7 minute read

Material Costing

from EWB Project Report

by jtc_design

Total Product cost: £60 (pprox..)

Total labour cost: £11 per hr

Advertisement

Figure 13 – A table of costing for the product

Figure 14 (left) – A Render showing the HDPE Bottom Storage Barrels

Figure 15 (Middle) – A Render showing the Heating and Sterilising Sphere at Focal Point

Figure 16 (Right) – A Render showing the Metal arms and Supporting Structures

Final Concept

Figure 17 – a render of the final concept with it’s labelled components

Our Project Goal It is expected that the materials and components used in this project are: - Sourced locally - Environmentally Sustainable - Economically Viable The components chosen for this project were used to push this product to be viable in the real world. Through rigorous research the design team found the most easily accessible local materials to ensure that there was no issue or need to substitute essential components. If this were not the case, the product could have been manufactured from scratch and be far more efficient but the target area does not currently have the infrastructure or facilities to be able to fully implement this service unless designed through the local community’s current means. Our aim is to build just one of these systems to kickstart a sterilised and clean water solution for the areas of Lobitos and Pedritas. The team will guide a group of the local community through the manufacture process as a blueprint for future iterations so that the process is as repeatable as possible. It is our goal to have hundreds of these systems implemented across the target areas to ensure that everyone has clean and sterile drinking water.

3

2 1

Figure 18 – a render of the final concept with points to assist in understanding of the ‘How it Works’

How it works

A user will place the volume of grey water they require to be filtered into the IBC at (1a). Here it flows through a, basic and very easy to make, sedimentary filter (1b) to remove any larger particles which are contained within the water. The sedimentary filter consists of 3 levels. Gravel, sand, and then charcoal, which gradually filters out smaller and smaller sediments from the water. The use of the sedimentary filter not only removes any small organisms and debris, but it reduces the amount of sediment build up in the rest of the system – this in turn allows for the system to operate for longer time periods between servicing and cleaning before becoming congested and inefficient. A drip valve and syphoning system (1c) are implemented at the bottom of the IBC filter where the water is led to a large glass fishing float (2a) which is modified to store the water while it is sterilised. This is suspended above a large reflective parabolic dish (2b) using four steel arms (2c) at the focal point. (All of these components have been reused for this project using repurposed oil drums and old fishing floats). At the focal point, the suns rays head the water in the glass globe to temperatures exceeding 60C in an average use case scenario. This is hot enough to kill any waterborne bacteria such as cholera. In good weather conditions the temperature of the water can exceed 120C according to a case study carried out by Yaseen. H. Mahmood, Rafea Munef and Ayoub Abdulwahid Bazzaz. The drip valve exiting the globe can be operated after the water has been heated for a minimum of 60 minutes and is carried down a hose to the storage containers (3) which can be situated so that they are accessible to the user for collecting water. In these reused containers sterilised cold and hot water can be stored if the users choose to insulate the barrels. This can be done easily using reflective insulation which has been commonly used in the houses of Lobitos and Pedritas.

Figure 19 – An image of the layers of a natural filter system – 1b in ‘how it works’

Effects on the local community This product aims to help out out the community in a multitude of ways. Additionally to supplying an alternative source of clean water, this project aims to employ and improve the livelihood of the local people. Since the system requires assembly it will be required to employ some of the local workforce to initially build and then maintain. To assemble with all of the components to hand would not take more that 6-8 hours with two experienced adults. But since this system is so simple it can be used as a learning experience for younger generations as well. Long term the system requires regular maintenance at 6 month intervals and more regular inspections for faults every month. This ensures that the systems can operate at maximum efficiency and requires cleaning of hoses and water storage units which means out of the year, the product will be in operation for approximately 360 days. Further iterations of the product allows for larger parabolic dishes, higher temperatures, more water storage, and larger scale implementation not just nationally globally. Since the system is made almost entirely from locally sourced materials it has very little environmental implications and also helps to re-use materials which would otherwise have gone to landfill of be lost to the sea.

Content not Attributable to the Design Team

Throughout the development of the product, further research was carried out to ensure the most suitable technology and materials were used. During this process a research study which investigates “the modulation of a parabolic dish to produce boiled water” was identified. This investigation allowed the design team to further their understanding of how a parabola works and aided in the design process to ensure the product worked to its highest efficiency.

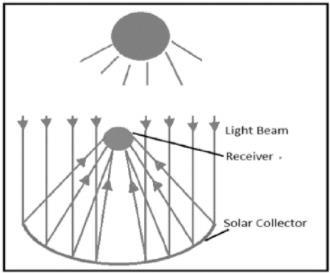

Figure 20 – A schematic Diagram of a parabolic dish concentrator reflecting Parallel light beams.

The Investigation run by the authors “Yaseen. H. Mahmood, Rafea Munef and Ayoub Abdulwahid Bazzaz” firstly addresses the science behind how a parabola works. This entails the scientific formulae on how to calculate the focal distance based on the dimensions of sed shape. The investigation also looks into how to calculate the concentrating ratios, heat and useful heat produced along with the efficiencies.

Following this, the report then details a breakdown of the equipment used to carry out the process and what each of the counterparts are made from justifying why these were selected according to their properties;

The solar condenser was created using a galvanized steel sheet, when pressed into shape, reflective plain mirror pieces (3cm x3cm) were applied and stuck to the surface of the dish creating a surface which reflects almost 90% of the suns rays.

Figure 21 – A Table showing the details of the Solar Condenser

The Receiver was constructed from stainless steel, covered with a thin coat of black paint to decrease the

reflection of solar rays located in the focal zone of the parabolic dish.

There were Two storage tanks made from steel filled with Freon gas and modifications of two additional holes for water inlet and outlet were placed for installation thermocouple.

The tracking system consisted of a DC motor similar to the motor of a satellite control was used with two

sensors (CdS) photo resistor.

Figure 22 – An image showing the schematic diagram of the solar dish Figure 23 – An image of a designed experimental solar condenser prototype

The results of the experiment proved successful. The parabolic solar concentration had exceeded operating temperatures of any other form of the solar radiation and in desalination of water for potable water and domestic usage. The experiment was analysed across multiple efficiencies but the main criteria the design team focussed within was the operating temperatures achieved. These readings were taken across several months and are as followed;

Figure 24 – A graph showing the relation between temperature and time within 2 months