2 minute read

Hoxton Analytics

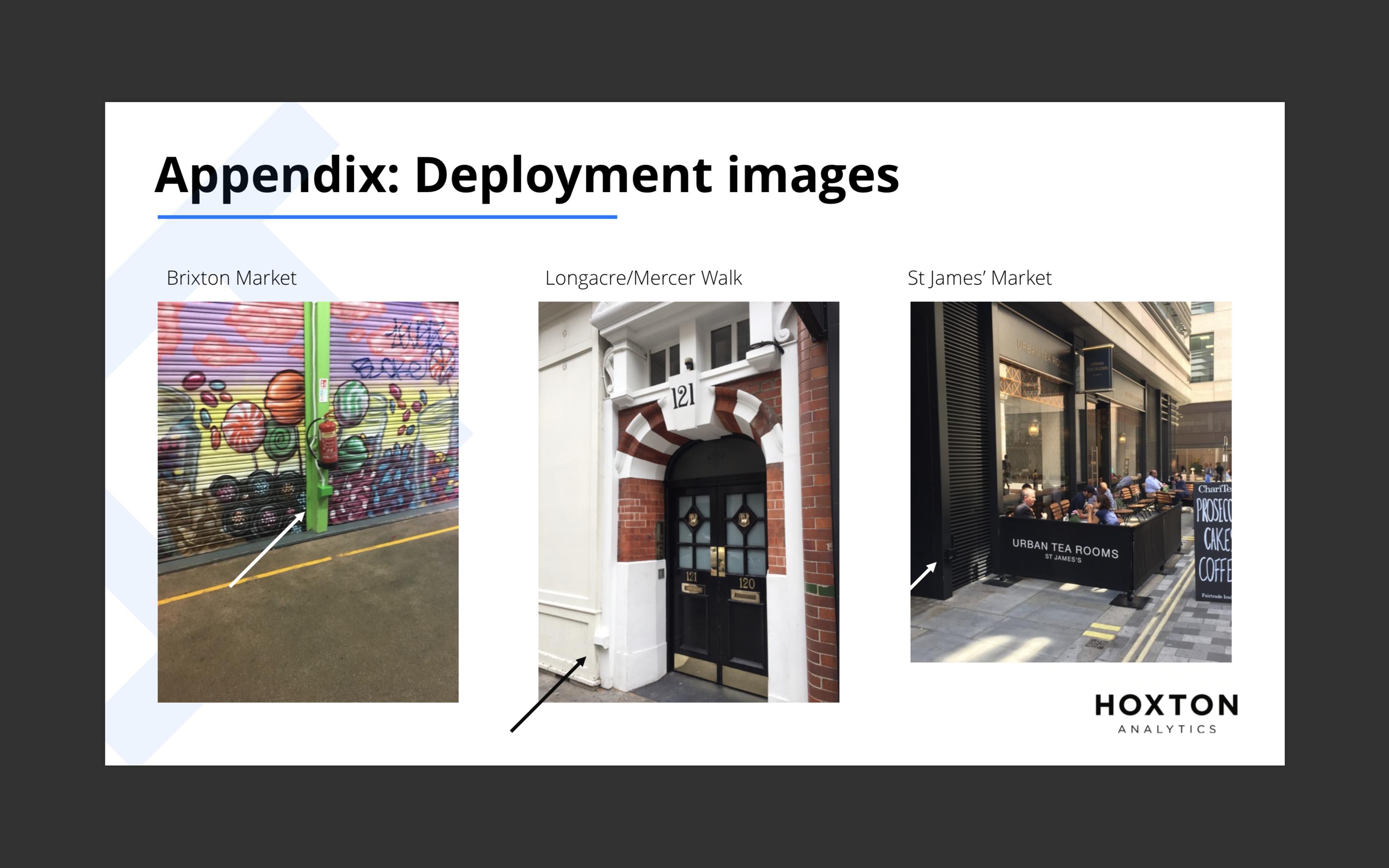

Hoxton Analytics is a company that creates sensors to count people and monitor occupancy using artificial intelligence. This is done using cameras to capture data from feet and understand behavioural trends. They approached me to understand how they could house their hardware in a low-profile manufacturable case.

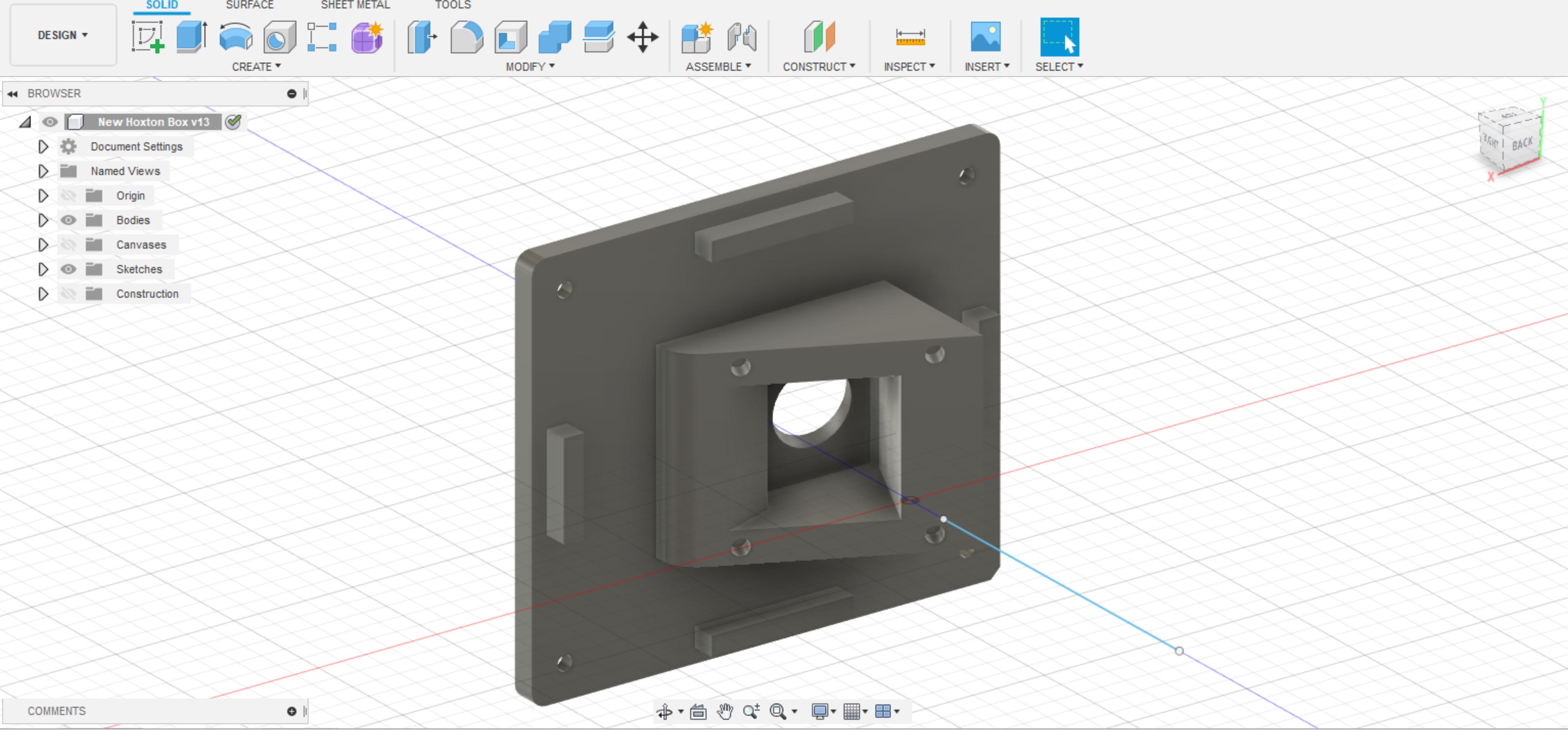

From back – Back plate screws into front caseFrom back – Back plate screws into front case Front case - Note the front face only reaches down half Front case - Note the front face only reaches down half way (to allow camera to see through)way (to allow camera to see through)

Advertisement

130mm Small hole for cable to pass through (diameter 20mm)Small hole for cable to pass through (diameter 20mm) 130mm Holes into which screws fitHoles into which screws fit 130mm 130mm

200mm 200mm Sunken Screw HolesSunken Screw Holes 200mm 200mm

100mm 100mm

65mm 65mm 65mm 65mm

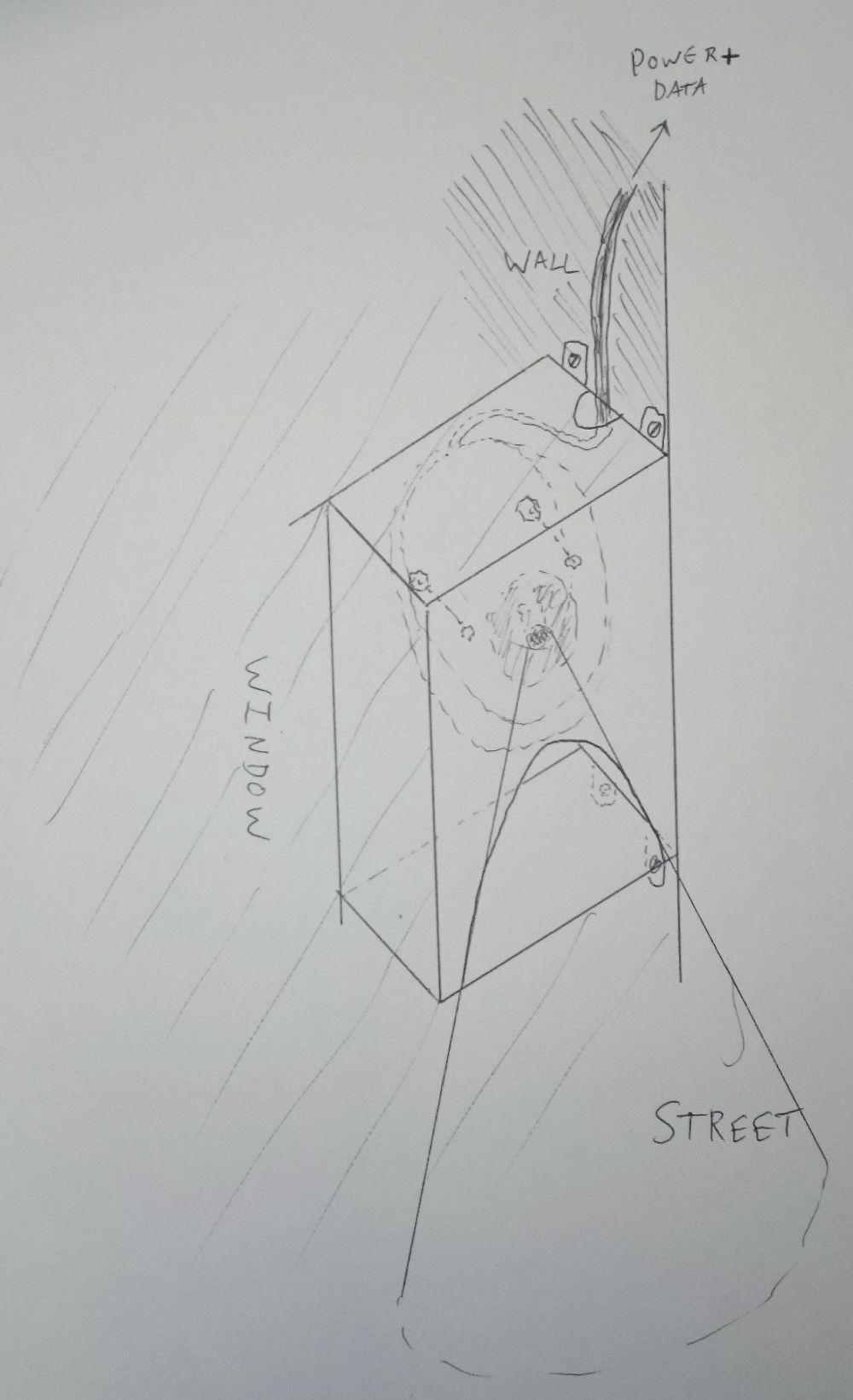

It started with a simple sketch where they could explain the needs for the product. We then made a quick diagram for dimensions and specific functions. It had to hold a unique camera filming at a certain angle and block out window reflections and peripheral video noise.

Hoxton Analytics

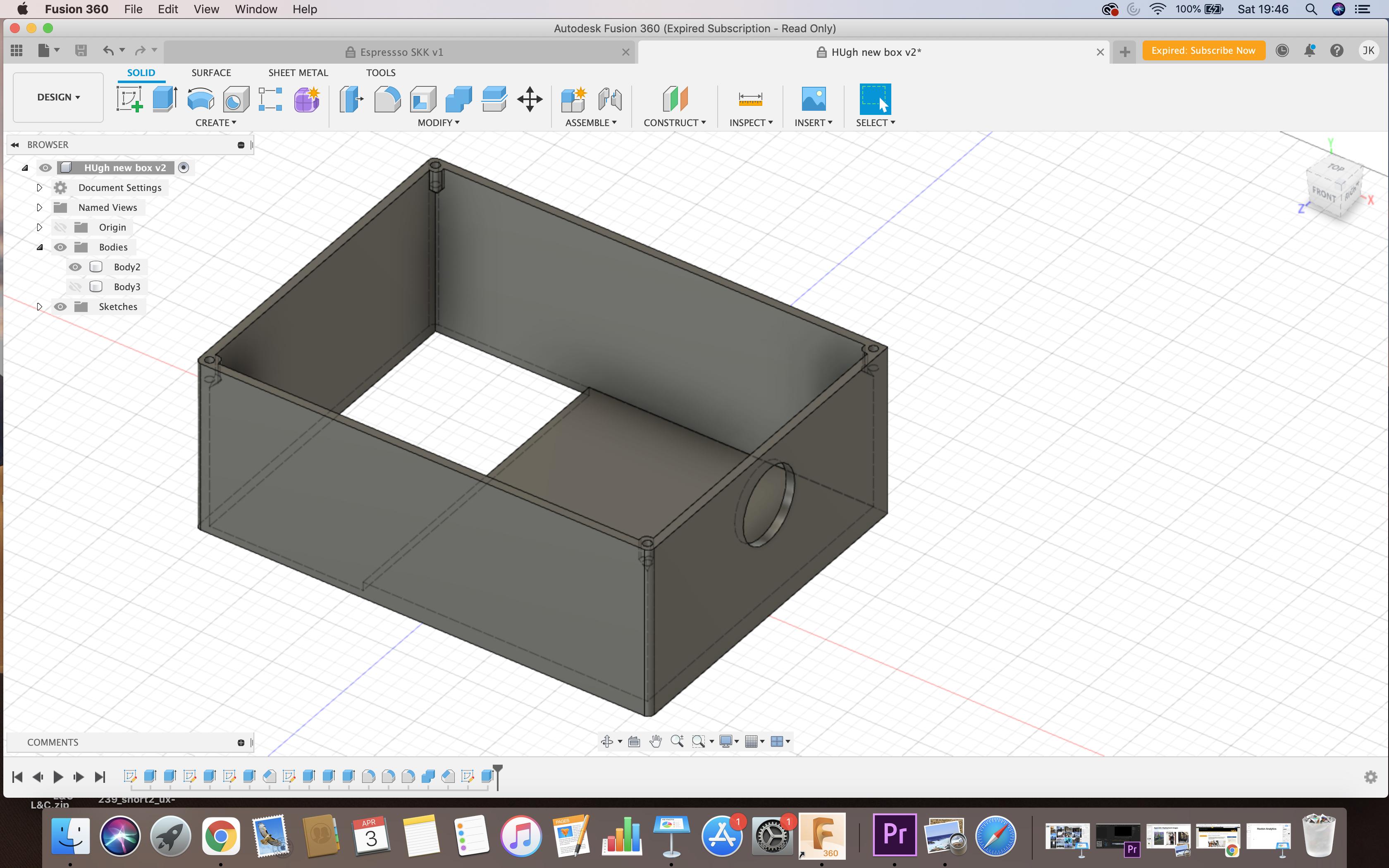

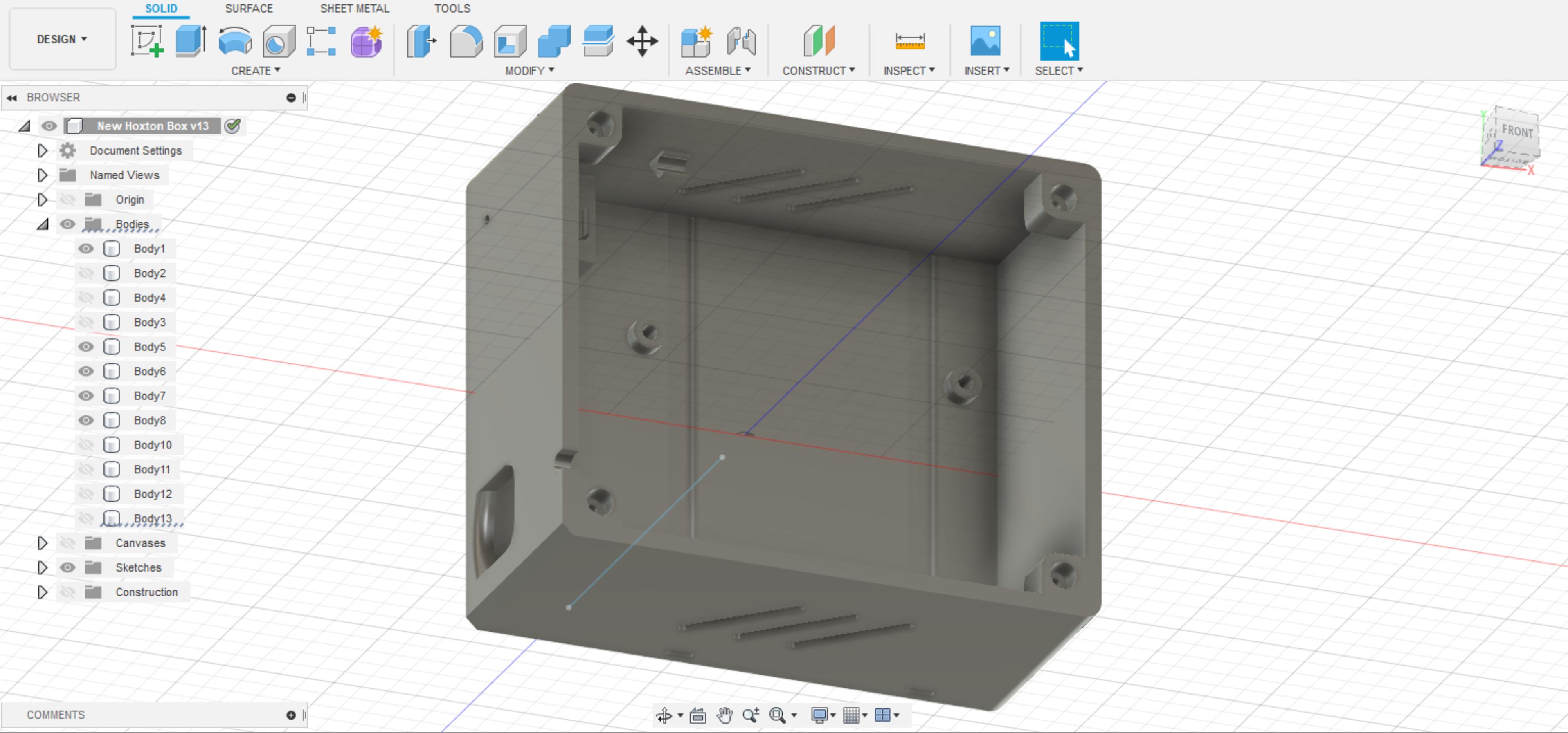

I then made a CAD file in Autodesk Fusion 360. This would hold the camera in the same position for repeatable future designs. I also incorporated tabs for countersunk flat head screws to secure the lid to the box. I 3D printed the prototype using polylactic acid filament. There were two parts (lid and case) and it worked well for the first camera iteration.

Hoxton Analytics

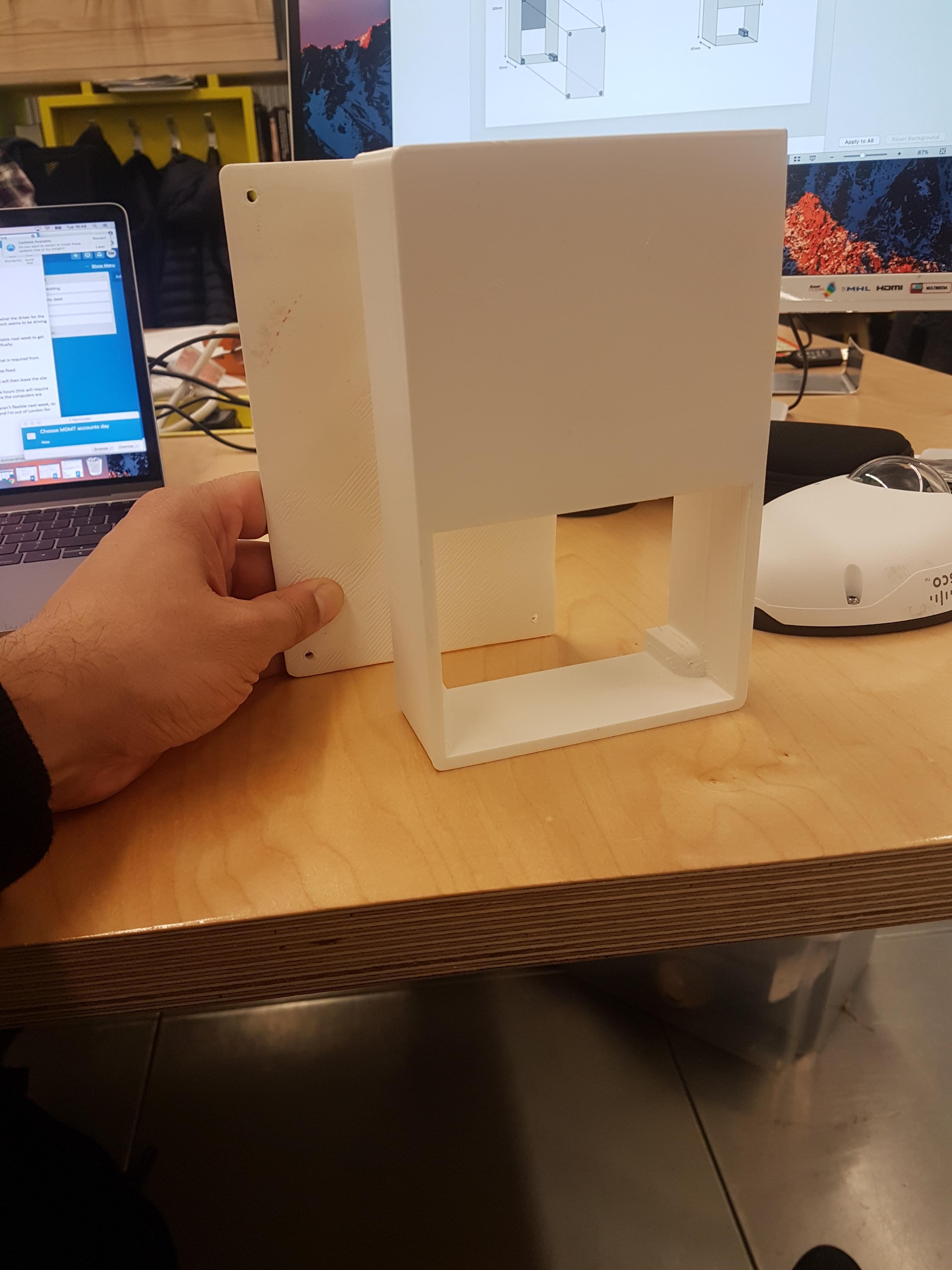

On the second iteration the hardware became more compact and specific uses changed depending on the desired function. For example, the low foot angle was different than the overhead version.

I made a quick cardboard case that would be used to understand dimensions. I needed to factor in the best use of space and how it would attach to the wall/ceiling.

I then made a model and created it on my personal printer. This version has the exact chamfered angles needed for the camera viewport, and clip in slots for the Raspberry Pi board.

It uses tapped threads for replacing parts and the ability to remove the lid multiple times. There is also a reset hole button that threads in perfectly to the lower corner.

Hoxton Analytics

The design took in considerations of weather, strength, and being able to blend into its surroundings. After testing the prototypes in the field, the company has manufactured many camera cases using sheet metal bending. The outcome has been a profitable startup story showing the process of early prototype through to final functional design.

Brixton Market