4 minute read

2 Trends driving demand for vertical mast lifts

Similar to what’s happening in the compact scissor lift and low-level access lift markets, demand today for vertical mast lifts is being driven by users’ need for machines that meet these core requirements.

• Smaller footprints to fit into smaller spaces

Advertisement

• Lighter weight to be used on different types of sensitive surfaces, like finished flooring

• Small (or zero) turning radius for enhanced manoeuvrability

• Ability to fit into freight elevators

Two trends increasing the demand for machines that match these requirements are:

1. The need to access narrower, more confined work areas

2. The ability to work in weightrestricted applications

Let’s take a closer look at these trends and how JLG is responding. The need to access narrower, more confined areas

One of the biggest benefits of vertical mast lifts like the JLG® E18MML is that these machines allow users to access tight, confined indoor spaces like doorways, stairways, hallways and other areas obstructed by infrastructure like in between tight racking, ducts for heating/cool work, pipes for plumbing and/or ceiling tiles and joists.

And because many models, like the JLG E18MCL machine, are rated for indoor and outdoor use, these models are well-suited for work in restricted outside areas like alleyways, on sidewalks and/or close to exterior walls of buildings. These types of machines are purpose-built to provide workers with access to high-reaching or overhead tasks in hard-to-reach places where ladders or scaffolding have traditionally been used.

Measuring between 2-3 ft wide, vertical mast lifts are the most compact type of aerial lift available to fit into small spaces. Additionally, vertical mast lifts boast up-andover capabilities, which means they can easily manoeuvre around fixed obstacles at height.

The ability to work in weightrestricted applications

Many construction and facility maintenance jobs need to be done in areas that are difficult to navigate with larger, heavier machines, including traditional slab scissor lifts. In fact, that’s the biggest difference between vertical mast lifts and slab scissor lifts — the size. Not only do vertical mast lifts like JLG’s models boast a smaller footprint (a little more than 60 cm in width and length and less than 2m in height) and zeroturn capabilities for excellent manoeuvrability around job sites and facilities, but these machines are also lighter weight— many models weigh under 900kg.

Thanks to their lightweight design, JLG’s machines can be driven through a facility and used on finished or weight-restricted flooring such as carpet, concrete, ceramic or porcelain tile, hardwood, laminate, stone and vinyl.

And, being small enough to fit into tight spaces and lightweight enough for use on sensitive flooring also means that JLG’s models can fit into and be moved between floors in standard elevators.

Another benefit of these machines weighing less and being so compact is that once the work is done, they can (when stowed) fit into small spaces like utility closets for storage when not in use.

A look at jlg vertical mast lifts

To meet market demand for these types of small, lightweight aerial lifts, JLG has two new vertical mast models available in the market: The E18MML and the E18MCL.

Both are tried and true, fieldproven products that offer an efficient and productive way to tackle up-and-over work and are an alternative to ladders and scaffolding.

These models feature a choice of castor-type steering that is ideal for use in maintenance, stock picking and warehouse applications (E18MML model), or scissor-type steering for construction use

(E18MCL model).

Thanks to the batteries being mounted under the platform, these JLG machines also are designed with improved machine weight distribution for efficient loading and unloading.

And, there are five different platform options to choose from to increase productivity.

Every JLG E18 platform option is equipped with exclusive “Quick Change” mountings for one-minute change-outs.

Both JLG models are engineered with a modern DC electric drive system, which comes available with long-running batteries for lasting performance.

Also, both models are available with a Stock Picker Package Option for stock and ordering picking applications in warehouses and distribution centres.

Eazi Access, +27 (0) 87 086 4900, info@eazi.co.za, www.eazi.co.za

Genie® 13 ft / 4 m platform for boom lifts now available for use with three XC™ boom lifts

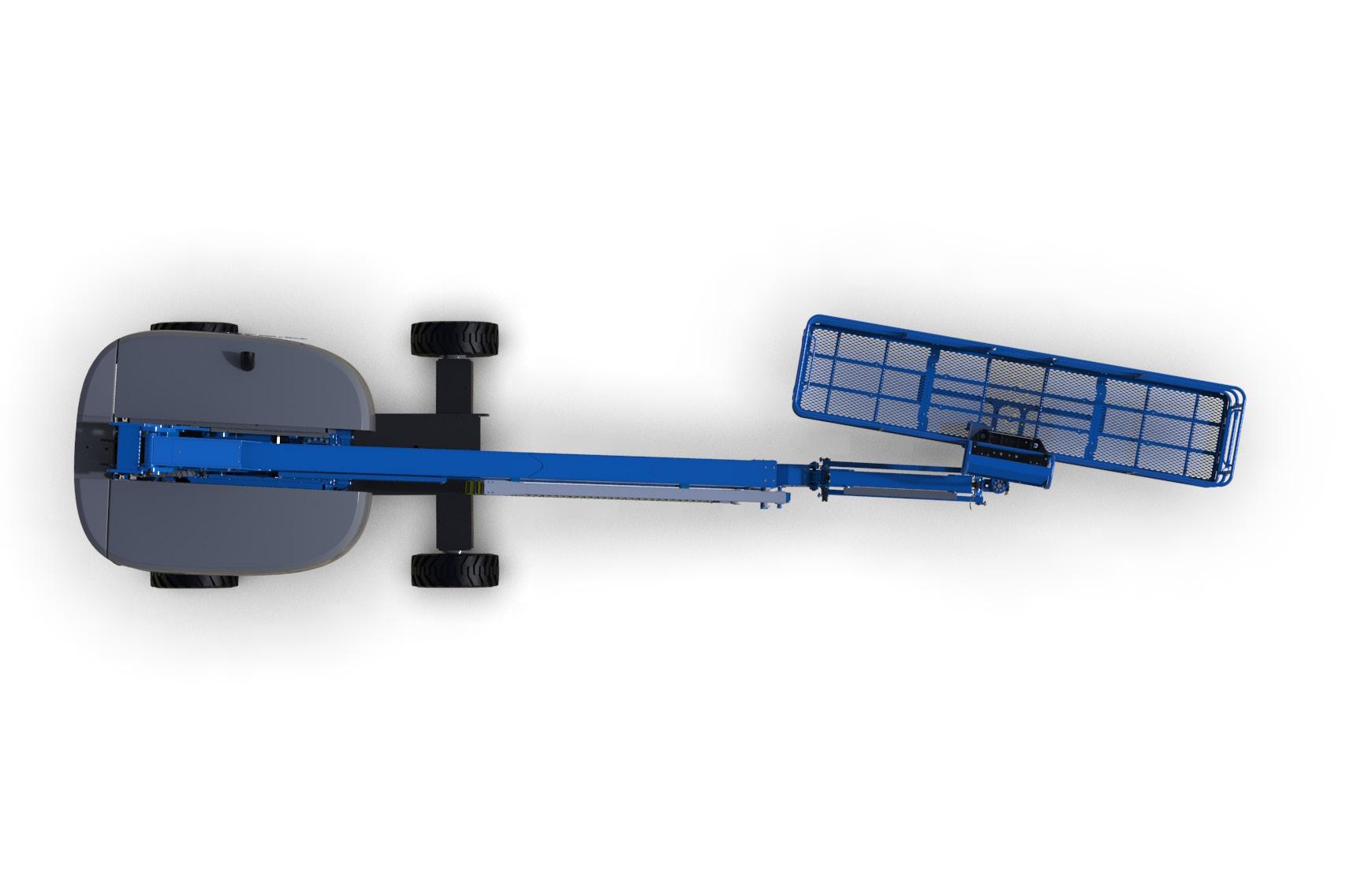

The Genie® 13 ft / 4 m platform for boom lifts is now available for use on three Genie XC™ (Xtra Capacity™) boom lifts in North America and the EMEAI region (Europe, Middle East, Africa and India).

The platform adds more than 60% additional room in the platform, increasing the versatility of rental companies’ boom lift fleets while boosting jobsite efficiency.

"This new platform offers benefits for equipment owners and operators. Because the expanded work space allows operators to cover more area, the number of boom movements required to get a job done can be cut in half, significantly boosting jobsite productivity,” says Logan Wood, Genie Associate Product Manager.“ At the same time, because the platform is compatible with multiple Genie boom lift models and can be swapped for the machine’s standard platform the same day, it also offers rental companies a simple, cost-effective way to boost the versatility of the booms in their fleet.”

The 13 ft / 4 m platform will be on display in the Genie booth (#4247) at The ARA Show in Orlando, Fla., in February. Compatible with Genie S®-45 XC™, S-65 XC and S-85 XC boom lifts, the 13 ft / 4 m platform is especially well suited for tasks that involve an extensive working area, such as renovation and painting of buildings and window cleaning and cladding, as well as jobsites with limited space to maneuver on the ground. In addition to increasing operator comfort, the extra space in the platform also allows workers to do more, faster, by providing access to twice as much work area with the same number of boom movements compared with a standard sized 8 ft (2.44 m) platform.

After following instructions to install the 13 ft / 4 m platform and calibrating the machine, the S-45 XC, S-65 XC and S-85 XC can take up to two workers to height and deliver a 600 lb (272 kg) lift capacity. Additionally, operators benefit from other features of Genie’s XC machines, including automatic envelope control, a smooth working curve and active load sense.

An off-center transport lock allows the machine to be transported on a standard trailer in most countries, keeping transport costs comparable to a boom lift with a standard-sized platform.

Goscor Access Solutions, +27 (0) 11 393 6437, accesssolutions@goscor.co.za, www.goscoraccesssolutions.co.za