BIGGER PICTURE

IMPROVING THE energy e ciency of buildings has highlighted the issue of poor indoor air quality (IAQ) and the negative impact it can have on human health. In our feature (p18), members of the HVAC industry discuss the urgent need for better ventilation and strategies that can be implemented to improve the air we breathe.

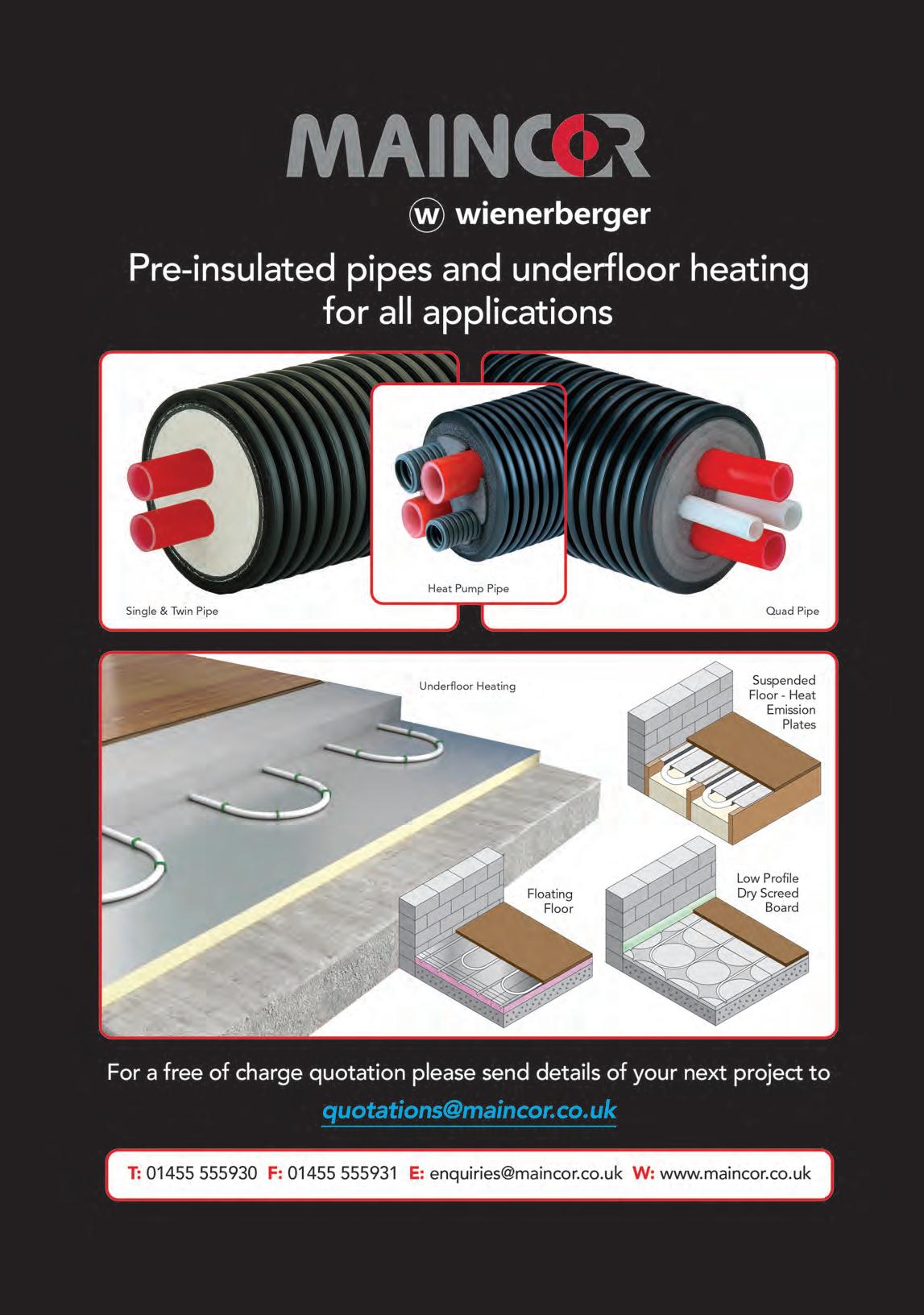

The government’s continued focus on low-carbon heating systems will see greater numbers of heat pumps being installed across Britain. With air source heat pumps being sited outside, insulation of pipework is essential. In this issue, P&H Engineering takes a look at the updates to BS 5422 and the measures installers need to take to ensure maximum e ciency and longevity of equipment (p22).

Ensuring the health and safety of workers is always important, but when it comes to installers working alone, extra consideration needs to be taken. The Wellbeing feature (p50) explains how to manage the risks to keep employees safe.

SARAH WELSH Editor

pandhengineering @jamespembrokemedia.co.uk

Editor Sarah Welsh Project manager Lizzie Hufton

Design and production manager Christina Richmond

Publisher James Houston

Published by James Pembroke Media, 90 Walcot Street, Bath BA1 5BG Tel 01225 337777

Advertising sales Oliver Willison, 0203 198 3092 oliver.willison@jamespembrokemedia.co.uk

Chartered Institute of Plumbing and Heating Engineering (CIPHE) Saxon House, 27 Duke Street, Chelmsford CM1 1HT Tel 01708 472791

18 Improving indoor air quality

Strategies for healthier buildings

22 Insulating external systems

Maximising efficiency and longevity

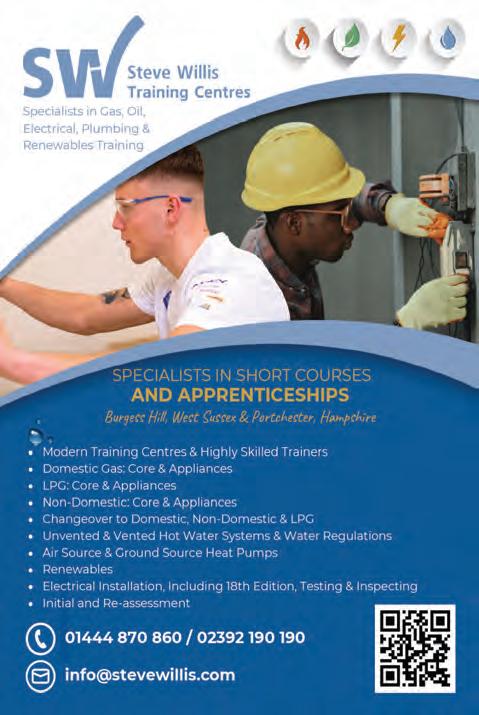

26 New apprenticeship standards

Making apprenticeships more accessible

32 Project focus

A sustainable development in Scotland

48 International

How Spain's EIC is setting the standard for energy transition

5 From the CEO

Kevin Wellman on the development of new plumbing apprenticeship standards

Membership Founded in 1906, the Chartered Institute of Plumbing and Heating Engineering (CIPHE) is the professional body for the UK plumbing and heating industry. Membership is made up of consultants, specifiers, designers, public health engineers, lecturers, trainers, trainees and practitioners. The CIPHE has a membership of 7,500, including over 150 manufacturers and distributors. The majority of members live in the UK, although over 1,500 are residents in Hong Kong. The CIPHE is a member of the

6 Frontline

Energy policy, industry news and more

16 Meet the member

Ian Hall on training the next generation

30 Education

Training to help protect the vulnerable

36 The Fix: Heat networks

Advice on optimising efficiency

43 The Fix: BTU bingo

The great heat-loss calculation gamble

45 Products

The latest innovations

46 Membership

Reaching new milestones in 2025

50 Wellbeing

Ensuring the safety of lone workers

Construction Industry Council and a licensed member of the Engineering Council.

Subscriptions P&H Engineering is the magazine for the Chartered Institute of Plumbing and Heating Engineering, containing technical articles, latest industry news and environmental and educational updates. It is published four times a year and sent free to members.

Annual subscription for non-member £80

Annual subscription for overseas non-member £100 To join CIPHE, email tims@ciphe.org.uk

KEVIN WELLMAN Chief executive officer

kevinw@ciphe.org.uk

“The new apprenticeship standards are designed to address the skills gap”

The CIPHE’s involvement in drawing up new level 2 and level 3 apprenticeship standards is just one of the ways it is helping our sector move forward, says Kevin Wellman

DURING THE FIRST week of January, I was delighted to receive confirmation that the Institute for Apprenticeships and Technical Education (IfATE) has formally approved the CIPHE’s proposal to develop new level 2 and level 3 plumbing apprenticeship standards.

These new standards are designed to address the widening skills gap threatening our sector and have been developed by the Plumbing Employers' Group. I believe the new apprenticeship will:

• maintain and enhance high training standards

• give more businesses operating in the plumbing industry the opportunity to o er apprenticeships

• support apprentices, providing practical, real-world readiness

• provide career pathways for advancements in low-carbon technologies.

The health and wellbeing of the public remains uppermost in CIPHE’s priorities. Our latest manifesto (2025-27), details our concerns, as well as our work in raising awareness of key issues.

labelling scheme in 2025, so watch this space for further developments. I believe this o ers another opportunity to produce mandatory CPD to raise awareness of compliant products and ensure conformity with Water Regulations (Byelaws in Scotland). There is no doubt that water e ciency and minimising leakage is high on the government’s agenda, so I would not be surprised if measures are introduced to reduce and safeguard water supplies and consumption.

Heating and powering buildings accounts for 30% of the UK’s total energy usage, so our homes will play a vital role in the UK’s e orts to reach net zero carbon emissions. It is anticipated that later this year, compliance with the Future Homes Standard (FHS) will become mandatory. Its aim is to ensure that new homes built from 2025 will produce 75-80% less carbon emissions than homes built under current Building Regulations.

Learn about the CIPHE’s aims in our new manifesto, which you can download using the QR code above.

Working with government, we continue to promote the need for mandatory CPD and are hopeful that low-carbon training will be mandated this year, introducing a level playing field across the industry. Over 2,000 people have completed CIPHE’s low-temperature training qualification since it was introduced a couple of years ago. I urge you to sign up to a course as soon as you can, as places will no doubt be in short supply later in the year.

Defra has rea rmed its commitment to introduce a mandatory water e ciency

In preparation for the FHS, Parts F and L of the Building Regulations have been reviewed to increase the energy e ciency of homes. It is anticipated that, in taking these steps, the construction industry will be better placed to meet the specifications of the FHS in 2025 through improved supply chains, skills and construction practices. With so much anticipated change within the industry, there is no better place than the CIPHE to keep up to date with all of the developments.

Thank you for supporting our activities. If you are interested in helping with our technical, education, membership or employer groups, please let me know.

THE GOVERNMENT HAS unveiled its Clean Power 2030 Action Plan, which details how it proposes to reform Britain’s energy system and tackle the climate crisis by improving energy security, protecting households from fluctuating fossil fuel prices and creating new energy industries supported by thousands of skilled workers.

In a statement, the government said that for too long, there had been no plan for building new energy infrastructure based on an assessment of the country’s long-term needs. As a result, billions of pounds of clean energy projects have been held up by a clogged-up planning system and a dysfunctional power grid queue

that means renewables projects cannot get online.

The plan sets out measures to provide people with better access to clean power, including: cleaning up a dysfunctional grid system by prioritising the most important projects and ending the ‘first-come, first-served’ system; speeding up decisions on planning permission by empowering planners to prioritise critical energy infrastructure; and expanding the renewable auction process to stop delays and get more projects connected.

Delivering these reforms could unlock £40 billion a year of mainly private investment in clean power projects and infrastructure, creating

jobs in engineering and mechanics.

Energy Secretary Ed Miliband said: “The era of clean electricity is about harnessing the power of Britain’s natural resources so we can protect working people from the ravages of global energy markets.

“The clean power sprint is the national security, economic security and social justice fight of our time –and this plan gives us the tools we need to win this fight for the British people.”

For more details about the government’s Clean Power 2030 Action Plan, visit: gov.uk/ government/publications/ clean-power-2030-action-plan

A RISE IN RENEWABLES, a fall in demand and cheaper power imports have all helped to reduce the use of fossil fuels in the UK to record lows. For the first time last year, more electricity was generated by renewables than fossil fuels.

Homegrown UK renewable power from wind, solar and hydropower generated 37% of UK electricity in 2024 (103TWh) compared to 35% from fossil fuels (97TWh). Just three years ago, in 2021, fossil fuels accounted for 46% of UK electricity, while low-carbon renewables generated 27%.

Fossil fuel generation has fallen by two-thirds since 2000, due to the long awaited phase-out of coal, and gas being increasingly displaced by cheaper, cleaner power sources.

Kelly Becker, president UK and Ireland, Belgium and Netherlands, at

Schneider Electric said: “This marks a significant milestone towards the government’s Clean Power 2030 ambition and firmly positions the UK as a global leader in tackling climate change.

“However, there is still a long way to go before we can reach our wider emissions reduction targets. There need to be concrete plans for wider sectoral decarbonisation, namely industrial and building decarbonisation.

“Digitalisation will be key to this, and we need greater coordination between government and business to increase the uptake of digital technologies for energy efficiency and productivity.

“The energy transition will not only reduce environmental impact, but will also unlock economic growth as well as job creation – with our research finding that 247,000 jobs can be created in the UK by adopting clean energy technologies across the UK’s building stock. This will be crucial for the UK’s progress towards a more sustainable and technologically advanced future.”

To read the full report and recommendations, visit: nepc. raeng.org.uk/healthy-buildings SUSTAINABILITY

A new report from the National Engineering Policy Centre (NEPC) explains how building retrofit can help the UK achieve its net zero goals, while delivering health benefits in homes and public spaces.

The report outlines why building retrofit programmes are essential for improving homes and buildings, meeting national net zero goals and addressing health inequalities.

Indoor air quality has a significant impact on health and wellbeing, with disadvantaged groups facing higher risks. The report proposes solutions to ensure that retrofitting buildings creates healthier environments, avoiding issues with mould and indoor air pollutants.

The report concludes with five recommendations for policymakers to embed a systems-based approach in retrofit, including insulation and airtightness, ventilation and air cleaning, and low-carbon heating.

A recommendation that automatic fire suppression systems should be mandatory in all open-sided multi-storey car parks has been welcomed by the Business Sprinkler Alliance (BSA).

A report on the Luton Airport car park fire by the Bedfordshire Fire and Rescue Service highlighted significant gaps in current building regulations regarding fire suppression systems in multi-storey car parks.

“The Luton Airport fire has exposed a troubling disconnect between our current regulatory guidance and the reality of modern vehicle fires,” said Tom Roche, secretary of the BSA. “What’s particularly worrying is that this £20 million structure, built as recently as 2019, was completely compliant with current regulations yet proved vulnerable to devastating fire spread.”

ALMOST ALL OF the social landlords in the UK have reported having mould issues in properties under their remit and many are at a loss on how to deal with the issue.

The survey, from indoor climate solutions provider Zehnder Group UK, found that 99.2% of social landlords have experienced mould issues in properties under their remit and almost half (41%) believe that the main cause is the weather.

More than one in 10 landlords said that mould a ects over half of their housing remit and almost a third (32%) of tenants said their homes had mould in five to six rooms.

Commenting on the findings, Zehnder RMI national manager, Mark Trowers, said: “Over half of tenants (54%) admitted to turning o extractor fans in their bathrooms and kitchen, yet the reasons for doing so are rooted in a lack

of understanding, with 36% claiming heat loss from the fan, running costs (34%), noise (33%) and nearly a fifth (18%) claiming they just don’t need them.

“Extractor fan technology has come a long way and no resident should feel the need to turn o their fan due to noise or cost. As an industry, we need to help landlords navigate this epidemic and arm them with information and tools to make their properties healthier – we are part of a bigger and quite complex puzzle where education, accessibility and collaboration is key.”

CISTERMISER HAS launched a campaign to raise awareness of the benefits of direct flushing. The firm says direct flushing can o er a more e cient, hygienic and cost-e ective solution to water saving in washrooms, and is ideal for today’s high-usage environments.

Cistermiser MD Richard Braid said: “With the UK facing a growing water

crisis, where projections suggest that by 2050, nearly five billion extra litres of water will be needed daily to meet demand, something needs to be done. While a dripping tap can waste 5,500 litres a year; a leaking toilet can waste 400 litres a day. It is vital that water is managed and conserved e ectively wherever possible – and direct flushing really works.”

Waterwise has announced that Diane McCrea MBE will be its new chair. McCrea has many years’ experience as a chair, including for Natural Resources Wales, Sustain Wales and homeless charity, Shelter Cymru.

CEO of the environmental campaigning organisation, Nicci Russell, said: “Waterwise is very lucky to have Diane McCrea steering us through the next exciting stage of our journey. She has been on our board for two years and was our interim chair, so we know that her approach is very inclusive.”

Hive has announced an upgrade to its smart thermostat technology which now includes OpenTherm, delivering customers with OpenTherm compatible Combi boilers a reduction of up to 12% in gas consumption.

OpenTherm allows constant communication between the thermostat and the boiler, resulting in greater modulation of the flow temperature within a home heating system. The technology enables the boiler to adjust its output more accurately based on the current heat demand, making it run more efficiently and, therefore, reducing household emissions.

A NEW FULLY-FUNDED 15-minute course designed to provide an essential introduction to heat networks has been launched by GTEC.

Covering the design and feasibility of heat networks for various applications, the course can be accessed remotely and contributes towards CPD points.

Funding has been awarded by the Department for Energy Security and Net Zero (DESNZ), which plans to accelerate the rollout of heat networks by identifying geographical areas where they are expected to provide the lowest cost solution for decarbonising heat (heat network zoning).

Griff Thomas, MD of GTEC, part of the United Living Group, said: “With much potential to decarbonise built-up environments, the government sees heat networks as an important growth area for the UK, sustaining jobs, boosting the economy and helping urban and out-of-town commercial developments move away from fossil fuels.

“Our course will provide those with an interest in district heating with the background information to make informed decisions, equipping candidates with the fundamentals of this approach to multi-building

DAVID BATEMAN-SMITH of South West College NI and Ashley McFarland Plumbing & Heating has been named the SkillPLUMB 2024 UK Champion and gold medal winner.

The 19-year-old was followed by three joint second winners and three joint third winners in what turned out to be a closely contested event held at Oldham College as part of the WorldSkills UK National Finals.

Silver medals were awarded to Shaun Wilcox (Moray College UHI / Moray

heating: whether they’re designing, installing or managing heat networks in the future.”

Funded training places will be allocated on a first come, first served basis. To secure your place, visit: gtec. co.uk/funded-heat-network-training

Council), Elliot Julian (Cornwall College / Nicholls Plumbing & Heating), and Jackson Gill (New College Durham / CGE Yorkshire).

Bronze medals went to Jack Fenton (Belfast Metropolitan College / Ian Reid Heating), Samuel Page (Suffolk New College / Whitwell Services), and Dillon Newton (Cornwall College / Justin Eyre Plumbing & Heating).

Across two-and-a-half days, the competitors had to tackle a complex plumbing installation task and, in a first for 2024, demonstrate their low carbon knowledge in a new heat pump module, developed in collaboration with Ideal Heating.

UP TO 300,000 homes are set to benefit from upgrades this year as the government continues the rollout of its Warm Homes Plan.

Measures to help households save money on their bills and deliver cleaner heating include boosting the budget for the Boiler Upgrade Scheme (BUS) and removing restrictions that currently prevent homeowners installing a heat pump less than a metre from their property’s boundary without planning

permission. Figures from Octopus show that 34% of those who order a heat pump are discouraged or drop out for reasons attributed to planning restrictions.

According to Ofgem, October 2024 saw the highest number of applications for the BUS, which offers grants of up to £7,500 to encourage households to switch to a heat pump or biomass boiler.

Social housing residents, low income

THE CIPHE HONG KONG branch recently visited Q-Leak, the underground water mains leak detection training centre.

Constructed by the Water Supplies Department (WSD), the centre provides facilities for strengthening the industry with training and research capabilities on leak detection. During

the visit, members were informed about methods and technologies for effective leak detection and shown how to implement water mains improvement work.

The WSD envisages that Q-Leak will serve as a teaching and research cooperation platform for the department, the trade and post-secondary

households and renters will also receive funded energy efficiency upgrades, including insulation and low-carbon heating, through the Warm Homes Social Housing Fund and the Warm Homes Local Grant.

The incentives have been welcomed by heat pump supplier NIBE, but it says more installers will be needed to meet increased demand for heat pumps, and the BUS should be expanded to include more products.

Paul Smith, MD of NIBE, said: “We applaud the ongoing expansion of the Warm Homes Plan and the government’s move to streamline heat pump installations by cutting red tape around permitted development. However, to accelerate the transition to heat pumps, the installer network must also be expanded. We join the Heat Pump Association in urging policymakers to address the spark gap, which remains a significant barrier to the widespread adoption of heat pumps.

“We also welcome the boosted budget for the BUS, which is a vitally important mechanism for retrofit homes. However, to truly unlock the potential of renewable heating and further accelerate decarbonisation, the scope of the scheme must be broadened to include a wider variety of heat pump solutions such as exhaust air heat pumps.”

education institutions in Hong Kong, elevating the territory’s technical skills in the field of water mains

leak detection and contributing to the management of its precious water resources.

A SURVEY HAS revealed the most pressing issues facing heat pump installers, from customer misconceptions about heat pump technology to challenges with costs and system sizing.

Conducted by Heatly, the survey found that there is still a firmly held view that heat pumps only work in new builds – 72% of respondents stated this was the most common customer barrier. When it came to installation issues, oversizing was the main complaint, with over 50% of recipients reporting this as the biggest problem.

Other barriers to take-up included consumers fearing heat pumps are too expensive to run (nearly 65%) and a pervasive ideology that heat pumps don’t work in cold weather (more than 60%) – despite their widespread adoption in much colder parts of Europe. Noise concerns also featured highly (just under 50%), something that can be countered by recent reports, such as that by NESTA which found modern heat pumps to be no noisier than other household appliances, such as fridges and gas boilers.

Consumer misconceptions can be allayed by facts, case studies and providing more evidence that well-installed heat pumps can work in (almost) any home. The survey showed,

however, that some engineers still feel there are sticking points at the system design stage that need addressing.

Apart from oversizing, which can lead to ine ciencies and higher installation costs, 35% of installers felt that heat loss calculations sometimes failed to match real-world performance – over 20% reported that this happened often.

Issues with system design are being addressed by the latest digital tools, which standardise these processes and make them easier and more accurate for installers. Heatly is launching an app that will streamline and speed up heat pump specification.

Paul Spence, technical manager at Heatly, said: “It’s great that the installation figures are on the up, but they still fall well short of where they need to be. Our findings show that consumer misconceptions still blight adoption, while highlighting areas where installers require further support, particularly at the design and specification stage. Consumer education and installer support are the key takeaways here, both crucial to the continued success of the heat pump rollout in the years ahead.”

To read the full survey results, visit heatly.com/blog/ heat-pump-installation-survey-2024

London-based gas and heating installer Shoaib Awan, known as The Gas Expert, was among the winners at the On The Tools Awards 2024.

As the founder of Trades United, Awan advocates for better regulations for tradespeople and raises awareness of tool theft, and his community involvement and passion for his craft made him a standout candidate for the Heating Installer of the Year award, sponsored by The IPG.

The awards, which took place in November and are sponsored by Jewson, celebrate talent, dedication and innovation within the UK’s construction sector.

The judges said: “Awan’s contributions to addressing tool theft in the trade earned him special recognition.”

To see the full list of winners, visit onthetools.tv/awards

“I tell anyone who’s interested in becoming a plumber that it’s the best career to get into”

Ian Hall is passing on his in-depth knowledge of the plumbing and heating industry to the next generation of installers

WHEN IAN HALL left school in 1987 at the age of 16, his father encouraged him to pursue a career in plumbing and heating. Heeding his dad’s advice, he applied to take a Level 2 Craft Certificate at Bolton College.

“My dad’s friend was a plumber and he saw the value in working in a trade,” explains Ian. “My dad also encouraged my brother to learn a trade and he’s now an electrician. However, if I’m honest, when I applied, I was not fully conversant with the role and the wide range of activities plumbing and heating engineering covers.”

In the same year, Ian answered a newspaper advertisement for an apprentice plumber with the local housing department, Bolton Housing DLO (now Bolton at Home), which looked after 28,000 houses. He attended an aptitude test at Bolton Town Hall and was invited for a follow-up interview, which was successful.

“I began my apprenticeship on a YTS (Youth Training Scheme) and was then signed up as an indentured apprentice,” says Ian. “Before starting, the 12 new apprentices were taken on an outdoor adventure retreat for a week of team bonding. It was a fantastic experience, which included gorge walking, abseiling and kayaking. I was extremely fortunate to gain an apprenticeship with an employer that really cared about its young trainees.”

Laying the foundations

Ian worked on a variety of projects during his time with Bolton at Home.

“I was lucky to be trained by some wonderful people, covering a range of plumbing and heating skills,” he says. “Some, alas, are no longer in the course – sheet lead weathering and glazing, for example. All of this was covered in the workplace as we were responsible for the maintenance of domestic homes as well as schools and public buildings in the borough of Bolton.”

Ian covered day-to-day property repair and maintenance (emergencies); installation of bathrooms, kitchens and heating systems; glazing; working on above- and below-ground drainage, and servicing of heating systems, in addition to installing oil, gas and renewable technologies.

“The apprentices built new bungalows from start to finish, with guidance and support from the apprentice master who oversaw all the jobs that we worked on, including refurbishing a number of properties in the borough,” explains Ian.

Change of direction

After almost two decades in a variety of roles at Bolton at Home, including plumber, gas engineer

and installation engineer, in 2006 Ian left for a teaching position at Tameside College in Ashton-under-Lyne. He taught apprentices and full-time students working towards the Level 2 technical certificate in plumbing, Level 2 NVQ and Level 3 NVQ with gas and renewable pathways.

“The Level 2 course covered basic plumbing studies, practical and theory,” explains Ian. “Safety, scientific principles, common plumbing processes, cold and hot water, and heating in theory, in addition to a range of practical plumbing tasks in the workshop.

“The NVQ was taught along the same lines, but was also assessed in the workplace as the candidates completed their portfolio covering a range of installs across di erent systems.”

During his seven years at the college, Ian became an assessor, internal quality assurance (IQA) and resource developer.

In 2013, Ian secured a position as a senior tutor at Manchester College covering similar duties. However, having recently set up a centre at Tameside that focused on low-carbon technologies, he was keen to give college students who did not have access to gas work the chance to build their renewables knowledge and skills to complete their Level 3 NVQ.

Ian was deputy head of the construction department at Wigan and Leigh College, and even went back to Tameside for three years, between 2018-2021, before finally returning to Bolton College, where it all started.

“It was a very special moment,” he says. “I had come full circle from a 16-year-old apprentice learning my trade at Bolton at Home and Bolton College to returning as a 50-plus-year-old tutor to educate and train apprentices in my home town. My role was to help close the region’s skills gap by giving everyone who came through the door the chance to be employable, retain their skills and upskill to new technologies that meet the green agenda, locally and nationally.”

Positive experience

Ian recently became a member of the CIPHE as an individual, but all of his employers were CIPHE approved.

“I was lucky to be trained by some wonderful people, covering a wide range of plumbing and heating skills”

• Apprentice of the Year Bolton at Home

• Plumbing Craft Certificate & Advanced Craft Certificate Bolton College

• Innovation Award for the introduction of digital teaching methods: Tameside College

• Individual Award for development of new course material and courses that meet the need of the sector (LCHT): Bolton College

• Contributor to HIP Magazine covering all aspects of plumbing and heating themes

• Developing new resources

that meet the low-carbon heating technician standard and leading the way regionally and nationally for this new standard

• Working with the trailblazer group and MCS to meet the deadline for the rollout of the apprenticeship

• Development of the aptitude test that Bolton at Home used in its apprenticeship recruitment for building services

• Development of free resources via the website, www.halledu.co.uk, which is used by students up and down the country

“I became a member because of the prestige of the organisation,” explains Ian. “Its history, heritage and the help and assistance it o ers its members, as well as the resources available to stimulate tutors like me to assist in my delivery, is invaluable. The training academy is second to none, as are the CPD opportunities on o er.”

With a career spanning decades, Ian has nothing but praise for the plumbing and heating industry as a career choice.

“I tell anyone who’s interested in becoming a plumber that it’s the best career to get into,” he enthuses. “I’ve been in the industry since 1987 and I’ve never been unemployed. I am so thankful to my dad who started me on this path all those years ago. I have never looked back.”

Ian’s mission is to help train and develop the next generation of

Good HVAC systems go beyond heating and ventilation, helping to combat poor indoor air quality

The topic of air pollution has been highly publicised over the years, with people recognising the impact that it can have on their health. However, as homes have become more e cient thanks to better insulation, the subject of indoor air quality (IAQ) has become increasingly significant.

According to a recent study by Evelina London Children’s Hospital and King’s College London, air quality at 86% of planned new school sites in England exceeded World Health Organization (WHO) targets on major pollutants.

“This indicates that a large number of educational institutions, and likely other types of buildings, are failing to provide safe air for their occupants,” says David Millward, product manager at Elta Group. “The pandemic has further underscored the importance of IAQ, as people have become more aware of the air they breathe indoors.”

Behind closed doors

Poor IAQ is a growing concern, particularly as people spend a significant amount of time indoors where pollution levels can be higher than outside.

According to the Air Quality Expert Group’s Indoor Air Quality report, in the absence of indoor sources of pollution, IAQ is determined by ingress of outdoor air, balanced with pollutant loss processes such as deposition to surfaces and through ventilation.

Most enclosed spaces, such as homes, o ces, schools and public buildings, have a wide range of indoor emissions that come from building materials,

An HVAC system is only as good as the products installed within. It is vital that those specifying, designing and installing HVAC systems choose the right products to combat poor IAQ.

“By choosing certified products, professionals have a guarantee of performance and energy efficiency,” says Butler. “Manufacturer claims have been independently verified, providing the assurance that IAQ deliverables will be met.”

“Even the ‘perfect’ building can be a ected by outdoor pollutants”

furnishings, gas and solid fuel cookers, boilers and stoves, the consumption of solvent-containing products, pet dander, dust mites, pollen, and cleaning and personal care products.

Humans are also a source of emissions, including carbon dioxide, human bio-e uents and biological aerosols such as viruses. Although some factors are beyond individuals’ control, such as the building fabric or ventilation in public spaces or workplaces, certain actions can directly influence the concentrations experienced. Dispersion is far more limited indoors than outdoors, so even modest inside emissions can result in higher concentration levels. For example, indoor mould and damp can lead to elevated concentrations of biological aerosols when compared to those typically found outdoors. What emerged from the report is that there is a greater concentration of a diverse range of chemicals found in indoor air compared with outdoor air in the UK.

Standards for acceptable ventilation rates are included in Building

Regulations (Part F) and products with a high volatile organic compound (VOC), such as paints, have been regulated through EU Directives. However, these aren’t always well integrated or used to their best e ect, according to the report. Additionally, despite a number of labelling schemes for construction products across Europe, currently there aren’t any in the UK.

“Even the ‘perfect’ building with no indoor emissions can still be a ected by the ingress of outdoor pollutants, including transport emissions, dust and pollen,” says Stijn Renneboog, deputy secretary general at Eurovent. “That means all buildings are at risk. It also means that no two buildings are alike.

“To aggravate things further, buildings are becoming more energy e cient as

“The more airtight buildings become, the higher the risk of poor IAQ”

we prepare for net zero. Fully insulating buildings presents a double-edged sword. Energy efficiency is greatly improved and issues which lead to poor IAQ, such as draughts and condensation, are reduced. However, pollutants are trapped inside and can gather in higher concentrations. The more airtight buildings become, the higher the risk of poor IAQ, especially if the indoor environment is not adequately managed by correctly designed and installed heating, ventilation and air conditioning (HVAC) systems.”

Poor air quality in homes, schools and other public buildings can have a profound impact, particularly on vulnerable people, such as children and the elderly. Prolonged exposure to pollutants such as carbon monoxide, ozone, nitrogen dioxide and sulphur dioxide can lead to serious health issues, including respiratory issues such as asthma, underdeveloped lungs, increased susceptibility to pneumonia and even cancer. Poor IAQ can also contribute to cardiovascular, developmental and neurological issues. High humidity and insufficient ventilation can exacerbate these issues, creating an environment where pollutants and contaminants thrive.

“In schools, poor IAQ can affect students’ cognitive functions and academic performance, leading to absenteeism and long-term health issues,” points out Millward. “In homes and public buildings, poor air quality can contribute to chronic health conditions, reduced productivity and overall diminished quality of life.”

Poor IAQ can also have an impact on mental health, with potential consequences including stress, anxiety, low mood, insomnia and depression.

Hidden pollutants in homes can damage residents’ health

In fact, figures from the IAQ Matters campaign show that good IAQ helps schools reach their primary goal of educating children by increasing learning performance by 12%. It’s much the same for businesses. Poor air quality due to increased pollution/decreased ventilation is estimated to result in businesses experiencing a 5% drop in work performance. A 5% boost in work performance means:

• 25 minutes longer in the working day

• reduced number of breaks

• 10 less days of sick leave per year.

“The cost of providing good IAQ in office buildings is less than 1% of the labour cost,” says Renneboog. “It makes financial sense to invest in good IAQ.”

Aside from the worrying health issues, poor IAQ can also damage buildings. Condensation promotes mould growth on walls and window frames, which can lead to long-term structural and maintenance challenges.

Our increasingly warm climate can also have a profound impact on IAQ and public health. Elevated temperatures and high humidity can disrupt the body’s natural cooling process, causing discomfort when sweat fails to evaporate effectively.

“High humidity can exacerbate these conditions by creating a stuffy indoor environment and promoting condensation, which fosters the growth of harmful bacteria and mould,” points out Richard Soper of Unico. “Prolonged overheating in buildings can also affect equipment and infrastructure, leading to increased maintenance costs and reduced productivity.”

What’s more, high temperatures can increase the concentration of indoor pollutants by accelerating the emission of VOCs from building materials and furnishings. They can also exacerbate the infiltration of outdoor pollutants such as ozone into indoor spaces.

“The combination of heat and poor IAQ presents a growing public health challenge, that requires coordinated efforts to adapt buildings and urban environments to a warming world,” says Renneboog.

Updates to the Future Homes Standard includes revisions to Approved Document F, which outlines air quality targets and mandates specific ventilation rates to ensure good IAQ. For example, an occupiable room such as an office must receive at least one litre of outdoor air per second per square metre, or 10 litres per second per person.

“These targets are designed to maintain air quality within safe limits as defined by health organisations

such as the WHO,” explains Millward. “Additionally, the UK government’s Building Bulletin BB 101 [Ventilation, thermal comfort and indoor air quality] provides separate guidance on ventilation in schools, specifying performance levels to meet UK regulations.”

In England there are extra regulations relating to the air pollutant of most harm to health – fine particulate matter (PM2.5). The Environmental Targets (Fine Particulate Matter) (England) Regulations 2023 set two PM2.5 targets to be met by 2040, requiring that:

• the annual mean concentration is 10 µg m-3 or lower

• the population exposure is reduced by 35% compared to 2018 levels.

The most harmful contaminants in dwellings are PM2.5, PM10, nitrogen dioxide, formaldehyde, radon and ozone 14. The UK has set air quality targets (via the previous government) primarily through its Environmental Improvement Plan 2023, which aligns with WHO guidelines and focuses on reducing some of the most harmful pollutants.

The UK also has legal emission targets for reducing five damaging pollutants by 2030 (relative to 2005 levels), which are to:

• reduce emissions of nitrogen oxides by 73%

• reduce emissions of sulphur dioxide by 88%

Improving IAQ involves a multi-faceted approach:

• Proper ventilation Installing and maintaining effective ventilation systems is crucial. Mechanical Ventilation with Heat Recovery (MVHR) systems can optimise airflow based on occupancy, ensuring that new air is supplied efficiently while conserving energy.

• Monitoring and assessment

Installing monitoring equipment, such as room sensors, can help track

levels of pollutants such as temperature, humidity and carbon dioxide. This data can guide adjustments to ventilation systems to maintain optimal air quality.

• Expert consultation Consulting with ventilation experts can help you design bespoke air quality management plans for specific buildings. Experts can give recommendations on best practice for installation and maintenance.

• Compliance with regulations Adhering to building regulations, such as Approved Document F and BB 101, ensures that systems meet required standards and provide adequate air quality.

• Regular maintenance Checking ventilation systems is essential to keep them operating effectively. This includes changing filters, cleaning components and ensuring that all parts are functioning correctly.

“Poor IAQ can affect students’ cognitive functions and academic performance”

• reduce emission of PM2.5 by 46%

• reduce emissions of ammonia by 16%

• reduce emissions of non-methane volatile organic compounds by 39%.

“Public health advocates and parliamentary committees have highlighted the need for more ambitious and immediate action, especially in urban and disadvantaged areas disproportionately affected by air pollution,” says Ian Butler, partnership manager at Eurovent Certification. There is currently a campaign to incorporate IAQ into Energy Performance Certificates (EPCs) and reform of the system offers an opportunity to introduce the reporting of IAQ metrics.

“In the EU, the new Energy Performance of Buildings (EPBD) directive published in May 2024 is already bringing this into force,” adds Butler. “The EPBD indicates that temperature, humidity, ventilation rates and the presence of pollutants should be taken into account with the energy performance of buildings. Member states have two years to justify the application of the directive, and the means implemented to transpose it into their national text. While the UK is under no obligation to follow the EU’s lead, it is both possible and desirable to incorporate IAQ indicators within EPC certificates.”

Tackling the problem of poor IAQ requires a mixed approach that addresses the key issues, and should cover ventilation, air filtration, temperature regulation, humidity control and air disinfection (see left).

Millward concludes: “By implementing these strategies, building engineers and facility managers can significantly improve IAQ, protecting the health and wellbeing of occupants in homes, schools and other public buildings.”

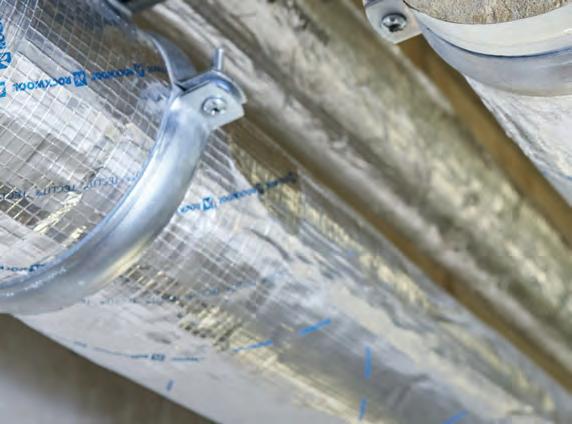

Updates to BS 5422 have simplified the specification of pipe insulation for plumbing and heating engineers

Energy efficiency is a huge focus for the UK government in its drive to reduce carbon emissions, while businesses and residents are keen to mitigate rising energy costs. Insulation can play a crucial role in preventing heat loss, corrosion of pipework and condensation, so it’s vital that plumbing and heating engineers are familiar with the standards, such as the updated BS 5422, which covers insulation of building services.

Why is the new standard important?

Proper installation and performance of pipe insulation is essential to maximise efficiency and safety, which is why there is an extensive set of standards and regulations that are overseen by governmental and industry organisations.

The British Standards Institution’s (BSI) BS 5422 specifies how to use thermal insulation materials for pipes, tanks, vessels, ductwork and equipment. This helps designers, specifiers, contractors and thermal insulation manufacturers to work out the minimum insulation thickness needed to control heat losses and gains from building services. The standard covers operating temperatures from 40°C to +700°C in domestic, non-domestic and commercial buildings, so will be applicable in almost every setting that British installers and engineers work on.

What is it intended to do?

BS 5422 addresses a range of applications, including:

• conservation of energy for both cooled and heated systems

• preventing slow freezing of contents

• controlling condensation on cold surfaces

• protecting personnel from exposure to extreme surface temperatures

• managing process or service temperatures

• limiting the effects of a system on indoor building temperature.

UK pipe insulation standards and regulations cover a wide range of requirements, including:

“The standard now features enhanced performance tables for certain applications”

• Insulation materials: specifications for materials such as mineral wool, elastomeric foam, plastic foams and calcium silicate.

• Insulation thickness: minimum insulation thickness mandated for pipe diameters and temperature ranges.

• Installation procedures: proper techniques for securing, sealing and covering insulation materials.

• Testing and certification: standards for evaluating insulation product performance through testing.

• Health and safety: requirements to minimise risks such as fire hazards, corrosion, surface condensation and other dangers.

• Energy efficiency: stricter limits on heat loss to reduce energy waste and carbon emissions.

Compliance with UK pipe insulation standards is required for new building construction, but it is also encouraged for retrofit programmes of existing buildings.

What has changed?

The latest edition of the standard, BS 5422:2023, came into effect on 30 June 2023, replacing the 2009 version. For new projects, including those with planning permission granted after this date, BS 5422:2023 applies. However, for projects where tender documentation was issued or contracts were awarded before the update, BS 5422:2009 continues to apply.

“While the minimum performance requirements of BS 5422:2023 remain the same as the 2009 edition, the standard now features enhanced performance tables for certain applications,” explains Will Wigfield, HVAC and fire protection product manager at Rockwool. “While

compliance with these enhanced tables is optional, they are presented as the default option. Should a specifier wish to continue using the base level performance tables, this must be noted in their specification.

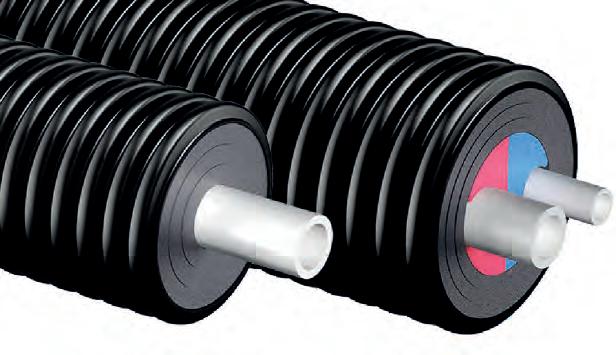

“The standard now covers district heating networks and provides maximum permissible heat loss figures for this application.”

The updates to BS 5422 also included a move from national fire classification of insulation material to the European system, which will align current building regulations and the relevant harmonised product standards for HVAC insulation. According to BSI, Euroclass fire ratings give a more comprehensive and clear definition of the behaviour of materials exposed to fire than the more limited legacy BS 476 (British Standard Fire Tests).

“The Euroclass system determines a product’s fire performance by measuring a comprehensive set of characteristics, including ignitability, flame spread, heat release, smoke production and propensity for producing flaming droplets or particles,” explains Wigfield. “The classifications run from A1 to F, with products achieving A1 and A2-s1, d0 typically defined as non-combustible.”

Tables have also been revised and simplified where possible and higher thermal conductivity values for obsolete or rarely used insulation materials have been removed, with single wall plastic pipes classified as having no insulative value of their own.

The changes to BS 5422 have been positively received by the industry, because the introduction of simplified tables has made the specification process easier. The thermal conductivity values in the new standards are also based on the most commonly used insulation materials. In the UK, the thermal performance of pipe insulation is typically measured using the U-value, which indicates the rate of heat transfer through a material, and is calculated based on the insulation’s thickness and

its thermal conductivity (lambda value), with lower U-values signifying better insulation performance.

“It’s important to note, however, that the thermal performance of some insulation materials deteriorates over time,” says Wigfield. “In such cases, an aged thermal performance is declared, which typically takes the form of a ‘time averaged’ lambda value over 25 years.”

The thermal performance of material such as stone wool does not change over time, so it’s important for installers to bear this in mind when deciding which material to use, based on the expected lifespan of the building or HVAC installation.

“When choosing insulation, plumbing and heating engineers need to make sure products are suitable for all weather conditions and that they include UV protection,” says David Smith, founder of Primary Pro and Condensate Pro. “Engineers need to take care not to damage insulation in transit or storage as this can impact its e ciency.

“It’s also important for engineers to remember that BS 5422 is for reference only and the guidance mainly applies to internal insulation,” he adds. “When engineers are specifying

Get to know the standard

You can access BS 5422, and other British Standards, through bsol.bsigroup.com It can also be accessed for free through your library.

Insulation manufacturers are up to speed on the latest guidance and can help you specify the right material and thickness for your job. Some firms, including Rockwool, have developed their own CPD materials to help installers apply the new standard.

Make your customers aware that correct specification and fitting of insulation in their building is a vital tool for saving money and improving sustainability.

external insulation for heat pumps and condensate piping, it’s essential that they use products that can withstand all types of weather to ensure thermal e ciency.”

Further guidance to help avoid thermal bridging has been included in the updated standard to avoid pipe supports and fixtures being overlooked during insulation calculations.

The standard states that load-bearing insulation should be used between the pipes and any support or fittings to avoid a gap in the insulation caused by compression of the material.

“When it comes to clips, it’s essential that they are fitted on the outside of the insulation,” says Smith. “If they are clipped directly onto the pipe, insulated over the top and secured with tie wraps, moisture will be able to get in between the gap and impact thermal conductivity. Every 1% of moisture ingress on external insulation will increase thermal conductivity by 7.5%, so if it doesn’t have a decent water-resistant coating this will have a massive impact on the insulation’s e ciency. Ensuring joints and gaps are sealed correctly is just as important as the insulation.

“Making sure all insulation is correctly installed and maintained is the key to maximising e ciency. Therefore, maintenance of insulation is vital over the lifetime of the heat pump, particularly external pipes, so when engineers are servicing heat pumps it is essential to check the external insulation.”

The Health and Safety Executive (HSE) has extensive guidance covering insulation standards to prevent corrosion under insulation (CUI) in workplaces. Recommendations include:

• using fireproofing only when also designed to prevent CUI

• ensuring water vapour barrier effectiveness

• sealing seams and joints completely

• providing sufficient air gaps when cladding over insulation.

Other structural elements, including sti ening rings, should be insulated externally to prevent thermal bridging. Pipe support inserts have historically been made from wood, and although they successfully support pipes and protect insulation, wood is combustible and doesn’t provide the thermal performance required by BS 5422.

“Pipe supports made from insulating non-combustible materials, such as stone wool, have now been introduced, which ensure that the fire classification of the system will not be reduced while also complying with the requirements of BS 5422,” adds Wigfield.

“Overall, the revised standard brings the insulation parameters for HVAC systems in line with current building regulations, making it easier to specify the appropriate insulation needed.”

The proposed new plumbing apprenticeship standards will make the profession more accessible to more people and, in doing so, help to protect public health

Following its work campaigning for a series of new plumbing apprenticeships in England, the CIPHE has announced that the Institute for Apprenticeships and Technical Education (IfATE) has approved the development of the new level 2 and level 3 plumbing apprenticeship standards it proposed.

“The Institute’s legacy of representing the collective voices of the plumbing and heating industry – not just in the UK, but worldwide – as well as the members and employers that it represents, continues with the introduction of the new Plumbing Apprenticeship Standard,” says Kevin Wellman, CEO of the CIPHE.

Cracks in the system

The journey to developing the new standard began with a government move to reduce water waste. The Department for Environment, Food and Rural A airs (Defra) estimates that over 400,000,000 litres of clean water is wasted every day in the UK through preventable leaks such as ‘leaky loos’, and the CIPHE was asked to help find a solution.

With the source of many other leaks stemming from plumbing systems inside domestic properties and commercial businesses, the question arose as to why some plumbers were no longer repairing basic items, such as float-operated valves, taps and WC siphons/flap valves that were causing the leaks in the first place. For those inside the industry, the answer seemed obvious.

“A study of the current Level 3 Diploma in Plumbing and Domestic Heating showed that maintenance of systems was no longer being taught as a practical subject, the way it had been when there were separate NVQ Level 2 and NVQ Level 3 qualifications,”

“Maintenance of systems was no longer being taught as a practical subject”

explains Wellman. “It seemed to be a case of a lost ability due to an insu ciency of a straight Level 3 qualification that wasn’t being picked up during the training or at End Point Assessment. Through IfATE, the Department for Education asked the CIPHE what could be done to rectify the situation.”

Industry opinion

The CIPHE’s investigation included an education survey, the results of which made interesting reading. An astounding 90% of respondents from across the plumbing and heating profession expressed a wish to see the return of level 2 and level 3 plumbing qualifications in England – a system that works well in Northern Ireland.

Additional concerns expressed through the survey centred around those potential apprentices who aren’t able to enrol on a plumbing apprenticeship course due to their employer not engaging in the installation of a fuel or source of heat, such as a boiler or a heat pump.

Many learners are turned away each academic year because they cannot meet the requirements of the pathways and on-site assessment in the current plumbing standard. However, the new standards will address this imbalance.

Following the publishing of the results of the survey, IfATE asked the CIPHE to form a Plumbing Employers’ Group (PEG) and draft out:

“Employers have the right to insist that their apprentice is taught on a course that is fit for purpose”

• level 2 and level 3 plumbing standards proposals

• End Point Assessment plan

• a Level 2 and Level 3 mandated qualification

• justification for a mandated qualification.

There are over 30 members of the CIPHE’s PEG and meeting minutes are shared with IfATE in the interests of transparency.

Poor performance

It’s understandable that the CIPHE’s intentions with submitting new level 2 and level 3 plumbing standards have been questioned, particularly when an updated version of the Level 3 Diploma in Plumbing and Domestic Heating has just been released. However, the results from the first three end point assessments (EPA) speak volumes about the qualification.

“The UK government’s own statistics show that overall, the success rate for

this standard is a mere 13% and for 2024 alone, a demoralising 11.44%,” points out Wellman. “It is obvious to those who care to examine the data that this cannot be allowed to continue. The feeling is that the latest version of the EPA, which features seven days of assessments, will only make a bad situation worse. Already, communications within the education sector show that many colleges and assessment centres are turning their backs on plumbing and closing their plumbing centres down. Newcastle College group, Stephenson’s College

and others have all removed the Level 3 Diploma of Plumbing and Domestic Heating from their portfolio of apprenticeships.

“Employers have the right to insist that their apprentice is taught on a course that is fit for purpose. Many colleges are turning learners away because of this very problem and employers, quite correctly, see this as a failing of the apprenticeship system. What was once an over-subscribed subject is rapidly becoming a pariah in the eyes of further education. It is a situation that our members, our employers and others within the building services industry recognise as one that cannot, under any circumstances, be allowed to continue.”

The sector has a long-held legacy of protecting public health. It was 180 years ago that Dr John Snow discovered the cholera bacteria in a standpipe on a busy London street where many locals drew their water supply. The tap had already played its part in the demise of thousands of Londoners, with many more dying before the problem was eradicated.

“It was legislation, regulation and the correct training of plumbers and other water professionals that helped to eradicate the disease from the UK water supplies,” points out Wellman.

But, he says, serious health issues caused by poor sanitation and

IfATE has good reason for choosing the CIPHE as a collaborator in the development of new training standards which will ultimately improve the health, wellbeing and quality of life of the British public.

The CIPHE is the only plumbing organisation in the UK that represents the interests of both the public and the profession. It is also the only professional body for the UK plumbing and heating industry, and the only professional institution within the plumbing and heating profession to have received Royal Charter status.

With over 7,500 members, the CIPHE has the largest

representative membership of any institution or association in its field in the UK and through its members, associates and educational links, its promotion, instigation and education are far reaching in the UK.

The Institute’s membership comprises professionals from across the plumbing and heating spectrum; from installers, employers, specifiers, designers and public health engineers to lecturers, assessors and even the apprentices themselves.

The CIPHE’s Industrial Associates range from manufacturers to merchants, from charities to public bodies. And the Approved

plumbing are not a thing of the past. “In 2024, other problems, such as legionnaires’ disease, still serve to remind us how vital a supply of clean, wholesome water is in the health and wellbeing of the population of the UK. It is a duty of the CIPHE to ensure that the training of the nation’s plumbers remains up to date, professional, correct and safe, which is why we campaigned for new the Plumbing Apprenticeship Standard.”

Following a lengthy consultation process, IfATE has approved the development of new Level 2 and Level 3 Plumbing Apprenticeship Standards, proposed by the Plumbing Employers’ Group (PEG).

“Against a backdrop of falling commencements and completions of the current apprenticeship, the PEG believes this development is crucial as we face a projected need for 73,700 new plumbers by 2032,” says Wellman. “Overall, current construction apprenticeship drop-out rates stand at around 47%, making this an essential

Training Centre network benefits from the Institute’s commitment and expertise to the betterment of the plumbing and heating profession, while its close professional links with government departments, influential NGOs and other like-minded associations serve to create a networkreach far in excess of its base membership.

As a Professional Engineering Institute (PEI), the CIPHE is licensed to the Engineering Council and able to assess and award professionally registered status, such as Engineering Technician (Eng Tech), Incorporated Engineer

“What was once an over-subscribed subject is rapidly becoming a pariah in the eyes of further education”

step toward strengthening our workforce.

“The approval of IfATE, soon to be Skills England, is a vital development for our industry. We need to attract and retain talent in this sector, ensuring that apprenticeships maintain high standards and provide more career pathway opportunities.”

The proposed apprenticeships, led by the PEG, will:

• maintain and heighten training standards

• enhance course accessibility

• offer new entry points for aspiring plumbers.

The Level 2 apprenticeship will cover foundational skills such as hot- and cold-water installations and sanitation

(I Eng) and Chartered Engineer (C Eng).

As a registered charity, the CIPHE has a mandate to: “Protect the health and safety of the public through a strong qualified membership that is reinforced by their competency and technical expertise”.

“The CIPHE is a founder member of the World Plumbing Council (WPC) –the only non-governmental organisation in the plumbing sector recognised by the World Health Organisation (WHO) – and continues to be influential regarding plumbing and sanitation related issues all across the globe,” says Wellman.

systems, while Level 3 builds upon these with advanced techniques, including low-carbon heating and plumbing system design. The proposed changes will support apprentices aspiring to achieve professional recognition from Engineering Technician to Chartered Engineer.

“The CIPHE would like to extend our thanks to everyone involved in this process to date,” says Wellman. “We are committed to working across the sector to get the final standards available in colleges across England and Wales as soon as possible, so that we can deliver gold-standard apprenticeships that will meet the needs of modern plumbing and heating businesses and, ultimately, their customers.”

If you’re interested in helping to shape the future of the plumbing and heating industry, those involved in further education colleges or private training centres are invited to join the Industry Education Engagement Group. For further information, contact Lizzi Lake at elizabethl@ciphe.org.uk

The cost of energy in the UK has risen dramatically, with annual bills for a typical household soaring from an average of £1,042 in 2020-21 to £1,738 today, according to the latest figures from Ofgem.

That unprecedented increase in the cost of gas and electricity over the past five years has resulted in many

“We will teach learners how to identify vulnerable households and provide them with useful advice”

UK residents falling into fuel poverty.

The Committee on Fuel Poverty’s 2024 report estimated that 3.17 million households (13%) in England were in fuel poverty in 2023, and that the average fuel poverty gap (the reduction in fuel bills needed to take a household out of fuel poverty) had risen to £417, up by 20% on 2022.

Figures from the UK fuel poverty charity National Energy Action (NEA) suggest that 10,000 excess winter deaths each year can be attributed to a cold home. Fuel poverty can also have a significant impact on mental health and is a known risk factor for suicide.

According to the CIPHE’s updated Manifesto 2025-27,

The UK government’s definition for fuel poverty in England uses the Low Income Low Energy Efficiency (LILEE) metric. A household is considered to be fuel poor if they are living in a property with a fuel poverty energy efficiency rating of band D or below, and are left with a residual income below the official poverty line after spending the required amount to heat their home.

In its 2024 report, the Committee on Fuel Poverty recommended that this measure should be reviewed, as it no longer captures the full range of households facing unaffordable bills.

In Scotland, Wales and

Northern Ireland a household is considered to be fuel poor if it is required to spend more than 10% of its income on fuel to maintain an adequate standard of warmth.

“In 2000, UK-wide legislation first defined a person living in fuel poverty as a member of a household living on a lower income in a home which cannot be kept warm at reasonable cost,” explains Ellis.

“While our understanding of fuel poverty is still broadly consistent across the four nations of the UK, it is measured in different ways. However, an inability to heat a home is still driven by three common factors: a household’s income, fuel costs and energy consumption.”

“Installers have a great opportunity to identify people who are particularly vulnerable”

high energy costs are also hindering the adoption of renewable technologies, such as heat pumps, due to the imbalance between gas and electricity prices. Investment in renewable energy, including wind and solar, could reduce prices and encourage consumers to switch. However, this requires both government and private-sector funding, as well as installer training and homeowner incentives.

Kevin Wellman, CEO of the CIPHE, says: “The ongoing unpredictability of fuel prices leaves no doubt that bills will be impacted. I fear times are going to get tougher during these periods of colder weather, particularly for the more vulnerable members of society, with some people regrettably being faced with the difficult decision to choose heating or eating.”

Frontline support

It’s clear that more needs to be done to help vulnerable people who are living with the reality of not being able to afford to heat their homes. Plumbing and heating engineers are ideally placed to help recognise customers in need and arm them with the knowledge to help deal with their situation.

NEA has been working across England, Wales and Northern Ireland for over

Course aim

This bitesize e-learning module will help installers recognise someone who is potentially vulnerable and equip them with the basic tools to signpost that person to the relevant assistance.

The short virtual training module is designed for frontline staff from a range of organisations who might encounter households in vulnerable situations in relation to their domestic energy use. This includes staff who undertake home visits or who speak to customers on the phone. It is designed to be viewed either on an individual mobile device or as a group ‘toolbox talk’ presentation.

Individual organisations will need to be mindful of their own procedures for safeguarding and signposting customers to outside agencies.

How does the bitesize e-learning work?

Self-led e-learning gives learners the flexibility to study as and when they wish. The ‘bitesize’ format means that the course is brief and designed to provide a basic introduction to the topic (more in-depth courses are available upon request).

The course is designed to be viewed on a smartphone, device or a computer, meaning that it can be accessed on the go if required. Once

40 years, with frontline practitioners, companies, regulators and the government, campaigning for everyone in the UK to be able to afford to live in a warm, safe and healthy home. Its training courses and education programmes are designed to help learners understand issues affecting households in fuel poverty and increase knowledge and skills in areas such as energy efficiency, fuel debt and decarbonisation technologies.

Installer training

NEA’s courses aimed at installers include Understanding Fuel Poverty and Health, and Providing Advice to Vulnerable Clients, as well as a bite-size course

registered, learners will have access to the course for four weeks and be able to study online at a time and location that is convenient to them.

A flyer covering the relevant topics will also be available to download and keep. Individual and organisation licences are available.

Tutor support will be available upon request. This is usually done via telephone or video call.

This bitesize module will take approximately 20-30 minutes to complete, however each learner is different and e-learning offers the flexibility to study at your own pace. Learners will have access to the course for four weeks from their selected start date.

Visit www.nea.org.uk/training/course-outlines/ bitesize-vulnerable-situations to find out more.

Please note, the course content will focus mainly on England and Wales. If you are based in Northern Ireland or Scotland, contact trainingadmin@nea.org.uk before booking to discuss.

on Identifying Customers in Vulnerable Situations (see box, above).

“We teach learners how to identify vulnerable households and provide them with useful advice,” explains Chris Ellis, head of training and development at NEA. “They learn how to signpost people to further assistance and support. NEA also runs courses that cover technologies such as smart meters and renewable energy, which can help households to embrace the green transition.”

Courses are run both inperson and remotely, with some leading to qualifications.

As well as offering courses to frontline workers, NEA also delivers learning resources aimed at residents to enhance

their understanding of keeping warm and safe at home, how to use energy wisely and ways to reduce carbon dioxide emissions.

“When carrying out emergency works during this time of year, installers have a great opportunity to identify people who are particularly vulnerable,” says Wellman. “I welcome training programmes for installers to help them provide the necessary support to their customers, which includes signposting them to helpful resources.”

A social housing development in Scotland has provided residents with healthy and affordable homes thanks to Loreburn Housing Association’s commitment to Passivhaus standards

Adevelopment of 16 social homes designed and built to Passivhaus standards has been constructed in Dalbeattie, Dumfries and Galloway, for Loreburn Housing Association (HA).

The project is part of a new-build programme that commits to delivering Passivhaus-standard affordable housing across the unitary council area.

Loreburn HA’s five-year development programme, which began in 2023, aims to deliver up to 250 affordable homes that meet Passivhaus standards, providing a mix of extra care, supported and general needs accommodation.

Each home is fitted with an air source heat pump in place of a gas boiler, as well as solar panels and electric vehicle charging points –all of which will help the housing association achieve its net-zero targets.

The project has completely transformed and regenerated a previously derelict brownfield site, creating bright, new energy-efficient and accessible homes.

Building standards

Loreburn HA has been vocal in its support for Passivhaus, providing statements and feedback to the

consultation on the Proposed Domestic Building Environmental Standards (Scotland) Bill, which has now been adopted by the Scottish Government.

“We’re committed to building strong and sustainable communities,” says Loreburn HA’s chief executive, Lorraine Usher. “Our new-build standard consolidates our approach towards offering affordability for our tenants and sets us on the road towards achieving net zero carbon.

“By adopting Passivhaus standards, we’re making sure that our tenants can afford to live comfortably in their homes, while future-proofing our housing stock by ensuring long-term energy efficiency.

“Fuel poverty is a real and serious issue faced by many households across Dumfries and Galloway. Our Passivhaus programme is a step towards addressing this issue as we work to provide our tenants with a comfortable and healthy indoor

Crunching the numbers

£3.8m

Contract value

14

two- and three-bedroom two-storey houses

2

two-bedroom bungalows

8

Passivhaus-certifi ed homes

environment, while minimising the energy demand of their homes.”

Designed by architect Robert Potter & Partners and built by main contractor Ashleigh (Scotland), the two- and threebedroom properties meet the highest standards of energy e ciency and comfort – part of Loreburn HA’s commitment to delivering new homes fit for the future. This type of home will play a key role as local authorities and housing associations look to deliver new homes in line with the New Build Heat Standard (Scotland) or the 2025 Future Homes Standard.

The homes, which were designed to achieve the best energy e ciency, are

“We’re committed to building strong and sustainable communities”

well insulated and use mechanical heat recovery ventilation to help remove condensation and moisture, and regulate temperatures.

In order to meet Passivhaus standards, everything from the insulation to the windows needed to be correctly specified, including the size of each home’s heat pump.

Space was also a consideration as the design needed to guarantee there was ample room for the internal and external elements of the pumps, without compromising the comfort of the tenants.

Heating contractor James Frew was tasked with providing the air source heat pumps and it partnered with Baxi, which was able to o er onsite support to implement the technology.

The team at James Frew worked closely with Baxi experts – Craig McVicar, specification manager, and Ryan Kirkwood, engineering solutions manager – to ensure the heat pump specifications were correct for the

Passivhaus (or Passive House) is one of the world’s most rigorous design standards for both residential and commercial buildings. Enhanced air tightness and exceptional levels of fabric insulation underpin the Passivhaus design ethos, which can bring the space heating requirements in dwellings down to around 90% of that of typical building stock, and in many cases to zero.

For more information, visit: recoup.co.uk/technical/ passive-house

design requirements of each house. Baxi’s air source heat pumps, compatible cylinders and uSense controls were specified to provide the heating and hot water provision for each of the properties, with three radiators per dwelling.

James Frew’s engineers were able to access Baxi’s specialist training, which allowed them to familiarise themselves with the specified solution, so they were confident when it came to installation. The team also benefited from expert support on site, ensuring the full system was designed correctly and could be installed within

the space. Baxi’s commissioning engineers, Michael Murray and Adam Stock, were on hand to oversee the commissioning of each of the heat pumps and to ensure they would operate as expected once installed at each home.

“The design support and training meant the team had peace of mind that the most suitable products would be going into the homes and that our engineers were comfortable with the installation of them,” explains Evan Peat, senior contract manager at James Frew.

“It was also really important to have the support on site from Craig and Ryan. Having their expertise on the ground meant we were able to overcome this challenge and still meet the Passivhaus standard.”

The project is an example of how collaboration and consultation can help social housing providers achieve net-zero homes.

“The standard of these homes is testament to Loreburn HA’s commitment to building warm and highly energy efficient homes, where technology and intelligent design come together to create a sustainable future for our tenants,” says Alison Maxwell, project delivery officer for Loreburn HA.

“By adopting Passivhaus standards, we’re making sure that our tenants can afford to live comfortably in their homes”

Although some tenants were unsure of what Passivhaus would mean for them, there has been an extremely positive response to their new and enhanced energy-efficient homes.

Gavin Johnston, director of property and development at Loreburn HA, explains: “These tenants are embarking on a new chapter of sustainable living in homes where they can flourish.

“With a focus on the future, the design ensures that tenants can create a lifetime of memories within their walls, fostering a sense of belonging and a deep connection to their community and new home.”

The Dalbeattie residents told the team at Loreburn HA that the improved air quality in their Passivhaus homes has provided them with significant health benefits, particularly among those suffering from asthma and eczema. Data regarding air quality and CO2

levels has been described by the housing association as ‘encouraging’.

Speaking about his experience of living in one of the properties, Alan Vinnie, a Loreburn HA tenant, said the reduction in his energy bills would be a huge relief and that his new home had also improved his quality of life: “You can really notice the change in the air and it’s so quiet. I think all future builds should be of this standard.

“I had no idea what having a Passivhaus home meant and, before moving in, I didn’t appreciate it for what it was. It’s so interesting how it all works – you can just tell there’s something different about the way the house operates.

“I’ve been smiling ever since I moved in. It’s such a lovely community and I’m in a very central location. I couldn’t be happier about being back.”

Future-proof your career and play your part in helping us reach net zero with this new course aimed at helping installers and engineers to design low temperature heating and hot water systems, to work with more sustainable heat sources

The UK’s commitment to reaching net zero carbon emissions by 2050 will be impossible to achieve without a significant contribution by the plumbing and heating industry.

That’s why the CIPHE has invested in delivering a qualification that will help engineers to recalculate how heating and hot water is delivered at lower temperatures.

Find out more about the course, as well as membership and CPD opportunities, at www.ciphe.org.uk

The CIPHE’s Low Temperature Heating and Hot Water Design course covers the fundamental design principles of low temperature technologies and will help upskill those involved in the years ahead.

JAMES GRIFFITHS Head of projects, GF Building Flow Solutions (formerly

James Gri ths provides an overview of heat networks and how to optimise their performance