Innovation Drives Efficiency

Fill year-end gaps with an adaptable line of credit.

With all the various management needs of your operation – input costs, equipment repairs, labor and livestock expenses – you need a line of credit that can keep up. An operating line of credit from Farm Credit Services of America has convenience, savings and flexibility built in, so you can meet each season’s needs without slowing down

Only borrow what you need

Executive Committee

President

Brent Swart, Spencer | D1

President-elect

Tom Adam, Harper | D9

Secretary

Sam Showalter, Hampton | D2

Treasurer

Lee Brooke, Clarinda | D7

At-Large Director

Scot Bailey, Anita | D7

Board of Directors

Paul Kassel, Spencer | D1

Mike Yegge, Lake Mills | D2

Amanda Tupper, Ionia | D3

Josh Schoulte, Farmersburg | D3

Jeff Frank, Lake View | D4

Marty Danzer, Carroll | D4

Corey Goodhue, Carlisle | D5

Dave Struthers, Collins | D5

Joe Sperfslage, Coggon | D6

Brian Fuller, Osceola | D8

Summer Ory, Earlham | D8

Jeff Ellis, Donnellson | D9

Aimee Bissell, Bedford | At-Large

Jack Boyer, Reinbeck | At-Large

Neil Krummen, Linn Grove | At-Large

Sharon Chism, Huxley | At-Large

American Soybean Association Board of Directors

Tom Adam, Harper

Steph Essick, Dickens

Morey Hill, Madrid

Randy Miller, Lacona

Dave Walton, Wilton

United Soybean Board of Directors

Tim Bardole, Rippey

Robb Ewoldt, Davenport

Brent Renner, Klemme

Suzanne Shirbroun, Farmersburg

Staff Credits

Bethany Baratta | Editor

Aaron Putze, APR | CO Brand Mgmt and Engagement

Susan Langman | Creative Design Coordinator

Joclyn Kuboushek | Multimedia Specialist

Kriss Nelson | Senior Writer

Brock Johnston | Public Relations Manager

FARMER FOCUSED | DRIVEN TO DELIVER

ISA VISION

We advance the long-term competitiveness of Iowa soybean farmers.

ISA MISSION

Driven to deliver opportunities for Iowa soybean farmers to thrive.

Iowa Soybean Review is published monthly by: Iowa Soybean Association 1255 SW Prairie Trail Parkway, Ankeny, Iowa 50023 (515) 251-8640 | iasoybeans.com

E-mail: bbaratta@iasoybeans.com

For advertising information contact Bethany Baratta at (515) 334-1020 or bbaratta@iasoybeans.com

October 2025 | Vol. 39, No. 1

Checkoff investment spurs infrastructure upgrades.

Soybean farmers speak with confidence on Capitol Hill.

Seven farmer leaders elected to Iowa Soybean Association board of directors.

Photographer reflects on 150 years of farming legacy.

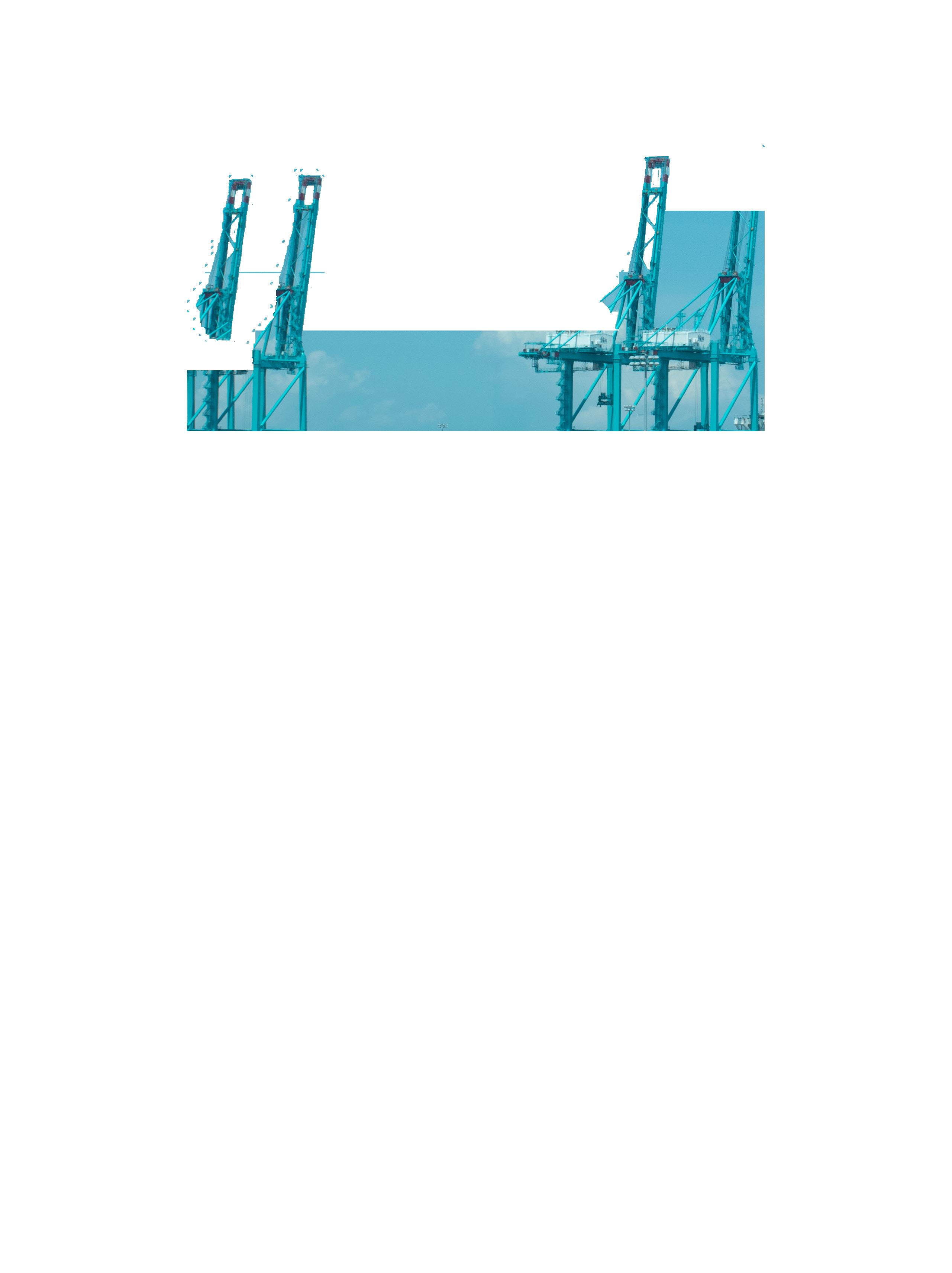

On the Cover: While a majority of U.S. soybeans and soy products are exported via the Pacific Northwest and the Gulf, investments in export infrastructure on the East Coast present an opportunity for U.S. soybean farmers to meet global demand. In this issue, read how and why farmers are investing in the region amid global trade uncertainty. Photo by Brock Johnston.

Comments and statewide news articles should be sent to the above address. Advertising space reservations must be made two months preceding publication. In consideration of the acceptance of the advertisement, the agency and the advertiser must, in respect of the contents of the advertisement, indemnify and save the publisher harmless against any expense arising from claims or actions against the publisher because of the publication of the content of the advertisement.

Aaron Putze, APR ISA Chief Officer of Brand Management & Engagement aputze@iasoybeans.com

“Keep it simple. When you get too complex, you forget the obvious.”

Al McGuire

I’m not sure when everything got complicated, but it is.

Phones, once a stationary device used for conversation (who can forget the party line?) are now mobile with screens possessing a million times more memory than Apollo 11’s guidance system.

The TV remote — once a simple, convenient tool for changing channels and adjusting volume — has evolved into one of the most maddening contraptions ever invented. Whoever decided it was a good idea to cram more and smaller buttons onto a device mostly used in the dark surely had a cruel streak. Most nights, I give up trying to find my favorite show and, after many attempts, finally find the “off” button and go to sleep in disgust.

The washer, dryer and thermostat? I threw in the towel on them a long time ago. Major League Baseball has even managed to ruin America’s pastime by imposing so many rules that it’s become a race instead of a game.

Simple is hard, which is why I’ve come to appreciate my mom and dad more as my hair grays. Among my fondest memories of growing up on the farm is how Mom and Dad kept things simple. No fancy equipment. No overburdened schedules. No work on Sundays. Meals at home. The years and

days were stress-free. Routine was embraced and we thrived.

Keeping things simple takes discipline. The Iowa Soybean Association funds strategic activities using the soybean checkoff managed across five Focus Areas: Engagement, Demand, Productivity, Advocacy and Operations.

Checkoff resources per the production and sale of soybeans by Iowa’s 37,000-plus soybean farmers are used to develop markets and uses for soy (including investments in the U.S. Soybean Export Council and Soy Aquaculture Alliance) and unbiased, on-farm agronomic research to help farmers improve production, reduce inputs and improve soil health.

ISA also invests checkoff funding in feasibility studies to improve our rail, roads, bridges, rivers and ports needed to move soybeans and ag inputs reliably and efficiently and increase domestic pig, poultry and dairy production. And the association puts checkoff resources to use to provide timely information to soybean farmers and engage with consumers about modern agriculture.

Simplicity keeps you accountable by ensuring that important details aren’t lost in paperwork or buried in bureaucracy. Every program plan and activity are reviewed and approved

by directors. Quarterly reports are prepared and shared. We track our progress using green, yellow and red coding to highlight priorities and flag areas needing the most attention.

As promised on this very page in January, we’re redoubling efforts to communicate frequently and openly about the use of the soybean checkoff. Elsewhere in this edition, you’ll find information detailing how checkoff resources are allocated across ISA’s focus areas. We have increased reporting on checkoff success stories — from increasing U.S. soybean market share in key export regions to the success of soy-based firefighting foam. And we continue to invite more farmers into deeper dialogue with ISA by enhancing our approach to membership and engaging with first purchasers of soybeans to better understand and communicate how the checkoff is paying off for you, the farmer.

I welcome your feedback on our efforts. E-mail me at aputze@iasoybeans.com and find me on Facebook and LinkedIn. Better yet, keep it simple and just give me a call at 515-334-1099.

“ What’s a ghost’s favorite fruit?”

my 8-year-old asked.

“Hmm. Scare berries?” I replied, hoping he wouldn’t recognize that I made it up.

“Booberries,” he says, laughing. “Get it?”

He was rehearsing his joke for the upcoming trick-or-treating in the neighborhood; some participants wait for the joke before handing over the loot.

The date has been set, the costume ideas are stacking up, the jokes are locked in and plans are underway for trick-or-treating later this month. (No sweaty plastic masks here, and we’re hoping there isn’t a need to wear winter coats under our costumes like I recall growing up.)

As we and other participating homeowners decide whether to fill treat buckets with Skittles or Silly Stix, Iowa farmers are out in the fields harvesting the real treats that provide everything from food to fuel. They’re treats you can’t fit into a 5-quart plastic

Editor’s Note by Bethany Baratta bbaratta@iasoybeans.com

bucket decorated with cats, bats and witches’ hats.

According to the August crop production report from the National Agricultural Statistics Service, Iowa soybean farmers expect to harvest 587.8 million bushels of soybeans this season. It’s the protein — in various forms — that helps humans and livestock to thrive. It’s the oil that provides fuel for tractors, cars and airplanes. It’s soy that’s even sold and shipped to customers around the world.

It’s no joke: farmers routinely face some of the tricks that outside forces have on their business. Having the inside scoop on the soybean industry in Iowa, it’s difficult not to think about unpredictable weather, volatile markets and confusing ag policies. While our son prepares his punchlines in anticipation of peanut butter cups and Pop Rocks, farmers continue working through the season, harvesting the treats of months of planning,

planting and perseverance.

The fruits of their labor last longer than the gumballs; soybeans and their related products are headed for feed mills, biodiesel plants and overseas ports.

As we enjoy the glow of jack-o’-lantern-lit porches, the crunchiness of the leaves below our feet as we hunt for additional treats, and the fun of the season, we also recognize the commitment of those in the fields and the support from those shuffling vehicles, providing field meals and catching grain on the go. Your work feeds, fuels and sustains more than you’ll ever know. The harvest season lasts longer than any Beggars’ Night, and I pray for your safety as you traverse your fields and roads to and from harvest.

Here’s to a safe, bountiful harvest — and maybe a few wellearned treats of your own.

East Coast facility to boost ag exports by 2026

AND

BY

Beneath the hum of construction on the East Coast, a bold vision is taking shape — one driven in part by the determination of U.S. soybean farmers to put more American agriculture on the global map.

It’s a vision quickly turning into reality for the Port of Virginia, already the second-largest commercial port on the East Coast by tonnage and third largest by container volume. With its strategic midAtlantic location, deep water access to the open sea, and ability to handle a diverse mix of vessels and cargoes, including containerized and bulk soybean products, the region is primed to meet agriculture’s desire to boost exports around the world.

Enter The DeLong Co., Inc., who celebrated the groundbreaking of the brand new, state-of-the-art Portsmouth Agricultural Intermodal Export Facility on May 29. Located in Portsmouth, Va., the facility is being constructed in partnership with the Port of Virginia, the Virginia Department of Rail and Public Transportation, the CSX Railyard, and the City of Portsmouth.

Phase one of the facility is slated for completion in early 2026 and will be the first on the East Coast capable of receiving unit trains and transloading agricultural products directly into export containers.

This innovative facility will offer 15,000 metric tons of storage and will handle 15,000–20,000 containers annually, significantly boosting the region’s ag export capabilities. Whole grains and feedstuffs — including soybeans, corn, wheat, distillers grains and soybean meal — sourced from local producers and the Midwest will be received by truck and rail, then shipped overseas via the Port of Virginia.

“This project represents a major step in strengthening the economic, agricultural, and logistical landscape of Virginia and the greater East Coast to Midwest corridor,” says Brandon Bickham, vice president of exports at The DeLong Co., Inc. “We’re proud to bring this facility to Portsmouth in collaboration with CSX and the Port of Virginia.”

In total, the facility is expected to have an annual export capacity of 500,000 metric tons, with primary export markets including Vietnam, Indonesia, Thailand, Taiwan and China.

Soybean farmers and industry leaders are working diligently to ensure their ability to meet the growing global demand for high-quality protein from this region is as reliable, competitive, and cost-effective as possible.

Through the Soy Transportation Coalition (STC), they are doing just that — committing $50,000 toward The DeLong Co.’s latest project. Other soybean farmerled organizations are also planning to contribute additional funding in the future.

The $26 million project is also supported in part by a $750,000 Rail Infrastructure Access (RIA) grant from the Virginia Department of Rail and Public Transportation. The site is leased from CSX and operated solely by The DeLong Co., Inc.

Construction of the new export facility is ongoing, amid a backdrop of global trade uncertainty and changing needs for the future of U.S. soybean exports. Growing demand for domestically produced renewable fuels continues to require new or enhanced export capacity for quality U.S. soybean meal, a factor that the facility will help to alleviate.

Despite the challenges facing American farmers, working with DeLong shows how the collaboration with others is helping to grow opportunities for U.S. soy, says Mike Steenhoek, executive director of the Soy Transportation Coalition (STC).

Mike Steenhoek, STC executive director

“You can’t get comfortable putting all of your eggs in one basket,” says Steenhoek. “This project is a great example of that. The more we can diversify our transportation options for our commodities, the more it helps our industry stay competitive, reliable and cost effective.”

Continued on Pg. 10

“ The more we can diversify our transportation options for our commodities, the more it helps our industry stay competitive, reliable and cost effective.”

Mike Steenhoek, STC executive director

Warren Bachman, former district 8 director for the Iowa Soybean Association (ISA), agrees. That’s why he joined fellow U.S. soybean farmers in Norfolk, Va., for STC’s board meeting and tour of the facility held just prior to the start of harvest season across much of the Midwest. Participants, which also included ISA farmer-members participating in the association’s Grassroots Fellowship program, visited the site of the new facility and heard directly from other stakeholders involved in bringing the vision to reality.

8 director

“This region is very important to our success and reaching buyers internationally,” says Bachman. “Several of the United States’ largest Class One railroads are connected to this area and can get to and from two-thirds of the country in under 24 hours.”

That’s a big reason why investing in the region, along with our other major export regions like the Gulf Coast and Pacific Northwest, is key, adds Bachman.

Phase 2 of the Portsmouth facility is already underway, with plans that will further expand storage and throughput capacity.

“Soybean farmers are very appreciative of DeLong for the significant investment they are making to expand U.S. soybean exports,” says Bachman. “They are ultimately the ones making this project happen, and it’s a great feeling to know that farmers have been able to collaborate with DeLong on bringing this project to life.”

STC previously collaborated with DeLong Co. in 2023, contributing $200,000 toward the company’s agricultural maritime export facility at Port Milwaukee, near Milwaukee, Wis. This project will ultimately help strengthen a supply chain for U.S. soybean exports in the Great Lakes/ St. Lawrence Seaway.

Established in 2007, the Soy Transportation Coalition is comprised of 14 state soybean boards (including the Iowa Soybean Association), the American Soybean Association and the United Soybean Board. The goal of the organization is to position the soybean industry to benefit from a transportation system that delivers cost effective, reliable and competitive service.

The DeLong Co., Inc., headquartered in Clinton, Wis., is the largest U.S. exporter of containerized agricultural products with 39 U.S. locations and was named the Port of Virginia’s 2024 Shipper of the Year.

Contact Brock Johnston at bjohnston@iasoybeans.com.

Strengthen soil quality by feeding it the power of the sea. Our cold-processed seafood hydrolysate liquid fertilizer builds soil health and, when applied post-harvest, manages residue to ensure future nutrient availability.

Soy Transportation Coalition provides snapshot of current initiatives

STORY BY BROCK JOHNSTON | PHOTOGRAPHY BY JOCLYN KUBOUSHEK

Across the heartland, U.S. soybean farmers are reshaping the future with bold investments to improve the safety, reliability and efficiency of their supply chain. With innovation and collaboration in mind, it’s a future where U.S. soybeans move faster, farther and smarter than ever before.

An innovative project using railroad flat cars to replace a rural bridge has reached completion in Buchanan County, located in northeast Iowa.

“Our nation’s rural bridges serve as the initial step in a lengthy journey to the ultimate customer,” explains Mike Steenhoek, executive director of the Soy Transportation Coalition (STC). “Unfortunately, the region of the country in which bridge conditions are most severe — rural areas — also happen to be the region in which available funding to improve these conditions is stagnant or on the decline.”

In 2024, the STC partnered with Buchanan County, in the construction of one of the longest railroad flat car bridges in the country. Measuring 135 feet in length by 28 feet in width, the bridge utilized six retired railroad flat cars in its construction.

The cost of the county to replace the bridge using the railcars is $300,000, saving the county and its taxpayers more than $600,000.

“Unfortunately, the economic reality is that rural counties have a large quantity of rural bridges to maintain and improve while having access to stagnant and, often, declining resources to accomplish this task,” says Brian Keierleber, Buchanan County engineer. “The math simply does not add up. County engineers and other rural stakeholders explore and promote more costeffective approaches to repair and replace rural bridges without compromising safety.”

Buchanan County assumed the cost of the bridge construction. The STC provided $15,000 to help offset the costs of pre-engineering and design.

The effort was highlighted in STC’s report, “Top 20 Innovations for Rural Bridge Replacement and Repair,” which promotes cost-effective approaches to replacing and repairing rural bridges without compromising safety. Looking ahead, STC and farmer leaders continue to engage with other local counties for additional cost savings on the critical infrastructure.

Construction of an enhanced lock and dam system on the Upper Mississippi River continues to progress. Located in Winfield, Mo., Lock and Dam #25 assists in moving 200 million bushels of soybeans annually from growers in Iowa, Illinois, Minnesota, Missouri and Wisconsin downstream to the Gulf of Mexico, according to the United States Dept. of Agriculture (USDA) Agricultural Marketing Service.

In 2021, the Iowa Soybean Association (ISA) offered $100,000 to address the initial engineering and design modifications necessary to improve the aging infrastructure of Lock and Dam #25 on the Upper Mississippi River. The contribution was part of a $1 million proposal made by state and national partners, including the United Soybean Board (USB), STC and other state soybean organizations.

“Many of these critical lock and dam projects along the Upper Mississippi River region have lingered for years — perpetually waiting for the necessary funding to increase their capacity and resilience,” says Steenhoek. “Farmers and other stakeholders believed it was time for Lock and Dam #25 and other priority projects to finally move from the on-deck circle to the batter’s box.”

With the necessary funds in place, Lock and Dam #25 is the first construction project under the Navigation and Ecosystem Sustainability Program (NESP). The program allocated $732 million for the project, due in part to the successful collaboration between agriculture, barge and towing and other industries.

The original infrastructure at Lock and Dam #25 opened in 1939 with a lock chamber of 600 feet. Once completed, the new 1,200 feet lock chamber will significantly reduce delays and increase safety.

Continued on Pg. 18

The Andersons, Inc., an American agribusiness company focused on commodity merchandising, renewables and more, is in the process of expanding its grain export terminal at the Port of Houston (in Houston, Texas) to handle and export soybean meal and soybeans from the facility. Once completed, the expansion will result in one million metric tons of soybean meal and soybeans being exported from the facility.

U.S. soybean farmers have committed $275,000 for research, analysis, pre-engineering and design expenses associated with the facility expansion at the Port of Houston. USB, STC, ISA and other state soybean organizations have committed funding to this project. Soybean farmer leaders and other project stakeholders held a ceremonial check presentation at the Port of Houston last month.

The project has the potential of meaningfully addressing several major priorities of the broader soybean farmer community, Steenhoek says.

Tangibly enhancing the ability to export soybean meal remains top of mind for soybean farmers.

importance to our industry, Steenhoek says the project could enhance multiple “base hit” marketing opportunities for U.S. soybean meal and soybeans. The identified markets for the Houston export terminal include key regions like the Middle East and Africa, including Saudi Arabia, Turkey, Jordan, United Arab Emirates, Egypt, Morocco, Algeria, Ivory Coast and more. It could also serve key purchasers in the Caribbean, Latin America and Asia.

president and CEO

“Given the continued challenges we’ve experienced with low water conditions on the Mississippi River, we’re continuing to identify opportunities that increase the diversity of our supply chain by ‘spreading the eggs across more baskets’,” Steenhoek says. “The soybean meal that will be shipped to the facility at the Port of Houston will be transported via BNSF Railway or Union Pacific Railroad. It will not utilize the inland waterway system.”

While large “home run” markets like China remain of great

“We are pleased to extend our relationship with Port of Houston as it remains a strategic location for The Andersons to support our customers in exporting to high-demand markets,” says Bill Krueger, president and CEO of The Andersons. “As domestic soybean crush rises to meet the higher demand for renewable fuels, we are seeing new opportunities for the export of soybean meal, and we are working closely with our partners to streamline delivery of product to the export point by installing capability to unload unit trains of soybean meal directly at the Texas Gulf.”

The Andersons, Inc. anticipates several Midwestern states, including Iowa, will feed soybean meal to their facility. It’s possible, however, that other states will feed into the facility as well given the expansion of soybean processing.

With storage capacity of 6.3 million bushels, the Houston facility supports the export of more than two million metric tons of grain annually and will now include up to 22,000 metric tons for storing soybean meal for export. Additional upgrades include a new conveyance system to transport goods from storage to the ship loaders, as well as a new ship loading tower to increase loading speed and efficiency.

The Port of Kalama (in Kalama, Wash.) and Tacoma Export Marketing Company (TEMCO), a joint venture by Cargill and CHS, are continuing efforts to expand rail efficiency in the Pacific Northwest. The facility, located in a strategic export region for U.S. soybeans and soy products, is undergoing construction enhancements to expedite terminal unloading and staging.

According to Steenhoek, expanding rail lines will increase efficiency by 25 to 30%, especially during the key export period for U.S. soybeans.

“Infrastructure investments that soybean farmers have made in the past have positioned us for future success,” adds Steenhoek. “We want to continue that level of investment, so U.S. soybean farmers and their consumers continue to benefit.”

The project has also since been awarded a Consolidated Rail Infrastructure and Safety Improvements (CRISI) grant of $26.3 million. The grant award continues to remain on schedule.

The STC, alongside USB, ISA and other state soybean associations committed funding to this project.

Contact Brock Johnston at bjohnston@iasoybeans.com.

In the year ahead, the Iowa Soybean Association (ISA) will boost demand for homegrown soy, drive on-farm resilience and bring value to the nearly 37,000 soybean farmers from across the state. Led by its 22 farmer leaders, ISA recently approved a 2026 fiscal year checkoff

budget, strategically allocating funds across vital research, promotion and education investments.

The board approved the budget during the association’s June meeting in Ankeny, prioritizing strategic investment in several areas such as animal health and nutrition,

infrastructure, production research and international trade. In addition, the board focuses its engagement efforts on strengthening relationships with farmers, industry stakeholders and key influencers benefiting ISA and the agricultural community.

Leadership will help steer the association’s strategic plan and drive opportunities for soy growers

STORY BY BROCK JOHNSTON | PHOTOGRAPHY BY JOCLYN KUBOUSHEK

Seven farmers, including two incumbents, have been elected to the Iowa Soybean Association (ISA) board of directors. The association’s 22 volunteer farmer directors represent the state’s nine crop reporting districts in overseeing the management and allocation of soybean checkoff and non-checkoff resources.

Newly elected farmers who will serve three-year terms on the board are: Josh Schoulte, Farmersburg (District 3); Joe Sperfslage, Coggon (District 6); Summer Ory, Earlham (District 8); Brian Fuller, Osceola (District 8); Neil Krummen, Linn Grove (At-Large).

Re-elected to three-year terms on the board are: Marty Danzer, Carroll (District 4) and Dave Struthers, Collins (District 5).

“Whether as a voter, candidate or both, we thank Iowa soybean farmers for engaging in this important process,” says Brent Swart, immediate ISA past president and soybean farmer from Spencer. “As a farmer-led association, their participation contributes to the success and longevity of ISA and our industry.”

Directors are elected by Iowa soybean farmers in July and take office in September. Members vote for two farmers from their crop reporting district and vote for four at-large directors. The seven directors elected join 15 soybean farmers in developing ISA’s policies and programs each year.

Those continuing their service as directors are: Paul Kassel, Spencer (District 1); Brent Swart, Spencer (District 1); Sam Showalter, Hampton (District 2); Mike Yegge, Lake Mills (District 2); Amanda Tupper, Ionia (District 3); Jeff Frank, Lake View (District 4); Corey Goodhue, Carlisle (District 5); Scot Bailey, Anita (District 7); Lee Brooke, Clarinda (District 7); Jeff Ellis, Donnellson (District 9); Tom Adam, Harper (District 9); Aimee Bissell, Bedford (At-Large); Jack Boyer, Reinbeck (At-Large); and Sharon Chism, Huxley (At-Large).

for over 40 years, your cooperative soybean processor

The Brandt DXT dual-auger grain cart delivers the capacity and speed to meet the demands of your fast-paced harvest season. Built in Illinois, the Freedom Edition is now available for order from your local Brandt dealer.

The high-slope tank and high-capacity auger deliver unload speeds of 1,000 bu/min.

Choose from five model sizes, 22" or 24" auger, and right or left side unload to fit your operation.

High-quality components and low maintenance requirements ensure maximum uptime.

PHOTOGRAPHY AND STORY

BY JOCLYN KUBOUSHEK

The 2025 Iowa State Fair will always hold a special place in my heart, as it was the year my family received the Heritage Farm Award, recognizing that our farm has been in the family for 150 years. Standing together with my grandparents, parents, aunts, uncles and cousins reminded me just how deep our roots run and how strong the legacy of our farmstead truly is.

What made this moment even more meaningful was the surprise we had planned for my grandparents. To celebrate their 60th wedding anniversary, our family applied for both the Century and Heritage Farm Awards without telling them. When we made the announcement, they were thrilled. I’ll never forget how my grandpa’s face lit up. He was proud, and rightfully so. Adding to the significance, the awards ceremony happened to fall on his birthday, Aug. 14, making the day one we will always remember.

Continued on Pg. 26

For me, the greatest part of receiving this award has been the chance to reflect and listen to the stories passed down through the generations — tales of perseverance, change and memories made on this land in the northeast corner of Iowa. Every fencepost, every barn, and every acre carries with it the hard work and dedication of those who came before us.

This farm is more than a piece of land to me, it’s where my passion for storytelling through photography first began. From capturing the cattle in the feedlots and photographing the everyday rhythms of farm life, this place taught me to see beauty in the ordinary and the power of preserving memories. What started as taking simple snapshots around the farm grew into a career rooted in telling stories of agriculture and family, all inspired by the land that has always been home.

As I sat in the Pioneer Livestock Pavilion, watching more than 200 families walk across the stage to accept their awards, I felt a deep sense of connection. Though our farms are spread across the state, the pride, challenges and love for the land we share are the same. Each family has its own story, but together, we represent the spirit of Iowa agriculture and the enduring legacy of family farming.

Contact Joclyn Kuboushek at jkuboushek@iasoybeans.com

Model 2054 54-Series Double-Auger Grain Carts

Model 742

42-Series Single-Auger Grain Carts

Model 1150

Double-Auger Grain Cart

During the busy harvest season, you need an equipment partner that you can trust to get the job done. Parker grain handling equipment has built the reputation of being the trusted name in moving grain. The 54-Series double-auger grain carts provide large carrying capacities with lightning-fast unloading speeds that get you back to the combine faster. The 42-Series and 24-Series single, corner-auger grain carts feature the greatest auger reach and height and use a sump design in the tank for enhanced cleanout. For an introductory model, the 1150 delivers an economical design and convenience.

season by seeing

Can you feel that? It’s the energy of Pioneer ® brand Z-Series soybeans igniting your yield potential. They’re delivering the next generation of soybean genetics for yield potential and return on investment like you’ve never seen before. So don’t wait. Join the soybean revolution with Z-Series soybeans, and start the next hundred years with your best harvest yet.

Enter the next era of performance at Pioneer.com/UnleashGreatness.

SChris Hay Owner, Hay Water Solutions LLC hay4agwater@gmail.com

aturated buffers are an innovative conservation drainage practice designed to reduce nitrate losses from agricultural drainage systems. By rerouting tile drainage water through a vegetated buffer area, these systems remove nitrate from the water, significantly improving water quality. A newly developed decision support tool now provides designers with a powerful way to optimize the design and implementation of saturated buffers, ensuring maximum nitrogen load reduction at the lowest cost.

Saturated buffers intercept tile drainage water and distribute it through a vegetated buffer as shallow groundwater. Unlike traditional grass buffers, they target tile drainage water, a major source of nitrate loss from tile-drained agricultural land. A water control structure on the drainage main within the buffer raises the water level, directing a portion of the drainage water into shallow, perforated distribution pipes running roughly parallel to the stream or ditch to seep back toward the ditch or stream. This process allows nitrate in the water to be removed by microbial denitrification or absorption by plants. The water control structure is designed to bypass drainage water that exceeds the buffer capacity directly to the outlet so that drainage in the field is not negatively impacted.

Developed by researchers at Michigan State University in collaboration with North Carolina State University, Iowa Soybean Association (ISA) and Iowa State University, this decision support tool optimizes saturated buffer designs. Development was funded by a grant from the USDA Natural Resources Conservation Service. ISA conservation staff tested the tool to help the developers make improvements. Current design practices are based on treating a percentage of the maximum drainage capacity. However,

Alex Buseman ISA conservation services manager abuseman@iasoybeans.com

more flow diverted to the buffer does not mean more nitrate is removed. The new tool uses local soils, climate and drainage system information to estimate drainage and nitrate losses over multiple years and finds the optimal saturated buffer to remove the most nitrate. Cost information allows the tool to be used to select the best performing and most cost-effective sites and designs.

Designers using this new decision support tool can help farmers gain more insights into the potential of saturated buffers to reduce nitrate losses from their farm and how different sites compare. Using this decision support tool ensures successful implementation tailored to their unique landscapes.

Now is the time to take the next step in conservation. ISA makes it easier than ever to install saturated buffers by offering both technical and financial assistance to Iowa farmers. From identifying suitable sites to securing funding, our team walks alongside you through every phase of the project.

Our conservation services managers, Brandon Iddings and Alex Buseman, take care of the heavy lifting .— handling the paperwork, permitting and coordination with agencies, so you don’t have to. We know your time is valuable, and we’re here to remove barriers that stand between you and conservation practice adoption.

If you’ve considered doing more for water quality, habitat or sustainability, we’re ready to help you make it happen. Reach out to ISA’s conservation services managers for assistance.

Contact Brandon Iddings at biddings@iasoybeans.com or Alex Buseman at abuseman@iasoybeans.com.

A typical saturated buffer design where a water control structure (1) intercepts field drainage, diverts water into a perforated distribution pipe (2) running along the buffer. A bypass feature (3) prevents any field drainage issues. Water seeps through the buffer soil (4), where microbes convert nitrate in the water to harmless nitrogen gas. Illustration by Susan Langman.

When fifth-generation farmer Brian Strasser returned to farming in 2013, he joined the Iowa Soybean Association (ISA) as a member. Since then, he’s expanded his involvement through policy and programming, learning more about the industry and the association.

A recent award ceremony noted just how much he’s leaned into ISA experiences. Strasser earned the Iowa Soybean Association’s (ISA) New Leader Award. Presented by Corteva, the New Leader Award recognizes an ISA member who has recently expanded their involvement in ISA programming and demonstrated outstanding leadership in their community and/or state.

STORY BY

BY BETHANY BARATTA JOCLYN KUBOUSHEK

Eight years after he first joined ISA, fellow farmer and thenISA District 9 Director Pat Swanson nudged Strasser to explore opportunities within the organization. He found his connection through ISA’s Grassroots Fellowship.

“That program really opened the door,” he says. “We focused on policy, traveled to Washington, D.C., and lobbied on behalf of the Iowa soybean farmers. It showed me the value of speaking up as farmers and of helping influence the people writing the rules.”

That experience ignited a passion for policy. Strasser has remained deeply engaged in ISA’s policy development efforts for more than three years, lending his voice as he and other farmers help shape the association’s stance on critical issues.

“We all have to do our part,” he says. “I can bring more to the table than just a farmer’s perspective. I’ve walked in the worlds of business, tech and agriculture. That makes me more effective when engaging with policy, customers and peers.”

Through ISA’s Experience Class, Strasser saw how ports and crush plants are an integral part of the global soybean supply chain.

“You see exactly where your soybeans go and how they get used,” he says. “It changes how you think about your role in the bigger picture.”

After earning his degree in computer science at Indian Hills Community College, Strasser launched a career as a computer programmer, spending nearly a decade in the tech industry. When a position at Sinclair Tractor in Kalona opened, it was a chance to connect his technology and ag experiences.

“I cut my teeth inside the technology industry,” he says. “Knowing the big picture of agriculture — from John Deere products to precision technology, to agronomics, to my own farm — I could relate and pull it all together. This experience has been an advantage in working with farmers.”

Since then, he’s joined Advanced Agrilytics as an interim regional sales manager. He works directly with farmers in various stages of data collection, using technology to enable farmers to be more efficient.

Strasser lives and farms with his wife and children near Homestead on the same land once belonging to his grandfather and mother. They grow soybeans and corn and also raise pigs. Twelve years after he returned to the farm and joined ISA, he remains driven by the people in agriculture, including those he’s met on his journey with ISA.

“ISA has great people at the leadership level, and I look forward to furthering my involvement with the association. Those involved seem to be down to earth and want to get stuff done,” Strasser says.

Looking ahead, he plans to expand his involvement in the association by exploring more of ISA’s conservation and research opportunities.

“A lot of organizations are just about meetings over coffee and talking,” Strasser adds. “ISA wants to further their benefit for Iowa farmers, and they truly believe in their mission and purpose.”

Contact Bethany Baratta at bbaratta@iasoybeans.com