SELECTED WORKS I 2019-2023 I LEKHANA GOWDA

SELECTED WORKS I 2019-2023 I LEKHANA GOWDA

Education

JSS Public School, Mysore.

Depaul International Residential School

Alavas English Medium High School

Alvas P. U College

Wadiyar Centre for Architecture

Weaving Colony

LEKHANA GOWDA

Phone no. : 9606933997

Mail ID: 2019_lekhana.p.m@wcfa.ac.in

Instagram: lekhanagowda_

Born: 7th september

Home: Mysore, Karnataka, India

Software Skills

Autodesk autocad

Trimble Sketchup

Adobe suite (Illustrator, Photoshop, inDesign)

Rendering (Lumion, Enscape, Vray)

Other Skills

Model-Making Sketching Diagramming

Kanchipuram, Tamil Nadu

Semester: 7th Semester

Typology: Sustainable Architecture

Professor: Porf.Kukke Subramanya

Assoc.Prof. Juile Ann Tharakan

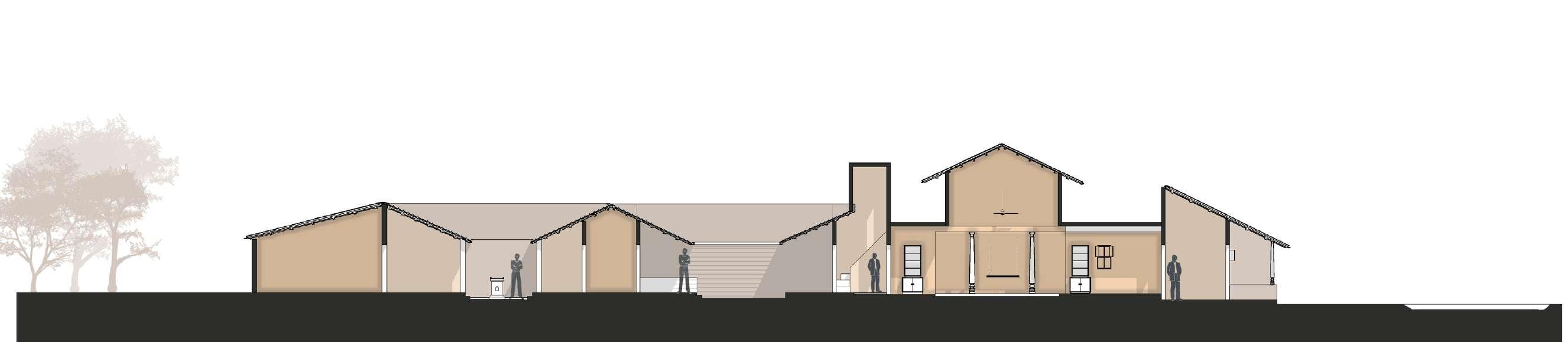

Upon documenting and understanding the working and the role of The Kishkinda Trust in the town of Anegundi, the brief was to design a centre for the trust which consolidates all their activities to one location. With sustainability as the major focus of the studio, the students looked at how a project like this can be sustainable at a larger level, not just architecturally but also in various other ways.

The site is bounded by a primary road and a secondary road in the north and west respectively. The context is densely packed and is well vegetated.

Temquaepedit as min eicturionem. Et es volupiducid eaquibus sit, consecto cus, net, corion cus endende lescia dolorem porepro vitius eosam re volendes

Masses placed around 2 central courts to allow maximum natural ventilation and thermal comfort within the spaces. Vertical zoning done according to proximity principle.

Exploded view (Isometric)

Section CC’ (Roof Truss)

Section BB’ (Roof Truss)

Section AA’ (Roof Truss)

Section CC’ (Roof Truss)

Section BB’ (Roof Truss)

Section AA’ (Roof Truss)

Section (Showing Natural Ventilation)

Section (Showing Natural Ventilation)

Views of the museum

Exposed brick in the facade with jali detail responds to the climatic condition as well as adds an aesthetic value to the building.

Typical Detail (Roof Truss) Detail A (Roof Garden)

Section (Showing Natural Ventilation)

Elevation (Material Detail)

Section (Showing Natural Ventilation)

Section (Showing Natural Ventilation)

Views of the museum

Exposed brick in the facade with jali detail responds to the climatic condition as well as adds an aesthetic value to the building.

Typical Detail (Roof Truss) Detail A (Roof Garden)

Section (Showing Natural Ventilation)

Elevation (Material Detail)

UNIT PLAN (1:100) FURNITURE LAYOUT UNIT PLAN (1:100) GRID LAYOUT WITH BRICKWORK

DRAWN BY LEKHANA GOWDA

4CM19AT048

WADIYAR COLLEGE OF ARCHITECTURE

BRICK MASONRY (MIN 115 MM THICK AND 230 MM THICK UNLESS MENTIONED)

1.FOLLOW WRITTEN DIMENSIONS,DO NOT

DRAWING.

2.ALL DIMENSIONS ARE IN MILLIMETERS.

3. THE DRAWING SHOULD BE READ IN ACCORDANCE WITH STRUCTURAL DRAWINGS.

4. ALL CONSTRUCTION IN BRICK MASONRY (MIN 115 MM THICK AND 230 MM THICK UNLESS MENTIONED)

1.FOLLOW WRITTEN DIMENSIONS,DO NOT SCALE

2.ALL DIMENSIONS ARE IN MILLIMETERS.

3. THE DRAWING SHOULD BE READ IN ACCORDANCE WITH STRUCTURAL DRAWINGS.

4. ALL CONSTRUCTION IN BRICK MASONRY (MIN 115 MM THICK AND 230 MM THICK UNLESS MENTIONED)

1.FOLLOW WRITTEN DIMENSIONS,DO NOT SCALE

THE DRAWING.

2.ALL DIMENSIONS ARE IN MILLIMETERS.

3. THE DRAWING SHOULD BE READ IN ACCORDANCE WITH STRUCTURAL DRAWINGS.

4. ALL CONSTRUCTION IN BRICK MASONRY (MIN 115 MM THICK AND 230 MM THICK UNLESS MENTIONED)

1.FOLLOW WRITTEN DIMENSIONS,DO NOT SCALE

1.FOLLOW WRITTEN DIMENSIONS,DO NOT SCALE

2.ALL DIMENSIONS ARE IN MILLIMETERS. THE DRAWING.

3. THE DRAWING SHOULD BE READ IN ACCORDANCE WITH STRUCTURAL DRAWINGS.

GOWDA

4. ALL CONSTRUCTION IN BRICK MASONRY (MIN 115 MM THICK AND 230 MM THICK UNLESS MENTIONED)

Semester: 4th Semester

Typology: Community Centre

Professor: Porf.Kukke Subramanya

Assoc.Prof. Juile Ann Tharakan

Program: Cherish: The experience is a housing for people interested in learning through travelling and exploring. More often than not one ends up in situations where we stay for long/er than intended. Sometimes these places lack facilities to comfortably accommodate such changes in the mundane fabric of the place. And in areas where such facilities exist, they either end up being buildings hardly emphasising on dwelling. Or they become cultural islands themselves.

“Cherish” is both a part of this fabric and the fabric itself. It is also a home and place for dwelling. And it is where sharing happens – knowledge, food and culture knows no boundary here. It is an opportunity given to discover oneself. It is also a mirror to the city/town and the mirror image of cherish. The task is to design a housing accommodating the requirements of “Cherish” while fulfilling the agenda. A housing that is the language of the place.

Badami, KarnatakaSite Location

Site Analysis

Access, climatic analysis and sensory analysis

Street network (Built vs Unbuilt)

Porosity : The permeable edge between public and private space that creates three dimensional complex public systems.

Site Surroundings

Form, space and voids are the basic elements used in architectural design process. Strong structural elements for a brutal architectural style.

Porosity in the space Public-Private

- polycarbonate surface, which makes the volume look lighter while also allowing sunshine to permeate the interior spaces - There is no direct looking out or looking in except for the openings, creating a sense of performance of shadows and light from the interior and

Section AA’

Interactive Spaces

Gathering Spaces

Section BB’

Projecting Balconies

Extended edge

Section AA’

Interactive Spaces

Gathering Spaces

Section BB’

Projecting Balconies

Extended edge

Introduction

Poressi sam nulpa quo bla dem. Cea dolum harum dolore ipicit raturendios sit, cum imagnis in niaturem harum que es molorio. Et autatiberum quatemquae deleces equatus, atatatur, tem fugia dolupta tiusdanda voloreiciae providunto consequi conem. Ut int.

Poressi sam nulpa quo bla dem. Cea dolum harum dolore ipicit raturendios sit, cum imagnis in niaturem harum que es molorio. Et autatiberum quatemquae deleces equatus, atatatur, tem fugia dolupta tiusdanda voloreiciae providunto consequi conem. Ut int.

period include Weaving Stone Cutting Pottery were exported to China , Babylonia and Egypt.

The gure above represents the relative humidity in the atmosphere during the day. The rst gure shows di erent grades of human comfort in di erent months of the year during the day.

Raw silk came from outside and even overseas.The weavers paid certain specific taxes to the officials of the Chola Government at Kanchipuram and its sub region. The tax on looms was one such example.

Kanchipuram is 45 kilometres from the coastline, hence exhibits tropical warm and humid climate.

Human comfort levels are optimum during the winter months, from December, till mid-February.

PALLAVA DYNASTY : The Crafts of the Pallava period include Weaving , Stone Cutting Pottery ,Carpentry and Ivory Works. The Cotton Clothes were exported to China Babylonia and Egypt.

KANCHIPURAM

Gangaikonda Cholapuram Nagapattinam Trade routes

Thanjavur

Chola Territories

Location: Kanchipuram, Tamil Nadu Trade

CHOLA DYNASTY In between 985 and 1014 the king of Chola dynasty ruled Kanchipuram who took wits of the silk trade. It was during the rule of Krishna Deva Raya, the famous weaving groups of Andhra Pradesh, the Devangas and Saligars, migrated towards the Kanchipuram.

Raw silk came from outside and even overseas.The weavers paid certain specific taxes to the officials of the Chola Government at Kanchipuram and its sub region. The tax on looms was one such example.

The merchants and weavers were important in the early medieval economy of Kanchipuram and in the taxation structure mediated by the market centre during the late tenth century A.D.Traditionally speaking, the weaving communities lived outside the village because the bleaching of cloth creates stench.

Summer peaks in the month of May, reaching a sweltering 42.5°C during the day. Winter months see a minimum of 18°C in January.

The merchants and weavers were important in the early medieval economy of Kanchipuram and in the taxation structure mediated by the market centre during the late tenth century A.D.Traditionally speaking, the weaving communities lived outside the village because the bleaching of cloth creates stench.

These gures represent the portion of the sky covered by the sun during various key time frames throughout the year.

Being in the tropical zone, Kanchipuram receives both North and South light, with Summer months receiving north light due to its being in the Northern Hemisphere.

The graph shows monthly distribution of sunshine days vs. overcast days throughout the year.

VIJAYANAGAR DYNASTY During Vijayanagar dynasty, the textile industry was highly regulated by merchant guilds, master weavers and weaving communities. Taxes collected on textile production and distribution included loom taxes; taxes on threads, carders, and the sale of cloth and taxes in marketplaces

VIJAYANAGAR DYNASTY : During Vijayanagar dynasty, the textile industry was highly regulated by merchant guilds, master weavers and weaving communities. Taxes collected on textile production and distribution included loom taxes; taxes on threads, carders, and the sale of cloth and taxes in marketplaces

Many of the weaving communities were granted economic and social privileges by the Vijayanagara court and ritual recognition by temples. Economic privileges included occasional tax exemptions.Social privileges included access to certain material symbols of status, such as the right to whitewashhomes, to construct two-storey homes, to wear caste insignias and to blow the conch shell on important occasions

The gure above represents the relative humidity in the atmosphere during the

According to 2011 census, Kanchipuram had a population of 164,384 with a sex-ratio of 1,005 females for every 1,000 males, much above the national average of 929. A total of 15,955 were under the age of six, constituting 8,158 males and 7,797 females.

Kancheepuram district is part of the composite east flowing river basin and spread over a part of the Palar and Cheyyar sub-basin – which are the important rivers. All the rivers are seasonal and carry substantial flows during the monsoon period.

legend, the Kanchi Silk Weaver descendant of Sage Marcanda, known the Gods’ Master Weaver. that Kanchipuram sarees were only for the deities and rulers showing the symbol of power.

Festival - The Ther Festival

grand temple chariots known as adorned with beautiful flowers and papers. This car dragging festival is the 9th day of ten day Brahfestival at Lord Varadaraja Perumal of devotees volunteer to drag mammoth chariots.

According to legend, the Kanchi Silk Weaver is a descendant of Sage Marcanda, known as the Gods’ Master Weaver. It is believed that Kanchipuram sarees were initially used only for the deities and rulers showing the symbol of power.

The colossal grand temple chariots known as ‘Ther’ is adorned with beautiful flowers and colorful papers. This car dragging festival is celebrated on the 9th day of ten day Brahmotsava festival at Lord Varadaraja Perumal temple. Lots of devotees volunteer to drag this mammoth chariots.

Ancient mango which is of 3500 years is located in the temple compound. This tree has four branches, which represents 4 Vedas (Rig Veda, Yajur Veda, Sama Veda, Atharva Veda). Interesting part associated with this tree is, fruits from the four branches will be of different tastes.

Eka means One, Amar means Mango Tree thus the name Ekambar derived from these two terms.

Every year the Annual festival is celebrated for 14 days in a grand manner in Kanchipuram Ekambareswarar Temple and the festival falls in the month of March/April.

Ancient mango which is of 3500 years is located in the temple compound. This tree has four branches, which represents 4 Vedas (Rig Veda, Yajur Veda, Sama Veda, Atharva Veda). Interesting part associated with this tree is, fruits from the four branches will be of different tastes.

Located in a cozy corner, the house that follows a typical narrow plan of a kanchipuram dwelling has been modified into a space used for dying of the silk yarns.

Eka means One, Amar means Mango Tree.Every year the Annual festival is celebrated for 14 days in a grand manner in Kanchipuram Ekambareswarar Temple and the festival falls in the month of March/April.

Serving as a workspace to around 4 to 5 men, the house accommodates a veranda, hall, a few rooms, a wash area and a backyard where the dying process is carried out. It has a floor above with two rooms and a terrace, which has been utilized to dry the yarns that are dyed.

This space is a typical example of how the a humble dwelling has been modified to carry out the age old profession

Located in a cozy corner, the house that follows a typical narrow plan of a kanchipuram dwelling has been modified into a space used for dying of the silk yarns.

Serving as a workspace to around 4 to 5 men, the house accommodates a veranda, hall, a few rooms, a wash area and a backyard where the dying process is carried out. It has a floor above with two rooms and a terrace, which has been utilized to dry the yarns that are dyed. This space is a typical example of how the a humble dwelling has been modified to carry out the age old profession

Located in a cozy corner, the house that follows a typical narrow plan of a kanchipuram dwelling has been modified into a space used for dying of the silk yarns.

Serving as a workspace to around 4 to 5 men, the house accommodates a veranda, hall, a few rooms, a wash area and a backyard where the dying process is carried out. It has a floor above with two rooms and a terrace, which has been utilized to dry the yarns that are dyed.

This space is a typical example of how the a humble dwelling has been modified to carry out the age old profession

CLIMATE RESPONSE IN TRADITIONAL HOUSES

Government has identified five zones of cultural and historical significance that need to be conserved and protected. One of the identical precincts is the Pillayarpalayam weaver’s zone. This zone has the highest density of traditional weavers’ residences in Kanchipuram. This weavers’ community is close to the Kailasanathar and Ekambareswarar temples which gives it an historic and cultural significance.

Pillayarpalayam weaver’s zone has mixed land use, but most residences have weaving units within the house, though not in use anymore. The traditional weavers have now collaborated with commercial sellers and governmentaided traditional weavers’ communities owing to changes in the socio-economic structure. The density of the urban fabric is increasing because the backyards and open spaces are being built upon. The low-rise structure of traditional Agraharam(focusing on the temple) typologies are being replaced by taller structures.

CLIMATE RESPONSE IN TRADITIONAL HOUSES

Government has identified five zones of cultural and historical significance that need to be conserved and protected. One of the identical precincts is the Pillayarpalayam weaver’s zone. This zone has the highest density of traditional weavers’

Roo structure accomoda es the oom pa ts

Roo accomoda es equipments sunch as spoo

Intricately carved wooden columns

Thuls katte n the cou tya d

Kanchi Kudil

Orientation — The along a north–south and west walls are jacent residences lar radiation, thus harvesting in such a way as to courtyards, from where well in the backyard ventilation ings are in a straight thinnai to the door yard of the house.

OPEN TO SKY MAJOR AX S

There are a series of inner courtyards following a common typology in the houses of the region, which is a verandah, which acts as the in between space of the inside and the outside, and the thinnai, which is the seating area, where the plinth is raised.

Buffer spaces — Shaded spaces like the front veranda with the thinnai and reinforced concrete veranda facing the backyard act as buffer spaces, reducing glare and doubling as comfortable spaces for social interaction.

Where are the weaver’s traditional settlements located in Kanchipuram?

Government has identified five zones of cultural and historical significance that need to be conserved and protected. One of the identical precincts is the Pillayar palayam weaver’s zone. This zone has the highest density of traditional weavers’ res idences in Kanchipuram. This weavers’ community is close to the Kailasanathar and Ekambareswarar temples which gives it an historic and cultural significance.

Orientation — The residences are oriented along a north–south axis. The longer east and west walls are shared between the adjacent residences and are not exposed to solar radiation, thus reducing the heat gain.

What is the condition of the traditional weaver’s community in the present scenario?

Clay tiles Lime Mortar

Rainwater harvesting a way as to collect the rainwater in the courtyards, from where it is channeled into the well in the backyard through stone culverts.

Pillayarpalayam weaver’s zone has a mixed land use, but majority of the residenc es have weaving units within the house, though not in use anymore. The tradition al weavers have now collaborated with the commercial sellers and government aid ed traditional weavers’ community owing to changes in the socio-economic structure The density of the urban fabric is increasing because the backyards and open spaces are being built upon. The low-rise structure of traditional Agraharam( focusing on the temple) typologies is being replaced by taller structures.

Brick jelly and lime mixture

Sun-dried bricks

Courtyard Courtya

KANCHI KUDIL PLAN

ventilation

ings are in a straight alignment from the thinnai to the door leading to the back yard of the house. This aids cross ventilation.

6X

WOODEN RAFTERS BRICKS RED OXIDE FLOORING WOODEN COLUMNS CLAY POT TILES ROOFING 0 1m 3m 3m 0 KANCHI KUDIL 0 1m 3m 0 2m 6m KANCHI

— Shaded spaces like the front veranda with the thinnai and reinforced concrete veranda facCourtyards — Courtyards, which form an integral part of the tradi tional residences, act as a microclimate modifier. The courtyard acts as

combination of warp and weft. held stationary in tension on a frame or loom inserted over-and-under the warp. Archaeonatural fibres

weaving started, mostly because it is fragile and it the tombs of ancient Egypt Of similar workdiscovered in Peru appeared around 3000 B.C. and the discovery of plate, dating back to 4400 B.C. were found in

It is the art of creating fabric through a combination of warp and weft. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft is drawn through and inserted over-andunder the warp. Archaeological evidence shows weaving with the use of natural fibres.

It is impossible to tell with certainty when weaving started, mostly because it is fragile and it is easily deteriorated. The oldest textile finds are fragments found in the tombs of ancient Egypt. Of similar workmanship of very fine linen, are the fabrics discovered in Peru.

The weavers receive the ready material required for weaving either from retailer or the society. It works like a contract where the orders, quantity of dyed silk thread, zaree and required design is given to the weaver who gives back the final product in the given period of time.

In the Pallava period there were weavers in the capital city especially employed to weave the Weavers often accompanied their patron-kings on military tours as woven garments were an intrinsic part of diplomacy. These weavers were switched over to weaving silk sarees in the course

Attaching wrap to loom Threads drawn through heddles taken through reeds, which is tied to the beams on both ends of the loom. The design cards are loaded. The weft thread is then wounded to the shuttle. takes around one to one and half days, with the help of around 3 artisans up the loom.

22.5 m of wrap thread is set up to the loom to make 3 sarees. Mainly the 3 locally known styles of weaving,

Shutter- A small boat type tool, to transfer the weft yarn, from one end of wrap yarn to other end.

Post weaving

Portion of unwoven wrap is left before and after the Saree weaving which Unwoven stands are cutout. Saree is folded in traditional manner.

Weft yarn threads

Wrap yarn threads

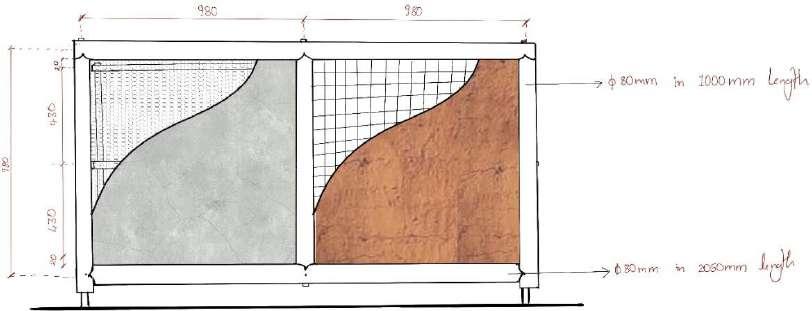

The aim was to create a space unburdened with the fear of presenting. Open to all students, the space has been divided among three main programs: Sheet Display, Model Display and Storage.

Added to this space is The Great Wall, a transition between the dynamic, extroverted lobby space and the heavy, curious exhibition space.

Few of these counters have storage beneath them. this adds some more area towrds the dire need of it

champhering the tops of few counters, for large scale models the platforms increase by 500mm or 250mm

04: nishing the top most counter tops

03: raising counters for the active model display

gradual increase of the viewing platforms as well as the model spaces the platforms increase by 150mm

Creating the Model Space Grid 1000mm X 1000mm space for model displaying

02: creating viewing platforms

01: creating the base grid

Counter-top for display of models

Platforms of varying heights to acheive maximum visibilty of the models

Counters with varying heights are used as model display areas to enable e cieft use of the rooms height Main Viewing platform, this ares provides a view with all models in sight

Model Space: Axenometry

Over the years of the architecture course, the student stays back in college quite often. Our aim was to create a pantry space, which works well during the active hours and especially great during the after hours.

The zoning of this small space was done according to the basic needs: a quick re-heat/ snack and making maggi.

The entrance lobby forms the first impression on the visitor’s mind. The aim was to keep this impression clean, and slightly ambiguous.

This carters to the goal of keeping the visitor curious, and of course to making them feel welcome.

Things to consider when building walls for bamboo buildings-

a)Desigining

b)Building The Bamboo Wall Frame

tiful, and also can be built faster This technique has been used traditionally in England; called wattle & daub and a similar technique in South America is referred to as bahareque. Bamboo, wood, or reeds were used as the structural frames whilst lime or mud was used as a filler material to seal the walls. Today is also called the lath and plaster technique

c)Preparing And Applying The Sealer

d)Finishing

Things to consider when building walls for bamboo buildings-

Introduction

a)Desigining

Designing

b)Building The Bamboo Wall Frame

Method of Construction

Wall Panel Construction

Introduction

c)Preparing And Applying The Sealer

d)Finishing

Designing

Bamboo can be utilized as a building material for scaffolding, bridges, houses and buildings Bamboo, like wood, is a natural composite material with a high strength to weight ratio useful for structures 1 Bamboo’s strength to weight ratio is similar to timber, and its strength is generally similar to a strong soft wood or hardwood timber

Firstly, start up the process of design where one designes the wall, its funtion and its construction on sheet of paper or with the help of model

walls for bamboo buildings that can be thinner, lightweight, flexible with shapes, beautraditionally in England; called wattle & daub and a similar technique in South America is referred whilst lime or mud was used as a filler material to seal the walls Today is also called

Firstly, start up the process of design where one designes the wall, its funtion and its construction on sheet of paper or with the help of model

Conclusion

Combination of bamboo and mud is an amazing building technique to build walls for bamboo buildings that can be thinner, lightweight, flexible with shapes, beautiful, and also can be built faster This technique has been used traditionally in England called wattle daub. The process of started where one designes the wall, its funtion and its constructionon sheet

The combination of bamboo and mud is an amazing building technique to build walls for bamboo buildings that can be thinner, lightweight, flexible tiful, and also can be built faster.This technique has been used traditionally in England; called wattle & daub and a similar technique in South to as bahareque Bamboo, wood, or reeds were used as the structural frames whilst lime or mud was used as a filler material to seal the walls the lath and plaster technique.

Things to consider when building walls for bamboo buildings-

a)Desigining

b)Building The Bamboo Wall Frame

c)Preparing And Applying The Sealer

d)Finishing

Designing

Firstly, start up the process of design where one designes the wall, its funtion and its construction on sheet of paper or with the help of model

Wall Panel

Wall Panel Group 05

Wall Panel Group 05

The workshop kick started with common session where we knew almost nothing about it but for sure knew it would be gratified experience The artisans, during the common session instructed us on the basic knowledge of working with bamboo The respective groups then moved on with their respective topic of work Our group was up with a quick solution for the game of cricket we played In mini courtyard Our intent was creating a wall that continue along the katte and act as a stopper for the ball.

The workshop turned out to be a very intuitive and helpful, for learning this amazing technique while we were also indirectly benefitting for playing cricket We experimented types of joineries through the wall panel frame we created The sustainable design semester also made us think of easy uprooting structure, so we had hammered the steel pipes into ground rather than casting concrete The panels were filled with infill material of mud plaster and cement plaster Though we were working with our wall panel, we also had the right circumstance of viewing our fellow studio mates work too We were helping each other out while gaining knowledge mutually Through these various process we had the opportunity to understand the material as a wall, work with the material and the possibilities it provides architecture with The process also showed us the process requires skilled workmanship and labour whom we should respect

Wall Finishing

It is always challenging to achieve clay paints it can be possible.

desired colour finishes but using pigmented lime washes and

Smoothening it is also a part of finishing, where the surface is rubbed/sanded. There can be additional layer applied to it to get more smoother finish.

Bamboo Workshop MMBC 07 Bamboo Workshop MMBC 07Phone no. : 9606933997

Mail ID: 2019_lekhana.p.m@wcfa.ac.in