No matter how challenging your needs, AGRIMAX V-FLECTO is your best ally when it comes to soil tillage and haulage applications The tyre features excellent traction along with enhanced driving comfort both in the fields and on the road With the exclusive VF technology, AGRIMAX V-FLECTO can carry very heavy loadswith alower inflatingpressure even at high speeds providingreducedsoil compaction, bestself-cleaning properties as well as fuel economy.

AGRIMAXV-FLECTO is BKT’sresponse in termsofboth technology and performancefor high-power tractors

Last month I was questioning whether grants or subsidies on machinery are a good thing. Yes, everyone likes to have a little extra off, yet the resulting short boom in demand is a double-edged sword, as explained at last week’s Kuhn press launch for the firm’s new products due to debut at Agritechnica. One of the people tasked with looking after our press group is the sales manager for Italy and Scandinavia. When chat turned to the current state of the market, he noted there has been a massive shift in the spec of machines Italian farmers are demanding. Compared to the likes of Austria, Germany or the Netherlands, the Italian market has traditionally purchased relatively straightforward machines. Over the past five years, however, the demand for ISObuscompatible machines with connectivity has rocketed. The reason? Machinery subsidies … with the extra connectivity being used to provide the required documentation of various field operations. And now that Italian farmers have tasted the benefits, they are wanting even simple machines to be at least ISObus capable. Or that was the picture being painted by the Kuhn man.

But this wasn’t the only bit of useful market insight to be gleaned from the Kuhn event, as well as at a catch-up with Massey Ferguson (see the news pages and the profi website for a flavour of the hardware that will be coming in 2026).

As you might expect, there was a lot of chat from both Kuhn and Massey on how the market has been in decline over the past two years, the reasoning why, and the repercussions. On the latter point, Kuhn Group’s CEO, Thierry Krier,

No, you’re not going mad. We already tested the 6R250 in our 08/2018 issue … or the 6250R as it was back then. So, seven years on, has this best-seller managed to mature still further since our initial assessment? Read our exclusive tractor test on page 14 to find out.

made some interesting observations. When discussing the Karl autonomous tractor, for example, he stated that Kuhn is not prepared to rush to the market, adding that the firm isn’t under the same time pressure as a start-up. With the reduction in global machinery sales, seed money for start-ups, be it from investors or government funding, has dried up, and he reckons that new tech start-ups will find it difficult to survive.

And it’s not just the money for new companies that’s running out. He also believes that established tractor manufacturers producing less than 10,000 units per year could struggle to generate the research and development cash required for incorporating ISObus, connectivity and future autonomy into their products. For Kuhn, even if the Karl tractor never hits the market, it will have been a useful resource in making implements smart so they can work with future autonomous tractors from other manufacturers.

Mr Krier, who comes across as the level-headed and frank talking sort of chap, also noted that it’s not just the high-tech smart machine makers that are suffering in the current climate. He reckoned that half of the vast number of trailer makers in France are on the verge of closing their doors, as there is simply not enough volume to justify continued investment. For example, at today’s prices, the installation of a high-quality paint system comes at a cost of north of one million euros.

The better news from both Kuhn and Massey is that the machinery business is turning a corner, and, even though sales aren’t booming, they are levelling out. This particularly applies to the livestock and grassland sectors, with arable growers still needing a bit more confidence to get them spending. It will be interesting to see whether the other tractor and machinery

makers sing from the same hymn sheet in the coming months, because there are another dozen launches planned before the climax of Agritechnica.

This month we’re giving readers the opportunity to win a Porsche driving day in conjunction with Michelin. So, if you fancy a go, then please find the details on page 85.

Best of luck and, until next time, stay safe and happy farming

Mervyn Bailey, editor, profiinternational You can get in touch with me via mervyn. bailey@kelsey.co.uk or head to page 97 for further contact details.

This famer has been inspired by Krone’s Vendro storage stand system by fabricating these parking stands for his tedder rather than letting the two central depth wheels take the brunt of the load. The box section stands are held in place on the parked machine by a pair of wing nuts.

14 TRACTOR TEST: John Deere 6R250

John Deere has freshened up its 250. Has this popular model still got what it takes to be a best-seller?

42 DRIVING IMPRESSION: KRM Grass Seeder

We assess KRM’s entry to the grass drill market and see how Sola has used various proven components from its other drills to give grassland a tonic.

28 PRACTICAL TEST: Shallow ploughs

Both Kverneland and Ovlac offer a shallow plough in the UK. See how they compare in our head-to-head test.

46 DRIVING IMPRESSION: Agriweld Min Dis

The minimal disturbance Min-Dis uses an angled disc to clear a path for the leg — and that can work equally well in grassland.

50 USED MACHINERY: Claas Axion 800

With an updated Axion 800 getting unveiled later this year, we thought it an opportune time to refresh our used machinery buying advice. We last looked at these long-serving tractors way back in 2014.

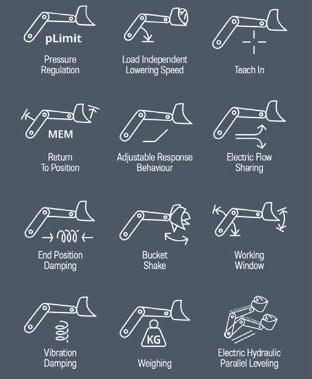

36 DRIVING IMPRESSION: Stoll ISObus

Stoll can now tap into a tractor’s ISObus capability to operate its front

Shallow

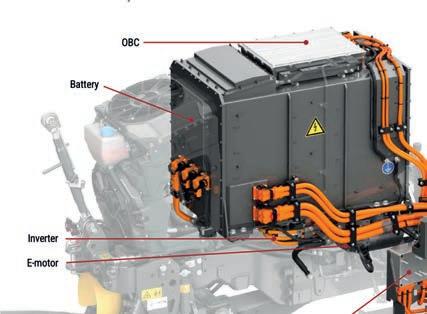

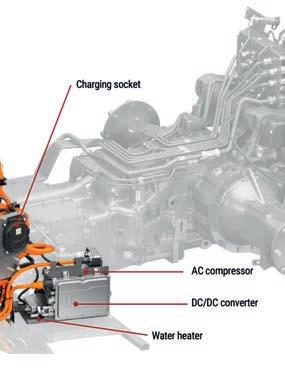

72 TECHNICAL: Fendt E100

Vario

62

Brookside

The Canadian-made Versatile Nemesis will make its European debut at Agritechnica in November. The Cummins-powered range comprises five models from 175 to 255hp. According to German dealer magazine Eilbote, the arrival of the Nemesis this side of the Atlantic is part of a push by the Canadian manufacturer, and its new owner, European ASKO Group, to grow its European presence. A 30fx15r powershift is standard on the 175, 195 and 210, and the ZF CVT on the 235 and 255 is optional on the three smaller models. Rear lift capacity of the 175, 195 and 210 is 7.05t. This increases to 7.4t on the 235 and 255 (8.8t optional).

Versatile sees the addition of the Stage V tractors to the European portfolio as a way to target new customers, and also offer an attractive power range to existing and new dealers.

The company is currently investing €10m at

Czech manufacturer Bednar has added a 12.3m model to its Galaxy GE roller range. Joining the 6.3m and 8.3m models introduced a year ago, the reinforced chassis on the trailed 12300 (12m) supports the five roller gangs.

Fitted with alternating 500mm smooth and 530mm breaker rings, the hydraulic system is said to ensure an even distribution across all five sections, and on the road the nearly 10t roller runs on 500/50-17 tyres.

Options include track eradicators, a hydraulically-operated levelling board to break up large clods, and an Alfa 800 seeding unit. It depends on the spec, but

the Winnipeg plant to further increase production and update machining and tooling.

Two Nemesis tractors (175 and 255hp) will be unveiled on the Canadian Pavilion in Hall 6 at Agritechnica, plus, two articulated 4wd

Spy pictures are circulating of what appear to be the successors to the short wheelbase versions of the Case IH Puma and New Holland T7. There is nothing official, but the design, like the cab, are certainly new. We will have to wait and see if the new models are on the stands at Agritechnica.

tractors; including the flagship 620hp Deltatrac. The initial focus is with tractors, but longer-term Versatile plans to grow its implement business in Europe, and the Europeanized Fury disc harrow will have its first airing at the German show.

the company is talking about a power requirement from 160 to 250hp. The plan

Polish farmers will soon be able to buy Lovol Aupax branded combines. Lovol importer Korbanek plans to start selling the Chinese made machines from 2026.

Two models are currently in tests; the straw walker GV100 for small and medium-sized farms, and the GM100, a single (3.12m long x 600mm diameter) longitudinal rotor combine that is already available in Serbia. Both models are powered by 190hp four-pot Weichai engine.

Aupax is the new brand for Lovol products made by the WeichaiLovol group, following the disappearance of the Arbos name. It is not known if Weichai-Lovol plans to market the harvesters in other parts of Europe.

The long running dispute between Agco and India’s Tafe (Tractors and Farm Equipment) is over. Terminating all outstanding agreements between the two parties, in short, the new one gives Tafe exclusive ownership of the Massey Ferguson brand in India, Nepal and Bhutan. Agco will sell its stake in Tafe back to the Indian company for US$260 million. Tafe remains a shareholder in Agco but has pledged not to increase its 16.3 percent share. The agreement has been submitted to the American stock market watchdog SEC.

Manufactured by Comer, and marketed under the Kramp brand through its distribution network, the new range of pto shafts (T10 to T60 series) includes both with and without clutches. The black guards are said to provide higher UV resistance and a longer service life than conventional yellow guards. “We believe farmers will find these ptos are very competitively priced, and it’s a named brand from a recognised manufacturer,” says Adam Hubbard, product specialist for Kramp. “There is also the added benefit that any spare parts, such as a yoke or universal joint, are readily stocked by Kramp and its dealers, meaning farmers can expect next-day delivery or same-day collection.”

A Kverneland five-furrow LO 300/85 plough and rubber-tracked AgXeed AgBot 5.115T2 have set the first world record for autonomous ploughing, achieving an output of 20.8ha in 24 hours. The challenge was carried out at Birch Farm, Stonegrave, North Yorkshire. Working on-land at furrow widths of 40cm and at a depth of 22.5cm, forward speeds of the 156hp AgBot varied from 5.6 to 8.0km/hr, and fuel consumption from the diesel-electric powertrain totalled 382.72 litres over the 24-hour period (18.4l/ha). Scan now to get our

The new operating system is one of the most significant changes on the Astronaut A5 Next. Allowing technicians to perform pushbutton upgrades, the system lays the foundation for remote servicing and overthe-air software updates. The 2+ teat detection system on the redesigned robot arm combines lasers and cameras to enhance visibility, improve attachment times and reduce stress during heifers’ first milking. A fully automatic milk filter removes the last repetitive task of replacing filter socks and the new robotic milker integrates with electronic ear tag identification. Existing A5 users can upgrade to the new software, although the automatic milk filter is not compatible with sand-bedded systems.

Claas has earmarked €6.5 million to further expand its French tractor production site in Le Mans. Scheduled for completion by the end of this year, the new 3,800m² multifunctional production facility is viewed as a decisive step in preparing the site for the expected growth in production over the next ten years. Claas took over the Le Mans plant, as well as sites at Trangé (test and validation centre) and Vélizy (development) in 2003, and has since produced more than 200,000 tractors for the global market. The company has invested more than €80 million

to date at the French plant, which currently makes tractors from 75 to 450hp.

Following on from the French company’s recent transition to a single unified brand combining Sulky, Sky, and Prolog under the Burel Group, dealers and farmers in Ireland now have full access to the complete product line up following the appointment of Kilkenny based IAM Agricultural Machinery as exclusive importer and distributor for Sky Agriculture across the Irish market. The wide range of kit includes fertiliser spreaders, power harrows, shallow cultivators and trailed no-till and min-till drills.

Kverneland parts can now be ordered through a new online portal called Terrako. Access requires customers to sign-up, creating an online account which highlights their nearest Kverneland dealers. Doing so gives the customer direct access to stock levels when searching for parts. Payment is made at the time of ordering by credit card, and customers then receive an email confirmation of their order. Online ordering also offers quick and easy parts identification through the Smart Search photographic parts identification tool. This can be accessed using a smart phone, tablet or PC.

The Minsk Tractor Works (MTZ) has developed the prototype of what is claimed as the world’s most powerful conventional rigid chassis tractor; the Belarus 542hp Titan 5425.

Under the bonnet, the 13.5-litre Chinese Weichai Stage IIIa six-pot turbocharged block develops 2450Nm of torque at 1,500rpm. Mated to an 18x6 speed hydromechanical box with electro-hydraulic control, the result is said to provide uninterrupted gear changing up to the top speed of 40km/hr, and the 900-litre fuel tank is said to be sufficient for 10 hours of operation.

The engine, hydraulics and tyres are outsourced, but more than 80% of the parts used to make the 5425 are of Belarusian

origin. These include the frame, powertrain, cab, electronics and precision farming systems.

Still in tests, and there is no information as to when the 5425 could go on sale, how

The chassis on the new single-axle version of the Tramspread contractor trailer is over 2.0m shorter than the twin-axle model making it easier to navigate through narrow gateways and awkward yards.

Filling a gap in the range for a more compact format, the newcomer carries everything needed for an umbilical spreading system, including a self-contained engine-driven pump unit, compressor for blowing out the drag hose, hose spool carrying cradle and storage for tools, couplings and sundries.

Powered by either a 175hp or 238hp six-cylinder FPT engine, the new model is available with Bauer, Doda or Cri-Man pump, compressors of 140 or 180CFM output and optional GSM or radio type remote

much it will cost and of any plans to fit it with a Stage V engine. It is rumoured that more powerful Titans are on the way, and there is a faint hint that the range could ultimately exceed 600hp.

Spread-a-Bale has extended its M range of straw spreading machines with the Mega. Designed to handle the largest bales, complete with Hardox wear plates to the front floor section and 1.3m high rotors, the Mega has the capacity to spread all bales - round up to 1.8m diameter while it also includes the XL body option giving it additional 300mm bed length to accommodate up to 2.8m-long rectangular bales.

Requiring a handler with a minimum lift capacity of 3.0t, the Mega is able to load one bale in approximately one minute followed by a further minute to discharge and spread. The 2VR (two vertical rotors) head delivers an arc spread pattern up to 9.0m.

control systems. The 900-litre fuel tank has been repositioned underneath the engine and pump, and the 1,000m hose spool is loaded into its cradle from the front and secured with pins – no straps are needed.

The sprung axle is fitted with 50km/hr rated 435/50 R19.5 tyres and air-brakes. The drawbar is configured to allow the towing tractor to carry a dribble bar in the linkage, allowing one operator to move an entire umbilical system.

Pöttinger has updated its 12m Tinecare Master precision tine harrow. It has also changed the model number from the V12200 to the V12050. This is due to the working width in standard configuration of precisely 12.0m (previously 12.18m).

Tine pressure is hydraulically adjustable from 0.5 to 6.0kg (previously 0.5 to 5.0kg) and the longer tines have a larger wear range of 125mm. Other updates include larger jockey wheels with grooved profile (standard) or field lug profile (optional). Optional steerable jockey wheels at the rear of the frame increase ground tracking accuracy, and the position of all the wheels is adjustable to match standard planting configurations and row crops.

The optional track harrow prevents uprooted weeds from being pressed into the soil again by the rear jockey wheels. The frame folds to a transport width to 2.95m and the new precision tine harrow will be available from September 2025.

The six- to eight-furrow Lemken Diamant 18 is believed to be the only single-wheel semi-mounted plough on the market that can be combined with an integrated furrow press as standard. The inclusion of the furrow press on the new in-furrow plough was made possible by tweaking the design of the transport wheel and moving it behind the base frame.

The FlexPack furrow press can be hydraulically pressurised to adapt to different soils, and each pair of rings is suspended individually from spring steel elements. It can also be used together with the plough’s OptiStone hydraulic overload protection system. Designed for tractors of up to 650hp, the Diamant 18 is available in small numbers this year. Full series production will start in 2026.

A massive 14.5m fully mounted mower and a new range of trailed sprayers will be among the range of fresh-faced machines on the Kuhn stand at Agritechnica. And we reckon there'll be other new items from Kuhn unveiled at the show itself. Roll on November.

It is not often something new comes along in the world of mowing, but Kuhn has managed to do just that with the GMD15030. This fully mounted machine has a working width of 14.5m using four 3.1m, seven-disc beds at the rear, paired with either a 3.1m wide GMD plain or FC-F conditioner front mower (the latter allowing the grass to be placed in a narrower swath).

The 3.8t rear unit folds to a 3.0m wide, sub-4.0m tall package. To do this it uses the housing of the gearbox between the two outer units to form a 180⁰ hinge. The two mowers are also synchronised rather than being offset so there is no additional overlap. A ram between the two beds limits the amount of movement when inwork from -4.0⁰ to +6.0⁰.

The left and right wings have hydraulic breakback, and there are friction clutches on either side to protect the driveline. Power requirement is said to be in the region of 230hp, and at 15km/hr it would be possible to drop 20ha/hr less the mowing time lost to headland turns. A price has not yet been announced.

The latest generation of mergers gain a new cranked tine design and easier repair of the bearings and cam tracks. There are three models: the base 762, middle 952 (ISObus option) and 1092. Among the changes are more cab-based setting options such as the ground pressure, swath width, belt speed etc. Maintenance costs have also come under the spotlight, with the new tine design said to suffer less from stress. Meanwhile only two bolts have to be removed to access the plastic bearings running inside the Hardox cam.

This ram controls the mower movement in work for contour following. The two mowers are synchronised, so the overlap is no different than on the other discs.

Kuhn has been missing a larger-volume, higher-spec trailed sprayer, a problem that will be solved by the arrival of the four-model 4,500- to 8,000-litre Karan. There will be three variants, with the midspec Power expected to the be the most popular. Boom widths of up to 48m will also come when the range is complete. Filling capacity is 250 to 900l/min depending on pump choice, while in-field application rates are 250-500l/min. To make use of that application rate, there is a new ‘Eagle’ smart boom control system for forward speeds of up to 25km/hr. It also gets a variation of Kuhn’s Autospray PWM system.

The Diluset filling station is new, allowing auto filling management, and the induction hopper is closed transfer system ready, meaning you can use the pre-equipped holes to attach the coupling for whichever system you prefer. The suction capacity on the hopper is 220l/min.

Mechanical leaf spring is standard with hydro-pneumatic optional. Steering angle is up to 28⁰ for the up to 2.05m diameter VF tyres. A 6,000-litre, 36m Karan will tip the scales at 5.7t.

The smaller Lexis sprayers will stay in production, but the Metris II will be phased out in favour of the Karan, which starts production in January.

Sitting between the ultra-shallow Prolander and deeper working Cultimer is the new Highlander. Its four rows of tines have a range of 3 to 20cm. This semi-mounted cultivator is available as a 6.0m or 7.6m machine. As well as the 350kg tripping force of the spring-protected tines, they also have 10cm of lateral movement. There is a choice of point and wing configurations up to 280mm. Along the front you can have additional depth wheels, a levelling board or leading discs. For the back, there are levelling blades or discs, three rows of tines or a roller.

Kuhn UK’s Rhodri Jenkins shows the new Opticut 33 pull-out knife bank on the VBP7190 round baler. The 33 blades produce a theoretical chop length of 34mm but can be operated as 0, 8, 16, 17 or 33. As well as being powered up, the knives are also powered down when they retract, helping them to keep the knife bank clean, even when they are not chopping by cycling up and down as the bale leaves the chamber.

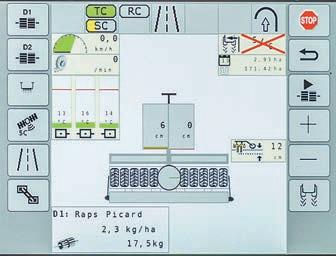

With a capacity of 2,360 litres, the TF 2300C is a pressurised front hopper that is split 60:40, allowing you to handle two products or mix them. There is a new metering system, where the whole cassette, not just the metering wheel, is replaced so operators do not directly handle parts that may have come into contact with various seed dressing or treatments. Spare cassettes are stored at the front of the machine, and an over-centre clamp releases them from the housing metering unit — no tools required.

There is the option of a tyre press that uses four larger 822mm diameter wheels. You can also fit up to 800kg of ballast.

Standard Features

● 460 Oblique discs (ODS)

● Depth adjustable disc bar

● Standard 20mm Hardox legs with GLS points @ 500mm centres

● Shear-bolt leg protection

● Agri-PackerTM roller and Easy Clean Scraper BarTM

● Replaceable packer stub axles

● Reflective chevron board

● Rear LED lights with 7 pin plug

● 12 Months manufacturers warranty

Optional Extras

● Auto-Reset leg protection

● Alternative roller options

● Seeder and step kit mounting

The exhaust stack has also been slimmed down, so it is like the 9S, helping improve visibility. Another Xtra change is to the lights. The 8S gets new LED lamps (still sourced from Hella) with the option of enough of them to achieve all-round illumination.

One other change relates to the two manual spool valves; these now get pressure relief levers at the couplers.

Looking to get owners back on board, Massey Ferguson has announced a number of updates to the 8S. It has introduced the new ‘Xtra’, which is now rolling off the line at Beauvais.

The Xtra name is back at Massey Ferguson as it freshens up the 8S series. It is more about refinements than a complete revamp, with no changes to the quoted power outputs of the six models, which still span a nominal 205305hp.

Instead, there have been improvements to the software, to give better performance from the Dyna-7 and Dyna-E transmissions, and the introduction of self-preservation into the mix as well, where constant flicking between gear ranges and working through powershift steps led to unnecessary ratio movements.

Now if you operate Dyna-E in auto mode, it will look to miss out overlapping powershifts

AgriPass, based in Tel Aviv, is the latest start-up to throw its hat into the robotic weeding arena, developing its AI-driven RHIC (Robot of Human Inspired Cultivation) unit, which relies on camera tech for real-time individual plant identification. Machine learning is used to create an optimal weeding strategy, which includes establishing the minimum working depth needed for the tools — designed to work in a similar way to hand rogueing — to remove the weed and thus minimise soil disturbance.

so, rather than stepping through the total of 28 powershift steps, (four ranges, sevenpowershifts) it will only utilise 21 in field and 22 in road mode. For instance, when on the road, it will start off in ‘gear’ five, and then, if you're looking at the overall speed chart, as it comes out of 1E only use range two, powershift D before moving to 3B. Likewise, in field mode, it will do this same ratio skipping exercise. For the operator, the A-pillar display will show which of the 21 or 22 speeds it is currently in. There is still the option to use the transmission in manual mode, but, when the oil is up to temp, the auto Dyna-E shifts pretty smoothly with only the range changes being distinguishable. Giving the tractor's drive stick a gentle push

Bob Jones Jr, of Ohio-based grower The Chef’s Garden, host to one of the USA on-farm trials taking place this year, says that this fits in with the ethos of regenerative farming. “We’re targeting reduced soil disturbance to improve the microbiome. But mechanical weeding also helps solve labour issues and comes in at a better price point than laser weeding.” First developed in tractor-drawn format, version IV is a battery-powered autonomous machine; AI is being developed for weeds of different sizes in Europe as well as the USA.

A reversible fan has been added to the options list, and this can then be engaged from the cab. Not only does this help with self-cleaning, but, by matching required airflow to cooling needs, the system minimises the power required and improves fuel efficiency.

forward increases the target speed that the transmission is working to.

Dyna-7 does much the same, with the new software making use of speed matching, but the robotised range changes are that bit more noticeable than the double-clutch setup in the Dyna E. Delve a little deeper into the transmission setting menus and you can tinker with the rate of acceleration and deceleration. You can also tell the ‘box to not change range, so, when working under load with a cultivator, it is not constantly hopping between ranges while also wrestling with high levels of torque.

This updated software has been rolled out to the existing 8S ‘mechanical’ transmission tractors.

Yet the MF Xtra moniker is not just about software, as you can see from the pictures. For the more sharp-eyed readers that have

At the launch of the 8S Xtra, there were also some examples of the ‘MF by you’ which is the firm’s bespoke service for nonstandard options including things like central tyre pressure control or different colour schemes. One that stood out for us, was this auto-greasing system on a 5S. This pumps out a shot of grease every time the loader is lowered, cycling its way through the various lube points. The additional lines are routed neatly through the boom, just like the hoses. It is a time-consuming fit, but because it is being done more often at the 'MF by you' centre, they can do the install quicker than a dealer which reduces the labour and therefore overall cost of the package.

already peeked at the photos you will notice some other changes from the original 8S range that was launched in 2020. The more noticeable are the black side panels and top grille. To boost airflow, the vent at the rear of the bonnet (between the engine and cab) has been made bigger.

The entertainment package can be Android Auto or Apple CarPlay compatible and better Focal speakers are a welcome option, too. The microphone for the hands-free kit has been repositioned. The sunblind no longer uses the toggles that tended to constantly tap the glass.

Back to the technology, and there have been more updates to the headland management system, with the section control now able to operate up to 96 boom sections.

Mervyn Bailey

One item that had changed on the later 8S models, but garnered some attention in its early days, is that the ignition key has been moved to the side of the steering column. Previously it was at the front where it was prone to hitting the operator's knee.

John Deere 6R250

On the market since 2017, the big-frame six-cylinder 6R has become the best seller in the 6R range. Reason enough, then, to take a fresh view on this refined Mannheim heavyweight in its sports package.

Seven years have passed since our last JD 6250R tractor test in profi 8/2018. Back then we went with the headline ‘That Vario feeling’, as it wasn’t hard to see who Deere was targeting. And it has had some considerable success. Yet those crafty folk from Marktoberdorf

have been doing some hunting of their own of the Mannheim-created deer, and, should the rumours be true, more hunters are soon to be added to the pack. Anyway, the 6R250 is fundamentally still the same tractor as it was then, but John Deere has learned a few lessons. So let’s take a look at the arguments put forward for the 'experienced' 6R250. Under the bonnet is the familiar six-cylinder, 6.8-litre motor armed with two turbochargers and a rated output of 250hp, which then climbs up to a maximum output of 275hp without boost. That boost kicks in when hydraulic power is needed, during pto work at over

2km/hr or when travelling at speeds of 15km/hr+. In this case, the 6R250 delivers around 300hp, of which 265hp arrived at the tail end — very good.

And what about fuel consumption with the same hardware? 244g/kWh use (+8g/kWh AdBlue) at the rated speed and 235g/kWh (9.4g/kWh AdBlue) at maximum pto output are almost exactly the same results as in 2018. No record-breaking fuel figures, but they’re still acceptable.

The results from the rolling-road test bed haven’t changed either. Although our 2025

test model improves its Powermix result by 1g, 256g/kWh proves that the deer has nothing to hide, especially as it consumes just 10g/kWh of AdBlue — despite stricter Stage V compliance. The latter is achieved with the help of exhaust gas recirculation, a diesel oxidation catalyst (DOC), a diesel particulate filter (DPF) and SCR catalyst. Things get a bit more interesting when it comes to the maximum drawbar power through the continuously variable ZF Eccom transmission with its four automatically shifting travel ranges. The DLG engineers measured 165.5kW/221.9hp at 10km/hr and almost 174kW/233hp at 16km/hr as the boost was already kicking in. At 254 and 250g/kWh respectively, fuel use was also at a very good level.

John Deere is promoting the 6R250 with a ‘Sport Package’, among other things. This package includes a new steering column and small leather-clad steering wheel as well as wider wheel rims, which actually give the 6R230 and 6R250 models better roadholding.

But it’s not just good operator comfort on the road; fuel consumption on tarmac is also good: 350g/kWh use at 40km/hr and 353g/kWh at 50km/hr. And since a lot more tractors have done the Powermix Transport test, the newer big 6R performed better than it did in 2018. The fuel consumption is an impressive 24% better at 40km/hr and even 18% less at 50km/hr than our current average.

However, we also have to dish out some criticism. Although John Deere can fit a PTG tyre pressure control system as a factoryfitted option, there is no additional higher capacity compressor available. And speaking of tyres, the test tractor was wearing Michelin Axiobibs, VF600/70 R30 at the front and VF710/70 R42 at the rear. Our rims weren’t yet fitted with the valves on the outsides of the rims, making tyre pressure changes a faff. Also annoying was that, up at 50km/hr travel, the tyres caused unpleasant vibration noise in the cab.

Moving on up, it’s not just John Deere users who feel at home in the cab. In terms of

The 6R250 boasts good performance results.

Sports package improves straight line stability and steering behaviour at higher speeds.

The steering system and related software are almost perfect.

build quality, the 6R cab continues to set the standard, but it’s a shame the seat rail can only be extended with the help of a dealer-fitted solution, and the area cleaned by the wiper remains too small. The small leather steering wheel feels good in the hand, although if you are hopping between 6R models that have a big or small steering wheel, the varying distance to the powershuttle can mess with your head. It’s a good thing that direction changes can be selected not just on the small control lever but also the CommandPro — either with the familiar left flick or by moving it to the left and then pulling back. Other functions that got a thumbs-up from our test team include the coasting mode (push the joystick to the

The biggest 6R has become a big seller, popular with farmers and contractors wanting that bit more power and bulk.

The small leather steering wheel offers a nice grip. However, the distance to the shuttle is that much more than with the larger steering wheel. Some operators won't like it.

front left), maximum speed activation by kicking the stick forward past the detent and quick speed range adjustment by turning the scroll wheel.

As in the 2018 tractor test, diesel consumption in the Powermix fieldwork tests is consistently (and in some cases significantly) below the current average for all of the tractors tested up to now. This commendable performance also applies to the Powermix transport test, especially as DEF consumption is just 3.0% of the diesel use.

Superior and way ahead of the Vario is the ability to switch between joystick and pedal modes. This makes driving incredibly easy and customisable. The active standstill with automatic parking brake and, consequently, start-off without operating the clutch, were also praised. The 6R currently doesn’t have an automatic engine start/stop.

The joystick’s numerous functions and up to five toggle switches, some of which are hidden round the back of the lever can be individually assigned. While the driver may have learned to feel the switches after a few hours, occasional novice users could find themselves accidentally activating them. This is one of the potential downsides of such a flexible operating concept. At least some of the buttons are backlit — for example, when the pto control is on the joystick. A small LED screen in the stick would probably be the icing on the cake and possibly a project of the future. But if you don’t need the CommandPro with its full array of aux-in functions, you can still opt for the old Command Arm set-up and save yourself £1,774.

The G5 Plus display is perfect. Not only is it HD sharp, even in strong sunlight, but the boot-up time after starting the engine is impressively short, too.

Operators and job organisers will now be getting used to hearing about John Deere’s Operations Centre facility. Whether it’s data transfer of jobs, maps for drilling or even

Leaders in the field, Dromone, manufactures mechanical and hydraulic pick-up hitches to suit most tractors. Features include an in-cab release mechanism for quick, easy implement changes and a safe, secure, patented latching and locking system

For the ultimate in towing safety, operator comfort and reduced maintenance costs, Dromone’s Ball and Spoon is the go-to system It offers fully automatic coupling f rom the cab, eliminates rattling and shunting noises and reduces wear and hitch damage by up to 90%

Regardless of it being a 5.0t combi drill or a 2.0t fully-mounted plough, the 6R250 doesn’t produce record results. However, it will still manage to lift most machines that it's likely to be expected to use. The same applies to the front linkage.

Long lift arms: continuous 7,659daN, 75.2cm lift height

Short lift arms: continuous 8,487daN, 68.8cm lift height

Front linkage: continuous 4,140daN; 70.6cm lift height

just navigating to different fields via the familiar Google Maps interface, John Deere is simply ahead of the competition when it comes to this sort of tech.

And if you have questions about operating the 6R250 when away from the yard, then you can have the necessary steps explained via Remote Display Access, although video calling from a smartphone could achieve much the same thing. Another useful driver aid is the 'help' function on the terminal, which is ideally positioned with a question

mark and saves time flicking through the operator’s manual.

Automatic lane planning including headland manoeuvres using AutoPath (Boundaries) and AutoPath (Rows) completes the steering system package. The only things missing for the ultimate American ‘way of farming’ are the ‘Harley bar’ footrests down in the right footwell; these appear on the bigger Deere models.

Finally, with autosteer engaged, the seat can swivel up to 40° to the right so you can

After about a day, you will have sussed out most of the features on the CommandPro armrest. The 70.1dB(A) noise level in the cab is pleasant and eases the stress of a long working day.

keep an eye on the implement. If the tractor then auto reverses at the headland, you’re close to autonomous driving; it's just a pity that the ITEC functions can only be triggered by distance, but not by time.

The rear linkage manages a lift range of just 75cm and, at 7,659daN, lifts less than its competitors. Thanks to almost 10,000daN within the upper range, bigger cylinders can also handle heavy attachments in this power class. Thumbs-up for the simple way of altering the lower link spacing and the spring-loaded top link to ease handling. If there was an easier way of putting the lift arms in their top position without having to juggle lynch pins, that would be great.

As for hydraulic couplers at the rear, the 6R250 offers five spool valves and PowerBeyond couplers (six valves without PowerBeyond). The couplers also have a pressure relief lever as well as handy time and flow adjustment. The swash plate pump delivers up to 195l/min.

The neatly integrated front linkage is also available with two additional couplers as an option. It is a bit of a head scratcher that the free-return line obstructs the front clevis so that the pin can only be inserted from below.

John Deere’s sales pitch for the 6R250’s Sport Package is that it provides smooth, straight-line stability and improved steering precision — courtesy of the new steering

This is not a summary but a list of positive and less positive details.

B POSITIVE

B Work lights are switched in groups

B Front linkage with ball mount

B Engine air filter very good to access

B Air outlet on the steps

B LED dipped beam

The pull-out screen provides quick radiator cleaning.

LED packages deliver very good all-round illumination.

linkage with fewer joints. We can confirm this trait.

Compared with the smaller 6R175, however, the front axle suspension with its external cylinders is still very firm. The same applies to the brakes: with a tap of the foot, they bring the near 9.6t tractor to a standstill with a deceleration of 5.45m/s². Speaking of weight, the nifty EZ-Ballast drive-over weight from the 7R is now also available on the 6R. This allows the tractor to hydraulically couple just under 2 tonnes

E NEGATIVE

E The mobile phone holder fouls with the rail for the terminal bracket

E The fuel level pointer is too unresponsive

E DAB reception was good but only after a foil was retrofitted

E Rear cable gland

Back wiper can scratch the glass if care isn't taken.

quickly and easily, with the major benefit being that the weight distribution is ideal for heavy drawbar applications. However, this convenience is £2,090 and can't be fitted if you have a pickup hitch. A gross weight of 15 tonnes translates into an impressive payload of 5.4 tonnes. Similarly impressive is the turning circle of 13m — although the much-cited competition does turn tighter. On the other hand, the 6R250 with its LED lights dwarfs many a competitor.

The engine/transmission relationship is impressive for both pto work and when towing heavy loads. Unfortunately, the painted mirrors scratch easily and can quickly start to look tatty.

Seat doesn’t move back enough for taller operators.

The basic version of the 6R250 is priced at £259,412. Buyers can then tuck into the options list, adding bits like a front linkage, Starfire receiver, CommandCenter with G5 Plus screen including a G5 extra monitor, leather package, Ultimate seat and stainless steel exhaust stack, so you get the Signature Edition sticker. The bottom line for our test tractor according to the configurator is a hefty £325,595.

Deere’s Mannheim-built 250 has been on the market for a good few years now, but it is maturing nicely. The test results are still impressive, even if you can see that the competition is working hard to win back any customers who have turned green and yellow. That said, the 6R has several reasons why it should remain as a best-seller: the Operations Centre, the well-finished cab, the G5 terminal and more. How things change can also be seen in the price tag. Back in 2018, a base spec 6250R was just under £200k; fast forward to now and the 6R250 starts from closer to a scary £260,000!

Tobias Bensing

ENGINE: 184kW/250hp (according to ECE-R 120) rated power at 2,100 rpm; 222kW/ 301hp max. w. boost; water-cooled six-cylinder DPS PowerTech PSS with 6.8 litres, in-line turbocharger (variable+fix), Stage V with DPF, DOC and SCR catalytic converter; 470-litre fuel, 25-litre AdBlue tanks

TRANSMISSION: Stepless ZF Eccom 2.9 with four automatically changing travel ranges, powershift shuttle, cruise control, 50km/hr at 1,630rpm; 33km/hr in reverse

BRAKES: Wet disc brakes front and rear, allwheel drive, automatic parking brake, air brake system

ELECTRICS: 12V battery, 174Ah, alternator with 250 amps, 3.8kW/5.1hp starter power

LINKAGE: Cat. III/IIIN; ELC, vibration damping, optional front linkage

HYDRAULICS: Axial piston pump, 195l/min, 205 bar, max. 6+3 control units with time and volume control; 80-litre oil reserve

PTO: 540/540E/1,000 (alternatively 1,000E), 1⅜ inch, 6 splines, electro-hydraulic control, optional front pto

AXLES AND RUNNING GEAR: Flanged axle, multi-plate differential locks, electrohydraulic engagement as on front axle. Tested tyres 600/60 R 30 up front and 710/70 R 42 at the rear

SERVICE AND MAINTENANCE: Engine oil

19.5 litres (change every 750 hours); transmission/hydraulic oil 160 litres (1,500 hours), cooling system 34 litres

PRICES: Basic equipment £278,150 euros; Ultimate seat (£4,539); Starfire receiver (£3,135), G5 and G5 Plus terminal (£5,486); Ultimate front hitch (£7,079) etc... Test specification machine £325,595

Width: 274cm; Length: 583cm; Height: 325cm

PTO OUTPUT (unboosted/boosted)

Max. at 1,800/1,900rpm 180.5/195.0kW

At rated speed 156.1/182.2kW

FUEL CONSUMPTION (no boost/with boost)

At max. output

235+9.4/ 236+10.1g/kWh

Rated speed 244+7.9/243+7g/kWh

Absolute max./rated speed 55.1/53.0l/hr

TORQUE (unboosted/boosted)

Max. 1,047/1,079Nm (1,500/1,600rpm)

Torque rise/speed drop 30.3/24%

Start-off torque 114%

TRANSMISSION

No. of gears in 4-12km/hr range Stepless

REAR LIFT CAPACITIES (90% max. oil pressure, corr.)

Bottom/middle/top 7,659/9,291/9.918daN

Lift range under load 75.2cm (23.0-98.2cm)

FRONT LIFT CAPACITIES (90% max. oil pressure, corr.)

Bottom/middle/top 4,140/4,802/5,634daN

Lift range under load 70.6cm (21.3-91.9cm)

HYDRAULIC OUTPUT

Operating pressure 202 bar

Maximum flow 195l/min

Output 51.1kW (192.7l/min, 159 bar)

DRAWBAR POWER

Max. 165.5kW at 1,800rpm 254g/kWh

At rated speed 145.9kW 261g/kWh

NOISE LEVEL (under load at driver’s ear)

Cab closed 70.1dB(A)

BRAKING

Max. mean deceleration 5.45m/s2 Pedal force 36.8daN

TURNING CIRCLE

4WD disengaged 13.00m

TEST WEIGHT

Front/rear axle 3,835kg/5,755kg

Kerb weight/gross weight 9,590kg/15,000kg

Max. axle load 6,900kg/11,400kg

Payload 5,410kg

Power-weight ratio 51kg/kW

DIMENSIONS

Fuel consumption at typical performance (boosted) Fuel consumption

Good performance characteristics; low consumption, especially during transport; low AdBlue use.

Stepless transmission with very good engine/transmission control including fine tuning; pedal and joystick mode freely interchangeable; just three pto speeds.

AXLES AND RUNNING

Very good manoeuvrability; good directional stability on the road; over 5.0t payload; brakes difficult to control. LINKAGE/HYDRAULICS B

Low lifting force in the lower range; good hydraulic power; exemplary operation and spools; assignment of coupler functions is satisfactory.

very

armrest and main controller very good; large, high-resolution screens.

Grading: BB very good B good Z average E below average EE poor Individual marks are merely excerpts from our assessments and do not necessarily result in a mathematically conclusive overall mark.

This is a comparison of three similar hp tractors that have been tested by profi in past magazines

This is a comparison of three similar hp tractors that have been tested by profi in past magazines

Tractor Test report in issue

No. of cylinders/capacity

John Deere 6R 250 profi 9/2025 Case IH Puma 260 CVX profi 5/2024

(ECE-R 120)

Six/6.8 Iitres/V

(ECE-R 120)

Six/6.7 Iitres/V Six/7.5 Iitres/V

Manufacturer/model DPS/PowerTech PSS FPT/NEF 67 AgcoPower/Core 75

Fuel and AdBlue consumption Specific

Max torque 1, 047/1, 079Nm (1,500/1,600rpm) 1,076/1,187Nm (1,200/1,400rpm)

The Aerosem VT with integrated power harrow scored well in our test with its good accessibility and being relatively compact.

Pöttinger Aerosem VT DD cultivator drill:

By making its wider power harrow drill combination a semi-mounted unit, it's not only easier to take on and off but also considerably reduces the amount of load on the tractor. We tested Pöttinger’s 5.0m wide Aerosem VT DD combi drill.

Not only has Pöttinger got a beefy front tank/rear power harrow drill combi in its line-up, but it also has the Aerosem VT, a semi-mounted machine pitched at farms with medium to heavy soils. Subject of this month’s practical test is the 5.0m version, the VT5000 DD, which, along with the 6.0m combi model, was introduced in 2021.

5.0m and 6.0m machines

It's not just the hopper capacity that differs on the two Aerosem VT DD drills (the 5.0m is 2,800 litres, the 6.0m having 4,600l), but

also the power harrow. Our VT 5000 was paired up with a Lion 503C, rated for up to 320hp. This has since been superseded by the Lion V5040 — still with four rotors per metre, but this now has a two-speed gearbox that sees the rotors spin at 342 or 527rpm with a 1,000 speed pto. Another difference includes the modified side plates.

The 6.0m version (Lion V6030) also has a two-speed manual-shift gearbox for a rotor speed of 320 to 430rpm. Its 20 rotors can handle up to 500hp. Quick-release tines are an option on both of these machines. Back to our test machine. On the hydraulic

side of things, our unit had the entry-level ‘Smartline’ system. This means that the individual functions are controlled from individual spool valves rather than from the terminal. For many, this approach will be perfectly adequate because most tractors will have the required three double-acting and one single-acting spool plus a free-flow return line.

Colour-coded grips on the hydraulic pipes make identifying which is which easy once you've realised the identifying decal is on the inside of the door for the drill's storage compartment.

The tested Smartline specification should be sufficient for most growers.

Improvements could be made to the seed depth adjustment system and tyre packer at the rear of the drill.

Manoeuvrability, calibration, distribution head, harrow depth adjustment and the split hopper result in a versatile drill without the need for any big changes.

The alternative spec to the Smartline, is the Profiline, which sees all of the hydraulic functions operated by the load-sensing hydraulics.

No quibbles on coupling the Cat. III lower link crossbar, pto shaft, air brakes, ISObus and the power plug. One minor thing our test operators thought could be better was the retaining bolt on the parking stand — it’s a bit of a fiddle.

By moving the pivot point farther back on the drawbar (rather than at the crossbar), the VT is extremely manoeuvrable. Visibility down the slim flanks of the hopper is also excellent, which not only makes reversing with the drill very easy but also gives you an excellent view of the power harrow and coulters when in the field.

The VT is only available with a 50:50 split

Having the pivot point slightly farther back from the tractor makes the combination extremely manoeuvrable at the headland.

hopper. Of course, this means you can fill both compartments with the same variety of seed, in which case you will only have to calibrate one of the two metering units. Both units have corrosion-resistant components for handling fertiliser.

POWER HARROW: LION V5040

Track eradicator BB

Depth control BB

Setting the levelling board B

Adjusting the side plates Z

Seed slot/ridge formation Z

Levelling B

Changing tines B

Tyre press Z

DRILL: AEROSEM VT5000 DD

HARDWARE AND QUALITY OF WORK

Seed hopper BB Seed level gauge BB

Achieving the calibrated rate BB

Cross distribution1) E/Z/E

Tramline control BB

Quality of placement BB HANDLING

Filling the hopper BB

Converting to small seeds BB

Calibration testing BB

Setting the seed rate BB

Setting the seed depth E

Adjusting the coulter pressure B

Setting the tine bar B

Emptying the hopper B

Terminal user interface Z

Steps/platform B

Ease of hitching to tractor BB

Transport changeover BB

Warning panels/lights B

Maintenance/build quality Z/B

1) Rape/wheat/grass; Ratings: BB = very good; B = good; Z = average; E = below average; EE = poor

PÖTTINGER CULTIVATOR DRILL

POWER HARROW: LION V5040

No. of rotors 2 x 10

Rotor speeds1) 342/527rpm

Tine length 33cm

Tyre press 400/50-15.5 (Ø 79cm)

Max tractor power 235kW/ 320hp

AEROSEM SEED DRILL

VT 5000 DD

Seed hopper (two 1.4m3) 2.2 tonnes of wheat

Filling width/depth 1.86/1.22m

Filling height from ground/platform 2.17/1.04m

Distribution across rows in wheat CoV = 3.6%

Distribution across rows in rape CoV = 7.6%

Distribution across rows in grass CoV = 6.0%

Coulters 40

Row spacing 12.5cm

Disc diameter 35cm

Disc spacing 30cm

Coulter pressure (min/max) 10/60kg

Press wheel diameter/ width 33/5cm

OVERALL COMBINATION

Tractor attachment Cat. III

Work width 5.11m

Transport width 2.98m

Transport height/ transport length 3.07m/7.10m

No. of grease points 58

Empty weight/axle load 8.40t/7.00t

Price (in base spec) £103,299

Price (in test specification) £150,597

1) at 1,000 pto rpm

We liked the flexibility of the second hopper, whether for sowing a second variety, for fertiliser (it goes down the same spout as the seed) or for drilling at low rates.

Filling: Even if the lid is a bit stiff to open, the concept of it sliding down the right-hand side works well so you can load the hopper with nearly any type of loader. We were also impressed by the accessibility from the side platform — despite the high bottom steps — and the emptying of the pressurised tank. A connection for the airline would be the icing on the cake, as this would allow you to blow out the hopper when changing seeds. The screens inside the hoppers could do with being more easily removed, but then they are sturdy enough for storing small bags. Two ultrasonic sensors, one in each hopper, get top marks as they indicate the amount

An ultrasonic sensor in each compartment continuously measures the amount still in the tank with centimetre precision — a very good solution.

in the tank to centimetre precision. Also, the metering units have low-level sensors, and as an extra-cost option the seed flow within the delivery tubes can be monitored, with their flow sensitivity varied on a scale from 1 to 10.

Calibration testing, too, was given a thumbsup by our test team. Not only are the sidemounted metering units quick to access, but the tared calibration bags, external calibration buttons, hopper slides and the simple-to-open cell wheel cover all play their part to just make the rate checking job a more enjoyable task. Any niggles? Just that the design of the storage compartment for the metering accessories could be better laid out.

The power harrow positioned ahead of the tyre packer is also nice to use. It's suspended from a parallel linkage and hydraulically damped. Depth of work can be adjusted with cm precision, with current depth displayed on the terminal — practical for changing conditions.

One minor drawback is that, when you make a big change to the harrow’s depth, you'll need to manually reset the

The drill performed best when planting wheat seed (CoV 3.6%). Grass (CoV 6%) and rapeseed (CoV 7.6%) distribution was only adequate.

To alter the sowing depth, you have to climb onto or into the middle of the machine — one of the biggest bugbears during

side deflector plates with the on-board tools. To adjust the two halves of the optional levelling board you need to hop out and again use the supplied tool. A laser-etched scale shows the depth — it works well. The space between the power harrow and the tyre packer has since been increased.

There were some issues with the trough seal during our season-long test, but Pöttinger quickly rectified this. Greasing up the cam clutch-protected drive shafts is a bit of a fiddle, especially with the hefty steel guards around the universal joints, because you can damage the speed sensors when refitting.

Equipped

The linkage used for the double-disc coulters allows very even coulter pressure.

Last bit on the power harrow: it folds in two parts and is pressurised so that it can offer 5° of upward travel but no extra downward travel.

Then there is the pre-sowing consolidation, which is done with a pneumatic tyre press: each wheel is 400mm wide and 790mm high. Unlike other Pöttinger trailed drills, there is no contour following for the section, so it can't adapt to the road camber which is no doubt going to cause inevitable damage. The scrapers located in front of and behind the tyres worked without any issues in our stone-free conditions. Speaking to users, they have had issues with stones jamming in the scrapers on earlier drills, but Pottinger has replaced them with a modified linkage to remedy this.

The drill's 350mm double-disc coulters are mounted on two beams, with equal length arms for the coulters. With a 30cm offset between front and back rows, the machine copes well with stickier soils and organic matter. We measured consistent pressures of up to 60kg on both the front and rear coulters. Overall, the 25mm offset-mounted discs worked without any issues on a variety of soil types, thanks in part to the internal scrapers.

A hole pattern between the coulter and the press wheel (330 x 50mm) is required for sowing different crops. To sow beans, for

A button and tared calibration bag make the two or three calibration runs very easy to carry out. Accessibility is excellent, as is the accuracy of the calibration process.

example, you need to refit one pin on each coulter. The middle position worked fine for us for sowing catch crops, rape and cereals. Seed depth setting, though, does come in for criticism. To make a change you move a spring-loaded pin to a different hole, but there is a scale for reference. This is done four times, but to reach the middle two, you have to climb into/onto the machine.

Regarding coulter pressure, on the Smartline version, this is altered via a manual throttle next to the fan, as the oil is diverted through a bypass. By slightly adjusting the fan speed, the coulter press can be increased slightly. On the Profiline drills, the coulter pressure is altered from the control box/screen. When it comes to all the cross-distribution measurements, the coefficient of variation in wheat of 3.6% was satisfactory but not so in grass (6%) and OSR (7.6%). These figures could be better.

The optional IDS distribution head offers lots of sowing possibilities. Equipped with one control flap for each row, you can switch sections up to 1.0m wide — also via GPS. It can also be used to drill various row and tramline systems. Unfortunately, a GPSsupported tramline system does not yet exist ... for now.

● The power harrow and coulter bank are raised and lowered at different times.

● ISObus interface offers lots of functions — fine for regular users, but complicated for occasional operators.

The ISObus menu layout works, but it's certainly not the most self-explanatory.

● The combination weighs 8.4 tonnes, of which 7.0t is on the packer when empty.

● Field emergence was uniform and good.

● A front packer is available as an option.

● Depending on the topography and how much power harrowing you want to do, we recommend a tractor of 240 to 320hp.

● Almost 60 grease nipples, some of which are difficult to get at. That's too many!

● The basic machine costs £103,299. Then add £19,404 for the seed bar, £5,348 for air brakes, £1,190 for the quick-change tines without wear pads, £1,467 for the levelling board and £4,205 for a set of bout markers. The seed flow monitoring costs £6,171, the IDS seed distribution head £7,803 and the following harrow £1,710. That’s £150,597 for the 5.0m we tested — and that’s without a terminal, spare metering rollers and eradicators.

It's the compact and functional overall design of the machine that makes sowing with the Aerosem VT such a pleasure. Nevertheless, criticism goes to lateral seed distribution, the tyre packer when travelling on the road, too many grease points and the seed depth adjustment. Overall, though, we still liked the drill for the mentioned positives. We think the base “Smartline” version should be sufficient for most farms' requirements. Sönke Schulz

Our head-to-head test compares the multiadaptable Ecomat with the beautifully simple Mini.

Shallow ploughing might not be everyone’s cup of tea but with increased focus on carbon emissions and the obvious cost advantages of just skimming under the surface, it’s a practice that is receiving renewed attention. We put two of the front-runners in the field side-by-side earlier this year..

hile there’s nothing new in the practice of shallow ploughing, it’s a technique that has never really taken a grip as a mainstream cultivation approach. Consequently, manufacturers of these niche

inversion tillage tools have come and gone but a few players remain steadfast in the game. French manufacturer Bugnot continues to have a decent following in its home market with its RapidLab skim plough but due to the small numbers shifted this

The Ovlac Mini is available in two to nine furrows.

Kveneland makes the Ecomat in five to eight furrows.

As tested the Ovlac is £25,488, the Kverneland £51,854.

side of the Channel, importer ArbForest doesn’t run a demo machine.

So, that leaves just two others - Ovlac and Kverneland. Last spring we asked each to supply us with their most popular shallow ploughs to assess just how well they work and how easy they are to set up.

Located in northern Spain, Ovlac has been building ploughs for over 75 years and today claims to be the country’s largest manufacturer of soil-engaging equipment. The firm is regarded as something of a specialist in shallow inversion tillage with a

range built specifically for that growing market.

Alongside a full offering of conventional and reversible ploughs from two to nine furrows – mounted and semi-mounted – the company has developed its Mini range to work at depths of between 8cm and 20cm. According to the company, reducing share depth to less than 15cm can half power requirements enabling smaller tractors to cover far greater working widths – it is apparently possible to have a 13-body plough spanning 5.0m on a tractor of just 260hp.

It’s a similar story with Kverneland which builds the entirety of is plough line-up in Norway. Despite having a short break in production of its shallow plough offering a few years back, the company has recently invested a good chunk its R&D budget in its Ecomat shallow ploughs, widening the range to include smaller in-furrow six-, seven- and eight-body models suitable for more modestly sized tractors.

For now though we’re told it’s the company’s eight-furrow on-land model that attracts most attention and so that’s the demo machine we were given.

On-land versions prove the most popular for the Spaniards too apparently and consequently it was a seven-furrow Ovlac

Mini NH that we received for our in-field comparison.

level a very straightforward process.

Albeit very similar on paper, it immediately becomes apparent that these are two very different beasts. Kverneland’s Ecomat OnLand looks much like a standard eightfurrow plough. And that’s because it is. It’s based on the company’s ever-popular LO-series ploughs and comes with either eight or ten bodies while the smaller infurrow variants are based on ES-series models and run from five to eight bodies. In contrast the Ovlac Mini employs a purpose-built multi-beam frame for its fiveto 11-body fully mounted models while

bigger 12- and 13-furrow versions borrow the single beam design used on the company’s semi-mounted standard ploughs. Our seven-furrow test model came equipped with a number of options including hydraulic auto-reset and an intriguing-looking front depth wheel.

The eight-body Kverneland landed with shear bolt overload protection and manual vari-width enabling pass-to-pass spans to be adjusted from 2.40m to 4.24m. The seven-furrow Ovlac has two manually set working widths of 2.48m and 2.68m with the ability to add another two bolt-on bodies to take it to a maximum of 3.45m.

Being able to bury trash and control weeds while not exerting huge loading on the tractor makes shallow ploughing an attractive proposition on the face of it. But as with anything agricultural it’ll only suit certain sites, soils and systems.

Much research has been done on the subject particularly in northern Europe and Scandinavia. Trials with organic pea and oat crops in Germany compared the effects of 7-10cm and 25-30cm ploughing depths. Unsurprisingly penetration resistance (compaction) was greater in the 14-28cm soil zone under the shallow regime whereas soil loading due to the increased draft requirements with deep ploughing increased compaction and had an impact on yields, reducing them by between 12.1% - 20.8%.

Annual weed infestation levels were generally higher in the shallow inversion areas. The overall finding suggested that shallow ploughing mitigates the risk of a decrease in crop performance as a result of heavy field traffic and its reduced power/labour requirement goes a long way in offsetting the potential increase in weed burdens when compared with deep inversion.

Comprehensive field trials in Norway throughout the mid 2000s looked at the impact of reduced ploughing depth alongside the difference between in-furrow and on-land approaches.

In-furrow ploughing was found to significantly reduce the air-filled pore space and subsequent permeability when soil conditions were sub optimal however it had very little effect when ploughing was performed with favourable moisture levels.

Shallow ploughing led to marked increases in perennial weed biomass and particularly allowed couch grass to flourish. However, reduced depth cultivation was shown to provide greater reserves of plant-available P & K. It is asserted that this is due to the fact that shallow inversion tillage favours the formation of cavities where air and moisture can work together to provide a microclimate to suit the bacteria that can decompose large volumes of crop residue, producing a clay-humic complex that mineralises nutrients and increases the natural fertility of the soil.

A six-year long investigation in the Netherlands set out to ascertain the minimum ploughing depth possible for sustainable weed control and acceptable yields. Working at depths of between 12-20cm depending on conditions, it was found that crop performance was similar with both conventional and shallow approaches but weed populations did increase when working depths reduced to less than 20cm.

The trial also looked at the impact of noninversion tillage practices for slurry and muck

incorporation, finding that ammonia losses leapt from 10% to around 60% when going from the plough to a stubble cultivator. There is still plenty of debate about the optimum depth of ploughing. Some studies suggest that organic farmers should reduce ploughing depth to a minimum of 8cm. However, in order to bury green manure, annual weeds and crop residues, working depth should be at least 12cm and for control of perennial weeds it should be 20cm or more.

After shallow ploughing the surface tends to be less undulating than after conventional ploughing. This is mainly due to the difference in depth-to-width ratios. Generally shallow furrows run at 2:5 instead of 2:3 with traditional deep inversion. Reduced surface roughness after ploughing can remove the need for a tillage pass for seedbed preparation, making the practice even more financially attractive. But in situations where deep ruts need to be levelled, for example after root crops or maize, shallow ploughing will struggle to alleviate the issues. If it’s possible to achieve almost complete surface burial working at less than half the depth of a normal plough with an implement that requires half the power, while doing a far better job of inversion than a cultivator, then there has to be some merit in the concept.

…with it set right, taps are shut to ensure it remains in the same position throughout the day. This arrangement means the hydraulic wheel can be used to lift the rear of the plough out of work but it cannot go deeper than the set working depth.

Bolted to the Ecomat’s landside knivess, trashboards slice through the soil as it curls up over the points. Optional plastic mouldboards are designed for sticky stone-free conditions. Judging by the scarring during our short trial they’re not well suited to flinty ground.

Once pulled into the field, set up with the Kverneland is much like that with a standard plough. A single bolt through the beam in each body bracket varies the angle to alter furrow widths in 5cm increments. Collars on the front furrow width adjustment ram then set the stroke length so that the bean returns to the same angle after each turnover. A large nut on the threaded end of the ram provides fine-tuning. Adjusting the depth on a standard model is done via a long threaded bar linked to the rear wheel. Our test machine had hydraulic depth control. To tweak it you open two taps, use a spool valve to raise or lower the wheel. Shut the taps and that’s the backend sorted. With a floating top-link it’s just a case of setting the link arms to the right height to get front and rear mouldboards running true.

As you’d imagine there’s a whole raft of body choices from the Kverneland parts bin. Plastic and steel mouldboards both come

No. furrows 7 (with +2 optional bolt-on bodies) 8

Min working depth 80mm 60mm

Max working depth 200mm 180mm

Working width per furrow 355mm & 383mm

300-500mm (mechanically adjusted in 50mm increments)

Overall working width 2.68m (3.06m with 1 extra body, 3.45m with + 2) 2.40m – 4.24m

Interbody clearance

Underbeam clearance

Headstock 140mm solid turnover shaft 150mm hollow turnover shaft

Depth/transport wheel

Price – base spec

200/60 x 14.5 BKT front, 340/55 x 16 Ascenso rear 420/55 x 17 Trelleborg

£16,251

£43,975 - as tested

£25,488 1)

£51,854 2)

1) Ovlac demo spec. included hydraulic auto reset, front depth wheel, road lights, rear transport wheel, landside wear plates and trashboards. 2) Kverneland demo spec. included TTS kit with 420 depth wheel and hydraulc depth wheel adjustment, plastic Ecomat mouldboards, knock-on points.

with the same wearing metal as No. 28 bodies and there are the options of carbide tips, knock-on points, quick fit shins, etc… A landside knife comes as standard to slice through the furrow as it peels off the point. On our test rig we had optional bolt-on trash-boards out in front of each body and there is the option of double fingers running

vertically along the top of each board to help flip cantankerous sods over on their backs. With the job done, it’s time to head for home. The Ecomat’s headstock has a pivoting lower cross-shaft that is locked when in the field. A handle is then flipped with the plough in butterfly position allowing the Kverneland to behave like a semi-mounted

Shared with Kverneland’s cultivator range, optional knock-on points make for quick wearing metal pit stops but the blunt bulletpoint tips aren’t the best for penetrating hardpacked soils.

A manually activated pin in the Ovlac headstock locks the frame in an upright ‘butterfly’ position for transport with the rear wheel steering and sharing the load.

rig on the road. With the top link detached, the rear wheel remains fixed while the headstock steers, making the whole setup follow much like a tractor-trailer combination.

It’s fair to say the Ovlac Mini is a simpler beast and consequently setup is more straightforward. First, it’s a case of positioning the sliding headstock in a position where the front furrow is well clear of the rear wheels. This is then easily tweaked on the move from the cab, shifting the whole plough frame left and right accordingly – a useful feature on side slopes where the rig may not track entirely true. Next up is front furrow depth. With the toplink in the slotted hole, the link-arms are the primary means of regulating how deep the plough works. The optional front depth wheel is there more as a guide – it should only be skimming the surface to ensure

there’s still decent weight transfer onto the back of the tractor. That said, it’s a musthave option in our opinion, making the rigidframed plough much more effective in maintaining a consistent shallow working depth on uneven surfaces.

With the front end sorted it’s simply a case of adjusting the turnbuckles on the rear wheel to set the whole frame running true. We can’t overstate how beautifully simple the Ovlac is to set up.

It also has another trick up its sleeve to ensure true tracking behind the tractor. The main headstock cross-shaft can oscillate. This means the plough can find its own line, pivoting around its central pull point and finding the midline between the forces exerted on the landsides and mouldboards. In this way it’s not necessary to make lots of adjustments to ensure the Mini pulls straight. It simply finds its own happy medium.

Again, there is a plethora of body choices for the Spanish plough, steel slatted or solid and plastic for the stickiest conditions. Reversible tips can be bolted on to the front of the flush-fit one-way points which is great for extending the life of wearing metal but creates a step which sticky soil can hang up on. Adjustable landside wear plate extensions are standard as are tweakable trashboards.

For transport the Ovlac has to be hoisted as high as possible to get the rear wheel into its road position. This requires a pin to be removed and positioned in the designated travel hole. Getting the weight off is an awkward finger-snagging process that requires generous doses of right boot. Once tucked under the frame the wheel pivots round corners while supporting the weight of the plough.

Like other Kverneland ploughs, the Ecomat is often viewed as the gold standard for shallow ploughs. Being arranged around the same basic design as the company’s standard models it has heaps of adjustment in all three dimensions. But that level of sophistication comes with its own inherent complexity. This is no drop it in the ground and go rig. You need to take time to get it set up right to do the best possible job. In contrast the Ovlac Mini is about as

straightforward as it gets. Front and rear wheel adjustments deal with ploughing depth while the sliding headstock sets the front furrow away from the tractor’s rear wheels. The Spaniards’ clever free-floating line-of-pull arrangement means that the plough can never run anything other than true. While this simplicity is great, it does mean there’s less refinement to the Mini and match ploughmen might feel they’re lacking all the tweak-ability they’d like.

The upside of this lack of complexity is that

Switching the Ovlac’s

pin from ploughing to transport positions appears straightforward enough…

…but requires a couple of sharp doses of size 10 treatment.

it’s a massively cheaper build. While the eight furrow Kverneland comes in at north of £50k, an equivalent 7+1 Ovlac stands at about £21,000.

Trelleborg ProgressiveTraction® tyres -available in the TM1060, TM1000, TM900 and TM800 ranges -are engineered to deliversuperiortraction, reduced slippage,and maximum durability.Now offeredfor rear axle, with up to 5,000 hour s of cer tified tread wear perfor mance.

Offer valid exclusively uponregistration to the Premium Care Program at premiumcare.trelleborg-tires.com

trelleborg-tires.com

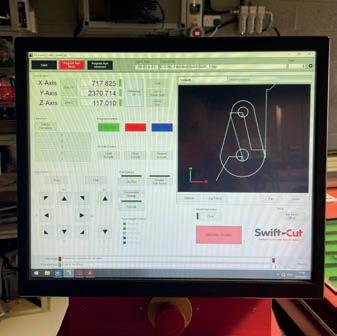

An all-wheel steer JCB Fastrac 4220 and Stoll ProfiLine FZ46-29 ISObus Connected loader combo make a formidable combination. Using the tractor’s integrated secondary joystick to seamlessly work the loader with good proportional control proved a plus, but it was the smooth operation of the loader itself that was the standout feature.

Stoll ProfiLine ISObus Connected:

Stoll’s ISObus Connected loader controls is now an option on the ProfiLine range making it not only easier to install and use via the tractor’s onboard joystick and ISObus terminal. With this simplified integration, installing a loader is easier but this is just part of a bigger story.

Stoll has packed a whole host of operator-friendly features into its ISObus Connected system. While none are absolutely essential, half an hour into using a ProfiLine FZ46-29 on the nose of a JCB Fastrac 4220 it was clear there is more to the set up than the features that come as a package with this ISObus system. Even a ham-fisted joystick jockey can become a smooth operator.

ISObus Connected can be set up to operate in different ways to match specific tractor models, but for most the loader will be operated via the secondary joystick that is part and parcel of many modern tractor controls. A few tweaks and operating the loader in its simplest mode will have most operators up and running with very little in the way of instruction. According to Stoll’s

long-established UK importer Lynx Engineering, most of the ISObus Connected loaders it has sold to date have seen customers get used to the loader initially by operating it in its basic Easy Mode setting. Once familiar with the basics, operators can then dive into the various set-up profiles that enable various functions to be tweaked, not just in general, but to suit specific attachments and tasks. These can then be personalised to suit different operators – a possible useful feature for tractors is used by different drivers.

Sounds great, but what is it like in practice?

Lynx Engineering had two ProfiLine loader set ups to try; a JCB Fastrac and Case IH Puma 165. This provided an opportunity to

sample the ISObus Connect set up patched into the integrated ISObus system of two different tractors. In both cases, the mini joystick fitted in these tractors was set up

ISObus Connect is only offered on Stoll ProfiLine loader models

Basic set up offers smooth loader control

Fitting a loader to a suitable tractor will take less time

System adds weigh system to a Stoll loader for the first time

PROFILINE FZ 43-27 STANDARD

Ability Lift height 4.30m, lift capacity at full height 1,890kg

Standard features

Mechanical self-levelling, third service, Comfort Drive boom suspension, Euro headstock, Pro control Electric Joystick.

Price £16,370 Case IH Puma 165 fitting

PROFILINE FZ 43-27 ISOBUS CONNECTED

Ability Lift height 4.30m, lift capacity at full height 1,890kg

Standard features ISObus, Comfort Drive boom suspension, mechanical self-levelling, third service, Euro headstock with Hydrolock hydraulic locking.

Price £17,590 Case IH Puma 165 fitting

PROFILINE FZ 46-29

Ability Lift height 4.55m, lift capacity at full height 2,280kg.

Standard features Mechanical self-levelling, third service, Comfort Drive boom suspension, Euro headstock, Pro control Electric Joystick.

Price £17,900 JCB Fastrac 4220 fitting

PROFILINE FZ 46-29 ISOBUS CONNECTED

Ability Lift height 4.55m, lift capacity at full height 2,280kg

Standard features

Mechanical self-levelling, third service, Comfort Drive boom suspension, Euro headstock, with Hyrolock hydraulic locking

Price £19,210 JCB Fastrac 4220 fitting

Operated via the tractor’s integrated ‘stubby’ secondary joystick, the loader was set up so the grab would apply a fixed squeezing force to pick up the bale. Just press the assigned button, and the hands grab the bale without you having to put much thought into the operation. It is the ability to set the loader up to suit the job, personal preferences and specific attachments that is a key plus. A new feature is the ability to weight a load, both statically and on the move.