8 minute read

THE WANDERER RETURNS

IMPORTING AN EXPORT

e wanderer returns

New Zealand was a successful export market for the MF135, and Lindsay McClounie now owns one that went there first, but has returned home to its roots, as Bob Weir discovers

Lindsay McClounie is delighted with the MF135 that he imported from halfway around the world.

The town of New Cumnock is in East Ayrshire and has some famous historical connections, including King Robert the Bruce and William Wallace, of Braveheart fame. It’s also the old stomping ground of Scotland’s most famous bard, Robert Burns.

Lindsay McClounie’s family specialises in building demolition and plant hire; a business that was established in 1962. There’s also a strong agricultural connection at the headquarters at Meikle Garclaugh Farm.

Working tractor choice

“Apart from the building work, we keep a small herd of beef cattle,” Lindsay explained. “We also rent out part of our land for grazing sheep, and farm a total of 600 acres. We’ve used several different types of tractor over the years, but our current workhorse is a Massey Ferguson 6470. It’s a local machine and we’ve had it for four years.”

The McClounies were brought up in the area, and have been there for several generations. Like a lot of Scottish families, they also have relatives living ‘down under’. “Members of the family started to move to New Zealand several years ago,” Lindsay told me. “Ironically, there are probably more McClounies living there now, than in Scotland, and some of them are also involved in farming.

“I was over there visiting two of our relations – Ted and Pauline Allen – in 2004, when I spotted the MF135. It was being kept in a small shed on their hill farm, and it was the dual rear wheels that first caught my eye. I wasn’t particularly clued-up about old tractors in those days, but it certainly got my interest.

“Pauline likes to visit Scotland every few years, and it was during a trip in 2010 that the subject of the tractor cropped up. I was showing her around our farm and jokingly said that if Ted ever wanted to sell the 135, I’d take it off his hands. I knew that he barely used the Massey, but that he wasn’t looking to change it, so I never imagined for a moment that it would actually happen.”

Done deal!

“Later that visit, Ted rang Pauline on a routine call from New Zealand. Apparently, his accountant had told him that they’d made a decent profit for the year, and had suggested buying a new tractor to offset the tax bill. So, Pauline asked Ted to sit tight until she’d flown home and, once she was back, they were in touch again.”

The upshot was that Ted and Pauline did buy a new tractor and, after a bit of friendly haggling, Lindsay agreed to buy the MF135.

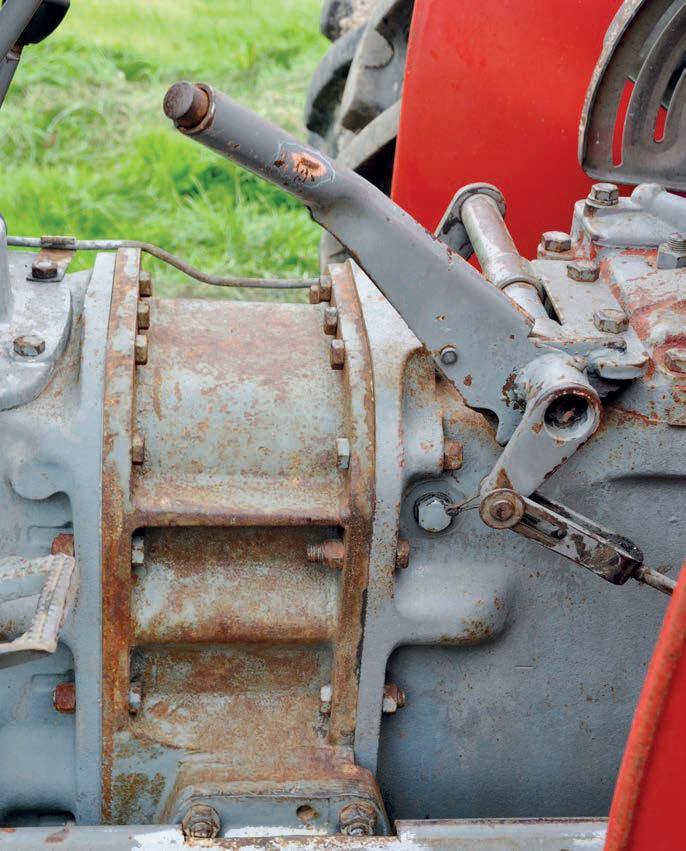

The reduction box on the Selene four-wheel-drive system. Then came the hard part; shipping the Massey halfway around the world!

“Ted had agreed to deliver the tractor to the docks in Auckland,” Lindsay recalls, “but the rest of the journey was down to me. I hadn’t attempted anything like this before, so it was a bit of a learning curve.

“I searched the internet and trawled through some shipping agents’ websites. The biggest decision was choosing whether I wanted the tractor to be transported across the oceans in its own container, or just tied down in the ship’s hold, similarly to a regular ferry. The first option included delivery from the port of arrival up to Scotland, but the total cost was a bit expensive. The cheaper alternative meant it was my responsibility to collect the MF135 once it arrived in the UK. In the end, I decided to drive down to Southampton docks with my 4x4 and trailer.” So, having made all the arrangements, all Lindsay had to do was sit back and wait.

Indirect route

“These ships are massive and they don’t just sail straight from A to B,” he explained. A quick glance at the route showed that our ship, the Tamerlane, had stopovers all over the Pacific Rim, including Japan, up towards the Barents Sea and down the coast of California. Like all ships passing from the Pacific to the Atlantic Ocean, it also had to negotiate the Panama Canal. Fortunately, I was able to follow its progress using marinetraffic.com That website tracks the progress of each ship, using a system based on GPS and, every time the Tamerlane approached the next port, I was automatically sent an email.”

After three months at sea, the ship finally docked at Southampton, on February 5th, 2012. After such a long wait, I was starting to get a wee bit excited,” Lindsay recalls. “One morning we set off from home at the crack of dawn. My eight-year-

The hills surrounding Meikle Garclaugh Farm are similar to those in New Zealand, so a home from home for this much-travelled MF135.

old son, Ewan, had taken the day off school to come along for the ride. Ironically, we only got as far as Sanquhar, just six miles down the road, when we were stopped by the local police. There had been a spate of sheep rustling in the area, and they wanted to know what we were doing at that time of the morning driving a 4x4 and pulling a flatbed?

“Thankfully, it was all plain sailing after that, and we arrived in Southampton docks in time for our 2pm appointment. I was a bit concerned that, with all the Health & Safety regulations, they’d refuse Ewan entry as he was so young, but it was all very straightforward.

“I was given a ticket and pointed in the right direction. Unfortunately, when I got to what I assumed was the right dispersal bay, I drew a blank. The foreman said that the only tractors on his section of the dock

were John Deere machines, awaiting loading for export. However, he added that I was welcome to take a look around.

Searching the dock

“So there we were, no safety helmets or high-viz jackets, walking up and down these lines of tractors. Nobody stopped us, or even batted an eyelid! Eventually, one of the forklift drivers remembered seeing my tractor, and we were able to follow him to the other side of the landing area. After a couple of diversions, we discovered the wee Massey sitting on the dock, all by itself.

“One of the stevedores mentioned that when they were taking the tractor off the ship the engine started up at the first time of asking. This meant we were able to load it straight onto our flatbed, after which we wasted little time in heading for the gate marked ‘Exit’. I think it’s a real testament to Massey Ferguson

The tractor is loaded onto a flatbed for its journey to the Auckland docks. (Pic: Lindsay’s family in New Zealand).

engineering that the machine was in such good condition after all that time.”

Once he’d returned safely to New Cumnock with the MF135, Lindsay was able to give it its first, thorough inspection. “The tractor was first registered in 1977 and had originally been supplied by the Massey Ferguson dealer in Te

Dual rear wheels are a rare accessory on an MF135. Awamutu, which is the town on the North Island where my relations live.

“It was originally specified as a 2WD model and equipped with the Perkins, three-cylinder diesel engine. The transmission is the later, eightforward-and-two-reverse unit, but the tractor had been converted to Selene 4WD by the local dealer. The area around Te Awamutu is quite hilly, which is why Ted had also fitted the dual rear wheels using rims that had previously seen service on his Massey Ferguson 35.”

4WD solution

Selene Engineering started using surplus front axles salvaged from American ex-army trucks at the end of World War Two. The intention was to provide extra traction for ploughing on heavy, clay soils. The conversions were initially fitted

The original New Zealand number plate is still on board.

to the Fordson E27N, Ferguson TE-20s and Ford 9N/2Ns. The firm eventually went on to supply kits for tractor manufacturers all over Europe. Selene also started converting Massey Ferguson tractors to 4WD in the mid-1960s, and patented the ‘sandwich box’ design, which took the transmission output drive to the front axle via a single prop shaft.

“The tractor turned out to be in pretty good condition, so it didn’t require a lot of work,” Lindsay added. “The climate on North Island is a lot milder than Scotland and, thankfully, the tractor was free from rust. It certainly doesn’t need restoring. I obviously gave it a good wash and removed the water from the rear wheels as they were waterballasted.

“I did have a small problem with the clutch last winter. I wasn’t aware that Ted had even fitted a new clutch but, thanks to the cold weather, the plate had got stuck to the flywheel and I couldn’t select a gear. Try as we might, we couldn’t free it until we split the tractor and gave it a little tap with a hammer.”

Now that he’s finally got the Massey, I asked Lindsay about his future plans. “The tractor is still capable of doing a day’s work,” he told me. “It sprayed several acres of weeds in our meadow this summer, and also did a turn on the sawbench, splitting logs. I’ve also taken it to the occasional show.

“My main aim is to preserve the machine just the way it currently is. This 135 is a true original, and these are hard to come by these days. It also acts as a fond reminder of my family living on the other side of the world.”