POWERED UP Using heat batteries to make the most of energy

OFF-GRID GOES GREEN Future-proofing rural fuel sources

POWERED UP Using heat batteries to make the most of energy

OFF-GRID GOES GREEN Future-proofing rural fuel sources

HOW TREATING CUSTOMERS’ WATER CAN SAVE THEM MONEY, ENERGY AND REPAIRS

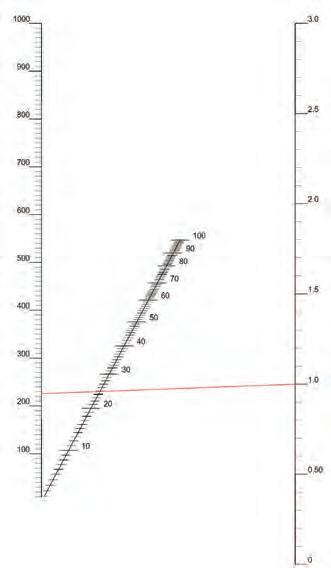

HEATING KNOW-HOW How to size an expansion vessel

HELPING GREAT BRITAIN successfully decarbonise has been a top priority for the plumbing and heating industry. With o -grid homes using fossil fuels such as coal and oil to power their heating systems, we explore sustainable alternatives (p28). With sustainable technology resulting in surplus energy, we also explore the critical role that heat batteries play in harnessing green power (p18).

As UK homeowners strive to improve the e ciency of their homes and enhance their wellbeing, there has been an increase in demand for water treatment and filtration systems. Our feature covers everything installers need to know, including the problems hard water causes, current legislation, specifications and finding solutions (p22).

Finally, it’s the InstallerSHOW in June. We take a look at what the CIPHE will be doing at this year’s event at the NEC Birmingham (p44).

SARAH WELSH Editor

pandhengineering @jamespembrokemedia.co.uk

Editor Sarah Welsh Project manager Lizzie Hufton

Design and production manager Christina Richmond

Publisher James Houston

Published by James Pembroke Media, 90 Walcot Street, Bath BA1 5BG Tel 01225 337777

Advertising sales Oliver Willison, 0203 198 3092 oliver.willison@jamespembrokemedia.co.uk

Chartered Institute of Plumbing and Heating Engineering (CIPHE) Saxon House, 27 Duke Street, Chelmsford CM1 1HT Tel 01708 472791

18 Power houses

The role of heat batteries in the home

22 Hard times

The benefits of water treatment systems

28 Missing link

Decarbonising Britain’s off-grid homes

32 Project Focus

How a rural pub became carbon neutral

5 From the CEO

Kevin Wellman on tackling water waste

6 Frontline

Energy policy, trade news and remembering a valued member of our industry

Membership Founded in 1906, the Chartered Institute of Plumbing and Heating Engineering (CIPHE) is the professional body for the UK plumbing and heating industry. Membership is made up of consultants, specifiers, designers, public health engineers, lecturers, trainers, trainees and practitioners. The CIPHE has a membership of 7,500, including over 150 manufacturers and distributors. The majority of members live in the UK, although over 1,500 are residents in Hong Kong. The CIPHE is a member of the

16 Meet the member

From the Army to a career in plumbing

36 The Fix: System efficiency

Introducing two British Standard updates

40 The Fix: Sizing an expansion vessel for a heating system

Paul Harmer offers step-by-step workings

43 Products

The latest kit for you and your customers

44 Membership

Join the CIPHE team on our stand at InstallerSHOW 2025

48 International

A collaboration across countries

50 Wellbeing

The importance of work-life balance

Construction Industry Council and a licensed member of the Engineering Council.

Subscriptions P&H Engineering is the magazine for the Chartered Institute of Plumbing and Heating Engineering, containing technical articles, latest industry news and environmental and educational updates. It is published four times a year and sent free to members.

Annual subscription for non-member £80

Annual subscription for overseas non-member £100 To join CIPHE, email tims@ciphe.org.uk

KEVIN WELLMAN Chief executive officer

kevinw@ciphe.org.uk

“Government is adamant that we must tackle

Leaky toilets equals money down the drain; tackling the skills crisis in the industry would go some way to addressing the issue, says Kevin Wellman

THE PASSING OF Geo rey

Marsh MBE at the end of last year was a sad day for the CIPHE and the wider plumbing industry. Living to the ripe age of 92, his dedication and commitment to plumbing was second to none. The obituary on page 14 provides a great tribute to Geo ’s immense achievements and his forward thinking over many decades.

In addition to his tireless e orts for the CIPHE, he was heavily involved with the Worshipful Company of Plumbers and was instrumental in the establishment of the World Plumbing Council (WPC).

I am delighted to tell you that the WPC Executive Board recently agreed to rename its Distinguished Service Award, of which Geo was the first recipient, as the Geo rey Marsh Distinguished Service Award.

Water wastage

also cost insurers, businesses and householders several millions annually.

Government undoubtedly recognises there are skills issues, and a number of departments believe competent person schemes to be the answer. This is certainly supported by the Building Safety Regulator through the development of mandatory technical competencies. If you have a view on this, please send your comments to elizabethl@ciphe.org.uk

Finally, plans are progressing with the 14th World Plumbing Conference and International Exhibition that the CIPHE is developing in collaboration with the InstallerSHOW. Nearly 20 countries have so far pledged their intention to attend the conference, which is being held at the NEC Birmingham from 23-25 July 2026.

FIND OUT MORE

Learn about the CIPHE’s aims in our latest manifesto, which you can download using the QR code above.

CIPHE’s engagement with government continues and there are increasing concerns about water leakage. I recently met with Fluidmaster, which supports government figures that state a leaky loo wastes up to 400 litres a day, and that over a year the total figure could be 146,000 litres. It estimates that the total cost of water for one leaky loo in commercial premises is £612; for domestic it is even higher at £860. Moreover, the carbon emissions for each leaky loo, regardless of whether it is commercial or domestic, is about 152kg. With water worth millions being wasted, it is no wonder that government is adamant that change must happen. In addition, there are escape-of-water problems which

The website is under development and registration costs will be announced at this year’s InstallerSHOW. Those wanting a sneak preview of the website can visit installershow.com/wpc2026

We will be talking about the conference and much more at this year’s InstallerSHOW, where we will also be hosting our Annual General Meeting (see page 44 for registration information). The Head O ce team looks forward to seeing you at both events.

The Unified Water Label Association, (UWLA) has welcomed a new managing director, following the announcement of Yvonne Orgill’s retirement. Lee Cartwright joined the UWLA on 10 March.

AS MOST MEMBERS will be aware, the CIPHE, in conjunction with the Plumbing Employer Trailblazer Group, was granted a mandate by the Institute for Apprenticeships and Technical Education (IfATE) in January of this year to develop new Level 2 and Level 3 Plumbing Apprenticeship Standards.

“Since our last update, a period of consultation has taken place, following the release of draft documents to a selection of training providers to gain feedback on the proposals,” explains Mike Maskrey, training manager at the CIPHE. “On the whole, the feedback received has been very positive and enthusiastic.

“Taking a positive step forward in the process, the CIPHE has been in meetings with the IfATE Construction and Built Environment team on a weekly basis in an attempt to finalise the content of the standards and, more specifically, the Knowledge, Skills and Behaviours for both Level 2 and 3.

“The awarding organisations and end-point assessment teams have also held meetings to discuss and refine the language and content, making these the most up-to-date and relevant Plumbing Standards yet written,” adds Maskrey. “We will, of course, continue to update CIPHE members with all the latest developments, as and when they happen.”

Cartwright said: “I am thrilled about this new role and looking forward to building on Yvonne’s legacy. During her time in the industry, Yvonne has become well recognised as a strong leader and influencer, and I am passionate about driving forward continued growth and future success for the organisation.

Orgill added: “I am delighted to welcome Lee into the UWLA and wish him every success. I know that under his leadership the UWLA will benefit from new opportunities and an exciting next chapter.”

Lee

CONCERNS HAVE BEEN raised about the slow pace of heat pump installations following the release of Freedom of Information figures. Data from the Home Energy Scotland (HES) Grant and Loan Scheme and the Private Rented Sector (PRS) Landlord Loan Scheme reveal that fewer than 9,000 heat pumps have been installed since 2019.

Fiona Hodgson, chief executive of the Scottish and NI Plumbing Employers’ Federation (SNIPEF), said: “While it is encouraging to see growing numbers of homeowners and landlords making the switch to clean heating solutions, the Scottish Government’s ambition of over a million homes converted to low- or zero-emission heat by 2030 is simply not achievable under current conditions.

“The data highlights the urgent need for clearer policy direction, greater financial certainty and stronger industry support.”

SNIPEF has also raised serious concerns over the HES scheme’s payment structure, which places a

heavy financial burden on installers. Many of them must absorb substantial upfront costs, leading to cash-flow pressures and administrative challenges that threaten business sustainability.

Hodgson added: “Installers are at the heart of Scotland’s green heating transition, but they need a stable, transparent funding framework to remain viable.

Addressing cash-flow pressures and streamlining payments is critical to scaling up heat pump adoption at the pace required.

“Today’s CBI report highlights the significant economic benefits of investing in the net-zero economy. In Scotland alone, the sector contributes £9.1 billion, 4.9% of the country’s total gross value, and supports nearly one in 25 Scottish workers.

“However, the financial strain of this transition cannot fall solely on already stretched businesses, especially as they face mounting pressures, including the upcoming National Insurance hike.”

GOVERNMENT FUNDING

Up to 170,000 homes in England could benefit from energyefficiency upgrades as the rollout of the Warm Homes Plan gathers pace, helping more families lower their bills and improve their homes.

From 11 March, £1.8 billion in government support has been allocated to local authorities and social housing providers. This funding is intended to support them to deliver warmer, more energy-efficient homes in local communities across England.

The money will be targeted towards low-income households and tenants living in social housing, with thousands of families set to receive energy-performance and clean-heating upgrades in the form of insulation, solar panels and heat pumps.

At a time when many are getting high energy bills driven by the UK’s reliance on international gas markets, this funding via the Warm Homes: Local Grant and the Warm Homes: Social Housing Fund schemes could help households save hundreds of pounds a year.

This move will help deliver a milestone of higher living standards in every part of the UK by the end of Parliament by boosting people’s Real Household Disposable Income – a key part of the Plan for Change.

Minister for Energy Consumers, Miatta Fahnbulleh, said: “Living in a warm, comfortable home should not be a luxury. It is a right that has been out of reach for too many people for too long.”

Following First Minister John Swinney’s recent comments in The Scotsman describing hydrogen for heating as a ‘really exciting opportunity’, the Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF) has called on policymakers to instead fast-track proven low-carbon options such as heat pumps, heat networks and building upgrades.

Scott Sanford, technical and skills manager at SNIPEF, said: “Extensive evidence shows that hydrogen is neither cost-effective nor efficient for domestic heating, and it remains largely untested in that context.”

Even the Climate Change Committee suggests that hydrogen’s role is primarily in industries where there are few or no alternatives.

“That leaves little room for its use in heating our homes, especially given that producing green hydrogen typically requires more renewable energy than heat pumps. Instead of diverting resources into speculative hydrogen heating schemes, we should be focusing on proven and readily deployable options.

“Homeowners, landlords and businesses need clarity and confidence about which technologies are truly safe, affordable and effective as we transition to low-carbon heating.”

NEW RESEARCH BY On The Tools reveals that UK tradespeople overwhelmingly oppose shortening apprenticeships, with 85% rejecting the idea of reducing training to eight months. A further 83% believe shorter apprenticeships would fail to prepare learners for the realities of the trade. The findings highlight a clear concern about training quality and its long-term impact on the industry.

Businesses can now decide whether adult learners need GCSEs in English and maths to complete their training. Proposed changes include reducing apprenticeship durations from 12 to eight months in certain industries. To take effect in August, pending legislation, construction may be included.

Many in the trade recognise that apprentices need time to build practical experience and confidence before

transitioning into full-time work, ensuring they can contribute effectively from day one. A rushed apprenticeship could leave new entrants lacking crucial skills, making them less employable and increasing risks on site: ultimately affecting productivity, safety and the industry’s long-term talent pipeline.

Lee Wilcox, CEO and co-founder of On The Tools, said: “The skills shortage is one of the biggest threats to the future of the UK construction industry; it’s clear the current system isn’t working as it should. While reducing entry barriers is a step in the right direction, this alone won’t solve the issue. We need to ensure that construction is seen as a desirable career, employers feel supported in hiring and training new entrants, and we explore a range of routes into the trade.”

SCHNEIDER ELECTRIC is doubling its intake of veteran talent as it looks to address the UK skills shortage, recognising the valuable transferable skills of military personnel.

Following a successful first year of the programme in 2024, in which all participants exceeded their performance targets, Schneider Electric plans to increase its intake in 2025 from six to around 13 recruits.

Schneider Electric’s Veterans Talent Programme equips people leaving the armed forces with the technical skills and industry knowledge needed for hard-to-fill operational and senior management roles in the energy management and electrical industry. Demand for skills in these areas is growing fast as the UK shifts towards cleaner energy and net-zero targets.

Early bird registration for applications is open, and Schneider

Electric is looking for potential and passion rather than technical skills. The 12- to 18-month programme, on full salary, offers veterans classroombased and on-the-job training, needing no prior technical experience.

Kelly Becker, Schneider Electric’s president, UK and Ireland, Belgium and Netherlands, said: “We are passionate about growing a diverse workforce, and veterans are no exception. Our programme not only helps us to build talent to support the green transition, but veterans also bring a wealth of skills and unmatched benefits to our company.”

THE TRADE took over London’s Parliament Square on Monday 3 February for the Stop Tool Theft Protest, and Talon showed its support too, standing shoulder to shoulder with tradespeople demanding tougher laws against van break-ins.

According to industry reports, 44,514 tool thefts were reported in 2023 – one every 12 minutes – and it’s costing tradespeople an estimated £82 million in lost jobs.

The peaceful demonstration, organised by Shoaib Awan of Trades United, brought together frustrated electricians, plumbers, carpenters and other trades, all calling on the government to introduce harsher penalties for tool theft.

Awan, a gas engineer, knows the devastating impact first-hand after thieves stole £8,500-worth of tools from his van.

“These are our o ces,” he told reporters. “We work from them. It’s no longer acceptable. They need to understand the implications – mentally

and financially – it has on us. The vans get broken into and we’re out of work because we’ve lost our tools. We’ve lost our vans.”

Talon’s Annette Murphy, aka ‘Chatty Netty’, and its social and marketing manager Mike Morris stood in solidarity with the protesters, supporting the push for real action and the message that enough is enough.

“Tool theft doesn’t just hit wallets – it destroys livelihoods,” said Morris. “Obviously it takes a huge financial toll, but it takes a huge mental toll too. Construction workers are already four times more likely to die by suicide than the national average, and the stress of losing vital equipment only adds to the pressure.

“What is really positive is that despite the tra c jams and inconvenience that the protest caused, local people – and even tourists – were incredibly supportive of the campaign.”

Check out the video on Instagram: instagram.com/p/DFxWOckN7U1/

“Ventilation installers can recommend continuous-flow fans whenever there’s a job that requires replacing an intermittent-flow fan, or an installation in a new home or for bathroom redesign projects. Continuous-flow fans can dial up and down their performance to better extract moist, stale air at all times, reducing the chance of damp and mould growth.” PUBLIC HEALTH

VENTILATION INSTALLERS and electricians are being encouraged to move away from installing intermittentflow fans, and instead fit continuous-flow fans.

The call comes from governing bodies and industry experts as the country continues to battle against damp and mould in homes.

In England, there are around two million people currently living in a property that has significant damp or

mould problems (3-4% of residences).

Elta suggests that intermittent-flow fans may be indirectly contributing to the damp and mould problem as they only work when homeowners turn them on and stale, moist air is able to build up in bathrooms, ensuites and kitchens. With homes becoming increasingly airtight, continuous-flow fans ensure stale air is extracted continuously, increasing the airflow at

times when in-built sensors detect a high level of humidity.

Nick Higgs, national sales manager at Elta Trade, part of Elta UK, said: “Intermittent-flow fans have been the status quo for many years, fitted in rooms such as bathrooms and ensuites and only working when occupants take a shower or bath. However, quite often, the level of extraction is not enough – especially with homes being more insulated –

which keeps moisture trapped inside.

Waterwise has unveiled a new-look website and branding designed to help it engage with fresh audiences and build on its reputation as the leading independent voice in the UK for using water wisely, for the benefit of people and the planet.

The not-for-profit organisation has also published a summary of its impact plan, which builds on its 20 years of expertise in water-e ciency policy, regulation, research and behaviour campaigns.

Nicci Russell, CEO of Waterwise, said: “As the UK’s conscience on water e ciency, our impact plan is focused on our purpose – to lead and inspire change so that water is never wasted.” www.waterwise.org.uk

Interest in heat pumps slowed considerably across Europe in 2024, with France and Germany showing a combined Google search volume at around 5% of equivalent UK searches. Two of Europe’s largest countries typed ‘heat pump installation’ into Google just 550 times at the start of 2024, compared with over 3,000 in Britain, a trend that has been repeated in January 2025.

A RECENT REPORT has highlighted the importance of degree apprenticeships to the manufacturing and engineering sectors and the critical role they play in driving productivity, social inclusion and tackling the skills gap.

The findings come from Manchester Metropolitan University, a University Vocational Awards Council (UVAC) member organisation, which studied data from over 5,000 apprentices and more than 600 employers.

From a recruitment perspective, 93% of firms are investing in higher and degree apprentices to bolster their talent pipeline, while 91% agreed they help address skills gaps within their business. SMEs also regard them as vital, with 58% claiming they bring new talent to their organisation.

The report also provides an insight

into the potential impact of the government’s proposed changes to the Apprenticeship Levy, which aims to shift funding priorities towards lower-level and new foundation apprenticeships for young people and those starting out. Removing funding from higher-level apprenticeships could be detrimental to employers and impact opportunities for young people. James Walker, director of apprenticeships at Manchester Metropolitan University, said: “Our Force for Impact report shows these programmes have been transformative, enabling thousands of apprentices to access high-quality training in roles where there are vital skills shortages. Our data shows how vital it is to protect essential training pathways, while safeguarding the future of workforce development in a range of sectors.”

IN JANUARY, T Level students from Newbury College visited Grant UK’s headquarters to learn more about air source heat pumps, attending a dedicated training session to support their wider plumbing and heating studies.

During their visit, the students enjoyed a tour of Grant UK’s facilities in Swindon including its Training Academy, where they had hands-on experience with heat pumps in the Academy’s dedicated air-source heat pump workshop. In addition, Shaun McCarthy, one of Grant UK’s technical sales support engineers, held a tailored training session where the students gained insight into electric heating, received an introduction to heat pumps and learned how air-source heat pumps work, developing an understanding of the vital role the technology is expected to play in decarbonising home heating.

Newbury College found the visit beneficial, with students and sta being incredibly positive.

“As a careers professional, I believe in the value of employer engagement,” said Sarah Mackfall, industry placement co-ordinator at Newbury College. “To be allowed into the world of a business, through visits such as this one, gives the students ideas they maybe hadn’t considered as to the route they may go down. It’s thought-provoking for them.”

Geo

We are very sad to announce that Geo rey John Walter Marsh passed away in the early hours of 28 December 2024 at the age of 92

GEOFF WAS A man with ambition to make his neighbourhood, in the broadest sense, a better, happier, more friendly place. Born in Westerham, Kent in 1932, Geo started his career in the plumbing industry at the age of 16. He chose plumbing based on his understanding, even then, of “how fundamentally important this engineering discipline is to the existence of humanity”. This conviction guided his progress from apprentice to a leader in the global industry. Geo ’s life’s work was to create paths for plumbers to be continually trained, qualified and, ultimately, to be recognised as engineers.

Geo joined the Livery of The Worshipful Company of Plumbers in 1967 and was on the court of the company for over 40 years. He trained as an apprentice plumber, became technical director of Marley Extrusions and introduced several patented products into the industry. He served as president of the Institute of Plumbing between 1975 and 1976 (now the CIPHE), chaired its General Council and was an Honorary Fellow of the Institute. Geo was elected first chairman of the World Plumbing Council and holds its distinguished service award. Within the industry he ran two trade associations, served on the Construction Liveries Group and the Water Regulations Advisory Committee.

One of his important achievements was the introduction of the Master Plumber Certificate, and he served as chairman of its working group. He was Master of the Plumber’s Company in 1986 and holds the St Michael Medallion, the company’s highest honour.

In the 1987 New Year’s Honours List, Geo was awarded the MBE for services to the plumbing industry.

Geo ’s partner in everything he did since 1954 was Ann. They met at Chatham Barracks where Geo was completing his National Service, playing badminton (Geo hit Ann in the eye with a shuttlecock). Married in 1956, they were inseparable. Ann was his help and support and she was his rock. The importance of education and vocational training was instilled in their four children who all built fulfilling careers.

Family times revolved around sporting activities: Geo and Trevor, playing cricket at Knole Park; family days at Canterbury to support Kent CCC; Geo and Ann cheering on their children’s sporting endeavours and vicariously living through their travels and adventures.

At home, Geo was rarely without a pad of paper and a pen, writing about or sketching his thoughts and ideas. He was passionate about patiently developing a concept and turning it into reality through persistence and hard work.

Geo ’s faith was strong. In 2000 he wrote of his relationship with God while sitting in a hospital car park. We are so grateful to have this as a confirmation of his faith about where he has gone to. “When my consciousness, spirit or soul is called home I will leave love behind to grow in others and take loving thanks to God for my life on earth.”

Geo is survived by Ann, their children Trevor (Gill), Helen (Richard), Jo (Tim) and Elisabeth (David), grandchildren Alex, James, Louise (Cam), Hannah, Nic and Andrew, and great grandchildren Aurora and Owen.

Fernox recently partnered with its local council for a community tree-planting event. Fernox employees, customers, partners and children from a local infant school all joined the e orts to plant 300 bare-root whip trees and four fruit trees in the borough. The occasion, which formed part of the manufacturer’s 60th-anniversary celebrations and ongoing sustainability programme, was organised by Fernox to support its local council’s ambitious climate strategy. Surrey County Council has pledged to plant 1.2 million trees in Surrey, one for every resident, by 2030, as part of its aim to be carbon neutral by 2050.

RA Tech is celebrating 10 years since the launch of its pioneering Hotun tundish. Founder Russell Armstrong, a CIPHE-registered plumber, was working on an unvented hot water heater and couldn’t find an all-in-one solution to give visibility of water dripping from a safety valve while allowing flow and stopping smells coming up from the foul drain. Russell sketched out his initial design in 2012 and went through rounds of prototypes, testing and the patenting process before launching the product in April 2015. hotun.co.uk

A very enjoyable part of being selfemployed is the ability to control work/life balance”

Duncan Gordon’s role in the Army as a bomb disposal engineer led him to gain qualifications in the plumbing and heating sector, which have opened up a second career

DUNCAN GORDON’S FIRST JOB was working in the building trade as a labourer in his home town of Aylesbury in Buckinghamshire. He worked alongside his father as bricklayer on a variety of building sites in the during the first half of the ‘90s. However, he had another long-held dream to fulfil before he would return to the civilian workforce.

“At the age of five I watched The Longest Day with my Grandad (who had served with the Scots Guards), who said ‘You can do that’, so joining the Army was my focus from my early years,” explains Duncan. “I joined the Royal Engineers knowing that I would be able to gain a trade and qualifications which would help me when I finished my time in the Army.”

In 1996, Duncan joined the British Army as a Royal Engineer and by the following year he had qualified as bomb disposal engineer.

“In 1999, while on tour in Kosovo, we were informed that our trade stream was changing and that we had to apply for other artisan trades within the Corps of Royal Engineers,” explains Duncan. “There was a long list of artisan trades open and available for all my training party to choose from, such as plumber, electrician, carpenter, welder, painter and finisher for example. I looked across the breadth of the trades available and chose to become a plumber and heating engineer. I chose this option due to the complexities of the trade and I enjoy problem solving. It also o ered career progression.

“In 2000, I was fortunate to be selected to go to 1 RSME (Royal School of Military Engineering) in

Chatham, Kent to start my journey in the trade. The course lasted nine months and took us through Water Regulations, iron, copper, drainage pipework, system design and installation, leadwork, oil boilers, tools, and various other techniques to be awarded NVQ level 2.”

In 2002, Duncan returned to 1 RSME to complete the H&P 2-1 (Heating & Plumbing Class Two to One) course. This six-month course was for NVQ level 3 and was primarily focused on gas. To gain gas boiler experience and build enough credits for their portfolios, members of the course were attached to civilian contractors.

“This was a fantastic part of the course as it allowed us to work in the industry, gaining as much hands-on experience as possible at dealing with everyday plumbing problems, installing and fault-finding gas boilers under the watchful eye of our highly competent mentors.”

During the remainder of his 24-year-long career with the Army, Duncan was employed as a bomb disposal operator, serving in Kosovo, Bosnia, Iraq, Northern Ireland and Afghanistan. He ended his

“I chose to become a plumber and heating engineer due to the complexities of the trade and I enjoy problem solving”

career as a Warrant O cer and the head trainer at the Defence EOD (Explosive Ordnance Disposal) and Search School based in Bicester, Oxfordshire. Although his contracted time within the services as a regular has ended, Duncan is still in the Army Reserve.

When Duncan knew the end of his Army career was approaching, he began thinking about his next career and what he would like to achieve. He decided to pursue a career as a plumbing and heating engineer.

“I wanted to utilise the ELC (Enhanced Learning Credits) that had been accrued during my time in the service to retake my ACS (Accredited Certification Scheme) Core Gas skills and appliances,” says Duncan. “I was also fortunate to have time in the last few months of service to study and bring myself back up to date with current Water Regulations and plumbing legislation.”

Before leaving the Army, Duncan’s next steps were to buy a house, purchase a van, tools, insurance and establish himself as a self-employed plumbing and heating engineer. In Afghanistan, the callsign for Explosive Ordnance Disposal (EOD) for British forces was Brimstone. He created his company, Brimstone Gas & Oil, in 2021, servicing Rugby and the surrounding area.

“My first job, once I’d settled in Rugby, was to assist my friend in building his house extension, doing their plumbing and gas work while overseeing the work that was being completed by the contractors,” explains Duncan. “This led to helping on other extensions that the company was carrying out in the local area, and from there my name was being recommended to others and odd plumbing jobs/boiler services being passed on to me.

“I really enjoy engaging with the local community fixing problems, finding faults in boilers and other plumbing issues,” says Duncan. “I sometimes sub-contract work for local estate agents when they require additional specialist help with properties. This would normally be where a G3

SPECIAL ACHIEVEMENTS

QUEEN’S COMMENDATION FOR VALUABLE SERVICE

Duncan was awarded this in 2011 for training and then mentoring the first ANA (Afghanistan National Army) EHRT (Explosive Hazard Reduction Team) on Operation OMID CHAR, dealing with 11 IEDs (Improvised Explosive Devices) and multiple explosive remnants of war.

Duncan visited the CIPHE’s stand at InstallerSHOW at the NEC in 2021, and decided to apply to become a member after chatting with membership director, Tim Sainty.

“I returned the following day to hand in my completed membership paperwork,” recalls Duncan. “Unfortunately, for Tim and I, his bag containing the membership forms were stolen from him on a train when he was returning home. The following year I met back up with Tim, I hadn’t realised what had happened so started the membership process again. I’m sure that Tim put me to the top as I had my membership email later that same day – top guy.

“Becoming a member has opened up a lot of opportunities for me and my business,” enthuses Duncan. “Being able to gain Registered Plumber and Registered Heating Professional status through CIPHE has enabled me to join the Approved Contractor Scheme and become a member of WaterSafe, which in turn has led to my company being listed with Severn Trent as a reliable/professional Plumbing and Heating Engineer. I also recently joined the lead safe campaign as part of WaterSafe’s campaign on trades to use lead-free solder.”

Duncan has found that a lot of his additional work has come from customers who have used CIPHE’s Find a plumber tool, WaterSafe or Severn Trent, instead of utilising social media platforms to look for trades people.

“Being a member allows me to continue CPD through the CIPHE Academy, download technical information and shop for discounted or free materials and guidelines,” adds Duncan. “It’s a great resource to quickly check and confirm legislation that is needed on a job you are completing.”

qualified person, or plumbers on their books have not dealt with macerators before. Bathroom renovations have been a focus for the past two years – it is pleasing to help customers fulfil their bathroom and cloakroom dreams.

“A very enjoyable part of being self-employed is the ability to control work/life balance. I know that when not working unfortunately income stops but it is important to have a good amount of family time. This was something that I was not able to control previously. Both being members of the 100 Marathon Club, my wife and I enjoy running and quite often will have a weekend away running marathons around the country, clearing our heads, seeing new sights and meeting new people before the working week starts. That being said, a weekend relaxing watching movies with the kids and just spending time together is a great reset.

“I would consider a role teaching in the plumbing and heating industry in the future, after I have gained the knowledge and experience working in the trade for a few more years. I do see myself continuing to work in the trade until retirement age comes, but could reduce days to lecture where required.”

The government’s focus on renewable power may have been successful in terms of production, but the lack of infrastructure capacity to deliver it is causing frustration across the plumbing and heating industry.

In 2024, the UK experienced more than 149 hours of negative wholesale electricity prices, and that is predicted to grow to 1,000 hours by 2027.

“As renewable energy surges, these negative prices aren’t just anomalies; they are signals that our energy system needs to adapt, fast,” says Christopher Carver, engineering director at tepeo, who believes the solution lies in technologies such as heat batteries. “Negative prices are becoming a hallmark of large-scale renewable energy deployment.”

Several factors contribute to negative

electricity prices, including subsidies for energy producers, which encourage continuous renewable power generation – even when demand and prices are low.

“Big power plants, such as nuclear or coal, can’t always switch off quickly, so electricity suppliers sometimes end up paying others to take the extra energy off their hands,” explains Lukas Bergmann, head of product regulatory affairs at Sunamp. “It sounds strange, but it’s a sign

“For heat batteries to achieve widespread adoption, robust industry standards are essential”

of how our energy system is changing.”

One significant challenge posed by negative pricing is its impact on the profitability of renewable energy investments. Prolonged periods of low or negative prices can undermine future projects.

“Since investors and developers rely on stable returns to justify building new infrastructure, frequent negative prices create uncertainty for businesses dependent on predictable revenue from electricity generation,” explains Carver. “Addressing this issue is crucial for maintaining the momentum of decarbonisation. If renewable energy projects become too financially unstable, the rate of new installations could slow down.”

The UK’s current energy grid was built when power stations provided a steady supply of energy, as opposed to the

Heat batteries store excess electricity as thermal energy, which can later be used for heating and hot water. This offers several advantages:

• Demand flexibility: heat batteries enable homes and businesses to shift energy consumption away from peak hours, reducing pressure on the grid.

• Efficiency: converting and storing surplus electricity as heat provides a simple

fluctuating level supplied by renewables. The current grid struggles to handle peaks in energy, which results in waste.

“Upgrading the infrastructure – this is where thermal energy storage makes all the di erence, and smarter ways to balance supply and demand will be key to solving this,” adds Bergmann.

Government backing Government support and policies backing low-carbon technologies make them easier and more a ordable for UK consumers to adopt. However, for the UK to meet its zero-carbon goal, companies such as Sunamp are calling for the government to recognise thermal storage as a key part of Britain’s energy future and o er funding.

“The BBC reported how an increase in the Boiler Upgrade Scheme (BUS) grant led to a 52% year-on-year rise in low-carbon heating system heat pump installs,” says Bergmann. “The

way to make use of excess renewable energy that can deliver the high levels of instant heat output required for heat and hot water in homes.

• Cost savings: consumers benefit from lower energy bills by charging their heat batteries during periods of negative or low electricity prices.

Courtesy of tepeo

UK government recently launched the #WarmAndFuzzy campaign with the aim of raising awareness about heat pumps and the BUS. However, to ensure that all homes have access to clean, a ordable heating, it’s crucial that the BUS and VAT relief are extended to heat batteries as part of the Warm Homes Plan.”

Meanwhile, to foster consumer confidence in heat storage technology, the Microgeneration Certification Scheme (MCS) is developing standards for thermal storage to ensure heat battery systems are properly designed and installed.

“For heat batteries to achieve widespread adoption, robust industry standards are essential,” says Johan du Plessis, founder and chief executive of tepeo. “Establishing clear guidelines will support market growth and accelerate the integration of heat batteries into homes and businesses across the UK.

“Negative electricity prices highlight the urgent need for better energy storage and flexibility. Heat batteries present a practical, scalable solution to convert surplus renewable energy into valuable heat, reducing waste and supporting net zero goals. With strong policy backing, regulatory reform and continued industry innovation, heat batteries can play a key role in the UK’s transition to a cleaner, more e cient energy system.”

Harnessing excess energy

Industry experts believe that negative energy prices present an opportunity to rethink how energy generation and consumption is managed in the UK. According to tepeo, when it comes to how energy is generated, stored and used, flexibility is the key to integrating renewable energy at scale.

“Energy storage systems play a critical role by decoupling energy demand from generation,” says Carver. “They allow

surplus energy produced during periods of low demand to be stored and used when demand rises. While grid-scale storage, enough to power entire towns or cities, has more than doubled in the past year, the UK still lags behind where it needs to be. The National Grid has stated that 50GW of storage is needed by 2050, but as of May 2024, the UK only had 3.5GW of operational battery storage capacity.”

It’s clear that the ability to store and shift energy on a large scale is essential to balance the grid, but for more intermittent renewable sources that operate on a smaller scale, such as domestic uses, heat batteries are becoming more common.

“Instead of letting extra energy go to waste, we need better ways to store it for later,” says Bergmann. “This is where heat batteries, electric batteries and smart grid technology come in. By shifting when we use energy – i.e. storing it when it is cheap and abundant and using it when it is needed – we can balance out demand and supply, reduce strain on the grid and make the most of renewables – all the while cutting energy bills by making the most of o -peak tari s.”

The UK government has signalled support for heat batteries by including them in the Warm Homes: Social Housing Fund, allowing social housing providers to claim up to £15,000 per property for low-carbon heating solutions.

“Solutions such as grid-scale batteries, pumped hydro storage and flexible demand response play a role, but decentralised storage solutions at the consumer level are arguably even more critical,” says du Plessis. “Heat batteries provide an innovative, scalable solution that can bridge this gap e ectively.”

Thermal energy storage systems, such as heat batteries, work by storing excess heat energy –typically from renewable sources including wind, solar panels or heat pumps,

■ Electric upgrade: Heat batteries run on electricity, so the fuel source is likely to be changed if replacing a gas or oil boiler. This means a new high-current circuit will be required to power the unit directly from the consumer unit via an isolator (50A breaker/RCD, 10mm2 min cable size).

■ Controls: Most units are compatible with di erent types of heating controls. For example, the ZEB works with any sort of time or temperature control, including basic timeclocks and thermostats, through to programmable thermostats and smart thermostats.

■ Plumbing: The ZEB is a regular boiler (heat only) and integrates into the existing heating system via a 22mm copper flow-and-return connection using solder or compression/ press-fit fittings.

as well as grid and microgrid electricity, waste heat, combined heat and power (CHP) and boilers – releasing it later for heating or hot water.

Materials such as phase change materials (PCMs) or solid masses are used to absorb and release thermal energy during a melting and freezing process in a similar way to the gel in a pocket handwarmer.

Heat batteries can store surplus energy for later use, particularly for a household’s heating and hot water needs, making them an energy-dense alternative to hot water cylinders. Instead of converting electricity into heat in real time (which can be ine cient due to heat losses), heat batteries store energy and release it when needed. This helps homes and businesses cut energy costs and reduce reliance on fossil fuels, all

■ Additional considerations include: Isolation valves – on both flow and return, so the ZEB can be isolated for maintenance without draining the heating system.

Automatic bypass valve – to ensure minimum flow through the ZEB, even when the heating system valves have closed.

Pressure relief valve – to ensure the system pressure stays within limits.

Magnetic system filter – to help ensure the ZEB heat exchanger stays free from contamination.

■ Hot water: If replacing a combi boiler, hot water storage will be needed. This can be an indirect cylinder heated by the thermal storage unit, a direct cylinder heated with immersion or a compact heat battery.

To find out more, visit tepeo.com/faqs

while making better use of clean energy when it’s available.

It is worth installers noting that heat pumps require additional thermal storage for hot water, which can make their installation di cult in homes with limited space. However, heat batteries are up to four times smaller than traditional hot water cylinders, making heat pump installations in smaller homes possible.

“For homes where heat pumps aren’t practical, a complete heat battery solution can replace traditional combi boilers,” explains Bergmann. “By combining Sunamp heat batteries with tepeo’s Zero Emission Boiler (ZEB), for example, consumers get a low-carbon, combi-like heating system that replaces gas boilers and shifts consumption to low-demand periods, making heating and hot water e cient and a ordable.”

Although challenging, negative energy prices are a sign that the UK is moving in the right direction towards a lowcarbon, sustainable energy system. By adopting a variety of flexible low-carbon technologies, including those that store and manage surplus energy, the UK will move closer to decarbonising home heating systems.

Recommending water-treatment options to customers will benefit the environment, customers’ finances and installers’ profits

Although water is perfectly safe to drink in the UK, the quality varies significantly from county to county. Water quality is graded from soft to hard and refers to the mineral content. It is classed as hard if it has over 200ppm of CaCO3 (calcium carbonate). Hard water contains higher levels of minerals, such as calcium and magnesium, which can a ect its taste and cause limescale. Although the minerals in hard water are harmless for humans to consume, once heated they calcify, forming limescale inside household equipment, which can cause a range of issues.

Installers should encourage customers in hard-water areas to consider watersoftening products as an investment that will protect their home and finances, and share the benefits they o er:

and cleaning products (according to British Water, based on a four-person household).

✓ Improved e ciency Having no limescale enables equipment to work e ciently.

✓ Better wash results Customers can enjoy sparkling cutlery and glassware and softer laundry.

Building Regulations Part L, specifically when dealing with domestic heating and cooling systems, now mandates adherence to BS 7593: 2019, which is a code of practice for their preparation, commissioning and maintenance, requiring water treatment and system cleaning. While BS 7593 is an advisory code of practice, its integration into Part L makes it a mandatory action within building regulations.

✓ Financial incentives Customers can save around £200 a year on toiletries, detergents

Limescale build-up on household equipment makes it less e cient

Due to the geography of the UK, around 60% of Brits receive a hardwater supply and will experience problems like limescale in kettles and scum marks around taps. Scale will also build up out of sight, inside other pieces of household equipment, such as showers, washing machines, dishwashers and boilers. The limescale coats heating elements inside these items, decreasing their e ciency and meaning they cost more to run. In fact, according to British Water, just 1.6mm of limescale build-up on a

✓ Fewer breakdowns The working life of household equipment such as boilers, kettles, showers, dishwashers and washing machines will be increased.

✓ Softer hair and skin Evidence suggests that soft water can help to alleviate symptoms of skin conditions such as eczema, psoriasis and dermatitis.

∞ Testing the water – Conducting a water-quality test is essential to determine the hardness. This ensures that any water-treatment solution is tailored to the specific requirements of the household or facility

∞ Fitting location – Ensure the system is installed close to the water mains source, ensuring that any spurs are included for optimal treatment

∞ Accessibility – Adequate access for refills, repairs and maintenance is crucial to ensure the longevity and effectiveness of the system

heating element makes it 12% less efficient because it has to heat the scale before it can heat the water.

“Sharing these numbers with consumers is a great way for installers to show just how much the build-up of limescale could be costing them –especially given the price of energy,” points out Dario Palumbo, marketing manager at Monarch Water. “If the physical presence of limescale on taps and inside kettles isn’t enough to convince customers about the damaging effects of hard water on their homes, a simple test can be carried out to show them just how hard their supply really is.” Tests can be carried out in a matter of minutes with a water test kit, or a water hardness test meter.

Contamination within the heating system can also negatively impact the efficiency, performance and lifespan of boilers and other key system components. This is why it’s vital that installers recommend cleaning to customers to protect and maintain their systems. Following Part L and

Softeners remove minerals through ion exchange, whereas conditioners modify mineral structures to prevent scaling without altering water composition

BS 7593:2019 will not only improve the efficiency of heating systems, but prevent premature system breakdowns.

“One of the biggest issues for heating systems is contamination, which comes from a variety of sources,” explains Richard Crisp, head of chemistry at Fernox. “This includes iron oxide sludge caused by the corrosion of steel in the system, as well as other metal oxide debris from non-ferrous metals (eg copper, brass and aluminium). These contaminants

block heating pipes and prevent radiators warming up effectively, causing far more energy to be used.

In addition, aluminium components are vulnerable to pitting, which often leads to component and, ultimately, system failure.”

Increased consumer interest in improving the efficiency of their homes, coupled with the growing trend towards health and wellbeing,

has driven innovation in the watertreatment sector. Water softeners, purifiers and filtration systems are becoming more popular among consumers, which is great news for plumbing and heating installers who are perfectly placed to help their customers choose a system that’s right for them.

Water softeners are a simple solution to whole-house protection against limescale caused by hard water. Using an ion-exchange process to remove minerals from the water, these units not only prevent limescale build-up in appliances and pipes, but remove any existing deposits too. They also improve soap and detergent effectiveness, while significantly contributing to energy and financial savings, plus they extend the working life of boilers and any other equipment that heats water.

Preventing limescale build-up can cut CO₂ emissions by 0.5 tonnes per year per household, which

“Water purifiers help ensure safe and tasty drinking water”

means lower energy bills. The great news for installers is that modern, highefficiency water softeners are compatible with any boiler, and this makes every building a potential profit maker.

In-line filters play a vital role in keeping centralheating systems clean and working at optimum efficiency, by capturing sludge and debris that has built up. It is, therefore, no surprise that the installation of a filter has now effectively become mandatory after the inclusion of BS 7593:2019 into Approved Document L.

Filtration systems remove innocuous impurities such as sediment and chlorine, as well as microplastics and bacteria that can be harmful to health. These systems improve the taste of water, while making it safe for consumption. Some filters can also add beneficial minerals including zinc and magnesium, which can improve people’s wellbeing and enhance the flavour of hot drinks such as tea and coffee.

“Water purifiers help ensure safe and tasty drinking water and are used to remove unwanted elements such as bacteria, chemicals and viruses from the water where they exist,” explains Simran Ghata-Aura. “This is crucial for situations where water quality must meet stringent standards, including hospitality and medical applications.”

The latest generation of watertreatment systems are more efficient, sustainable and easier to maintain than their older counterparts. Water softeners, for example, now feature smart regeneration cycles that reduce water and salt consumption.

Advanced water conditioners use technology to alter the structure of the minerals, preventing limescale build-up without the need for salt or ongoing maintenance. Other limescale prevention devices dispense food-grade polyphosphate into

Regulations stipulate that provision is made to reduce the rate of limescale in hard-water areas

the water supply, without removing essential minerals.

“Modern water treatment products often feature smart technology, where users are able to monitor usage, quality and even schedule the regeneration cycle,” explains Ghata-Aura. “This allows for a more personalised product to suit its user’s requirements.”

Further developments in technology include multi-stage filtration, which combines different types of filters and even reverse osmosis membranes (RO) to treat water. For example, a system might include a sediment filter, an activated carbon filter, an RO membrane and a remineralising filter to produce safe drinking water.

and installation

When specifying and installing watertreatment systems, installers need to first assess the existing plumbing system and understand the specific issues their customers want to address.

Different solutions serve different purposes:

• Limescale prevention: essential for homes in hard-water areas to maintain heating-system efficiency.

• Water softening: recommended where true soft water is needed, such as for preventing skin irritation or protecting delicate appliances.

• Legionella prevention: a key consideration for commercial buildings and healthcare settings where water-borne bacteria pose health risks.

As part of the most recent updates to Approved Document L, the government has continued to address the harmful impact that limescale can have on the energy performance of a

∞ The BS 7593:2019 code of practice applies to both closed-loop heating and cooling circuits

∞ A permanent in-line filter must be fitted, and a chemical clean and fresh-water flush should take place before inhibitor is added to a system

∞ In-line filters are required for ALL systems

∞ An annual on-site water test is required to check inhibitor levels and system cleanliness

∞ Inhibitor should be re-dosed every five years, or a full-system water test should be carried out

∞ External magnetite-capture equipment and mechanical vibration of radiators can be used to enhance cleaning

∞ Biocide is required in cooling and lowtemperature heating systems

∞ Biocide can also be added to highertemperature systems for extra protection during downtime

Courtesy of Intatec

property’s heating system.

“The regulations stipulate that provision is made to reduce the rate of limescale in hard-water areas that exceed 200ppm and this can be achieved with a quality electrolytic/magnetic scale reducer,” explains Crisp.

Before installing an inhibitor, it’s vital that the existing system is cleaned of debris. Once complete, installers must ensure they use the correct level of inhibitor, as stated in the manufacturer’s guidelines, to prevent further build-up.

“To ensure the system is adequately protected and therefore running e ciently, Approved Document L regulations require an annual on-site test of the system water, and this process can be confirmed on the Benchmark Checklist,” adds Crisp. “In addition, the system must be either redosed with inhibitor or a full laboratory analysis of the system water conducted (and re-dosed with inhibitor if required) every five years.”

Installing a mini-filter is a relatively straightforward step to help protect a customer’s system

“Proper installation and customer education on maintenance can ensure long-term benefits”

When specifying a filter, engineers should consider the type of filtration technology as this will impact on the volume and type of debris contained and, subsequently, the energy performance of the building. There are filters available designed for specific applications, including heat pumps and restricted spaces.

“For systems with a lower flow temperature, such as those with a heat pump, microbiological protection is also required,” points out Crisp. “At these temperatures, typically between 35°C and 55 °C, micro-organisms such as bacteria and fungi will thrive. This not only poses a health risk, but

can also cause accelerated corrosion through Micro-biologically Influenced Corrosion (MIC) and reductions in system performance due to the formation of biofilms. With these lower-temperature systems, a biocide should be added to the heating system water, which will kill the microbes by altering the cell wall permeability and interfering with biological processes, destroying the cell as a result.”

Once a water-treatment system has been installed, it’s important to educate customers on maintenance to ensure long-term benefits.

“Recommending and fitting water softeners, conditioners and filtration systems presents an opportunity to o er added-value services,” says Braid. “By preventing limescale build-up, these systems help protect heating components, reducing the likelihood of breakdowns and costly call-backs. This not only strengthens customer trust, but also provides repeat business through ongoing maintenance and filter replacements.”

Transitioning oil-heated homes to renewable liquid fuels could achieve carbon-reduction benefits

The key to successfully decarbonising off-grid homes is offering sustainable solutions tailored to each customer’s needs

As of 2021, there were estimated to be 4.4 million homes not connected to a gas grid, accounting for around 15% of domestic properties. Approximately 1.5 to 1.7 million of these homes rely on oil for central heating, representing around 6% of all UK households. Although this number seems low compared to the 84% of UK homes that are connected to the gas grid, homes that use fossil fuels such as coal and oil to power their heating systems account for 13% of all domestic heating emissions.

Decarbonising the heating systems of off-grid homes plays an important role in the UK government’s climate targets, as they use some of the highest

carbon-producing heating fuels. The Future Homes Standard dictates that, from this year, all new homes cannot be connected to the gas grid.

However, in 2023, Rishi Sunak announced a delay to the phaseout date for installing new oil and liquefied petroleum gas (LPG) boilers and coal heating for off-grid homes, pushing it back from 2026 to 2035, as part of a broader review of the UK’s net-zero policies.

There have been significant changes in the off-gas grid sector over the past couple of years, from new government policy and technical developments to a focus on training. Despite emerging challenges, OFTEC, the UK’s oil industry body, says

there are also huge opportunities for heating installers.

The Boiler Upgrade Scheme (BUS) currently offers grants of £7,500 to homeowners in England and Wales to switch to a heat pump (air or ground source) or £5,000 towards the cost and installation of a biomass boiler.

Changes were made to the BUS scheme earlier this year, removing the requirement that there should be no outstanding recommendations for loft and cavity wall installation on a property’s EPC to secure funding. The aim was to remove any barriers to uptake, but it could mean some homes are not suitable for the upgrade.

“On the face of it, this may seem like a small change to the criteria,” says Malcolm Farrow, head of public a airs at OFTEC. “However, it could potentially have significant consequences o grid. Both the previous Conservative government and new Labour administration are focused on heat pumps as the primary technology to achieve net zero. However, the requirements were there to protect consumers by ensuring their home was suitably optimised for a heat pump before funding was allocated.”

Upgrading a property to make it suitable for a heat pump can be costly and disruptive for homeowners, often requiring new radiators, insulation and a hot water tank. Removing this requirement in the BUS makes it seem as though heat pumps are less expensive to install. If this low-carbon heating technology is installed without buildings being fully optimised, households could experience poor results, including expensive heating bills and a system that’s less e cient overall. However, modern properties that are well insulated and more suited to a heat pump are an opportunity for installers, according to OFTEC.

“Competent technicians who diversify their skill set can advise homeowners on the best solution for their home, whether it’s a heat pump or another low-carbon technology,” says Farrow. “That’s why it’s the perfect time to upskill and take advantage of both markets.”

Alternative liquid fuels

Labour’s election pledge to scrap the 2035 target to ban the installation of new fossil-fuel boilers was welcomed by o -grid homeowners who previously faced a deadline with no viable alternative solution if a heat pump wasn’t suitable.

“It’s the perfect time to upskill and take advantage of both markets”

OFTEC-registered technicians can self-certify that their installation work meets building regulations, avoiding the need for it to be checked by a building control officer. This makes the whole installation process much easier, saving time and money. Work that is self-certified by an OFTEC-competent person carries a workmanship warranty against building regulation non-compliance. OFTEC offers registration for liquid fuel, solid fuel, biomass and heat-pump systems, plus MCS, Part P electrical and Trustmark.

OFTEC has suggested that transitioning oil-heated homes to renewable liquid fuels such as Hydrotreated Vegetable Oil (HVO) could achieve carbon-reduction benefits similar to installing 150,000 heat pumps, o ering a potentially more a ordable and less disruptive solution.

Switching from traditional kerosene liquid fuel to a virtually zero-carbon option such as HVO, LPG or bioLPG (biopropane) would, in most cases, require no changes to the boiler or other elements of the heating system, which would operate in exactly the same way.

“Building regulations state that homes have to meet minimum carbon emissions, but there is nothing to say that the form of heating has to be

“OFTEC-registered installers are also regularly assessed to ensure they uphold the highest standards of both safety and customer service,” explains Farrow. “As we navigate new low-carbon technologies, consumers will need to rely on trusted technicians to support and guide them through these processes. OFTEC delivers training for both renewable liquid fuels and heat pumps, which means registered technicians can be at the forefront of a successful off-grid transition to net zero.”

heat pumps,” points out Alan C Black, FCIPHE and principal consultant at Oil Heating Consultancy Services.

“For homes reliant on liquid fuel, in order to switch to HVO, all that would need to change are the boiler settings, and a di erent atomising nozzle would need to be fitted. If the boiler is older, installers may have to replace the burner to get better combustion, but this should cost less than £500.”

According to Farrow, the HVO costs around twice as much as traditional liquid fuel and there is not currently enough to replace the estimated four million tonnes of heating oil used annually in the UK.

Additionally, Black suggests that the cost of HVO is artificially high because

HMRC is yet to recognise it as anything other than an automotive diesel. He predicts that this could be overcome if the government relaxed taxation and duties on biodiesel required for heat applications.

Currently, fossil fuels such as gas are fiscally supported as a heat application energy source, but wastederived sustainable biodiesel fuels including HVO aren’t, which seems counterintuitive.

“Let homeowners decide how they would prefer to decarbonise”

“Eventually decisions are going to have to be made about how harder-totreat o -grid properties can transition to low-carbon heating,” says Farrow. “That’s why we were pleased to see an amendment to the Energy Act in October 2023.

“Within the Act is legislation that, if invoked by government, would create the renewable liquid-heating-fuel obligation, and pave the way for the introduction of these fuels more widely. The legislation was introduced with the promise of a consultation on the technical details within a year. The Conservatives didn’t act on this. The new Labour government, which supported the legislation at the time, also hasn’t brought the consultation forward.”

OFTEC and industry partners are continuing to campaign for the government to keep this commitment and publish the consultation. This would not only provide a realistic and a ordable solution for many o -grid properties, but also deliver long-term certainty for technicians.

“HVO is cheaper for homeowners than installing a heat pump,” asserts Black. “Currently, according to the Renewable Transport Fuel Obligation policy, if HVO is sold for automobile use, suppliers receive a carbon credit. The Energy Act consultation would give the equivalent fiscal legislative support and lower the cost. We need to bring all options to the market and let homeowners decide how they would prefer to decarbonise.”

There are quite a few proposed changes that cover heating sector regulations, mainly for appliance manufacturers. However, the proposed changes to gas boilers include LPG boilers used in off-grid areas.

The proposed changes include, but are not limited to:

∞ all combination boilers must be able to modulate down to 15% of their maximum output

∞ all combination boilers must use open protocols to communicate to the chosen control system selected

∞ all oil-fired combination boilers must be capable of modulating down to 30% of full output

∞ heating engineers are to demonstrate competence on low-temperature heating design

∞ the banning from sale of controls in classes 1-3. This would include on/off room thermostats.

FIND OUT MORE

Find out more about how HVO can decarbonise off-grid properties on p32

This 300-year-old pub’s kerosene-fuelled heating system has been brought into the 21st century with the installation of a fully modulating HVO boiler, elevating its EPC rating from D to A

The Five Horseshoes Inn in Barholm, Lincolnshire, has successfully achieved significant carbon reduction with the installation of a sustainable HVO condensing liquid fuel boiler. The change has reduced the building’s CO2 emissions from 8.26 tonnes to 0.702 tonnes per annum (nearly 90% reduction), and increased its EPC rating from D to A.

The pub has committed to offset the

remaining carbon to achieve net-zero status by planting trees, making it the first rural establishment in the country to achieve net-zero emissions.

‘‘It’s a fantastic bonus for us,” enthuses Emma Freeman, joint landlord of the Five Horseshoes. “We’re not eco-warriors, but you have to do your bit. When we were shown the figures for the carbon reduction, it made sense. If we continued to use our old heating

for the next 25 years, we would need to plant 200 trees to offset the carbon emissions. With the new system it’s just 13 and these will be planted around primary schools in the area.”

Spreading the word

Keen to demonstrate the advances in relation to liquid fuel-fired fully modulating burners to trade, industry, consumers, government representative groups and individuals, OFTEC, the UK's oil industry body, sought a collaboration with EOGB Energy Products to create a demonstrator site.

As a typical rural property with an existing oil-fired central heating system and a low EPC rating, the Five Horseshoes was chosen for conversion and adoption to serve as a practical example of how carbon-intense

Crunching the numbers

235m² total fl oor area

300 years age of the old building 0.702 CO 2 emissions per annum 100% HVO-fuelled

fossil-fuelled boilers can be transitioned away from kerosene and gas oil, via the adoption of waste-derived, sustainable, low-carbon, liquid fuels such as HVO (Hydrotreated Vegetable Oil).

“Much work has been done evaluating and identifying that HVO provided a realistic and practical decarbonisation solution for ‘hard-totreat’ existing oil-fired properties,” says Martin Cooke, managing director of EOGB Energy Products. “Instead of decarbonising the heating system by

“When we were shown the figures for the carbon reduction, it made sense”

displacing the existing building services, this approach provides a low-cost, low-impact solution for end users by simply decarbonising the liquid fuel utilised for heat and hot water purposes in their existing equipment.”

With the consent of Barholm Estate owners and the tenants of the property, the project began. A number of upgrades were made to protect the fuel, equipment and the owners and occupiers of the premises, and to make it suitable to be scrutinised by members of the general public, as well as MPs and government o cials.

In order to further improve the e ciency of the building, the existing oil-fired boiler was replaced. The old Myson Velaire 50/70 boiler, set

Hydrotreated Vegetable Oil (HVO) is a renewable biofuel produced through the hydrotreatment of vegetable oils, fats and waste lipids, resulting in a para nic diesel fuel and a sustainable alternative to fossil fuels.

It is interchangeable with kerosene and can, in most cases, be used with existing oil-fired heating systems with minor modifications to the boiler.

Benefits of switching to HVO:

• Cleaner and greener – reduces carbon emissions by almost 90% compared to traditional heating oils

• Simple conversion – can be carried out during annual boiler service or upgrade

• Low cost – conversion typically costs around £500, depending on the system

• Fossil free – made from certified sustainable waste materials that don’t contribute to deforestation

• No noticeable di erence – odourless and runs just as e ciently as other liquid heating fuels

For more information, visit: futurereadyfuel.info

mid-range at 60,000 BTUs (circa 17.5kW), was somewhere in the region of 25 to 30 years old, but of a type, design and efficiency typical of boilers of 50-plus years. This was replaced with an EOGB fully modulating Sapphire condensing liquid-fuel boiler ready for HVO.

“Don’t be deceived by the traditional outward appearance of the Sapphire fully modulating boiler,” says Cooke. “Remove the front cover and you will see it looks a little different, but it’s extremely easy to work on and service. It has a fuel pump, a fan, an ignition system, a control box, flexible oil lines and an atomising nozzle. Sounds familiar, but all connected to a 25-year guaranteed fully stainless steel heat exchanger so, no mild steel corrosion here, and a modulating range of outputs from 6-32kW.”

“Remove the front cover and you will see it looks a little different, but it’s extremely easy to work on and service”

The existing wet central heating and hot water system were retained, minimising disruption and cost. The 15 existing radiators were fitted with OpenTherm radio remote individual thermostatic flow and temperature-sensing remote radiator valves piped top, bottom and opposite ends. This provided individual radiator zone control functionality enabling app-controlled separate time- and temperature-demand control over private residential and public areas of the property.

‘‘The fuel, combined with our new, energy-efficient boiler, works so much better than before and we often forget that we’re no longer using kerosene,” says Matthew Thompson, joint landlord of the Five Horseshoes. “For pubs like us, this hassle-free low-cost solution to going green will be a real lifesaver.”

The advancement in modulating boiler and controls technology applied by EOGB to this site uplifted the 300-year-old property from a high-end Band D property to a mid-range Band C property and thus out of the area of government concern, while still using kerosene.

RICHARD CRISP

Richard Crisp is an experienced chemist with a strong background in medicinal and industrial chemistry. He is currently head of chemistry and external affairs at Fernox. Outside this role, Richard actively contributes to the HVAC sector, serving on multiple industry committees across Europe and North America. Since 2019, Richard has been Chair of the CII/62 group, which is responsible for the British Standards for treatment of water for boilers, and the performance of corrosion and scale inhibitors for domestic central-heating systems.

Richard Crisp introduces two new standards that aim to maintain heating and cooling-system e ciency

The British Standards Institution (BSI) has recently published two innovative companion standards

BS 7593:2019+A1:2024 and BS 9593:2024

– intended for the heating and coolingsystem industry, including manufacturers, consultants, water-treatment specialists and testing laboratories.

The aim of these standards is to reduce levels of energy consumption, minimise breakdowns and extend the lifespan of systems, ultimately minimising the need for costly repairs or replacements. Additionally, they o er significant environmental benefits.

What’s new?

BS 7593:2019+A1:2024 is the new code of practice for the preparation, commissioning and maintenance of domestic centralheating and cooling-water systems. It introduces a connection to the newly developed BS 9593:2024, which assesses the performance of chemical inhibitors in domestic central-heating and coolingwater systems.

This linkage ensures that heating systems operate at peak e ciency, contributing to the UK’s ambitious target of reducing CO2 emissions by 78% by 2035.

BS 7593 provides comprehensive guidelines on best practices for preparing circulating water in both open-vented and sealed heating and cooling systems within individual domestic premises. These recommendations are crucial during initial commissioning or re-commissioning after significant remedial work, such as boiler replacement. The standard also advocates for ongoing water treatment to protect and maintain the e ciency of appliances and systems.

The revision of BS 7593 was conducted by the BSI Technical Committee CII/62, which focuses on the treatment of water for boilers. The drafting of Amendment 1 involved recognised industry stakeholders and UK experts, including the Institute of Domestic Heating and Environmental Engineers (IDHEE), Builders Merchants Federation (BMF), Fernox, Industrial and Commercial Heating Equipment Association (ICOM), British Plastics Federation (BPF), BEAMA Water Treatment, Society of Chemical Industry (SCI), Sentinel Performance Solutions, Public Health and Safety Organisation (NSF International), Heating and Hotwater Industry Council (HHIC) and Veolia.

It’s more important than ever to make sure systems operate at peak e ciency

BS 7593:2019 is a well-established code of practice that is referenced in the Building Regulations, Approved Document L. The amendment linking BS 7593:2019 with BS 9593:2024 supports the e ective operation of existing boilers and the correct installation of new boilers, heat pumps and other systems. It aligns with industry energy initiatives and the government’s net-zero climate action agenda.

BS 7593:2019+A1:2024 is an industry code of practice on how to prepare circulating water during the initial commissioning (or re-commissioning) of domestic central-heating and water-cooling systems.

BS 9593 was developed to provide a method for assessing the recommendations for testing corrosion inhibitor, as outlined in BS 7593. This standard describes a test method for assessing the performance of chemical inhibitors in preventing corrosion and limescale formation, and ensuring their compatibility with non-metallic components in domestic centralheating and cooling-water systems.

The performance of the chemical inhibitor is tested and evaluated in three distinct stages:

• a short-term laboratory evaluation, performed in conventional glassware, to determine the corrosion rate and any pitting of standard metal coupons in inhibitor solutions at the manufacturer’s recommended strength

• a short-term laboratory evaluation, performed in conventional glassware, to determine the tendency of the inhibited solution to form limescale

• an evaluation of the e ect of the inhibitor on non-metallic materials.

BS 9593 does not apply to commercial or municipal premises, or to multiple residential premises served by one common circuit, unless that common circuit can be e ectively cleaned and flushed with domestic equipment. It does apply to individual heating and cooling circuits within individual dwellings in multiple residential premises.

By adhering to BS 7593 and BS 9593, industry professionals can ensure the e cient and trouble-free operation of heating systems, contributing to a sustainable and reliable energy future.