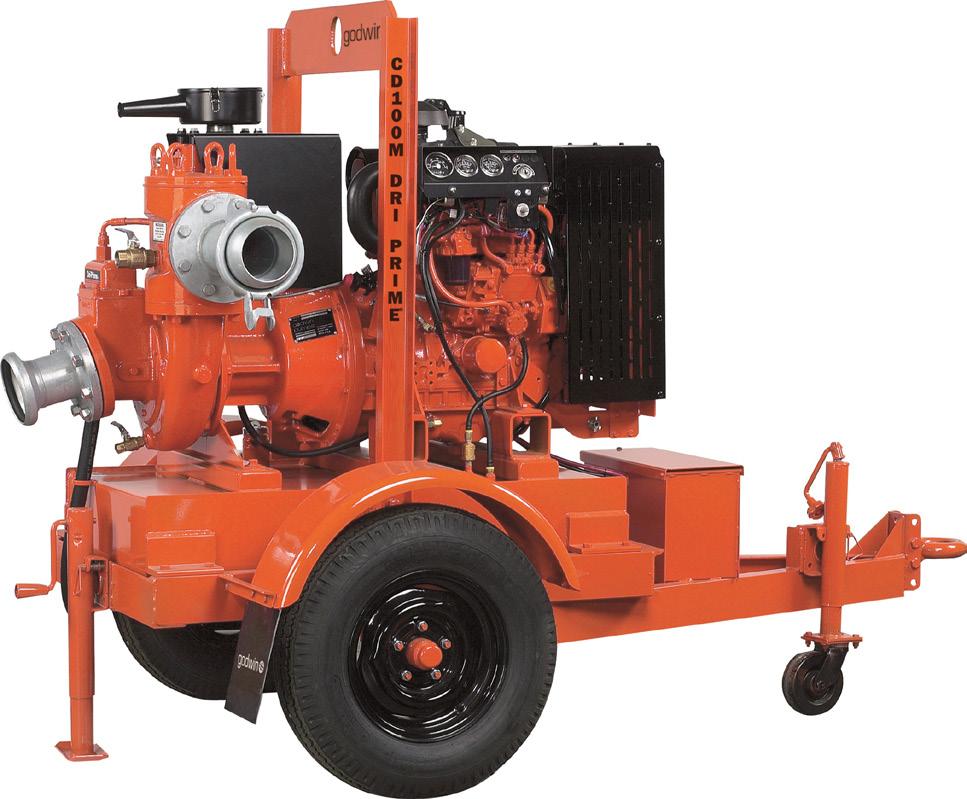

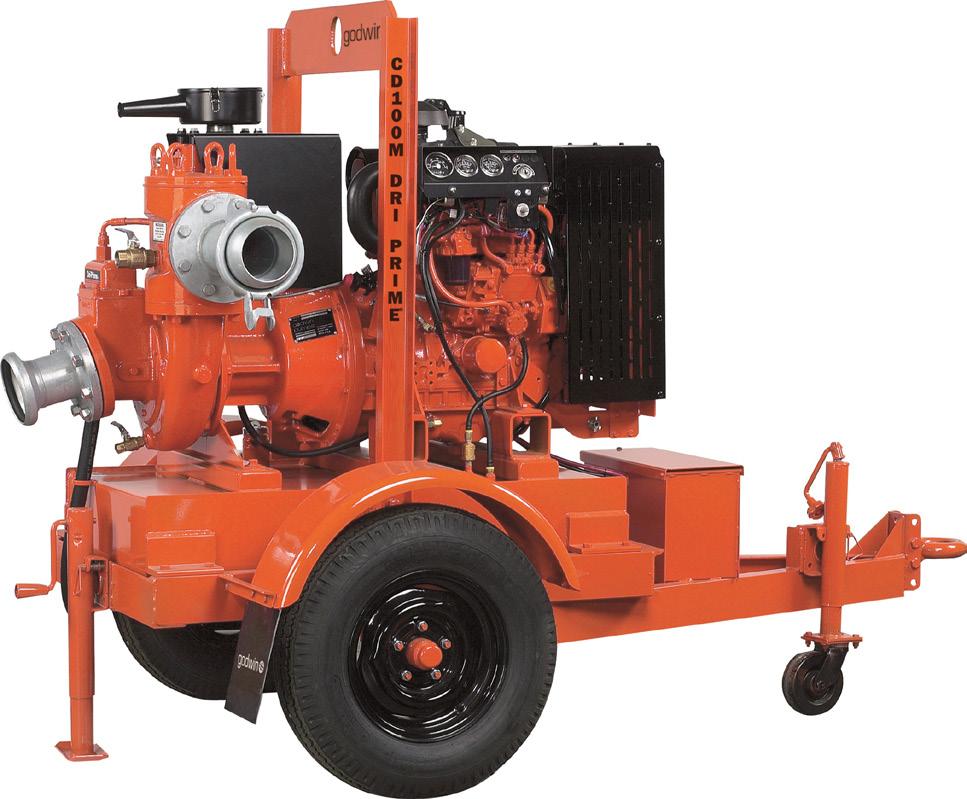

Dewatering leader offers growing range of pumping solutions

With its solid technical expertise and market experience in dewatering, slurry and sludge pumping solutions, Integrated Pump Technology has proved its capacity to support the highest quality pump brands.

Its offering recently grew from its established range of Grindex and Faggiolati submersible pumps to include the well respected Godwin range of diesel driven pumps.

Justin Bawden, Key Accounts Manager at Jet Park-based Integrated Pump Technology, explains that this adds considerable value to customers – as the pumping business is all about matching the right pump to each specific duty and application. “The Godwin range of diesel powered pumps is a great boost for customers wanting to deploy a robust pumping solution in locations where electricity is not available,” says Bawden. “As important as the quality of these pumps, though, is our ability to support them to the demanding standards set by the original equipment manufacturer (OEM).”

To service its submersible and diesel driven ranges of pumps, Integrated Pump Technology boasts a modern technical workshop and warehouse which ensures that customers experience quick access to the equipment, servicing and spare parts they need. He highlights that the company’s active network of distributors around southern Africa visit customers regularly to offer support and technical advice.

“We are pleased to now be able to offer the diesel driven option too, allowing customers to conduct pumping operations in areas where there may be no electrical power supply,” says Bawden. The versatile Godwin range extends from entry level units reaching heads of 15 metres and maximum flow rates of 200 m3 per hour – right up to large units pumping to 180 metre heads and achieving flow rates of 1300 m3 per hour.

The company is also the Southern African distributor of the world class Grindex submersible pump range, and among the smart features of the Grindex pumps, which range from 0,42 kW to 90 kW, are extra protection such as phase rotation and phase loss to avoid overheating. There is also high chrome, wear resistant material in the slurry pumps to extend service life. Included in the company’s pump offering is the Faggiolati pump range which addresses important specific applications as it can be flameproofed, and can also be fitted with chopping impellers to deal with fibrous material in water.

Integrated Pump Technology, +27 (0) 11 894 2906, sales@pumptechnology.co.za, www.pump-technology.com

www.pump-technology.com

Pipes, Pumps and Valves Africa - Mar/Apr 2024 7 PUMPS

more than just a pump complete pumping solutions IPT-adv-180x50.indd 1 2022/11/21 11:54

PAH series® (Prime Aire Plus)

PAH Series® priming-assisted pumps are designed and engineered for the most rugged and demanding mining, construction, municipal, agricultural and industrial applications. All Prime Aire Plus® models are backed by an industry leading two-year warranty and are factory tested before they leave our facility.

Prime Aire Plus pumps utilize the same venturi/compressor priming system as the Prime-Aire product line. Increased head, flow and enhanced maintenance features are additional benefits of the PAH Series line. Models feature sizes up to 16” and are suitable for clear liquids and liquids containing large solids. All Prime Aire Plus pumps are configured with EPA Tier compliant engines or premium efficiency motors. CD4MCu - duplex stainless steel Prime Aire Plus pumps are available in multiple drive variations including basic units, trailer mounted engine-driven units, or skid mounted electric-driven units and are suitable for corrosive and abrasive liquids containing large solids

Features

Dry run capability

A dry run capability is designed into the Prime Aire® system. An oversized, oil-lubricated mechanical seal allows the pump to run dry continuously without damage. For positive, reliable priming time after time, Gorman-Rupp Prime Aire® pumps are the ones you can count on.

Compressor-over-pump

Popular Prime Aire Plus® models are available in a “Compressor-Over-Pump” arrangement. This innovative configuration offers a compact, flexible design while allowing ease of operation and servicing when needed.

Standard auto-start controls

Auto-Start control starts and stops the pump in response

to a liquid level. The pump only starts when there is water to pump and turns itself off when the water reaches the desired level. There is never any need to waste fuel and add to costly engine overhauls.

Abrasive handling seal

Prime Aire Plus® pumps are equipped with oversized, mechanical, oil-lubricated, double-floating, self-aligning seals with silicon carbide rotating and stationary faces that are designed to take the wear and tear of pumping solids, slurries and other abrasives.

Impeller selection

Priming-assisted pumps utilize a variety of impeller types based on your specific application.

Many models feature rugged, two-vane, ductile iron, semiopen solids handling impellers that handle up to 4” (101.6 mm) diameter solids.

For clean water applications, pump models use higherefficiency enclosed impellers.

Resources

Prime Aire & Prime Aire Plus Brochure Performance Curve

Gorman-Rupp Pumps, +27 (0) 11 397 3536, www.grpumps.co.za

PUMPS 8 Pipes, Pumps and Valves Africa - Mar/Apr 2024

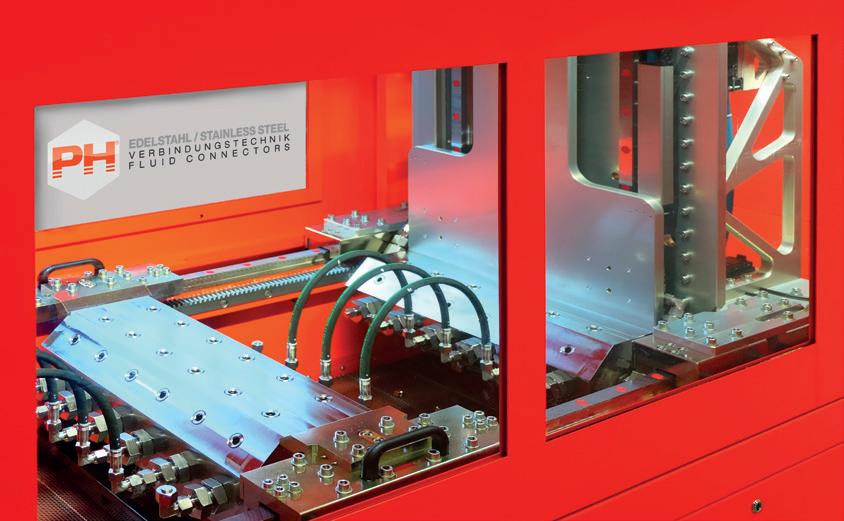

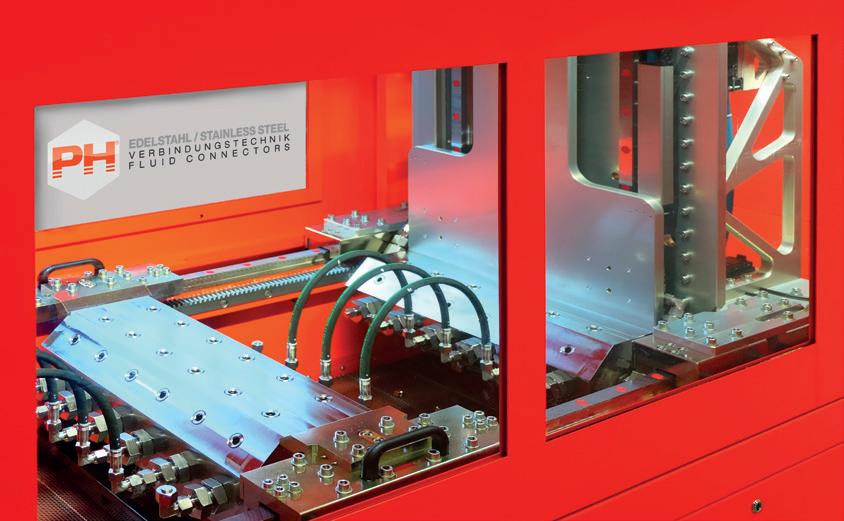

Maximum precision Approvals & Norms High availability PH Industrie-Hydraulik GmbH & Co. KG Wuppermannshof 8, 58256 Ennepetal, Germany Tel. +49 (0) 2339 6021, Fax +49 (0) 2339 4501 info@ph-hydraulik.de, www.ph-hydraulik.de Application Hydraulic engineering and shipbuilding Railway technology

technology Machine construction SAFETY FIRST. STAINLESS STEEL CONNECTORS FROM PH. PH catalogue available as app for Android and iPad

Offshore

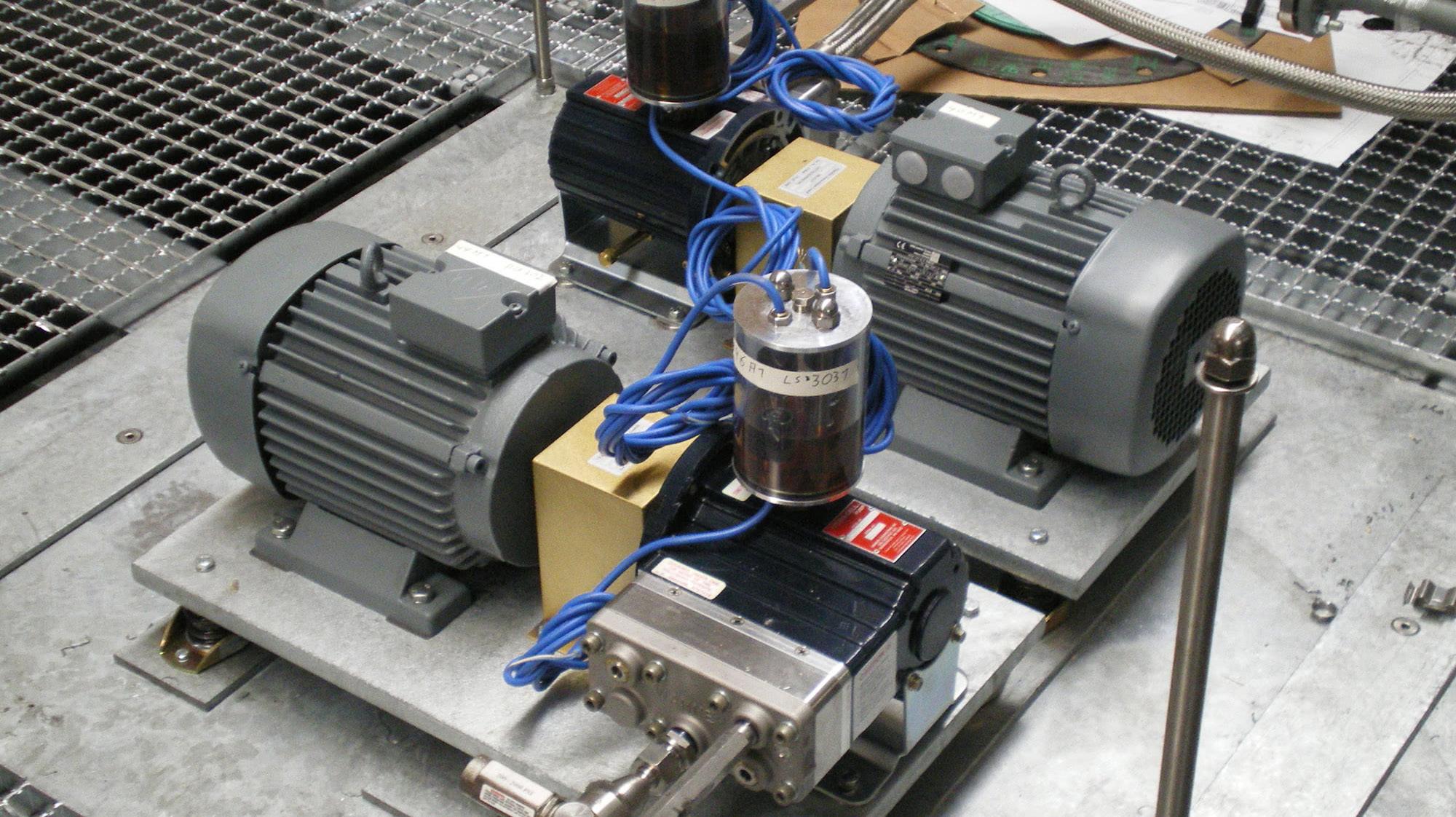

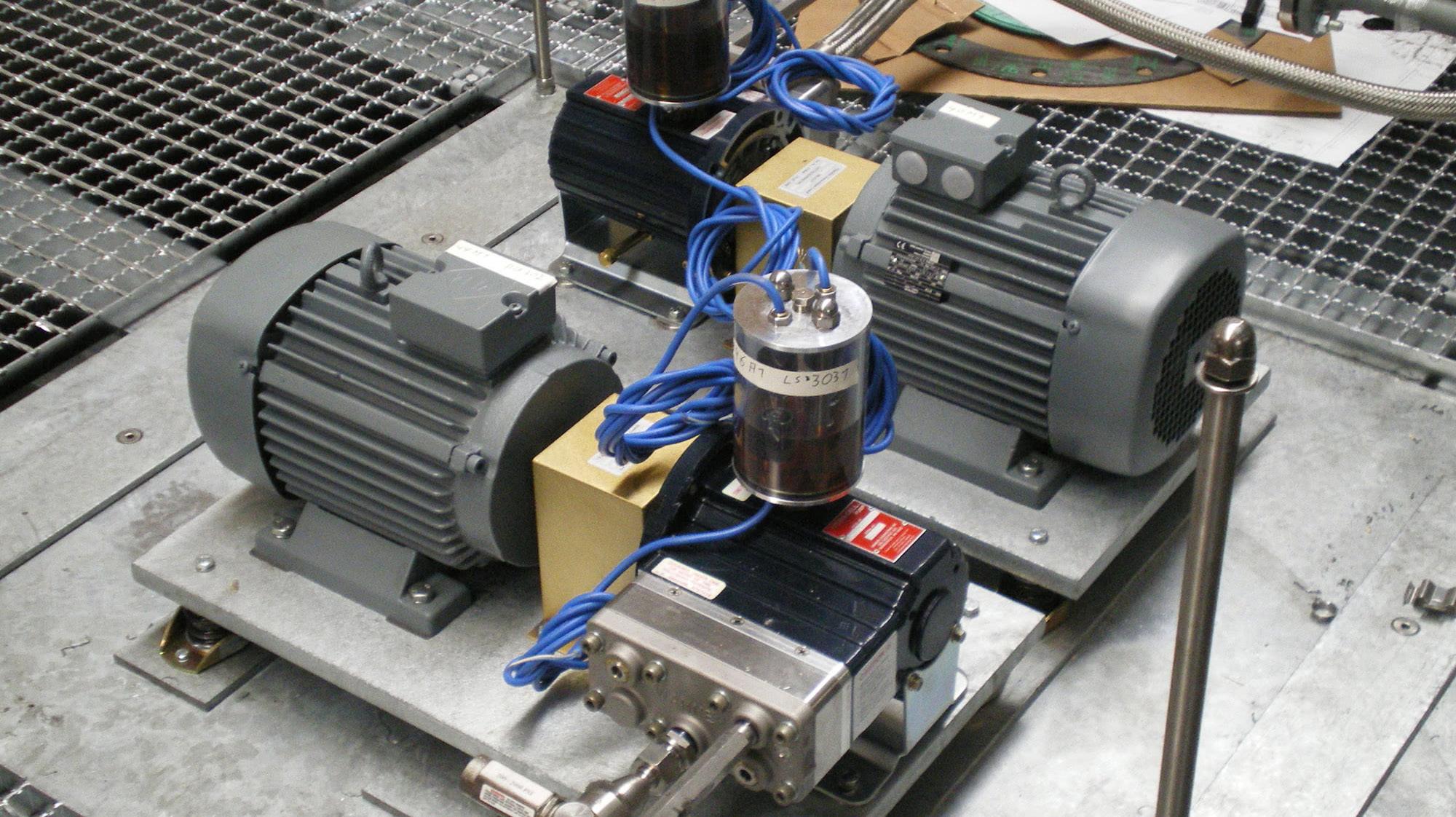

New Enerpac XC2-series redefines battery-powered hydraulic pump performance and usability

Enerpac continues to raise the performance of its range of battery powered pumps with the announcement of the XC2-Series cordless hydraulic pumps. The new pumps offer higher speeds, longer battery run-times and greater oil capacity allowing larger tool and multiple cylinder applications to be undertaken on a single charge.

Powered by a high-capacity 54 Volt battery, the XC2 pump matches the speed of a 0,37 kW electric pump with the added benefit of cordless convenience, eliminating the need for extension cords and noisy and emission producing generators. With the XC2 pump, managing cable trip risks are eliminated and environmental health and safety concerns are significantly reduced.

More projects on a single battery charge

The XC2 pump’s brushless motor provides twice the life of brushed motors and high-flow rates for increased productivity, allowing significant work completions on a single battery charge. In addition to increasing engineer efficiency, it also enables a more flexible approach to completing projects. Available in either 2 or 4 litres oil capacity, the 4 litre XC2 pump can be used with larger and multiple cylinders, up to four 50 ton cylinders, two 75 ton cylinders or a single 100 ton cylinder, for example.

XC2-Series manual valve models also include a variable speed trigger enabling greater control of tool or cylinder movement.

The pump’s bladder reservoir design reduces the risk of contamination and allows pump use in any position; ideal for projects where access and working space are limited.

The XC2 pumps are highly portable with weights ranging from 11.9kg to 16.8kg depending on valve function and oil capacity, effectively bringing previously difficult to service remote projects within easy reach. They also include integrated steel rings to attach the accessory carry strap.

The XC2-Series 54 Volt fast battery charger minimises downtime with a 1.5-hour charge cycle. An LED display provides charge status, over temperature and damaged battery indication.

Heavy duty pendant controls

Heavy-duty pendants are used to operate any Enerpac XC2-Series pump. Easy to connect or disconnect when not required, the pendants feature large buttons, an over moulded grip, lanyard loop and a hanger magnet. Multiple seals within the pendant provide IP64 environmental protection. When working in confined spaces where using any cord can be problematic, the pendant control is easily detached, and the pump operated by the trigger.

Torque specific model available

For bolting applications, there is the XC-2 cordless torque wrench pump featuring an adjustable pressure relief valve which can be locked when the desired pressure is set. It can be used with a wide range of torque wrenches and features a 100 mm glycerine-filled pressure gauge for easy viewing and a 6 metre detachable pendant control.

Stay Connected - Enerpac Connect

The Enerpac Connect app gives XC2-Series pump users a complete picture of the tool and its usage, both important factors in job safety and productivity.

Using either a SmartPhone or tablet, XC2-Series owners can scan the QR code on the pump nameplate for instant access to product specifications, manuals, videos, job specific usage data, and wireless firmware updates through smart enabled tool technology.

Redefining Pump Portability, Usability and Efficiency

“The XC2-Series cordless hydraulic pumps demonstrate the focus that Enerpac is offering customers in terms of portability, usability and enhanced job performance. The increases in speed, battery runtime, and oil capacity compared to the previous XC-Series is where the XC2Series excels,” says Angie Wallace Global Product Manager, Enerpac. We’re translating our outstanding pump innovation and technology into tangible customer benefits designed to improve competitiveness and service delivery, as well as providing the ability to take on larger and higher cycle applications with a cordless pump.”

Enerpac, +27 (0) 12 940 0656, africa@enerpac.com, www.enerpac.com

PUMPS 10 Pipes, Pumps and Valves Africa - Mar/Apr 2024

We offer valves for precision processes - and demanding applications.

Our valves fulfill the highest of standards and are designed for many years of safe and reliable operation. Our service specialists regularly check, monitor and maintain all relevant system components - depending on what has been agreed. Our modular framework agreements offer you individual service and spare parts concepts. And we even go one step further. We additionally check systems for efficiency in order to reduce operating costs and increase productivity. For example, with the SES System Efficiency Service.

ZTS GATE VALVE GATE VALVE AKG - A/AKGS - A NORI 500 BOA - H Contact our dedicated Valves Sales Engineers for all your Valve requirements Tel: 011 - 876 - 5600 • E mai l: info - za@ksb.com KSB Pumps and Valves (Pty) Ltd www.ksb.com/en-za Your Level 1 B-BBEE Partner

GATE VALVE AKDS/AKD

STAALWEDGE

Sulzer launches controller for optimized performance of wastewater pumping stations

Network pumping stations invariably encounter challenging conditions, and operators can face an uphill struggle to maintain reliability and low operating costs. BlueLinQ Pro, the latest addition to the Sulzer pump controller lineup, uses an intuitive, quick setup wizard for simplified configuration and uses experience-designed presets to solve complex operating scenarios.

Operators can interact seamlessly via the 7” touchscreen and use the integrated variable frequency drive (VFD) control to maximize pump efficiency and reduce energy costs. The new BlueLinQ Pro offers excellent scalability and is capable of controlling up to six assets including pumps, mixers and valves for the most effective operations.

Plug-and-play performance

The Sulzer BlueLinQ Pro offers advanced control features and a setup wizard that improve pump availability and reduce energy consumption - all within a small footprint that makes retrofitting easy. Built-in best efficiency point (BEP) and proportional integral derivative (PID) control logic functionality ensures that all pumps in the station operate as close to peak efficiency as possible. This reduces running costs and minimizes stress on the mechanical components. Smart control functionality provides multiple

features that optimize pump operations and minimize the need for interventions from the maintenance team. The ability to calculate in and outflows, measure the speed of level changes and vary pump start and stop points ensures each pumping station operates to its full potential. This includes the addition of mixers and valves, which can also be included in the control logic delivered by the BlueLinQ Pro. Sulzer is setting a new standard for pumping station controllers. Simple module installation and configuration optimizes any retrofit by using multiple preset features to enhance performance. Round-the-clock remote monitoring and detailed analytics provide enhanced insights that support maintenance projects and minimize unnecessary call-outs.

Simplifying complex tasks

With so many very similar pumping stations in each network, the variety of controllers across sites can add unnecessary complexity for operators. The inherent flexibility of the BlueLinQ controller makes it ideal for many locations. Once the first station has been configured, all the settings can be easily transferred to others using the SD memory card facility, minimizing commissioning time. To further enhance the benefits of the BlueLinQ Pro, modern communications protocols offer excellent connectivity and remote access possibilities to maximize the effectiveness of operators and technicians. Centralized monitoring and programing ensure valuable staff and resources are only dispatched when absolutely necessary. In all, the features of this unique pump controller from Sulzer can support strategies to reduce operating costs, maximize reliability and optimize the productivity of the whole network.

12 Pipes, Pumps and Valves Africa - Mar/Apr 2024 PUMPS

Sulzer Pumps, +27 (0) 11 820 6000, CSSEnguiries@sulzer.com, www.sulzer.com

Lifecycle approach with OEM parts for sustainable pumping solutions

Capital equipment like pumps operate only as well as their components and wear parts allow, so it makes little sense to risk this performance by installing a replicated part.

“Mining and other industrial applications rely heavily on continuous operations to reach the productivity levels that make them profitable,” says Marnus Koorts, General Manager Pumps at Weir Minerals Africa. “This productivity is in turn the result of decades of partnership with original equipment manufacturers (OEMs) like Weir Minerals, who provide much of the technological foundation underpinning a mining operation.”

Koorts emphasises that the lifecycle cost of key equipment like pumps is many orders of magnitude higher than its upfront capital cost – as they all need a high standard of maintenance that matches the quality of their initial manufacture. As long as the equipment performs to expectation, it will contribute to the mine’s success.

“What is often not fully understood, however, is that OEM spare parts are as carefully designed and manufactured as the core equipment itself,” he explains. “As an OEM with over 150 years of field experience, we have deep insights into how our parts perform – and can confidently provide our customers with performance predictions and service

intervals.” These promises that an OEM makes become the basis of its long term partnerships with customers, he says, and allow the mining industry to effectively mitigate operational risk so that mines succeed. By contrast, a replicated part is a reverse-engineered product that tries to look the same as the original, and must simply fit in the appropriate space.

“This is where the similarity with the OEM part ends,” argues Koorts. “The performance and longevity of the replicated part can seldom be guaranteed, and this undermines the principles of risk mitigation and productivity that the mine is trying to achieve.”

Weir Minerals’ original spares form an essential part of the journey that it walks with customers toward sustainability and commercial success, he explains. While the efficiency and robustness of the parts reduce mines’ energy consumption and carbon footprint, the sustainability efforts of Weir Minerals also contribute to improving customers’ Scope 3 emissions.

“Having a parts supplier with a concerted sustainability commitment – including the use of renewable energy in many of our facilities – further assists our customers in reaching their strategic corporate objectives,” he concludes.

Weir Minerals Africa, +27 (0) 11 929 2600, Africa.minerals@mail.weir, www.minerals.weir

Pipes, Pumps and Valves Africa - Mar/Apr 2024 13 PUMPS

Tsurumi brings smart solutions for wastewater management at Craft Brewers 2024

Tsurumi returns to the show this year to showcase its wide array of wastewater pumps and process equipment, catered specifically to the needs of breweries. Highlights will include the HS Series solids extraction pump and VANCS Series submersible pumps and aerator mixers, which handle wastewater, sewage, corrosive, industrial and commercial sump pump applications.

Tsurumi Pump will share its cutting-edge wastewater equipment and industry expertise at this year’s Craft Brewers Conference in Las Vegas from April 21-24. A team of experts will be at booth #1421, offering insights into Tsurumi’s latest pumps and process equipment tailored for brewery needs.

Attendees will learn more about Tsurumi’s VANCS Series, a high achiever delivering solutions across many applications, notably wastewater treatment. The HS2.4S submersible pump will also be on display as the smallest of the company’s solids extraction pumps.

Tsurumi’s wastewater products support beer brewers in various ways, ensuring proficiency and quality in beer production.

“Efficient brewery operations rely on the smooth coordination of both front- and back-end processes for overall effectiveness. The days of dumping into the sewer are over; Tsurumi’s pump and process equipment covers all wastewater needs and is a necessary part of brewers’ waste discharge compliance,” said Tony Misiak, process equipment manager at Tsurumi.

Misiak further emphasizes that Tsurumi’s equipment is designed to handle several types of jobs, including conveyance, aeration, mixing, decanting, skimming,

thickening and screening. Just select the right type of equipment for the application.

“Breweries need reliable pumps for harsh environments to transport wastewater, and our VANCS models are excellent for this,” Misiak said. “Our aerators are ideal for aerating and mixing tanks, whether for partial or full treatment.

The MR, BER and TRN aerator-mixers are great for mixing products for onsite wastewater treatment in brewery spaces. Our screening (KW) and dewatering (MDQ) dehydrators are also designed for solids separation and water reuse recovery. The list goes on!”

Additionally, Tsurumi’s products allow brewers to achieve wastewater management goals, especially when sustainable operations are paramount. This is particularly important as brewery facilities face increasingly stringent regulations regarding the quantity and quality of wastewater discharged into municipal wastewater plants.

Tsurumi will have the following products on live display at its booth:

• VANCS Series Submersible Pump

• TRN VANCS Self-Aspirating Aerator-Mixer

• HS2.4S Submersible Pump

• Literature for all Tsurumi process equipment products, including Screening and Screw Presses

14 Pipes, Pumps and Valves Africa - Mar/Apr 2024 PUMPS

Built to treat

Tsurumi’s leading VANCS submersible pump series has a proven track record of offering long lifecycles in continuously harsh environments. The VANCS pump is corrosion-resistant and lightweight, equipped with industry-leading pump sealing and motor protection.

The TRN VANCS self-aspirating aerator-mixer is another corrosion-resistant, compact submersible pump with a patented, triple-sealed motor. It radially discharges fine air bubble water mixtures at high thrusts, providing ideal toroidal-type mixing in cylindrical-type tanks.

Finally, the smallest of the solid extraction pumps, the HS Series submersible pump, incorporates an agitator ahead

of the impeller, fluidizing solids and extracting high solids content from tanks.

“We’re really looking forward to returning to Craft Brewers this year. It’s a great opportunity to connect with brewery professionals and present our extensive product portfolio that serves this industry,” said Glenn Wieczorek, managing director at Tsurumi. “Our experts will help customers assess if their water is being treated properly and responsibly!”

Tsurumi Pump, elsab@tsurumiamerica.com, www.tsurumipump.com

Pipes, Pumps and Valves Africa - Mar/Apr 2024 15

PUMPS

UNIT NO 1, 33 APEX ROAD WEST, APEX, BENONI TEL: +27 11 421 8170 FAX: +27 11 421 8166 / +27 86 573 5862 EMAIL: INFO@VALVEHOSPITAL.CO.ZA WEB: WWW.VALVEHOSPITAL.CO.ZA

Engineered Solutions for Valve Refurbishment.

Electrically operated diaphragm pumping solutions improve fluid handling productivity

BMG has extended its range of Ingersoll Rand ARO fluid handling products to include the new EVO series™ electric diaphragm pumps, designed to enhance energy efficiency and improve fluid handling productivity.

These versatile electric diaphragm pumps - which incorporate features that have previously not been available in a single pump solution - are engineered to deliver high performance and serviceability, enabling users to achieve high efficiency and the best cost of ownership.

“The new EVO series is the next development from leading manufacturers, with almost 100 years’ experience in pumping technology. This series integrates key benefits of ARO air operated pumps incorporating important features from other pump technologies, to offer an efficient electric diaphragm pump with controllability,” says Joe Pinheiro, BMG’s National Product Manager, Pumps.

Conventional electric pumps normally have a double diaphragm design with a direct drive electric motor, while new ARO EVO pumps have a specially-designed triple diaphragm, with an integrated variable drive, maintenancefree gearbox and control panel.

The leak free design with a secondary containment system, prevents the escape of hazardous fluids and oils

and is enhanced by automatic leak detection. “These low-maintenance pumps, which have been designed for extended service life, even during high load conditions, offer low pulsation.”

Due to the high-resistant three chamber design, there is no need for a pulsation dampener. “It has a true deadhead when the downstream valve is closed, automatically preventing the pump’s spinning and holding the pressure.”

EVO electrical diaphragm pumps that can handle the most aggressive and corrosive fluids, are available from BMG in a choice of two sizes and five different materials of construction. Size 1” pumps are equipped with a 2.2 kW gear motor and 3.0 kW VFD that provides versatility for small batch and dosing applications.

Size 2” pumps are equipped with a 5.5 kW gear motor and 7.5 kW VFD for large fluid transferring applications.

EVO metallic diaphragm pumps are manufactured in Cast Iron, Aluminum and Stainless Steel for applications that require durability and tensile strengths. Nonmetallic options include Polypropylene and conductive Polypropylene for high corrosion resistance - especially useful in caustic services in the chemical industry.

These electric diaphragm pumps, which conform to stringent international quality and safety specifications, are also supplied with hazardous duty certifications for hazardous environments. Typical applications for these pumps are in processing, mining, wastewater treatment, manufacturing and general industry.

Other important features of EVO electrically operated diaphragm pumps are easy installation and maintenance –even in confined spaces and because this is a single pump system, there is no need for users to purchase accessories. This system, with built in control and monitoring capabilities, is IOT ready and offers full integration through PLC or HMI devices.

Also in BMG’s ARO range are the PRO series air-operated diaphragm pumps, designed to efficiently pump any type of liquid - from clean, light to medium viscosity fluids, to highly corrosive and abrasive fluids. ARO pumps can also transfer large particles without damaging the pump.

Notable features include a seal-less, self-priming design, with low material shear and minimal maintenance requirements.

These portable pumps are easy-to-install and can run dry without damage. Most ARO diaphragm pumps are ATEX

16 Pipes, Pumps and Valves Africa - Mar/Apr 2024 PUMPS

certified (CE Ex11 2GD X) enabling safe use in potentially explosive areas. This feature makes the ARO pumps ideal for underground applications, such as dewatering.

ARO PRO series air-operated diaphragm pump air motors, which are lubrication-free, have positive sealing characteristics and make use of a specially designed unbalanced air valve to prevent stalling issues associated with operation at low pressures. Exhaust valves divert cold air away from components that are prone to ice build-up.

Metallic and non-metallic air-operated diaphragm pumps are available from BMG in various materials and porting configurations to suit numerous applications, including transfer, loading/unloading/filling, re-circulation, system flushing and batching/blending in many industries.

A range of speciality pumps is also available from BMG, including Stainless Steel sanitary pumps (FDA compliant), 2:1 & 3:1 high-pressure pumps, submersible double diaphragm pumps, air driven submersible pumps, antifreeze blending pumps and UL-approved fuel transfer pumps.

BMG supports this range with a technical advisory service to ensure the selection of the most suitable pump for every application. The company also supplies a full range of ARO diaphragm pump parts and accessories for standard repair and maintenance requirements.

BMG, +27 (0) 11 620 7372, josep@bmgworld.net, www.bmgworld.net

Pipes, Pumps and Valves Africa - Mar/Apr 2024 17 PUMPS PUMPS

Energy savings begin with the pump

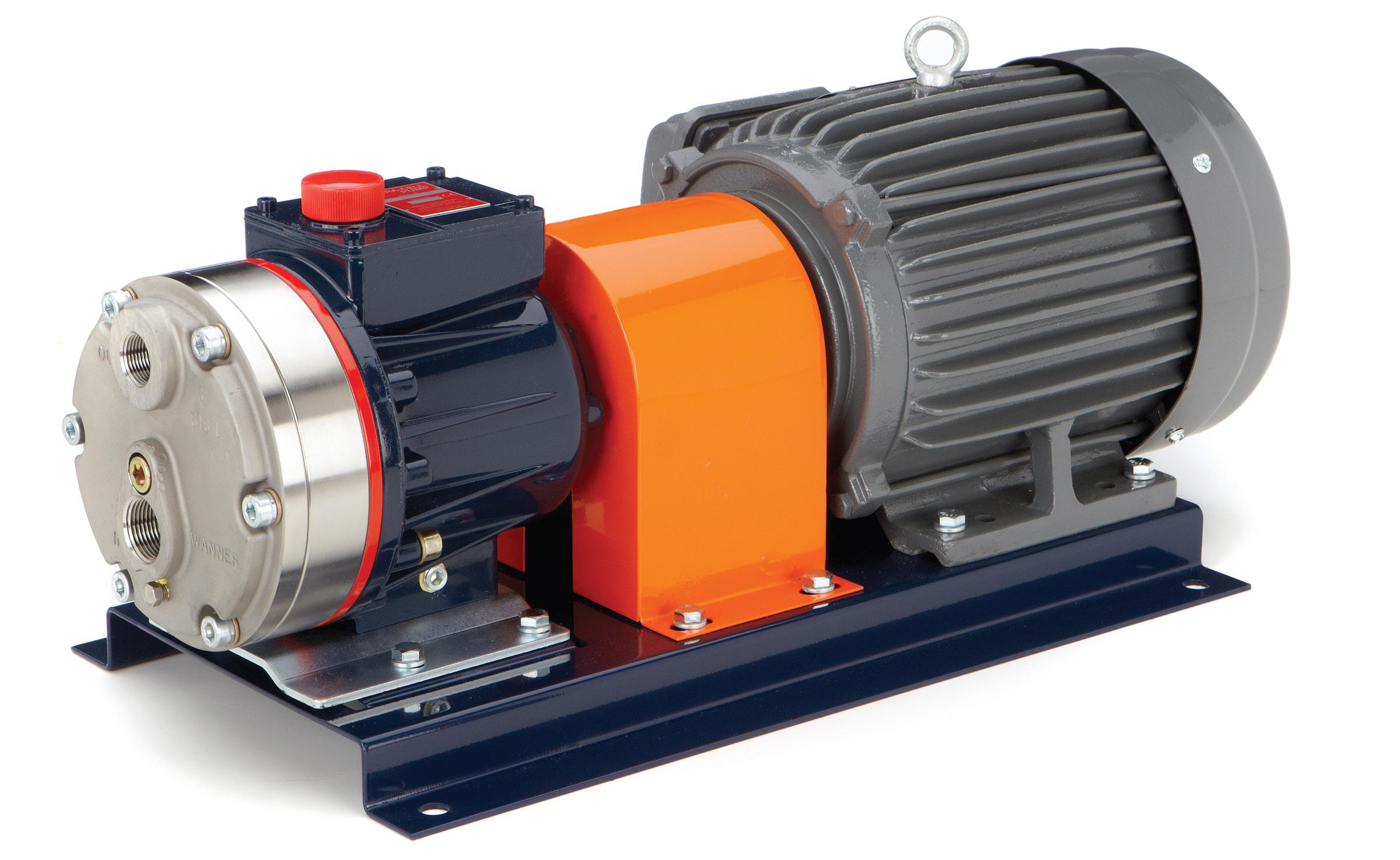

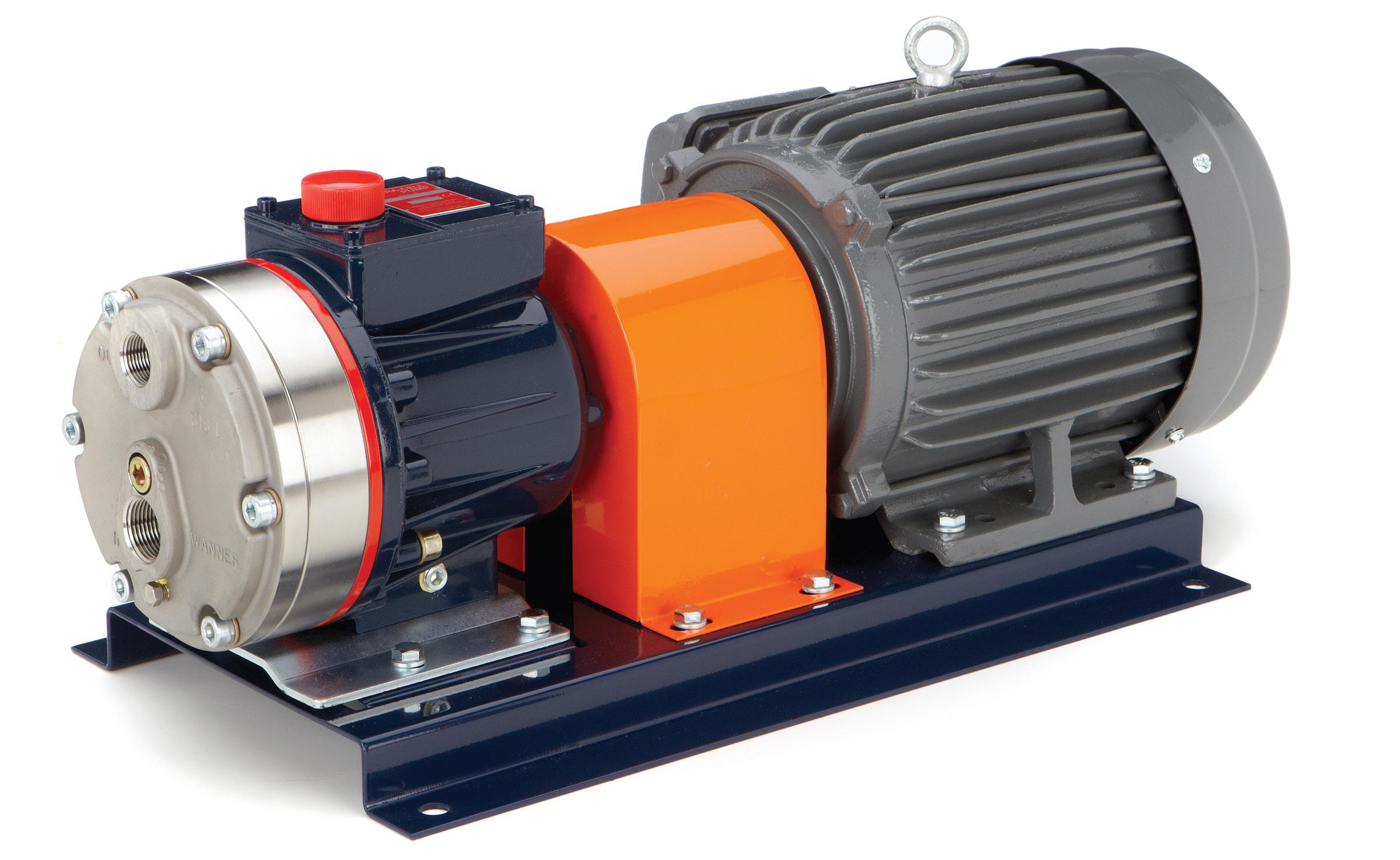

Sophisticated controls, VSD drives, efficient motors – but don’t forget the pump! Paul Davis looks at how design fundamentals and the effects of pump wear impact directly on energy costs. Can seal-less pumps lead the way to more efficient systems?

It is unusual these days to open a magazine, click on a web site, visit a trade show, or listen to a salesman and not be told how this product, that design or the other ‘approach’ will save you energy. Governments are involved, applauding, rewarding, penalising. Society approves – and rightly so, because concern is global.

Pump manufacturers and their customers have a special interest in energy issues. A report by US government department the Office of Energy Efficiency, cited in World Pumps last September, put the industrial sector’s share of all energy consumed in the USA as high as 33%, while pumping systems account for 27% to 33% of all energy used in industry. Figures may vary internationally, but the USA is not alone.

So it would be surprising if pump and system suppliers were not only striving to improve the energy efficiency of their product, but also devoting considerable attention to publicising these efforts. The cumulative effect has been an ongoing outburst of energy conservation claims that may well leave the customer a little confused.

VSD developments

Over the last decade, one of the more significant steps towards the reduction of energy consumption in pumping systems has been the development and availability of smaller, cheaper and more efficient variable speed drives (VSDs). Controlling system flow by altering pump speed, rather than diverting output via a by-pass valve or using simple on/off controls, makes it possible to operate the

pump closer to the fluctuating flow/pressure demands of the system, thereby avoiding what may be considerable wastage of power.

The relative efficiency of the motor must be taken into account, and some pumps are easier to control than others. But in any case, no matter how good the motor and how sophisticated the control system, two underlying factors directly affect the baseline energy costs of running a pump: the efficiency of the pump itself at the required pressure, and the extent and rate at which performance degrades through pump wear in a given application. Both these factors vary widely with the type of pump in use, and can have a dramatic effect on energy costs, measured through time.

Underlying efficiency

The first factor, determined arithmetically, was one of the elements used by Dr.-Ing F-W Hennecke in 2006 when the former BASF pump chief published the results of a comparative enquiry into the Life Cycle Costs (LCC) of a representative selection of five types of pump used in the process industries. A leading proponent of the LCC concept (he co-edited the jointly published by Europump and the Hydraulic Institute) and a member of the Pump Working Group of the VCI in Germany, he was well placed to conduct a survey based entirely on data supplied by the manufacturers themselves – five companies, each chosen as a leading producer of a particular type of pump.

The types considered were the centrifugal pump, the

PUMPS 18 Pipes, Pumps and Valves Africa - Mar/Apr 2024

sidechannel pump, the peristaltic pump, the membrane piston pump and the Hydra-Cell pump – each of these being generically different from other types of pump.

Measuring LCC

LCC, accepted as the true cost of owning and operating a pump, must historically include every element from purchase to scrapping, but in a general comparison of costs for pump types, some factors must be excluded as less useful, being common to all types or dependent on individual circumstances. The significant elements for purposes of type comparison in this survey were purchase cost, maintenance/repair costs and the cost of energy.

Operating values were invited for each pump type to match specified flow rates from 1 m3/ hr to 8 m3/hr and an assumed duty cycle of 4000 hrs/yr. In each case, LCC was calculated for working at specific pressures from 5 to 100 bar. For higher pressure applications, Dr Hennecke took into account only the membrane piston pump and the Hydra-Cell, both of which could be classified more generally as reciprocating positive displacement pumps – though with distinct differences. The other types in the cost survey ‘could not usefully be considered’ for working at pressures above 10 bar. He also noted that in practice not all the pump types were suited for operation in all circumstances. Limiting factors would include temperature, solid content, hazardous fluids and pump pulsation – all excluded for purposes of the survey. The bar chart in Figure 1 summarises the LCC comparison costs for pumps delivering 1.4 m3/ hr at 50 m head (5 bar), while Figure 2 shows the overall LCC findings for the same pump types delivering 4.2 m3/hr.

Energy costs in the Hennecke survey were based on manufacturers’ pump specifications, related to horsepower requirements at specific operating levels. They therefore reflect pump efficiencies. It will be seen that at low

pressure and flow, the LCCs for centrifugal, side-channel and Hydra-Cell pumps were broadly similar, though the energy cost figures indicated that the latter had some advantage in mechanical efficiency. Hennecke’s results for higher flows at the same low pressure bore this out. But at all flow rates, the effect of operating at higher pressures was to increase energy cost differentials.

The investigation confirmed an important principle: namely that the life cycle costs of pump ownership, and within that the energy cost, do vary significantly with the type of pump used. That still applies in 2010, when energy is a bigger factor than ever before.

Pump comparisons

In broad terms, positive displacement pumps are capable of higher efficiency levels than are centrifugal pumps. They are also more flexible, being relatively unaffected by changes in fluid viscosity or operating pressure (see Figure 3). The typical efficiency curve for a centrifugal pump shows why, to restrict energy consumption, it is important to avoid deviation to left or right and restrict operation to the centre section of the curve. In practice this may be difficult to achieve.

Dr Henneke was concerned with LCC (not just energy cost) and his sampling leaves out several types of positive displacement industrial pump for which high efficiencies may be claimed, in greater or lesser degree. Piston/ plunger pumps, gear pumps, twin-screw pumps and progressing cavity pumps are examples. But at pressures above 30-40 bar, power requirement differentials between one efficient pump and another can be significant (see Table 1).

Seal-less benefits

What none of the foregoing takes into account is the potential loss of efficiency through time. New is compared

Pipes, Pumps and Valves Africa - Mar/Apr 2024 19

PUMPS

with new, using power requirements as revealed by manufacturers’ data sheets – and the liquid pumped is generally assumed to be clean. Real life is not always like that.

The most common cause of loss of performance through time is wear – of seals and close tolerance moving parts. The faster the wear in a vulnerable part and the longer it continues, the higher the electricity bill through the letterbox. Even clean cold water is not a good seallubricant. Recycled liquids, dirty liquids, hot liquids, corrosives, very thin liquids or liquids carrying abrasive particles are potentially more damaging.

Generalisations are to be treated with caution, and every pump application is different. However, commonsense suggests (all other things being equal!) that pumps that do not rely on seals, or on closely meshing metallic surfaces, will be less prone to wear and its potential consequences. Case files at Wanner International record numerous situations where savings in energy costs were directly traceable to sustained efficiency resulting from seal-less pump design – energy savings often being accompanied by parallel reductions in maintenance and repair expenses. At the Seonam water treatment plant in South Korea, engineers scored a double success when they replaced leaking screw pumps with the seal-less G25. Though working pressure on a disinfection system was only 8 bar, the screw pumps could not satisfactorily handle the MgO2 abrasives in the liquid. Premature seal wear caused external leakage (Figure 4) and cumulative energy wastage as efficiency declined and wear increased. Since installing the replacement pumps (Figure 5) there have been no more leaks and energy costs have been reduced by 50%.

Meanwhile, a French chemical manufacturer reported ‘huge’ energy savings when a G25 with 11 kW motor replaced a centrifugal pump driven by a 37 kW motor on a central pumping system feeding tank washers and lances with ‘not necessarily clean’ water at 60°C. The working pressure was 66 bar.

In another example, piston pumps feeding raw turpentine to burner units at a Swedish plant, and others of the same type transferring pitch oil, were breaking down as often as 10 times a year. Low lubricity of both liquids and ash content in the pitch oil caused severe wear – leading to loss of performance and ultimate pump failure. When sealless pumps replaced the piston pumps, annual cost savings in power consumption and mechanical repairs were estimated at SEK 170,00 (18,000 Euros).

In Germany, a chemical processor had been using a magnetic drive centrifugal pump with 55kW motor to transfer polystyrol into a process line over a distance of 5.8 km. The original pump was successfully replaced with a Hydra-Cell G35 fitted with 13.2 kW motor. Other units in contention had included a 4-stage centrifugal pump with double axial face seal, and a multi-stage canned motor pump. The G35 had a clear price advantage and a pumping efficiency double that of the alternatives.

Systems control

On many applications there is also the issue of control. A major machine tool manufacturer wanted accurate control of coolant pressure and flow rate (20-30 bar, 10-20 l/ min) in order to vary conditions and optimise performance and energy use as different tools were selected. This was attempted by means of a centrifugal pump controlled by an inverter. But with this type of pump, flow rate is significantly affected by the discharge pressure – making control difficult and complicated. By contrast, the flow rate of a reciprocating PD pump is independent of discharge pressure, so all the relevant variables are easily controlled. Moreover, as can be seen in Table 2, at the required flows and operating pressures the PD pump offers substantial savings in energy costs.

Monitor Pumps and Systems, +27 (0) 11 6183860, sales1@monitorpumps.co.za, www.monitorpumps.co.za

PUMPS 20 Pipes, Pumps and Valves Africa - Mar/Apr 2024

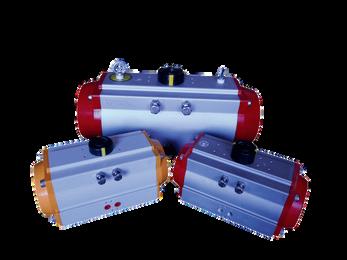

Supplier of world leading brands of:

- Electric, Pneumatic, Hydraulic and Portable actuators

- Valve gearboxes

Design and manufacture

Installation and commissioning

Onsite service and repairs

Training

info@aumanat.co.za www.aumanat.co.za

(0)

700 6954

+27

31

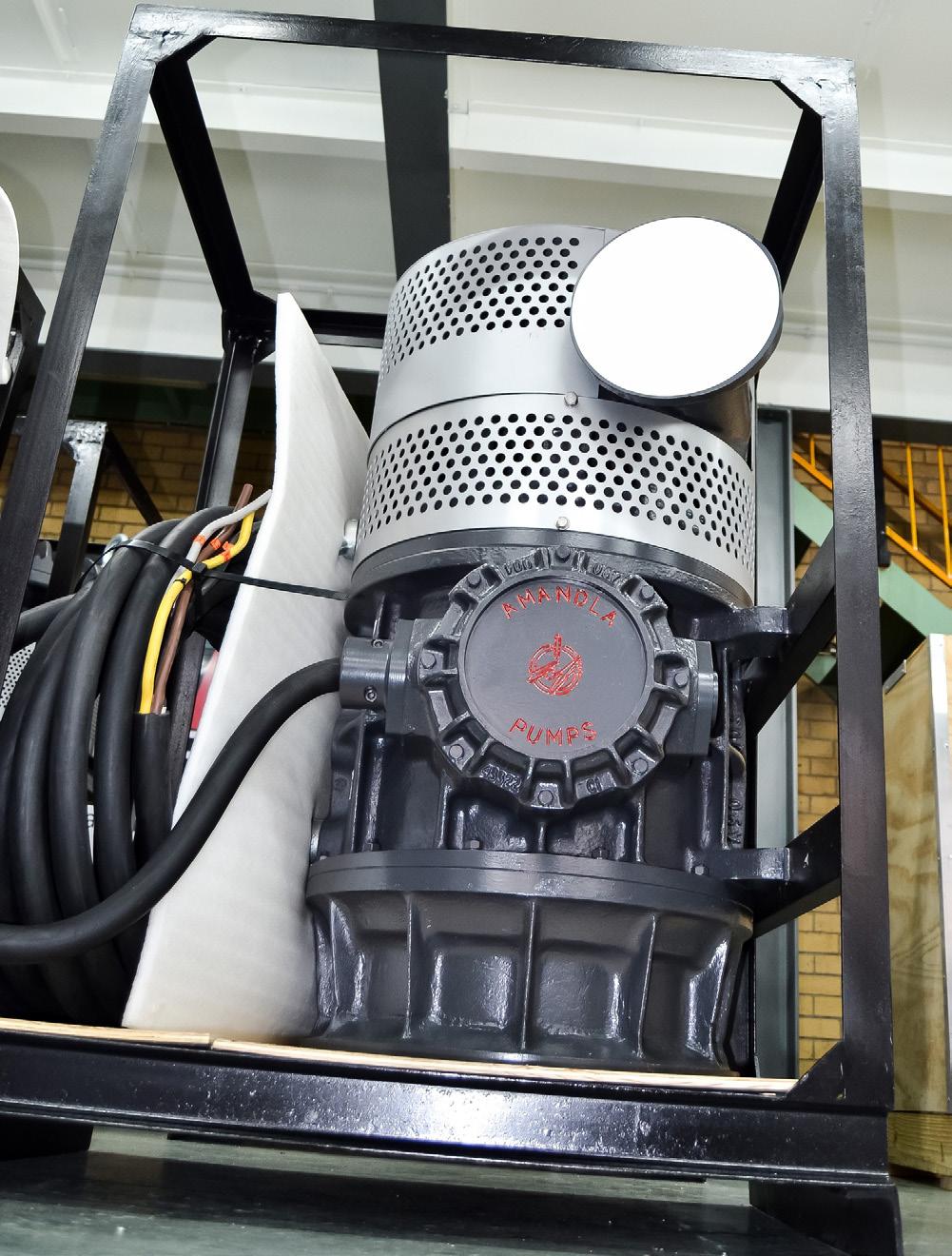

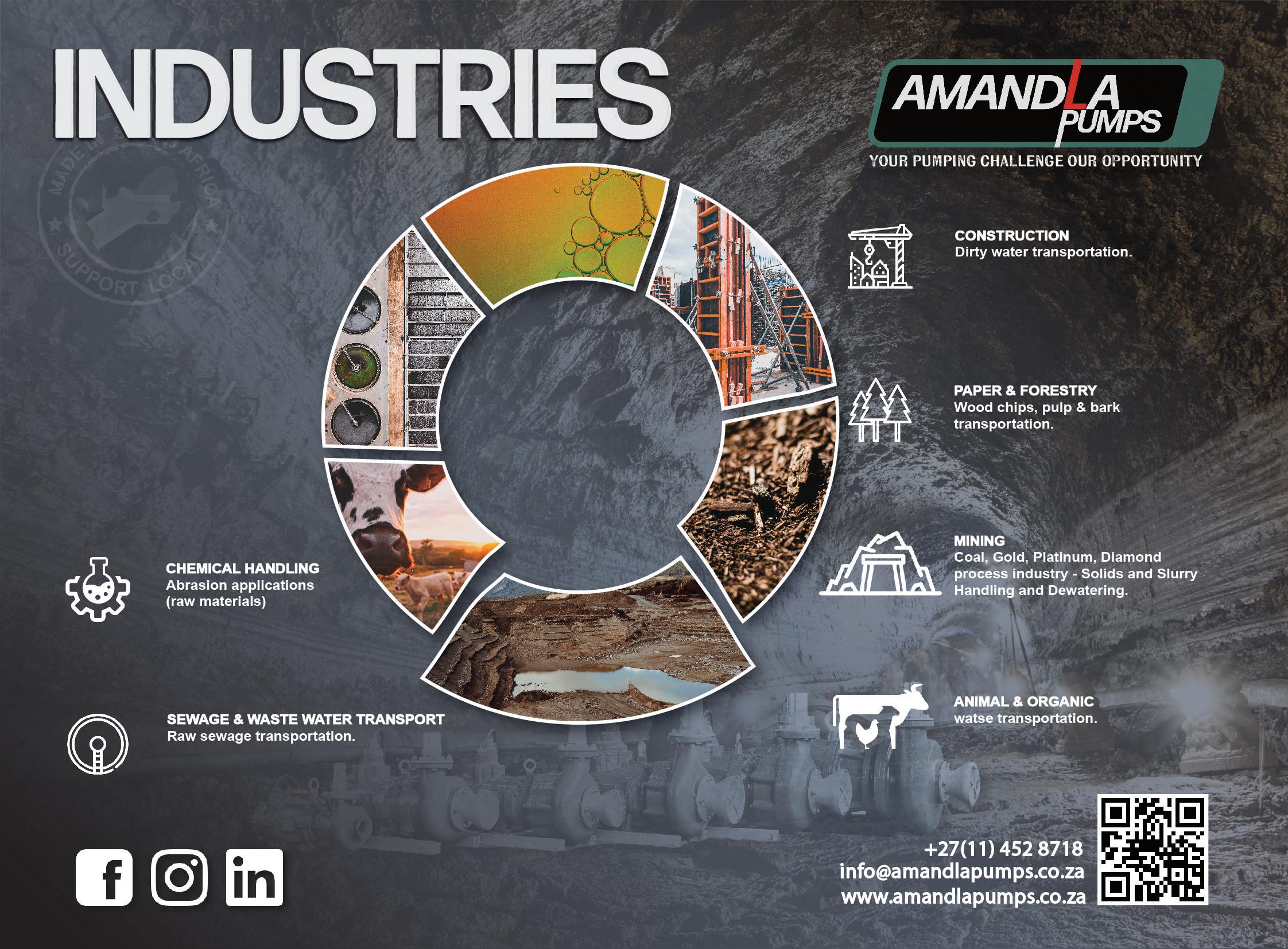

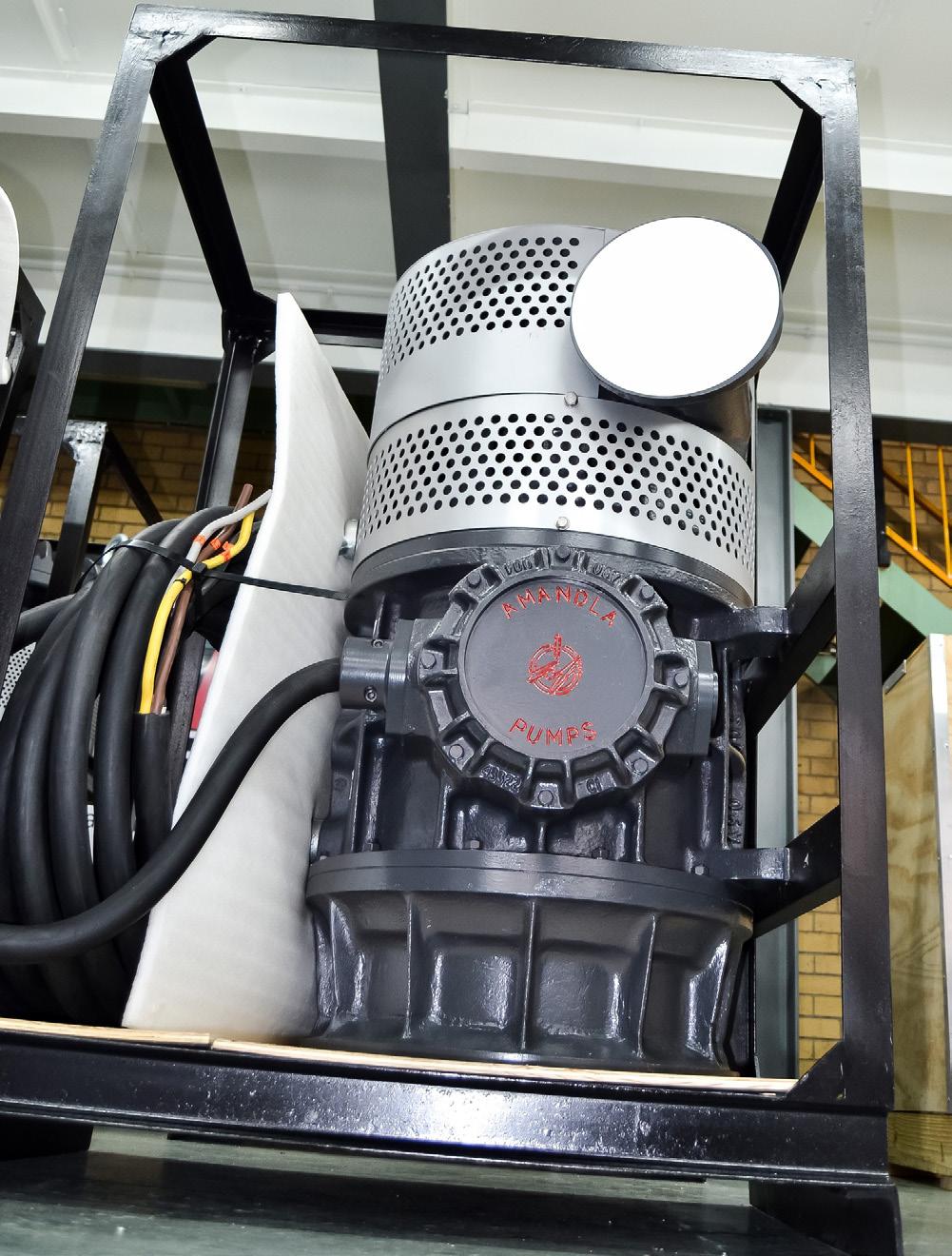

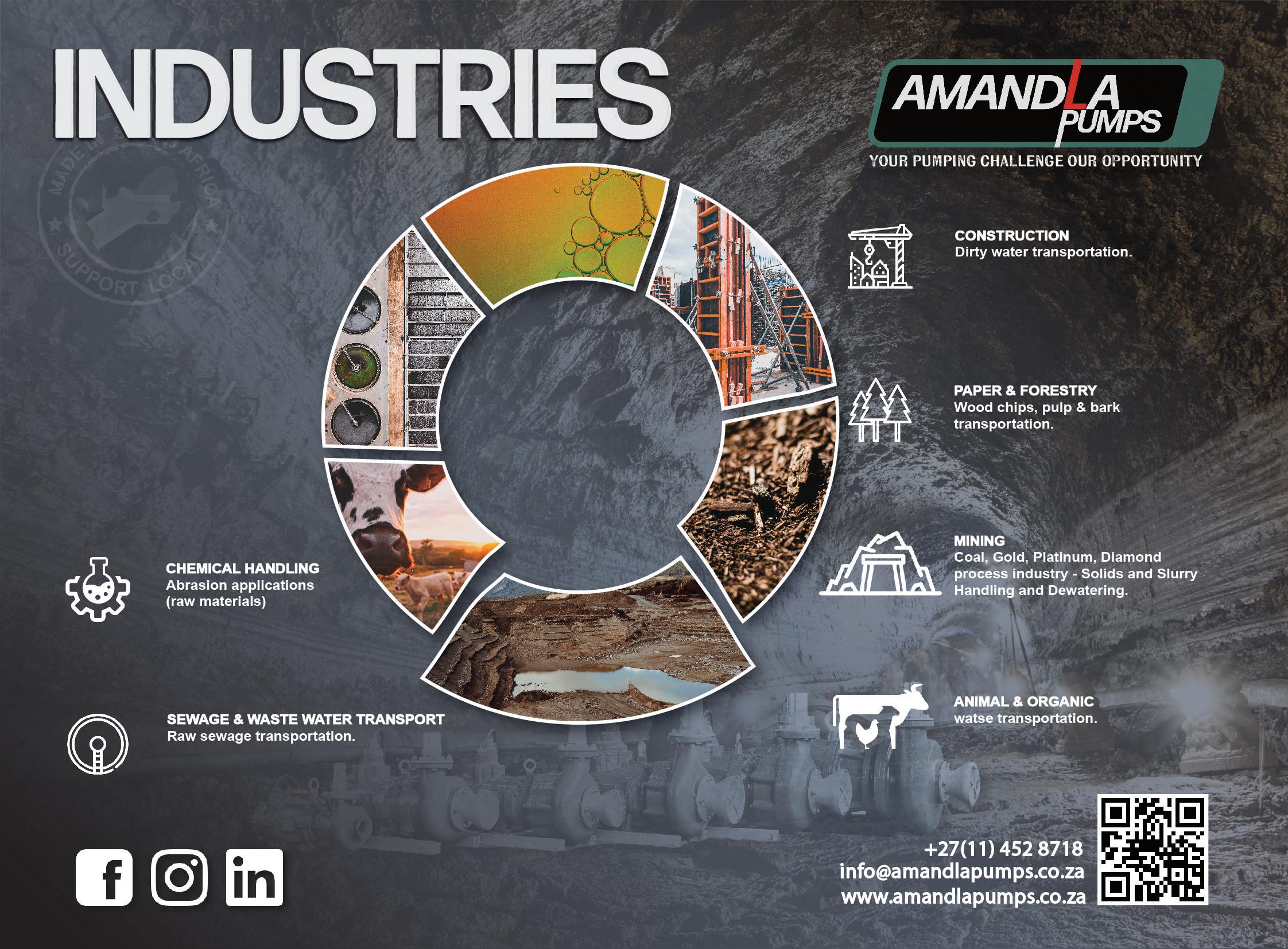

Amandla Pumps commitment to quality, reliability and service

As industry demands evolve and environmental consciousness rises, the criticality of quality sourcing transcends mere product selection, extending to materials, repairs, testing, and customer service in pump procurement. Pipes, Pumps & Valves Africa spoke to Garry De Mello Koch, Technical Director at Amandla Pumps, to learn more.

Proudly boasting 100% locally designed and manufactured products, Amandla Pumps sets a high bar for quality. With a commitment to reliability and performance, the company has earned itself a sterling track record in the industry. Each pump that rolls off its assembly line is not just a product but a testament to the dedication and craftsmanship that defines Amandla’s ethos.

“Reliability and durability start with a robust design,” explains Koch. “We also meticulously select quality materials and components that allow us to extend the lifespan of our pumps significantly.”

One key aspect of the design philosophy is the exclusive use of polyurethane lining in the pumps, eschewing traditional rubber for its exceptional wear properties. This choice not only enhances durability but also ensures sustained performance over time.

“The materials of the pump end of the unit are made from good abrasion and corrosion-resistant materials. In flameproof applications, the motor is fitted with thermal controls to stop the unit when it gets too hot. This extends the motor life. In chemical-type applications, getting a proper breakdown of the medium being pumped is important,” he says. “We can then specify the correct material from which the unit needs to be made to ensure a long working life, be it Stainless Steel 316, Silicon/Nickel Iron, or other suitable options - ensuring optimal performance and longevity. Furthermore, our

units are intelligently designed for repairability, not just replacement. In the event of a failure, our pumps can be easily repaired, minimising downtime and maximising efficiency.”

Ensuring reliability: trusted suppliers and continuous testing standards

For existing suppliers, the company maintains a comprehensive approved suppliers list. This list is a valuable resource in the procurement process, ensuring that Amandla Pumps consistently partners with reliable and trusted suppliers who meet their stringent quality standards. “When considering new potential suppliers, we conduct a thorough assessment, including on-site visits to evaluate their capabilities. Led by our experienced quality manager, this assessment ensures that prospective suppliers align with our standards of excellence. We also scrutinise the standards and systems employed by the suppliers to ensure compatibility with our quality objectives. To validate their capabilities further, we initiate trial orders, rigorously checking the quality of components before accepting them into our inventory. This meticulous process guarantees that only the highest quality materials are utilised in our products, maintaining our commitment to excellence and customer satisfaction,” says Koch.

Several factors contribute to consistently high standards of quality and delivering products. “We run on an ISO9001 management system and have a good management team.

22 Pipes, Pumps and Valves Africa - Mar/Apr 2024 PUMPS

Quality control processes throughout the manufacturing process help to identify defects early and prevent these defects from ending up on new units,” explains Koch. “Training is another key focus, which ranges from product to processes and standards, and we always use the latest technologies to improve processes and increase efficiencies.”

According to Koch, excellence stems from fostering a culture of continuous improvement within the company, where the emphasis lies on constantly identifying areas for enhancement and promptly implementing improvements. This proactive approach ensures the organisation remains dynamic and responsive to evolving challenges and opportunities.

Koch explains that a particular process is followed at Amandla to meet the high standards set. “Firstly, all components and raw materials are inspected when received. Non-conforming product is rejected immediately. We have an in-house machining facility where the first component of the batch is checked and signed off by a quality inspector. The batch is then checked on a 100% basis by the operator, and the last component of the batch is checked and signed off again by a quality inspector.”

He says all motor and terminal enclosures are pressure tested for leaks and strength to ensure that the enclosures can withstand an internal explosion. “We like some of our components with polyurethane. This is also done in-house. Components are prepared in a separate preparation area and coated with a bonding agent to ensure good bonding of the lining to the metal components. We use a computer to calculate the mixing ratios. A high-quality calibrated scale measures the materials to form the polyurethane lining. The curing process is done in ovens with accurate controllers that ensure the temperature is within 4 degrees of the required curing temperature.”

Once completed, all components are re-inspected by final inspection before being returned to the store. “The assemblers further have checks and tests to ensure the unit is correct. All pumps are 100% performance tested to ensure that the units perform according to specification, and finally, all of our units, once painted, pass through a final inspection to ensure each one is to standard as per the customer’s order.”

Sustained excellence: uninterrupted service for consistent performance

Service at Amandla Pumps extends far beyond the point of sale, encompassing ongoing support long after the initial transaction. “Our commitment to customer satisfaction is exemplified by our dedicated service centre, catering to the needs of our valued clients in the aftermarket,” says Koch. “Given the complexity of our units, we strongly advise customers to return failed units to Amandla for thorough assessment. Through a collaborative process, we conduct a witness strip alongside the customer to pinpoint the root cause of the failure. Identifying these underlying issues is crucial, as it enables us to implement effective measures to prevent or minimise future failures, thus enhancing the overall reliability of our products.” Koch underscores the fundamental principle at Amandla Pumps: unwavering dedication to the customer. “At every stage of our operations, from design to delivery and beyond, the customer remains the focal point of our endeavours. We prioritise understanding their unique needs, preferences, and challenges, shaping our products and services to provide tailored solutions that exceed expectations.”

Amandla Pumps, +27 (0) 12 819 1196, info@amandlapumps.co.za, www.amandlapumps.co.za

Pipes, Pumps and Valves Africa - Mar/Apr 2024 23

PUMPS PUMPS

The Busch Group is one of the world’s largest manufacturers of vacuum pumps

March 2024 marked a significant milestone for the Busch group in Africa when the state-of-the-art vacuum solutions centre was launched in Johannesburg. Busch Vacuum’s decision to build the African head office in Gauteng reflects our commitment to enhancing our operations and services across South Africa and the African continent.

The new building serves as a strategic hub for various technical initiatives aimed at advancing our products and solutions to better serve our customers.

The Busch Group is one of the world’s largest manufacturers of vacuum pumps, vacuum systems, blowers, compressors, and gas abatement systems. Under its umbrella, the group houses three well-known brands: Busch Vacuum Solutions, Pfeiffer Vacuum, and Centrotherm Clean Solutions.

The building launch was a significant milestone as it represents our ongoing commitment to innovation, excellence, and customer satisfaction. During the launch event we showcased the capabilities of our new facility, demonstrated our latest technologies, and engaged with clients to understand their evolving needs and challenges. It’s an opportunity for us to strengthen relationships, foster collaboration, and demonstrate the teams dedication to driving success for our customers in Africa and beyond.

Here is a little more insight on why we pursued this expansion:

• Advanced Facility Offering: The new building houses state-of-the-art facilities such as a fully equipped service

centre, Pfeiffer Class 10 000 clean room, volumetric flow testing equipment, liquid ring test bay, online condition monitoring systems, and a dedicated training room. These facilities enable us to maintain the highest standards of quality, precision, and efficiency in our operations.

• Enhanced Customer Experience: This purpose-built facility, was built to streamline processes, improve lead times, and offer more comprehensive support to our customers. The new premises also provide a platform for showcasing our capabilities and demonstrating the value of our products and services to clients and prospective clients.

• Increased Capacity: With growing demand for our products and services in Africa, we needed a larger facility to accommodate our expanding operations, including service and pump overhauls, warehousing of stock, system building, Pfeiffer expansion and technical testing capabilities.

The presence of our Co-CEO, Ayla Busch; the Deputy German Ambassador from the German Embassy, Mr. Enrico Brandt; and more than 200 key customers, underlined the importance of this event and highlights the strong partnership between Busch Vacuum Solutions, key stakeholders and clients.

The extensive product and service portfolio included solutions for vacuum, overpressure and abatement applications in all industries, such as research and development, food, analytics, automotive, chemicals and plastics. This also includes the design and construction of tailor-made vacuum systems and a worldwide service network.

By combining the expertise of Busch Vacuum Solutions in rough and medium vacuum applications, together with Pfeiffer Vacuum’s best-in-class high vacuum technology and leak detection, the Busch Group can provide comprehensive solutions as well as services for all areas of industry. This solidifies the Busch Group as a one-stop supplier with an extensive product portfolio to meet all customer requirements and for innovative, individual solutions. The team is ready to become your next solutions partner.

Busch Vacuum South Africa, +27 (0) 11 856 0650, info@busch.co.za, www.buschvacuum.com

24 Pipes, Pumps and Valves Africa - Mar/Apr 2024 PUMPS

LOOK FOR THE SIGN. GET THE BEST.

• Market leader in vacuum and overpressure

• Robust technology – built to last

• Most extensive experience in the market

Next-gen slurrysucker for silt-challenged water areas powered by Toyo

Not only does IPR’s SlurrySucker dredging system effectively clean process water ponds, return water dams or other water storage areas, it has become recognised as an ideal solution for cleaning water capture areas where silt is an issue, or where water retention and water holding capacity is being threatened.

Some of these areas are environmentally sensitive and must be protected from causing any pollution. Taking this innovative locally manufactured product to the next step, IPR recently launched its new generation unit - the SlurrySucker MK III. This powerful dredging system now incorporates the world renowned Toyo heavy duty slurry pump, making it the most efficient and cost effective electrically powered floating dredging system available on the market.

This is according to IPR Managing Director, Lee Vine, who says that the benefits of the SlurrySucker extend well beyond improving mines’ environmental footprints. “Bodies of water such as ponds, lagoons, dams and canals should be considered valuable plant assets and must be maintained to maximise their operational efficiency and contribution to optimised operational performance,” he explains.

“This is where the SlurrySucker has continued to deliver without fail, assisting our customers with some of their pressing issues including the need to increase water storage capacities, the recovery of minerals and improving process water quality,” he continues.

Equipped with Toyo heavy duty slurry pumps, the SlurrySucker MK III boasts enhanced solids handling capabilities. The pumps are fitted with robust cutter fans or agitators, facilitating the management of larger particles. Moreover, they can effectively handle slurries with a high specific gravity (SG).

Commenting on the effectiveness of the SlurrySucker MK III, Vine says the unit can be sized to meet an individual plant’s slurry removal requirements in terms of particle size, aggregation, distribution, cohesiveness, flow characteristics, sedimentation rates and specific gravity.

He is quick, however, to point out that while desilting or cleaning of settlement ponds may seem like a simple task, it is not always as straightforward as it would initially appear. Cleaning these facilities can become an onerous task, as it involves the pumping of high solids materials from the facility being desilted and should an incorrect system or equipment that is not fit for the task be specified this could cause issues including environmental harm.

“Historically many operations have used manual excavation methods for desilting and cleaning, but our established track record has proved that this is not only inefficient, but it often fails to remove the required volume of sediment,” Vine says.

There are several ways to accomplish effective desilting, but it has to be done effectively and cost efficiently, and this is where IPR’s skilled and experienced team comes into play. The best option, according to Vine, is a site visit to assess the application requirements and conditions.

PUMPS 26 Pipes, Pumps and Valves Africa - Mar/Apr 2024

“In some instances, it is possible to pump the high solids material to another nearby dam or reservoir. However, this is sometimes not possible and in this type of scenario we implement an alternate solution such as capturing and storing the content in specialised geotextile bags while the water is separated from the solid material,” he explains.

Once the actual condition of the dam or pond has been assessed the decision can be made as to how to proceed. The SlurrySucker itself needs sufficient volume of water on which it can be floated, and should there be areas where this is not possible, then a hydro-mining solution is applied to these drier areas.

“What is also important is that we can effectively ensure mine and industrial water contaminated sites do not negatively affect surrounding areas and being equipped with remote controlled height adjustment of the primary slurry pump and dredge head assembly allows the SlurrySucker to operate without causing damage to plastic liners in dams and settlement ponds.

Vine highlights two product options – the Maxi SlurrySucker which is capable of moving 250 m³ an hour at 20% to 30% by volume – equivalent of approximately 70 dry tons per hour. The Mini SlurrySucker® operates at 100 m³ an hour, again at 20% to 30% by volume for roughly 30 dry tons every hour.

The SlurrySucker comes standard with a galvanised frame structure and IPR’s flexible design provides the option

for stainless steel with polyethylene and UV-stabilised pontoons. In conclusion, Vine says that the opting for the SlurrySucker option is also far safer as the barge itself can be operated remotely from a defined distance away from the dam or pond edge. This is much safer than having equipment and personnel on the dam.

IPR, +27 (0) 87 759 8654, admin@pumprental.co.za, www.pumprental.co.za

PUMPS

Pipes, Pumps and Valves Africa - Mar/Apr 2024 27

The curtain goes up on IVS 2024, the fifth edition of the Industrial Valve Summit

The press conference to present the fifth edition of IVS - Industrial Valve Summit, the most important international event dedicated to industrial valve technologies and flow control solutions, took place in Milan at Sala Pirelli in Palazzo delle Stelline.

The event, promoted by Confindustria Bergamo and Promoberg, will take place in Bergamo from May 14 to 16, 2024. The session will kick off on the morning of May 14 with the early opening of the pavilions reserved for exhibitors, a novelty introduced to generate a valuable networking opportunity for the protagonists of IVS 2024. Highlight of the day is the opening conference of the Summit, where the event will be officially kicked off and where institutions, guests of honour, decision-makers and high-profile experts will take the floor.

In the afternoon, the extensive IVS scientific programme will start. A space that has proven over the years to be an agora where change can be interpreted and the latest technological innovations can be explored, identifying, and analysing the challenges of the sector. To support the development of the scientific calendar, the Summit organisers have created two additional conference rooms in Hall C. IVS 2024 includes 52 sessions including conferences, round tables, workshops, case studies and laboratories, providing a plan that is more than 50% greater than the 34 in-depth technical events of IVS 2022.

On May 15 and 16, the trade fair will go live and the halls will open their doors to the international valve community. Following the two-day exhibition, there will be a further opportunity for foreign delegations attending the fair to meet the players in the extended oil and gas supply chain on Friday May 17. The organisers have fuelled qualitative growth for the 2024 edition, increased the number of scheduled appointments in the trade fair programme

and enriched the side events, taking the Industrial Valve Summit from a two-day exhibition to a full-fledged valve week.

The fifth edition of the event takes place two years after IVS 2022 and continues on the path of growth that has marked it since the first edition. The Summit organisers are predicting record numbers for IVS 2024, starting with the companies taking part in the exhibition. There will be more than 310 exhibitors, of which the international component is growing strongly, with more than 20% foreign companies. The number of visitors is also expected to grow, with more and more countries expected to arrive in Bergamo, representing all continents.

Despite the travel restrictions in force in some areas of the world and the delicate global scenarios, IVS 2022 welcomed 12,000 visitors (+12% compared to 2019) from more than 60 countries. IVS hosted almost 300 exhibiting companies (+17% on 2019), from 12 countries: Italy, Germany, Great Britain, the United States of America, France, South Korea, Spain, the Netherlands, Belgium, South Africa, Turkey and the Czech Republic. These numbers tell how IVS has established itself as an essential showcase for the entire supply chain connected to industrial valves and flow control. The synergies with ICE (the Agency for the promotion abroad and internationalisation of Italian companies), AVR ANIMA (the industrial trade association representing Italian companies in the valves and fittings sector) provide a great stimulus for the increase in high-level international presence,

28 Pipes, Pumps and Valves Africa - Mar/Apr 2024 VALVES

Confindustria Assafrica & Mediterraneo (the Confindustria international office that supports Italian companies in their growth path in Africa and the Middle East) and SACE (the insurance-financial group directly controlled by the Ministry of Economy and Finance, specialised in supporting companies and the national economic fabric).

The partnerships will bring international delegations comprising institutional representatives, entrepreneurs, decision makers, speakers and specialised operators to the fair. The organisers have invited over 100 qualified enduser buyers of primary standing and international EPCs. A distinguished parterre that can interface with operators from the entire energy sector, giving rise to moments of exchange and discussion. In addition, through an operational collaboration with UNIDO ITPO Italy (the Italian Office for the Promotion of Technology and Investment of the United Nations Industrial Development Organisation), IVS confirms the participation of a delegation of entrepreneurs and representatives of Iraqi institutions.

IVS-Prometeia Observatory “The Oil&Gas Valve Industry in Italy” 2024

The 2024 update of the IVS-Prometeia Observatory “The Oil&Gas Valve Industry in Italy”, carried out with the support of the Confindustria Bergamo Studies Office, was also presented. The new report gives a clear picture of the state of the Italian industrial valve sector, which confirms its excellence in the European competitive context. In 2022, almost 4 out of every 10 valves for Oil & Gas produced in Europe were made in Italy, where the sector’s production value was close to 3.0 billion. The 2022 turnover of the domestic industry was up 12% compared to 2021 but has not yet regained pre-pandemic levels. Italy retains the leadership of the EU sector ranking, more than 8 points ahead of Germany and more than 30 points ahead of the third placed country (France). The numbers are achieved within an ecosystem of 139 companies (over 90% of turnover is generated within a radius of 100 km from the province of Bergamo), with over 10,000 employees (up from 9,300 in 2021).

Exports of Italian valves for the Oil&Gas industry started to grow again at a steady pace in 2023 (+5.7% in value over 2022), proving a growth rate higher than the evolution of international trade. The rebound in exports was driven by the Middle Eastern (accounting for almost 19% of total Italian exports) and Asian markets. Sales in Western Europe and, above all, Eastern Europe, slowed down by the aftereffects of the sanctions against Russia, performed less well. Investments by companies operating in the energy sector also grew, with increases in upstream, downstream and transport services. A positive trend that, along with the development of ‘green’ investments, offers positive effects that may also continue beyond 2023. There are opportunities for growth in both traditional and renewable and innovative sectors, such as Carbon Capture Utilisation and Storage (CCUS) and hydrogen. There are however elements of uncertainty, linked both to geo-political factors and to the timing and methods of the energy transition, which make strategic (even short-term) business choices more complex. Giovanna Ricuperati, President of Confindustria Bergamo, commented: «Actions to support production chains are of strategic importance for our

Association. In this context, IVS - Industrial Valve Summit confirms its role as a driving force also in this edition, a winning example of how it is possible to act in synergy to enhance the industrial valve sector of excellence. This is an event that, on the one hand, is expanding its international profile, as is also shown by the increase in the number of delegations attending, and, on the other, is consolidating its scientific value, with over 50 sessions scheduled including round tables, talks and company presentations. At the same time, the focus is on consolidating ties with the territory, as also demonstrated by the two initiatives aimed at young people in the IVS Young programme».

Giuseppe Patelli, President of Promoberg: «IVS is the flagship in the path of internationalisation of Fiera di Bergamo, with hundreds of companies and over 12 thousand high-profile operators from all over the world. We are honoured to play our part in supporting the economy and promotion of Bergamo, including tourism and culture. We have increased the number of days, up to three from the traditional two, with the first day dedicated exclusively to exhibitors, to discuss the hot topics of the sector and the trade fair in which they are the main players. Today the exhibition centre is a great added value, at the centre of one of the world’s most important macroregions and a nerve centre for mobility, thanks also to the BGY international airport that connects Bergamo with the whole of Europe, the Middle East and North Africa. And as for ‘tomorrow’ we welcome the announcement by the owners on the doubling of the exhibition centre that will allow us to further develop the growth of the summit».

Francesco Apuzzo, President of Valve Campus: «The goal of the IVS Scientific Committee has always been the provision of high-level content for the industry professionals and visitors attending. This year, we will introduce a series of themed sessions and interactive workshops covering the latest industry trends and challenges, from energy efficiency and decarbonisation solutions to new standards and business process digitisation. Among the novelties of this edition, there will be a special focus on the importance of sustainability and the introduction of artificial intelligence to underpin the future of the industry. The programme includes international keynote speakers, case studies and panel discussions, as well as the presentation of more than 40 papers by authors from every continent. IVS, me@thanai.it, www.industrialvalvesummit.com

Pipes, Pumps and Valves Africa - Mar/Apr 2024 29 VALVES

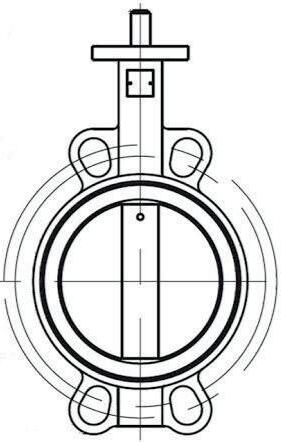

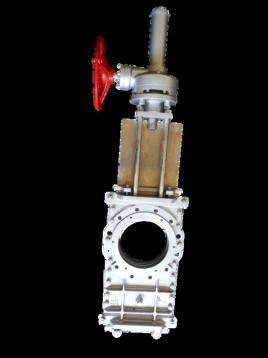

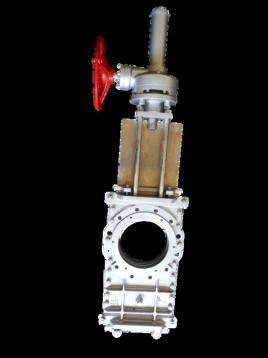

Paltech appointed as Meson Group Distributor in South Africa and parts of Africa

Paltech, a leading manufacturer and supplier of advanced valve solutions in South Africa, is proud to announce its appointment as the official distributor for Meson Group in South Africa and select African countries.

This strategic partnership will significantly expand Paltech’s product offering, particularly within the maritime industry, and marks another major milestone for the company following its maritime certification achievements.

www.paltech.co.za

Paltech, a member of the Two Roads Group (2Roads), has established itself as a pioneer in the South African valve industry, being the first local company to attain maritime certifications from both Bureau Veritas and Lloyds.

This achievement signifies Paltech's commitment to delivering the highest quality solutions for demanding marine applications. The new partnership with Meson Group, a renowned Swedish manufacturer known for its exceptional quality and innovation, further strengthens Paltech's value proposition.

"We are incredibly excited to partner with Meson Group," says Pierre de la Guerre, Technical Executive for 2Roads.

"This agreement allows us to offer an even wider range of advanced valve solutions to our clients, particularly in the maritime sector. Meson's commitment to quality perfectly aligns with our own, and we are confident that this partnership will be instrumental in our continued growth locally and internationally."