SUSTAINABILITY GOALS

Meet the new CIPHE President

SUSTAINABILITY GOALS

Meet the new CIPHE President

THE CRUCIAL ROLE INSTALLERS PLAY IN ENSURING CLEAN, SAFE SUPPLIES

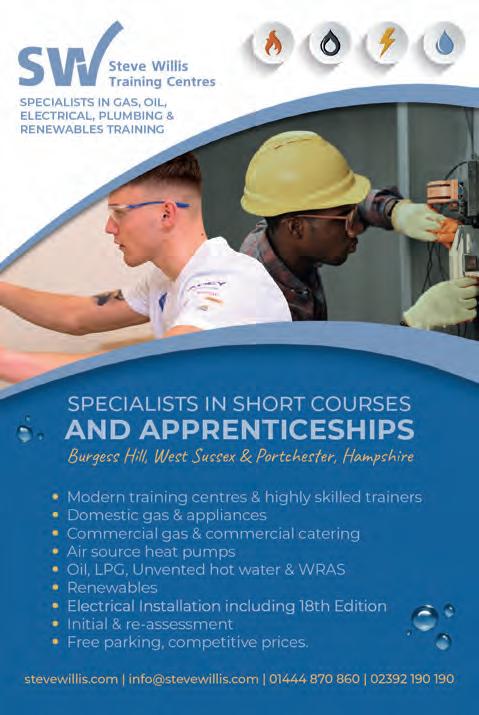

PLUGGING THE SKILLS GAP

The benefits of apprenticeships

TALL ORDER Safety guidance for working at height

THE KING’S SPEECH in July promised to “get Britain building” and “accelerate the delivery of high-quality infrastructure and housing”, in addition to pursuing “sustainable growth by encouraging investment in industry, skills and new technologies”. This is good news, but, as many people from the plumbing and heating industry have pointed out, these plans rely on the current skills crisis being properly addressed. Our education feature (p30) discusses the need for more apprentices to fill the skills gap and how they can benefit employers.

Following the Cryptosporidium outbreak in Devon and the fuel leak in Surrey, water safety and public health are issues that continue to trouble UK residents. The King’s speech highlighted the need to improve water quality and promised a Bill to strengthen the powers of the water regulator. P&H Engineering explores other risks to water safety and looks at how public health training can help installers keep their customers safe (p16). We’re also looking at water conservation and e ciency (p20).

SARAH WELSH Editor

pandhengineering @jamespembrokemedia.co.uk

Editor Sarah Welsh Project manager Lizzie Hufton

Design and production manager Christina Richmond

Publisher James Houston

Published by James Pembroke Media, 90 Walcot Street, Bath BA1 5BG Tel 01225 337777

Advertising sales Bevan Fawcett, 0203 198 3092 bevan.fawcett@jamespembrokemedia.co.uk

Chartered Institute of Plumbing and Heating Engineering (CIPHE) Saxon House, 27 Duke Street, Chelmsford CM1 1HT Tel 01708 472791

16 Safe keeping

Protecting water supplies from unsafe bacteria and chemicals

20 Manifesto: water efficiency

How you can be part of the CIPHE’s work to save precious water resources

24 Interview: Yvonne Orgill

Meet the CIPHE’s new national president

26 Project focus

Retrofitting heat pumps on social housing

5 From the CEO Kevin Wellman on new training plans

6 Frontline

Pressure to keep the apprenticeship levy, recent industry award winners, and more

Membership Founded in 1906, the Chartered Institute of Plumbing and Heating Engineering (CIPHE) is the professional body for the UK plumbing and heating industry. Membership is made up of consultants, specifiers, designers, public health engineers, lecturers, trainers, trainees and practitioners. The CIPHE has a membership of 7,500, including over 150 manufacturers and distributors. The majority of members live in the UK, although over 1,000 are residents in Hong Kong. The CIPHE is a member of the Construction Industry Council

14 Meet the member

Daisy Turner's award-winning career

30 Education

Filling the skills gap with apprentices

32 The Fix: Air admittance valves

How to install AAVs correctly

35 The Fix: Controlling Legionella

Approved Code of Practice L8 and water regulation compliance

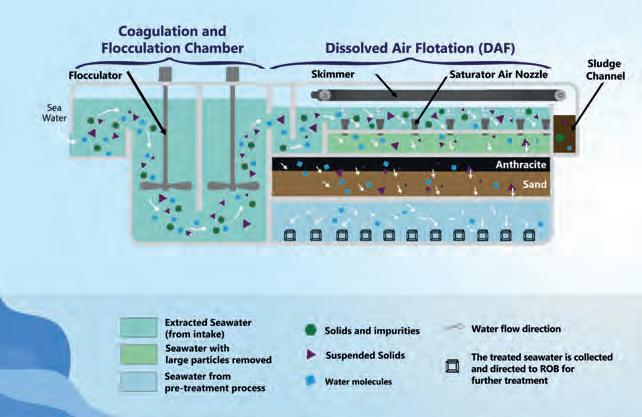

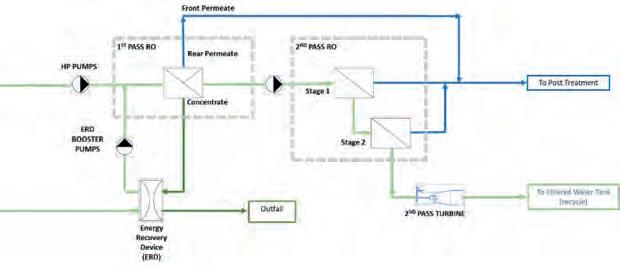

38 Water security in Hong Kong

The lowdown on a new desalination plant

42 Membership survey

We learn how to support you better

45 Products

Innovations big and small

46 Wellbeing

Managing the risks of working at height

and a licensed member of the Engineering Council. Subscriptions P&H Engineering is the magazine for the Chartered Institute of Plumbing and Heating Engineering, containing technical articles, latest industry news and environmental and educational updates.

It is published four times a year and sent free to members.

Annual subscription for non-member £80

Annual subscription for overseas non-member £100 To join CIPHE, email tims@ciphe.org.uk

KEVIN WELLMAN

Chief executive officer

kevinw@ciphe.org.uk

To enrol for our low-temperature heating course, scan this QR code:

• Enter your postcode

• Select Renewables Sector

• Select LCL Awards Level 3 Award in Low Temperature Heating and Hot Water Systems in Dwellings

Members get the accompanying training guide at a discounted price and a voucher for a reduction in your next membership renewal. Call 01708 463 116 for more information.

“Work

The level of industry support demonstrates that new Standards are long overdue, says Kevin Wellman

FOLLOWERS OF SOCIAL media will be aware that CIPHE has been asked to develop Domestic Plumber Level 2 & 3 Apprenticeships. Since the announcement there has been considerable interest and support for a new Standard.

We have created an extensive Plumbing Employers’ Group and their contribution so far has been immense. A formal application to develop the apprenticeships has been submitted to IfATE, which is to be renamed Skills England. What happens next through IfATE's response will determine the way forward. If their feedback is positive the PEG will formally submit the Level 2 and Level 3 End Point Assessment Plans. Further refinement might be required so the process could take some time.

In due course, and in the event that the Standards are approved, we will liaise with awarding organisations that wish to support the new apprenticeship.

Having also established a College/ Approved Training Centre Engagement Group we will keep training providers up to date with progress. It is not appropriate to discuss timescales at this stage as everything submitted to Skills England is subject to review and change.

Drainage misconnections

Through ConnectRight, water companies have reiterated their concerns about drainage misconnections (cross connections). Whilst this is not a recent problem anecdotally, it seems that such issues are on the increase. CIPHE will do what it can to raise awareness of misconnections and give guidance on how to avoid them. If you have details of issues you have rectified, please let the technical team know. Other dialogue with

water companies and Defra continues to raise concerns about water leakage through leaky loos. Once again, if you have examples of cisterns you have fixed, please contact jerryw@ciphe.org.uk

All information you send will help in our ongoing discussions with government. I would like to take this opportunity to thank those Industrial Associates who have been helping the development of a 3D learning environment for colleges. We anticipate it being available for the new college year in September and it will hopefully be the first in a series of tools available to Approved Training Centres.

There has been an increase in inquiries from members wanting to learn more about Competent Person Schemes and more government departments seem to be looking at introducing schemes. The Building Safety Regulator approached the CIPHE last year to assist with the development of Mandatory Technical Competences which will undoubtedly feature in future training. If you have an interest in Competent Person Schemes or are planning on joining one in the future, please let me know by emailing kevinw@ciphe.org.uk. I have mentioned previously that there is increasing interest within government to mandate plumbing and heating related issues including the water label and low temperature training. We wait with baited breath to see what the future impact will be on our industry.

The government must ensure new Growth and Skills Levy is e ective, says UVAC

ACCORDING TO A survey conducted by the University Vocational Awards Council (UVAC), 88% of the UK’s top universities believe that higher and degree apprenticeships hold the key to driving economic growth and addressing the talent needs across the engineering sector.

Those surveyed believe Labour should continue the progress made across higher and degree apprenticeships under the previous government, with 84% urging Labour to support their continued growth.

From a financial perspective, 64% believe the new government should commit to helping universities meet the cost challenges of delivering higher and degree apprenticeships in partnership with engineering employers and help them diversify their provision to meet the needs of more business sectors.

With attention now fixed on how engineering companies will contribute to funding apprenticeships, the research

explored the impact Labour’s Growth and Skills Levy will have when it replaces the Conservative’s Apprenticeship Levy, which is financed by a 0.5% compulsory contribution by employers with payroll costs of over £3m.

Despite being met with concerns, especially from levy-paying organisations, and regarded as another form of business taxation, 60% of universities felt the Apprenticeship Levy better supported the delivery of apprenticeships across all levels, ages and occupations when compared to Labour’s new funding solution. However, in a boost to engineering firms paying the current levy, 28% felt that apprenticeship provision for 16-18-year-olds should be paid for by general taxation in same way as A levels, T levels and Applied Generals.

Over three-quarters (77%) of respondents are concerned that Labour’s Growth and Skills Levy could allow engineering employers to spend

up to 50% of their payments on non-apprenticeship training, which could hinder the volume of top talent entering the sector via apprenticeships.

Those in favour of the creation of the future Growth and Skills Levy believe it will drive improvements within the sector, with 45% believing it will o er a fairer apprenticeship deal to both large and small employers. Around a third (32%) feel it will provide more funding to higher and degree apprenticeships than the previous government and 36% believe it will increase social mobility in relation to apprenticeship delivery.

Dr Mandy Crawford-Lee, chief executive for UVAC, commented: “Given that there is still some uncertainty around Labour’s skills policy and how it will meet its manifesto pledges, we were keen to gauge the mood of universities delivering higher and degree apprenticeships in partnership with engineering employers of all sizes.

“Our members clearly feel it’s vital that Labour continues to safeguard the future of apprenticeships and make them available to people of all ages and across all qualification and skill levels, so that a change in government doesn’t stifle their growth. Any risk to the funding of higher and degree apprenticeships seems unthinkable when you consider how critical they are to promoting social inclusion, bolstering the wider UK economy and addressing the skills gap across the engineering sector.

“Our survey is a real eye-opener into what the higher and degree apprenticeship landscape could look like under the newly elected government and we’d urge Labour to take on board our findings and the views of both universities and employers responsible for their provision.”

To find out more information on how UVAC is helping universities and employers support the delivery of higher and degree apprenticeships, please visit www.uvac.ac.uk

SNIPEF HAS CALLED for more industry-informed and less publicity-driven environmental targets as Scottish 2030 ambitions have been ‘predictably’ abandoned.

In response to the Scottish Government’s decision to abandon its 2030 greenhouse gas emissions targets, Fiona Hodgson, chief executive of the Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF), has called for a comprehensive reset of policy, engagement, and targets.

Hodgson commented: “The 2030 targets, which always seemed more driven by the pursuit of headlines than establishing a meaningful, step-by-step roadmap towards the 2045 climate goals, were sadly and predictably abandoned due to their unrealistic ambitions and the lack of a realistic plan to support them.

“This approach has inevitably led to their failure and fostered uncertainty among businesses and the public about the feasibility of future targets.”

Moving forward, Hodgson urges the government to pause and reset, adopting a more inclusive approach by incorporating all relevant stakeholders, including industry experts and community representatives, from the beginning of the planning process.

“To prevent further setbacks and foster an investment-friendly environment, the government must systematically overhaul the target-setting process.”

Hodgson highlighted the need for future targets to be based on detailed, sector-specific knowledge that addresses practical realities, including the necessary infrastructure from power generation to consumption. She added: “These targets should not be arbitrary or merely top-down, reverse-engineered mandates but should be collaboratively developed, realistic, and achievable objectives with clear steps and milestones.”

Key points of advocacy

• Inclusive planning: Engage a broad spectrum of stakeholders in the planning process to ensure comprehensive and viable target-setting.

• Practical targets: Develop sector-specific targets, informed by industry knowledge and infrastructural capacities, to enhance feasibility and public trust in climate initiatives.

• Sustained collaboration: Foster ongoing cooperation between the government, industries, and communities to maintain momentum towards the 2045 net-zero goal.

Reaffirming SNIPEF’s commitment to Scotland’s environmental aims, Hodgson said: “We remain committed to advancing low-carbon heating solutions. Through thoughtful planning, robust collaboration, and consistent government support, we are confident that strides can be made towards the 2045 net-zero target.”

New government policies, which include the Warm Home Discount Scheme, herald a green revolution in the heating and cooling industry, according to Dimplex. The scheme offers a one-off £150 discount on residents’ electricity bills.

Shaun Hurworth, marketing director at Dimplex UK, said: “We are encouraged by Labour’s pledges to invest in renewable energy infrastructure and incentives for businesses and households to adopt net-zero technologies. Dimplex has a long-standing dedication to innovation in this area, and advanced heat pump systems, storage heaters and smart home solutions have a major role to play in enabling the energy transition whilst reducing energy consumption and costs to consumers.

“However, the industry needs clarity and consistency in policy to help maximise the benefits. In particular, Dimplex would call on the new government to implement their Warm Homes Plan and create demand for clean heating, close the spark gap and make the lowest carbon energy the cheapest energy, and recognise thermal storage as an energy-saving material for reduced VAT.”

The Kick the Carbon sustainability campaign, rolled out by Grant UK and Bath Rugby, has been well received by local primary schools. In spring, 10 schools were visited and hundreds of children enjoyed the sessions, which aimed to educate them about the environment.

At the beginning of the 2023/24 season, Grant UK became the O cial Sustainability and Grassroots Partner of Bath Rugby, a Premiership team. Grant UK is supporting the club as it reduces its own carbon footprint and is also working to raise awareness about sustainability in the local community. This has included the rollout of its Kick the Carbon Grassroots Community Sustainability Programme.

One teacher said: “The Year 4 children really enjoyed the time they spent with the Bath Rugby visitors. The knowledge the children gained about sustainability, and then also having a chance to play some sport, was a wonderful experience for them. The children took lots away from it all and for that we are really grateful.”

ASHLEIGH STENT was crowned champion in TG Lynes’ Plumbing HERoes competition and is now in the process of enrolling onto the City and Guilds NVQ Level 2 Domestic Plumbing and Heating course with training provider Choice Training.

The course is worth more than £3,000 and the tool bundle a further £600.

TG Lynes launched Plumbing HERoes to help encourage more women into the trade, which is still heavily male dominated.

Ashleigh was selected as the winner by a team of judges from a clutch of entries.

Ashleigh said: “I am absolutely over the moon to win Plumbing HERoes. It’s a huge opportunity for me to take the next step in my career. This prize will allow me to develop my skills further and obtain the NVQ qualification I need to get out there and launch my career as a residential plumber. It’s so exciting!”

Andrew Ingram, managing director at TG Lynes, said: “Plumbing is still an overwhelmingly male-dominated profession, with latest statistics showing less than 3% of the workforce are women. We want to encourage more women to consider a career on the tools, which can be very rewarding and fulfilling.”

NIBE’s S1256 Ground Source Heat Pump (GSHP) has been awarded ‘Physical Technology of the Year – Heating and Cooling’ at the Energy Awards 2024, which took place on 3 July at Grosvenor House, London. The award recognises NIBE’s e orts to drive energy e ciency in building services with innovative developments that enhance performance, control and user convenience.

Commenting on the winning technology, judges commended the integration of sustainability throughout the design, minimising embodied

emissions and environmental impacts, alongside a user-friendly cloud-based platform to enable the transition to decarbonised domestic heating.

Paul Smith, managing director of NIBE Energy Systems, said: “We are delighted to receive this award, which recognises NIBE’s commitment to pushing the boundaries of energy e ciency and sustainability in heating. The NIBE S1256 exemplifies our dedication to innovation and environmental stewardship, o ering homeowners a high-performance, low-impact heating solution.”

The Unified Water Label Association visited Bolton College in July to introduce the plumbing students to the Unified Water Label. The visit was supported by McAlpine Plumbing Products who provided donations to the college. Plumbing tutor Ian Hall said, “It is important that we drive forward awareness of water conservation via our plumbing students who can take the message out into the workplace.”

Freedom Heat Pumps and Baxi are forging a new partnership, combining Freedom’s market expertise with Baxi’s heat pump range and award winning customer service and support network.

Chris Higgs, managing director of Freedom Heat Pumps, said “We’re excited to support Baxi’s growth in this increasingly important part of the industry.”

Grant UK has maintained carbon neutral status in line with PAS 2060 for the third year running. In 2023, Grant UK reduced its scope 1 and 2 emissions by further adapting its day-to-day operations.

KENSA’S ‘GAME-CHANGING’ compact ground source heat pump, the Shoebox NX, which was designed to deliver networked heat Pumps to the mass market, has become the latest award-winning product from Kensa after it was named Product Innovation of the Year at the 2024 Unlock Net Zero Awards in June.

Launched in February this year, Kensa’s Shoebox NX is five times more e cient than a gas boiler and is the latest small heat pump innovation from

the Cornwall-based manufacturer. It stood out against other innovative nominated products from across the housing sector, impressing the Unlock Net Zero Awards judges.

Small enough to fit in a cupboard and capable of heating anything from a high-rise flat to a five-bed home, the NX was designed with Kensa’s low-cost, low-carbon networked heat pump approach in mind. This system replicates the gas network model to present a viable mass-scale solution to decarbonise heat for over 60% of UK homes.

Commenting on their decision, the Unlock Net Zero Awards judges said: “Kensa’s Shoebox NX ground source heat pump is a highly innovative product that addresses multiple challenges facing the UK housing sector, from energy e ciency and decarbonisation to fuel poverty and climate resilience. A comprehensive approach to solving complex energy and environmental issues.”

Daikin’s Altherma hybrid heat pump can now be installed under the government’s ECO4 scheme. Hybrid heat pumps have been an eligible heating solution since August 2023.

When installed along with insulation and solar PV, the combination of measures with a Daikin Altherma hybrid heat pump exceeds the minimum ECO4 requirements for most types of solid and cavity wall properties, achieving a high SAP band B score. This qualifies for the maximum possible ECO4 grant.

Hamid Salimi, Daikin’s residential product manager, said, “Under the ECO4 scheme, MCS installers can install energy e ciency measures in their customers’ homes at almost no cost – making their homes more

energy e cient, lowering their carbon emissions, and saving them money on their energy bills.”

To meet the requirements of the ECO4 scheme, Daikin’s Hybrid Monobloc EJHA04AV3 must be installed alongside Daikin’s gas boiler EHY2KOMB28/32A. The monobloc and boiler cannot be combined with any other products.

THE VIESSMANN Academy, the training centre of Telford-headquartered Viessmann Climate Solutions UK, has partnered with Shrewsbury Colleges Group to o er a BPEC Level 3 Award in Installation and Maintenance of Air Source Heat Pumps.

The partnership has been developed to o er Viessmann installers a qualification route for heat pumps and to help increase the number of qualified heat pump installers in the region, to meet growing market demand. The formal heat pump qualification is designed for experienced heating engineers who are ready to transition from fitting oil and gas heating products to renewable systems in domestic and commercial settings.

The BPEC Level 3 Award enables installers to meet the training entry requirements for the Microgeneration Certification Scheme (MCS) or to join the Viessmann Access umbrella scheme, both of which allow homeowners to claim the government’s Boiler Upgrade Scheme grant of £7,500 towards the

cost of their heat pump installation. Darren McMahon, marketing director of Viessmann Climate Solutions UK, said: “Heat pumps are a key technology to help us reach net zero, yet just a fraction of the heating industry is currently trained to install them. We look forward to working together with Shrewsbury Colleges Group to empower the next generation of heating engineers to make a di erence.”

This three-day accredited course is delivered by Shrewsbury College lecturers at the Viessmann Academy in Telford. The cost of £449 includes three nights’ hotel accommodation with breakfast, followed by lunch and refreshments at the Academy. Attendees will be taught how to specify, survey, design and install air source heat pump systems up to 16 kW, enlisting manufacturers’ support where required.

Applicants must have the following qualifications: WRAS Water Regulations and Level 2 or Level 3 in Plumbing, Heating/ Ventilation, Gas or Oil certificates or have a minimum of three years’ experience of installing wet central heating systems.

Ideal Heating Commercial apprentice Emily Wright has won the prestigious Industrial and Commercial Heating Equipment Association ICOM Apprentice of the Year Award 2024. This is the second consecutive year the award has been handed to an Ideal Heating apprentice.

Emily is currently three years into an Engineering Design and Draughtsperson Apprenticeship Standard (NVQ), which she is undertaking alongside a Higher National Certificate (HNC) Level 4 in Mechanical Engineering.

“Engineering had never been a suggested option to me,” says Emily, “and I had no idea how broad the industry was. After researching into di erent engineering job roles and the variety of engineering fields, I developed an interest in the innovative and ever-evolving nature of design engineering.”

Commenting on Emily’s award win, Ideal Heating senior design engineer Chris Roberts said: “Emily thoroughly deserves this award not only due to her work ethic and her inquisitive attitude towards engineering and learning, but she has been a true pleasure to mentor.”

AFTER BEING named as the winners at JTL’s Regional Awards earlier this year, Edward Barber, Dammy Ajibade and Chris Lintern went on to compete against eight other regional electrical and MES winners at JTL’s annual apprentice awards ceremony.

Yeovil-based Chris, who completed his apprenticeship at Spectrum Electrical Group was named the winner of the JTL National Apprentice of the Year Award for 2024. While London-based Dammy, who completed his apprenticeship while working for T Clarke Plc., and Sutton Coldfield-based Edward, who works for Sandwell Metropolitan Borough Council, were named the national winners of the Paul McNaughton National Electrical and Mechanical Engineering Services (MES) Apprentice of the Year awards respectively.

As the recipient of JTL’s National Apprentice of the Year Award 2024, Chris was presented with a cheque for £1,500 from JTL. Edward, meanwhile, received a

£500 voucher donated by award sponsor UK Plumbing Supplies Ltd, while Dammy’s prize was a Megger multi-function tester worth over £1,000, donated by award sponsor Edmundson Electrical. All three also received engraved glass trophies.

Chris Claydon, chief executive at JTL, said: “Our National Awards celebrate the hard work and achievements of our apprentices throughout their qualification, along with the dedication of those who have supported them, such as our training officers and the employers we partner with.

“It has been a pleasure to learn more about Edward, Dammy, and Chris’ journeys, along with the other finalists. These awards are very well deserved by all three individuals, and I wish them all the best in their careers following this milestone.”

The eight student plumbers who scored most highly across the SkillPLUMB 2024 national qualifying heats have been named:

• David Bateman-Smith – South West College NI / Ashley McFarland Plumbing & Heating

• Dillon Newton – Cornwall College / Justin Eyre Plumbing & Heating

• Elliot Julian – a full-time student at Cornwall College

• Jack Fenton – Belfast Metropolitan College / Ian Reid Heating

• Jackson Gill – New College Durham / CGE Yorkshire Ltd

• Samuel Page – Suffolk New College /

According to Confused.com, air source and ground source heat pumps have been installed in less than 5% of newly built homes in the last five years. With a ban on new builds having gas boilers installed imminent, the Confused.com energy experts thought it was important to highlight how heat pumps are still not commonplace. New homes in England and Wales built with heat pumps from 2019 to 2023:

Whitwell Services

• Shaun Wilcox – Moray College UHI / Moray Council

• Shay Ewing – Moray College UHI / Andrew Barclay Plumbing & Heating

They have all been invited to go head-to-head at the UK SkillPLUMB final on 20 and 21 November at Oldham College. In total, around 50 WorldSkills UK National Finals will be taking place that week at nine different venues across Greater Manchester.

For more information on the competition visit www.bpec.org.uk/skillplumb

I decided to go into the plumbing and heating industry because it covers diverse subjects, which means I won’t get bored”

In her short time in the plumbing and heating industry, Daisy Turner has won numerous accolades for her hard work and determination, making her a valuable member of the P&H community

DAISY TURNER, trainee member of the CIPHE, decided to do an NVQ Level 2 diploma in Plumbing and Heating in 2018/19, which she funded privately in the hope that it would help her to gain an apprenticeship within the plumbing and heating industry.

“I’ve always liked the idea of being hands on,” says Daisy. “An o ce job just wouldn’t suit me. Being able to use practical skills and achieve job satisfaction is what matters most to me.”

Daisy o cially entered the plumbing and heating industry as an apprentice with Toucan Heating & Plumbing in 2020, aged 20. The following September, she started the NVQ Level 3 in Plumbing and Heating, with a gas pathway, at Barking & Dagenham College.

“I decided to go into the heating and plumbing industry because it covers diverse subjects, which means I won’t get bored doing the same thing every day,” explains Daisy.

“Although my Level 2 qualification didn’t directly lead to me finding an apprenticeship, it did help me

to settle in, as I had previous knowledge and experience that I could apply to my new role.

“I currently work in all areas of plumbing and heating, including bathroom refurbishments, heating system upgrades and maintenance.”

High achiever

Daisy likes to keep busy and her numerous accolades, which include winning HIP Magazine’s Learner of the Year and its Female Skills Competition, are testament to her dedication to the plumbing and heating industry.

“To win both HIP Learner of the Year and the Female Skills Competition is insane, it’s an incredible achievement,” she told WaterSafe, which, along with the CIPHE, is a sponsor of the HIP Learner of the Year competition. “It’s rewarding to know my hard work has paid o . It’s not just the competition days, but the lead-up to it, with extra hours spent at college practising techniques.

“The key thing I’ve gained from the competition is confidence in my abilities. Initially, the tasks felt

DAISY TURNER, TRAINEE MEMBER OF THE CIPHE is a multi-awardwinning apprentice who is currently in her third year at college, working towards her Level 3 Plumbing, Water Regs Certificate, Unvented Water Ticket and Gas Certificate.

“Being able to tell other tradespeople and customers that I won these competitions gives them confidence in me”

overwhelming but when I got stuck in, I was in the zone. I always say, as long as you do your best you can’t go wrong, and that was certainly my experience. It’s reassured my employer that I’m capable and that allowing me the time o to compete is worthwhile as it has helped to boost my skills.

“Being able to tell other tradespeople and customers that I won these competitions gives them confidence in me and means they don’t just see me as an apprentice.”

Team player

Daisy became a member of the CIPHE through the Professional Plumbing Development Scheme (PPDS). The PPDS, which started in January 2024, is a joint scheme delivered by the CIPHE and The Worshipful Company of Plumbers for the early-career development of talent in the plumbing and heating sector.

“I hold a trainee membership which gives me access to a range of resources, including contacts for help with problems,” explains Daisy. “I’ll be honest; I am yet to use them as I have the support I need from my employer, but it’s more that I know it’s there if I need it. Customers often look for tradespeople who are accredited to an awarding body and/or belong to an institution as it gives them faith in the tradespeople they are trusting to carry out projects.

“Plumbing and heating is such a diverse subject. There are many di erent paths you can go down, whether you choose to be competent in all aspects or specialise in a particular area depending on your interests and skillset.

“People really can make a unique business under the umbrella of plumbing.”

• Second place in Lewisham College International Women’s Day Competition 2022.

• First place in Lewisham College International Women’s Day Competition 2023.

• One of six winners of The Worshipful Company of Plumbers’ bursary award.

• First place in Lewisham College International Women’s Day Competition 2024.

• First place in HIP Learner of the Year South East regional competition 2024.

• Second place in HIP Female Skills South East regional competition 2024.

Current endeavours

• First place in HIP Learner of the Year final 2024.

• First place in HIP Female Skills final 2024.

• Apprentice of the month award in February 2024 at Barking & Dagenham College.

• Currently competing in WorldSkills 2024.

• Placed third in the South East regional for SkillPLUMB in June 2024 and is in reserve for the nationals in November.

• Apprentice learner of the year 2024 at Barking & Dagenham College.

Daisy is currently in her third year at college working towards her NVQ Level 3 Plumbing, Water Regs Certificate, Unvented Water Ticket and Gas Certificate.

“Gaining a gas qualification will widen my knowledge and job prospects,” asserts Daisy. “There’s no doubt renewables are coming into the industry at full force but, realistically, the thousands of pre-existing gas appliances mean there’s no way you could disregard the gas side of the industry.

“My employer is very supportive of all its employees gaining qualifications in subjects they’re interested in. If we are willing to apply ourselves and show dedication, they are more than happy for us to do the training.”

Protecting clean, safe water supplies is a key part of installers’ roles

In developed countries like the UK and Ireland, where there is ready access to clean and safe drinking water, public health water safety issues are predominantly caused by the presence of microbiological organisms and the relationship this has with the built environment and end users.

“The core water safety issues are all related around the risk of contamination such as bacterial or chemical,” says Dennis Coates, Master Plumber, FCIPHE, from DC Plumbing. “This is often caused by incorrectly installed appliances and fittings, but could also simply be due to issues such as stagnation from outlets not being used on a water system.”

Mitigating the risks

To minimise the risk of drinking unsafe water to public health, it’s vital that there are processes in place to prevent contamination, such as a multiplebarrier approach, to ensure safety if one measure fails.

“From a public health and safety perspective, in relation to microbiological risk, there are several ways to reduce the risk, usually by controlling exposure risk or by managing the environment to reduce proliferation of bacteria within the water environment,” says Bryan Hill, FCIPHE, director and authorising engineer (water and infection control) with WIPC Consultancy and principal engineer (water) for ISSUK&I. According to Hill, the most common risk mitigation method for reducing microbiological proliferation is to maintain the water environment in a manner that prevents growth. Regulatory guidance currently states that ensuring water is stored and distributed at certain temperatures may reduce this risk.

“There is excellent guidance and regulations in the UK on how to reduce and mitigate risks,” adds Coates. “My first go-to would always be Water Regulations and the Approved Code of Practice L8. Installation and maintenance of plumbing systems complying with these documents do a great job of reducing most risks to water systems. Installers of appliances and fittings should check whether the product has been approved under regulation 4 of the Water Regulations and ensure any installation requirements listed on the approval are

“There is excellent guidance and regulations in the UK on how to reduce and mitigate risks”

considered and followed carefully.”

In addition to temperature control, chemical dosing is a secondary control option that introduces a low concentration of biocide. However, careful consideration must be taken when choosing a chemical to ensure it can be used safely with the materials of construction and the drinking water limits.

“The importance of management and governance systems cannot be understated in terms of mitigating risks,” says Hill. “The use of water safety plans and safe systems of work is paramount, including clear procedures, competence requirements, engineering requirements and incident and emergency plans.”

Public health training

Problems often arise in public health engineering due to lack of awareness and therefore the absence of knowledge of how to control the risks. As part of the overall governance arrangements for water risk, competence plays a vital part in minimising those risks.

“Any form of upskilling or training that allows an individual to understand their responsibilities and undertake their duties is welcomed, regardless of what form of upskilling that takes,” says Hill.

“Many of the courses available today are simply related to sanitation and water supply in developing economies, usually with a focus on policy-making or looking at population growth and urbanisation. The public health competence shortfall should also look at the relationship between built urban environments in developed economies and the water risk, including clinical areas.”

There are courses available that offer training in specialist water hygiene from awareness courses right up to management of complex and high-risk systems. These are often City and Guilds Accredited and also delivered by experts

in the industry. There are also courses such as Water Regulations training that all work to increase awareness to installers.

“Water safety should be a core driver of apprenticeships; plumbers are often unaware how much of an impact they can have on water safety, from selecting the correct fittings and installing them correctly, to something as simple as good personal hygiene and keeping tools clean,” says Coats. “Once bacteria has entered the system it is often difficult to eradicate.”

Creating more apprenticeships in the area of public health and water safety will not only ensure public health, but create more opportunities and career paths within the industry.

Part L states that in new builds the wet heating system should be designed to provide an operating maximum flow temperature of 55°C. The provision of hot water to assets that could provide an aerosol would not normally be affected by this change unless it is a hot water storage system that used an indirect heating coil or similar from the boiler. In that instance, where the heating coil from the boiler with a flow rate of up to 55°C is used to heat up stored water in a cylinder, the stored water would be stored below the minimal required temperature you would expect from the workplace guidance.

“It would be difficult to determine if changes in the regulations will show an increase in an uptake of infection from waterborne pathogens without relevant data,” admits Hill.

For many years now, temperature has been the primary control for reducing the risk of bacteria such as Legionella. If the right conditions are provided for bacteria, such as a temperature above 20°C and below 50°C and stagnation of water, then bacteria can multiply to dangerous levels.

“Most low-temperature heating systems are unable to regularly provide temperatures above the required 50°C and could mean an increase in waterborne problems,” points out Coates. “However, if all taps and other outlets are regularly used and the system completes a thermal disinfection regularly then the risk could be minimal.”

Healthcare issues

Pseudomonas aeruginosa is a group of bacteria that commonly inhabits soil, water, and vegetation. Although this microorganism is found in the environment it usually poses no harm to humans. However, it can cause infections that are tough to treat.

“Pseudomonas aeruginosa is normally associated with closed systems, but can also be present in domestic hot and cold-water systems,” says Martin Shouler, FCIPHE, associate director at Arup. “It can prove particularly dangerous to vulnerable communities that includes immuno-suppressed and/or those who have undergone surgery.”

These bacteria can also be found amongst the normal flora in the human gut and selected out by antibiotics that are not active against it, and therefore, there can be infection from a patient’s own flora as well as from environmental sources such as water taps and drainage assets.

“This is why particular attention has been raised for several years now within healthcare,” explains Coates. “The bacteria often find its way into water systems through several routes such as during installation and maintenance work, cleaning of outlets with a cloth that is contaminated or even something as simple as touching the outlet with unclean hands.”

Once the bacteria have entered a water system, it can be very difficult to eradicate as it is adept at tolerating a wide range of environments by forming a protective mucus, called biofilm, that adheres it to pipework’s internal surfaces, protecting it from temperature changes and even chemicals.

“Eradication is, perhaps, a strong word — the most appropriate control strategies include patient environment standards, such as handwash basin and drainage design, the removal or design of complex water fittings such as manifolds and Thermostatic mixing valves (TMVs), water quality considerations, clinical risk assessments and cleanliness,” says Hill.

There has been much debate surrounding TMVs as they can be difficult to maintain and can provide optimal temperatures for bacteria to form as they are neither hot or cold.

“In healthcare there are very high standards for the operational requirements of TMVs and if installed, commissioned and maintained correctly they are unlikely to fail,” says Coates. “However, I am in agreement that they should be removed where not deemed as absolutely essential. This should be decided by completion of an accurate scald risk assessment.”

Ideally, the use of a mechanical device to prevent scalding should only be used in specific environments, like hospitals or care homes where the end user cannot detect thermal changes in water.

“A consideration for the installation of TMVs is that they create a cold-water dead leg in the piping system through operation depending on usage,” suggests Hill. “Additionally, there is some evidence to suggest the more complex a water fitting, the higher the likelihood of biofilm establishment.”

The Health and Safety Executive’s guidance states that TMVs need to be risk assessed to determine if they are required. If they are not required then they should be removed:

“Public health engineering awareness should be mandatory for those working with plumbing systems, and a level of awareness should be required by all who may impact public health,” says Coates.

“The guidance documents for healthcare water systems, HTM 04-01 suggests that all plumbers should be WaterSafe registered and this is a great starting point.”

Members can purchase the CIPHE’s guide to assessing Legionella risk in domestic properties, and the Safe Water Guide: Scald Prevention and Legionella, for a special rate. Visit ciphe.org.uk/public/plumbinghealth-hazards/legionnaires-disease/

To find out more about the control of Legionella bacteria in hot and cold water systems, visit hse.gov.uk/pubns/books/ hsg274.htm

Find out about City and Guilds Water Regulations & Unvented Hot Water Systems qualifications at bit.ly/4dHUwmX

Learn about WaterSafe accreditation at watersafe.org.uk

The industry is calling on installers to promote water e ciency as a top priority

Water is a precious resource that often gets taken for granted. However, increasingly erratic weather patterns, combined with population growth and changes in lifestyle, have led to growing pressure being put on our water supplies. Waterwise, which campaigns on water e ciency in the UK, predicts that if action isn’t taken now, by 2050 there will be a shortfall of nearly 5 billion litres of water per day between the sustainable water supplies available and the expected demand.

Showers, toilets, baths and bathroom sinks consume more than two-thirds (68%) of household water, so installers are in the ultimate position to help highlight the importance of reducing consumption and to recommend water-e cient products to their customers.

“It’s safe to say that conscious consumption is rising up the list of priorities for both homeowners and housebuilders across the country,” says Daniel Lintell, sustainability manager at Triton Showers. “With more homeowners seeking money-saving aspects in their everyday lives, there is undoubtedly an increased focus on bathroom products with built-in water- and energy-saving elements, for instance those that allow consumers to shower with a cleaner conscience.”

Using water-e cient products isn’t just about saving water; water and energy usage are linked. It’s kinder to the environment to use e cient products, but it will save the end user money in terms of utility bills too.

“Around 18% of energy consumption in UK homes is spent heating water and about 12% of a typical gas-heated home’s heating bill is from the water for showers, baths and the hot water tap,” explains Yvonne Orgill, MD at the Unified Water Label Association (UWLA) and national President of the CIPHE. “The Unified Water Label (UWL) is influencing market transition, with

• Water conservation must be made a priority by the government.

• Water companies need to increase resources dedicated to fixing leaks and reducing waste.

• A sustained campaign should be introduced to change consumer attitudes towards water conservation and increase knowledge of schemes such as the Unified Water Label.

• The government’s support and investment should be increased in environmentally targeted projects, including conservation and harvesting of water.

“Using water-e cient products isn’t just about saving water; water and energy usage are linked”

recent statistics showing that shower heads in the highest red category are now all below 13 litres/min, when just 18 months ago this statistic would have been up to 18 litres/min. Within the tap category, 68% of taps registered fall within the lowest green band.”

According to research conducted by Triton, showering with an electric unit could save 29,000 litres of water per year compared to a mixer shower, creating the opportunity to save 300kg CO2e – the equivalent of driving 1,050 miles in a diesel hatchback.

“It’s vital that installers champion e ciency and encourage customers to cut their consumption”

“When using an electric shower, homeowners can save a considerable amount of water, all while reducing energy consumption, generating long-term financial savings in the process,” points out Lintell. “If just one per cent of UK households were to cut their daily shower time by one minute on average, this could save over 673 million litres of water, equivalent to 270 Olympic swimming pools. It could also save nearly 6.7 million kg CO2e, the equivalent of removing 3,950 cars from the UK’s roads.”

Leading the way

With forecasted rises in water bills causing concern for UK households, it’s vital that installers champion e ciency by using water-saving products and encouraging customers to cut their consumption.

“Installers promoting smart upgrades in the bathroom space, like electric showers, is crucial to both boosting e ciency in the home and providing cost-conscious end-users with the opportunity to reduce their energy bills,” says Lintell.

According to government research, over 60% of sales were influenced by the installer, placing them in a unique position to recommend products that deliver the savings consumers are looking for.

“With so many innovative products available that deliver superior performance and significant savings on both water and energy, it can be overwhelming for consumers to know which product is best for them,” says Orgill. “The UWL displays product performance, water usage, energy e ciency, and product and technical details. The QR code also gives access to more free advice and brochures. By promoting UWL products, installers can help inspire consumers to make small but significant changes to how they use water at home.”

The UWLA has released the first in a series of animated films to help installers communicate its Water Matters message to their customers.

Via the media and CIPHE communication channels, the CIPHE aims to educate the public on water sustainability and low-carbon technologies.

This short film addresses the ‘Why should I bother?’ mindset and shows installers how they can play a leading role in changing consumer behaviour and make a tangible di erence to the sustainability agenda.

“The new government has an opportunity to support the industry and the UWL, enhancing its campaign to educate consumers to help them make more informed choices,” says Orgill. “The UWLA believes that there is no requirement for a mandatory water label [in addition to the UWL], which will create confusion and extra administration and expense for many manufacturers that operate across Europe and the UK. In addition, the cost of reinventing the wheel by developing new technical criteria, testing products and setting up a whole new scheme, when this already exists via the UWL, is

More than two-thirds of a household’s water usage is from showers, toilets, baths and bathroom sinks

“It can be overwhelming for consumers to know which product is best”

not only expensive for the industry but a waste of public money.”

Given the fragility of water supplies, the concept of water neutrality on new builds is a topic that has been under much discussion. Water-neutral building refers to buildings that don’t use more water than they can produce or replenish. This is achieved through using water-e cient fixtures and appliances, rainwater harvesting, and water treatment and reuse systems.

According to research from engineering consultancy Patrick Parsons, based on feedback from 100 senior executives of UK construction firms, in 2022 there was a poor focus on water e ciency, with 35% of respondents stating that only 5% to 15% of the developments their organisations were involved in were water neutral.

However, the research showed that the importance of water neutrality was set to increase significantly, with 44% expecting between 20% and 50% of new developments to be water neutral by 2025.

For more information on Waterwise’s UK Water E ciency Strategy, visit: www.waterwise.org.uk/ strategy2030

Triton’s Energy & Water Savings Calculator o ers personalised tips and the subsequent cost savings of changing showering routines: www.tritonshowers.co.uk/ calculator/savings?

For more information about the UWLA, visit: www.uwla.eu

The UWLA’s ‘Why should I bother?’ Water Matters video can be viewed here: www.youtube.com/ watch?v=AYM361Fg1No

When asked about the role of sustainable drainage systems when it came to flood prevention, promoting biodiversity or natural habitats and preventing pollution, 46% of respondents said that they expected them to become even more important by 2025, with just 12% expecting them to decrease in importance.

YOU SAY

“Easy access to water is something we should be grateful for and understand the privilege. However, it is di cult to control something which has been such an easy and reliable resource for so long.

“Correct installations in households can improve e ciency, so make sure you’re sizing correctly. If a product is e cient, we use that as a selling point with customers. Leaks will happen, but the reaction and resolution should be immediate.

“The government should promote the need to reduce water consumption more. I don’t see any promotion on it anywhere.”

Nick Cook, MCIPHE

“Water loss is a big problem in the UK; virtually every week a local road is dug up by the water authority to repair a leak.

“Water e ciency is a more manageable issue for installers. We use water e cient products wherever possible, although we are limited by HTM compliance. However, most HTM spec appliances are relatively e cient anyway. Installers can assist consumers by recommending and fitting water-e cient products, followed by good communication and instruction on how to use and maintain their appliances. As cost is usually the main factor when deciding who gets the job, it can be di cult when competing with people who are prepared to supply the cheapest alternative in order to win the contract.

“The government could help by providing a site to which contractors and tradesmen can direct their customers for water e ciency guidelines and recommendations.”

Quinn Bytheway, MCIPHE

New CIPHE president Yvonne Orgill discusses her role supporting the organisation in maintaining and improving the health and safety of plumbing in the UK

The CIPHE’s new president, Yvonne Orgill, has accrued over 40 years’ experience in the UK bathroom industry throughout her career to date. She was CEO of the Bathroom Manufacturers Association (BMA) from 2006 to 2019, as well as an associate of the Association of Plumbing and Heating Contractors Group of Companies and the Plumbing Manufacturers Institute. Yvonne is currently MD of the Unified Water Label Association (UWLA) and a non-executive board member of the British Institute of Kitchen Bedroom & Bathroom Installation (BiKBBI). She was also the first female chairperson of the National Home Improvement Council (NHIC) and the NHIC Trustees.

“I have worked alongside the CIPHE, championing its goals, and supporting its campaigns for many years and I’m honoured to be elected as president,” says Yvonne.

“All of my roles throughout my career have been di erent, but they have given me a broad understanding of the challenges that the plumbing and heating industry faces,” she adds.

“My experience extends beyond manufacturing into marketing, training and installation, giving a wider view of the industry. This will stand me in good stead when looking at the key issues around lack of skills, professionalism and training.”

Supporting sustainability

Yvonne’s work at the UWLA focuses on driving forward change in the bathroom industry by promoting the benefits of the Unified Water Label (UWL), working with partners across Europe to improve communications and manage the technical and marketing activities of the scheme. The overall aim for the UWL is to be recognised as the

label for water across Europe, improving knowledge on water e ciency and reducing waste.

An important role for the UWLA is communicating and educating the supply chain and consumers on the importance of changing behaviours, not just selecting the right product. A series of films has recently been launched to address the ‘Why should I bother?’ mindset and show installers and retailers how they can play a major role in changing consumer behaviour and make a tangible di erence to the sustainability agenda.

“We also have a range of other helpful tools and marketing packs which includes flyers, posters, social media posts and videos, with tips and advice on how to save water in the home,” explains Yvonne.

“It is important that we drive forward awareness of water conservation as early as possible. Our work with primary schools and plumbing students enables us to promote understanding and generate a future workforce that can take the message out into the workplace, sharing knowledge and good practice with the consumer.

“I am passionate about sustainability, in particular water e ciency and training, which makes it a great honour to become president of

“We must begin with our students, the professionals of tomorrow, helping them to develop the skills to create change”

CIPHE. Having the opportunity to work together and focus on maintaining high levels of training and competency is vitally important.

“Sustainability is so important that it should be incorporated into all training. The challenge we face is that there is a huge gap between those environmentalists that are making all the noise and those working in the industry. This disconnect needs to be addressed so that the messages can be conveyed in a more meaningful way. It is a complex issue and as we become more aware of the need to repair, recycle and reuse, it becomes even more challenging. We must begin with our students, the professionals of tomorrow, helping them to understand and develop the skills to create change and a better world for all.”

During her time as CIPHE president, Yvonne hopes to help installers recognise the important role that they play in influencing the householder’s or user’s choices and providing the information and tools they require.

“Together we can drive forward standards for professional design and install infrastructure, and ensure good availability of compliant products in the marketplace,” says Yvonne. “With an understanding of the complete system, installers are qualified to advise on the best products, to ensure full e ciency and move to a greener solution.”

Yvonne wants to focus on awareness, training, products and regulation, working with the CIPHE to engage with government and address these issues.

“The CIPHE is an essential part of the industry, championing important campaigns on professional standards, improved education, and training, as well as raising awareness of airborne pathogens and hot water scalding.

“The challenges are ever present –an ageing infrastructure, climate change, skills shortages, and standards that require reviewing to capture the world of sustainability, to name a few.

“We are making progress, but bodies such as the CIPHE are vital, and working together in partnership we will meet our goals.”

Arrowfield is a low-carbon living project in Manchester where gas boilers have been replaced with air source heat pumps as part of the city’s journey to net zero

The Arrowfield low-carbon living project is a multi-million-pound retrofit of social housing heating systems, undertaken by Southway Housing Trust (SHT) – a Manchesterbased housing association that manages 6,000 local homes.

In 2022, a survey of Southway’s residents found that 88% were keen to reduce their impact on climate change, so the trust made a pledge to become zero-carbon by 2038 and identified

switching its homes from gas to electric heating as a crucial element to achieving this target.

The project, which retrofitted 233 homes with air source heat pumps, represents an ambitious retrofit of a south Manchester neighbourhood that will reduce the estate’s carbon footprint by as much as 50%. This project has contributed to the removal of 370 tonnes of CO2 a year in Arrowfield.

“Air source heat pumps are essential to SHT decarbonising our housing stock and achieving our net-zero goals,” says Matt Roberts, strategic director of property and development at Southway Housing Trust.

People power

Ahead of this ambitious project, a community engagement programme was established to spread greater awareness of heat pumps as a low-carbon heating solution. This also provided the opportunity for the trust

“Air source heat pumps are essential to SHT decarbonising”

to listen and respond to feedback from residents.

The Arrowfield Hub, located in a repurposed empty house on the estate, became a venue for regular engagement between the residents and the project team, creating an open forum for questions and comments on the proposed scheme.

The Hub was also heated by an air source heat pump, allowing residents to witness a heat pump in operation and experience for themselves the warmth of the building.

Residents were also able to express their concerns surrounding the project, which could then be addressed accordingly. SHT credits this regular and open engagement with residents as key to keeping them informed and more familiar with their proposed new heating systems.

The Hub also allowed for the project team to dispel common myths and misconceptions about air source heat pumps and reassure residents that their homes would remain warm throughout the year.

“Community engagement for the Arrowfield low-carbon living project was central to the project’s aims,” says Matt Roberts, strategic director of property and development at Southway Housing Trust.

“Foregrounding the needs of Arrowfield’s residents as central to the project’s implementation helped us to better convey the benefits of low-carbon heating and address concerns and suggestions brought forward by homes set to benefit from the retrofit scheme.”

In line with long-term government plans to electrify heat, SHT has replaced Arrowfield’s ine cient gas boilers to improve the fabric of homes and make them more energy e cient.

The scale of the project, part funded by the European Regional Development Fund (ERDF), has made it one of the UK’s biggest home retrofit schemes.

“The work at Arrowfield has cost £4.2 million, supported by £1.9 million grant funding from the European Regional Development Fund,” explains Mark Tomkinson, head of assets and sustainability at SHT. “The project has given Southway a great insight into the benefits new systems like this can bring. We will use this experience for other projects to bring similar benefits to our

tenants living in other areas.

“In addition to our investment, Electricity North West spent about £2.5 million to reinforce the network and build new substations that could support the increased demand for electricity.”

Out with the old Rothwell Plumbing Group (RPS) was chosen as the installation partner for the project, with a track record for delivering high quality heat pump systems, in both the public and private sectors. RPS are also MCS & Trustmark accredited, with the experience and technical ability to install NIBE systems to high standards.

RPS Group took charge of designing, supplying, and installing all systems including the ASHP and ambient loop systems, installing the NIBE F2040-6 and Daikin EBLA04E3V3 models to provide heating for the homes in the estate.

Southway’s aim is for the project to act as a learning process and blueprint for how it can scale up the retrofitting of its entire housing stock over the next 15 years.

“Air source heat pumps are currently the most advanced and widely adopted forms of low-carbon heating,” says Tomkinson. “The technology is so exciting because it is very simple to control for tenants, yet so advanced that when the heat pumps are used in the most efficient way, for average usage it is more affordable than

traditional gas fired central heating. We’re working with residents to ensure they can get the best out of the system.”

Air source heat pumps have been providing heat and hot water to residents across the estate, adapting to the requirements of each home. The systems will provide homes across the estate with optimised energy and cost savings, whilst supplying a supply line temperature of up to 58°C regardless of outdoor temperatures – they are designed to supply heat even if the temperature outside dropped to -20°C.

“With the newly installed low-carbon heating systems, our residents can enjoy more comfort in their homes and, for many, the new systems can help reduce their bills,” says

“The technology is so exciting because it is very simple to control for tenants”

Tomkinson. “Their homes will also be prepared for the time when the UK moves to electricity-based heating and tariffs reduce.”

The trust also reviewed and improved the loft and cavity wall insulation in every home which had a new air source heat pump fitted so that the new systems can work efficiently.

“We also want to play our part in helping to achieve ambitious local aspirations for our area to be carbon zero by 2038,” adds Tomkinson. “The new systems will reduce residents’ carbon footprints, which will obviously help achieve that goal and benefit the environment.

“We’re undertaking an assessment of the savings residents can make and are also looking at other measures to maximise the benefits residents receive from having the air source heat pumps installed. These include ways to access more affordable tariffs that energy companies are starting to offer heat pump users and remote methods of flagging maintenance requirements so they can be attended to more quickly. We will be supporting residents to ensure they can get the most out of the new heat pumps.”

Apprenticeships are the key to tackling the skills shortage, so why are there so few businesses taking on apprentices?

Despite the initial increase in apprenticeship uptake following the pandemic, the heating and plumbing sector continues to fall short of the number of people needed to plug the growing skills gap.

Last year, reports advised that there were as many as 140,000 construction and trades vacancies in the UK. A survey by the recruitment specialist Search Consultancy found that 83% of businesses in the construction industry are feeling the strain from a lack of skilled workers. Plumbers and gas engineers are among the most in-demand trades, with 11,928 and 9,873 vacancies respectively. With the UK predicted to be the fastest-growing construction market of the major Western European economies over the next 15 years, hitting £381bn revenue in 2023, the skills gap is only going to widen (Oxford Economics).

The government’s Apprenticeships Reform Programme target of three million apprenticeship starts in England (2015–2020) wasn’t met. But the Department for Education’s 2021 progress report says apprenticeships are now longer, and co-designed with employers: ‘Our reforms mean that starts now on the Apprenticeship Programme are into higher-quality training, and are ensuring that apprenticeships are right for employers and apprentices. Our achievement rate for apprenticeship standards has gone up 11.8% – 46.9% (2018/19) to 58.7% (2019/20). But there is more to do.’

The statistics highlight the real need for more apprentices to join the heating and plumbing sector, so what’s the problem?

“There is a lack of understanding around

apprenticeships – from what funding is available, to how they can benefit businesses,” says Emma Raymond, head of business development –apprenticeships, at Windsor Forest Colleges Group, a CIPHE-approved training centre. “At Langley College, our apprentices can access fantastic resources, and replicate college-learnt skills when on site. Experienced teachers/coaches who come from the industry teach them.

“One major advantage is that the skills an apprentice gains on the job are best suited to the business. They also bring a fresh perspective and willingness to learn.

“Apprentices are a great way to fill skills gaps,” says Emma. “Hiring one allows SMEs [small and medium-sized enterprises] and individual installers

“There is a lack of understanding around apprenticeships”

to access fresh talent and develop a skilled workforce. Their enthusiasm for learning and new ideas can be valuable. We provide comprehensive support to those interested in taking on an apprentice to ensure a smooth experience.”

Hiring an apprentice can be cost-e ective for businesses. They are typically paid lower wages compared to experienced workers, which makes it a sound investment.

“Businesses that invest in these programmes tend to have higher employee retention rates, as apprentices are more likely to stay with the team after training is over,” says Emma, “and so a pipeline of skilled workers for the future is developed, filling skilled positions and contributing to the business’ long-term success. Apprenticeships enable the employer to tailor the training to their specific needs, ensuring that apprentices acquire skills and knowledge directly relevant to the business’ operations and requirements.”

As of 1 April 2024, the government fully funds the training costs for those aged 16-21, so SME employers will no longer have to contribute to the cost of apprenticeship training for this age group. Once a learner is 21 or over the government will cover 95% of training costs. Other incentives include £1,000 for taking on a 16- to 18-yearold, or a 15-year-old if the apprentice’s 16th birthday is between the last Friday of June and 31 August. Training providers can help employers access this funding.

“The value of using a trusted, certified training provider can’t be understated, particularly in the context of current skills shortages as we know businesses need highly skilled workers quickly, but also safely – imperative in the industries we work in,” says Chris Claydon, chief executive at JTL. “We pride ourselves on the quality of the training we provide and employers that take on a JTL apprentice receive a dedicated training o cer to manage the process from initial appointment through to completion.”

Education providers o er support and guidance to both SMEs taking on an apprentice, as well as the apprentices. Support for employers includes assistance with recruitment and training plans throughout the apprenticeship. “Programmes for apprentices are designed to be adaptable to the needs of the employer and apprentice,” says Emma, “so the training

“Apprentices bring enthusiasm and new ideas”

can be tailored to specific industry requirements and the employer’s work schedule. There are often financial incentives and funding available to SMEs and individual installers who take on apprentices. This can help o set the costs associated with training and employing an apprentice.”

A spokesperson for R G Evans Plumbing and Heating, which has an apprentice at Langley College, comments: “Apprenticeships are vital to our industry, with a unique blend of practical experience and theoretical knowledge. For our business, it allows individuals to develop essential skills and build confidence under our experienced mentors. This ensures high-quality workmanship and nurtures a strong sense of professionalism and dedication in new plumbers and gas engineers.

“As apprentices are often enthusiastic and eager to learn, this fosters a collaborative learning environment among our seasoned professionals.

Many apprentices that we’ve worked with have become highly skilled, valued team members. Their journey from apprentice to fully qualified plumber is a testament to the robust framework of programmes. They gain a genuine understanding, and can move forward with expertise and confidence.”

FOR MORE INFORMATION ON APPRENTICESHIPS

• www.apprenticeships.gov.uk/employers

• www.jtltraining.com/apprenticeships/employers/getting-started

• www.windsor-forest.ac.uk

The training programmes at Langley College enable employers to upskill their engineers in renewable technologies

The Green Skills Academy at Langley College is offering commercial training courses for adults

The Windsor Forest Colleges Group (Langley Campus) aims to address the long-standing skills shortage in the construction sector and to train a skilled workforce in green jobs essential for retrofitting the Green Economy. The group’s Training Centre of Excellence in Slough delivers industry-relevant training in environmentally friendly energy systems, and supports collaborative work between employers and educators, to target emerging green occupations.

“In autumn 2023 we began co-designing and delivering Skills Bootcamps with Berkshire-based employers, providing them with the opportunity to upskill their plumbing and heating engineers in renewable technologies such as domestic ventilation, solar thermal hot water and heat pump systems,” explains Emma. “In addition, supplementary modules such as water regulations, energy efficiency and the safe isolation of electrical installations were included.”

Bootcamps are bespoke 60-hour training programmes, substantially funded by the Department for Education, and enable SMEs to upskill employees in Level 2/3 technical training. Modules can be designed to best suit employees’ skill sets and a minimum of 60 hours/eight full days needs to be undertaken, around work schedules, within a 16-week timeframe.

Limited SME companies are required to contribute £380 VAT exempt per candidate. Sole traders can also apply and will receive 100% funding. All candidates need to meet the entry-level, pre-requisite qualification requirements in order to be accepted as a participant.

For more information, email greenskills@ windsor-forest.ac.uk or call 01753 793244.

“It’s a really big decision as a self-employed plumber to find a wage every month with no help from the government. My apprentice is in his final year after completing three years. I wanted to give back to the industry I love, and customers really appreciate seeing a young man getting skills for life. If I did it again, the government would have to give incentives for it to really benefit small businesses, as I would not be able to a ord to pay him once he’s qualified.”

Dave Grainger MCIPHE

The BPF Pipes Group has updated its guidance on air admittance valves (AAVs). Here’s what you need to know about installing them on your jobs

The BPF Pipes Group’s guidance on air admittance valves (AAVs) has consistently been one of its most downloaded reference documents, and it has now been updated to make designing and installing AAVs even simpler.

What are AAVs?

Ventilation of soil and waste pipes is essential for any system which drains wastewater from a property to function correctly. AAVs have been in use for around 45 years but are an oftenoverlooked technology as they are out

of sight in roof voids and lofts. However, they perform a vital role in today’s homes. AAVs ventilate soil and waste pipes so that waste water drains properly from a property. Without ventilation, air pressure changes inside the pipework due to the operation of domestic appliances would cause waste traps on those appliances to lose their water seals, creating unpleasant odours. Traditionally, or at least before the 1970s, open soil stacks were positioned above the roofs of properties (often distinguished by their balloon grates or wire cages to prevent

Part of the British Plastics Federation, the BPF Pipes Group is a trade association representing manufacturers and material suppliers of plastic piping systems across the UK. Committed to sustainable construction, its aims are to provide a forum for the exchange of technical expertise between member companies and to promote the importance of plastic as a pipework material, for the full spectrum of above and below ground, pressure and non-pressure applications. It also plays a key role in initiating and disseminating research, and informing and influencing the standards bodies pertaining to plastic pipe systems. It works closely with the BPF and TEPPFA, the European Plastic Pipes and Fittings Association.

access by wildlife) but they could be damaged or accidentally covered, for example when extensions were built. AAVs, positioned inside the roof space, provide a more aesthetically attractive alternative to open stacks, while providing the same level of ventilation for the drainage system.

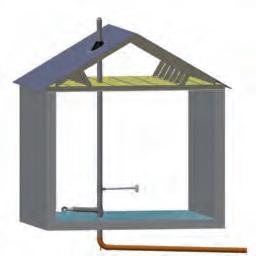

Designed to fit to a vertical pipe inside a building, the valve prevents the escape of foul air from the drainage system into habitable areas. The valve houses a seal, usually made of silicon rubber or EPDM, which lifts and falls in response to negative pressure caused by WC flushing or the draining of appliances (Figure 2). This simple mechanical principle allows air to flow into the

drainage system, thereby breaking the vacuum which would otherwise cause a siphon in the traps.

Legislation and ventilation options Building Regulations 2000 require for an adequate system of drainage to be provided to carry foul water from appliances within a building to a sewer, septic tank or cesspit.

Across the UK, Building Regulations and statutory guidance allow for both open soil pipes (stacks) or air admittance valves (Figure 1). Whereas the simplest and probably most familiar solution is an open soil pipe, it needs to terminate at least 900mm above any opening to the building, such as a window or balcony. It will also require capping with balloon grating or wire cage. AAVs are installed directly onto the soil stack, without the need to make a roof opening, which reduces both the amount of pipework needed and the amount of additional work required to ensure the roof does not leak. AAVs are normally positioned in the roof void and can provide the same ventilation capacity as an open system. They can also be situated on stub stacks from ground-floor appliances, avoiding the need for a full house height pipe.

While not permitted by statutory guidance, except in Scotland under controlled conditions, AAVs are sometimes installed on the outside of buildings to overcome problematic site solutions, such as space restrictions between the stack and a window opening, or to ventilate appliances without access

to the main soil stack, such as in a property extension.

The BPF Pipes Group guidance details the precise installation and use of AAVs under the various regulations and standards on pages 4 and 5 of its updated document for England, Wales, Scotland and Northern Ireland, as there are di erent regulations in place. It also strongly advises that compliance with BS EN 12380 is verified by a UKAS-accredited (or its equivalent) third party.

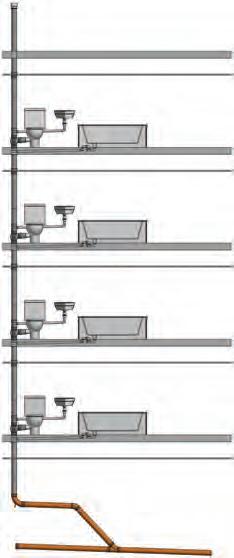

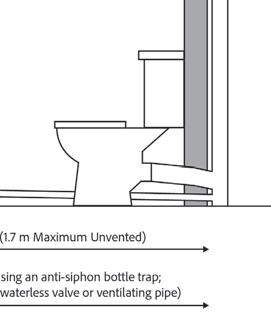

The BPF guidance contents cover how to position AAVs correctly, with new diagrams showing where they can be used alone to vent properties – or where additional ventilation may be needed in the form of open vents (traditional open soil stacks). For example, stack ventilation is achieved through two main approaches (Figure 3): primary ventilation, where pressures are controlled by air flow in the main stack, or primary and secondary ventilation, where pressures are controlled through the installation of a separate ventilating stack and/or secondary branch ventilation pipe connecting to the stack vent. Branch pipe ventilation is another option, where the air capacity in the branch pipework gives su cient protection to trap seals, controlling air pressure fluctuations without the need for additional ventilation. Examples of branch ventilation options are provided using the guidance in BS EN 120562:2000 and with clear diagrams (Figure 4) as well as examples of branch pipework with additional ventilation (Figure 5).

Within the design section of the guidance are capacity, ratings and plot drainage, illustrated in Figures 6, 7 and 8. For capacity, it is necessary to calculate the sum of the discharge units from all appliances in order to then calculate the expected flow rate of drainage water in the system, taking into account the frequency of use of the appliances. Tables and formulae can be obtained from BS EN 12056-2:2000 Section 6. The size of a primary ventilated soil stack can then be selected using the calculated

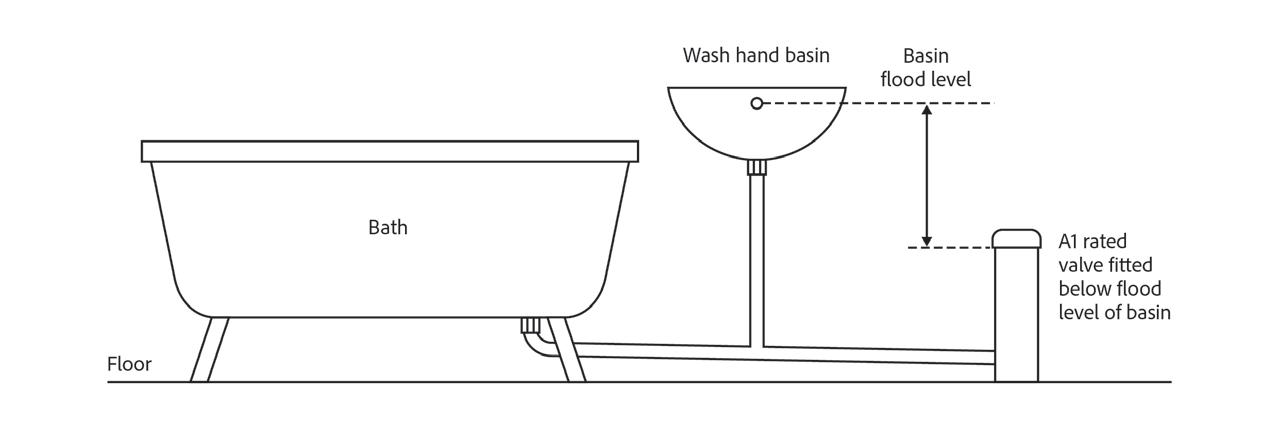

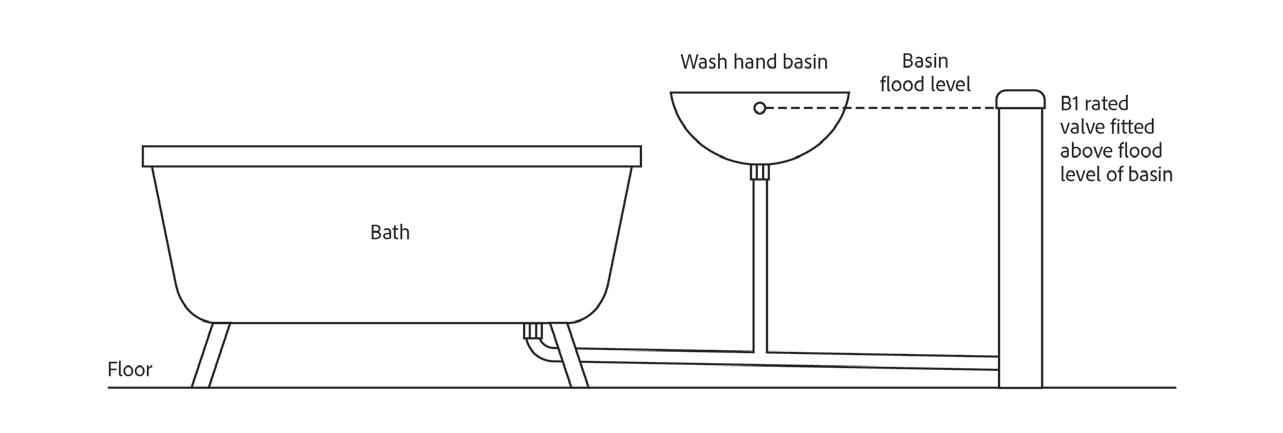

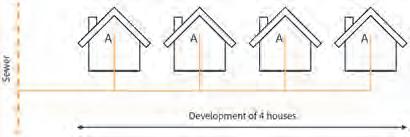

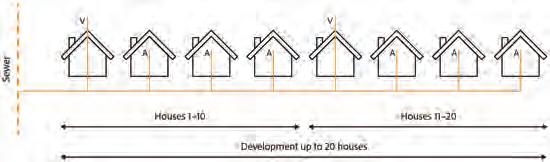

hydraulic capacity and Table 11 of BS EN 12056-2:2000.