3 minute read

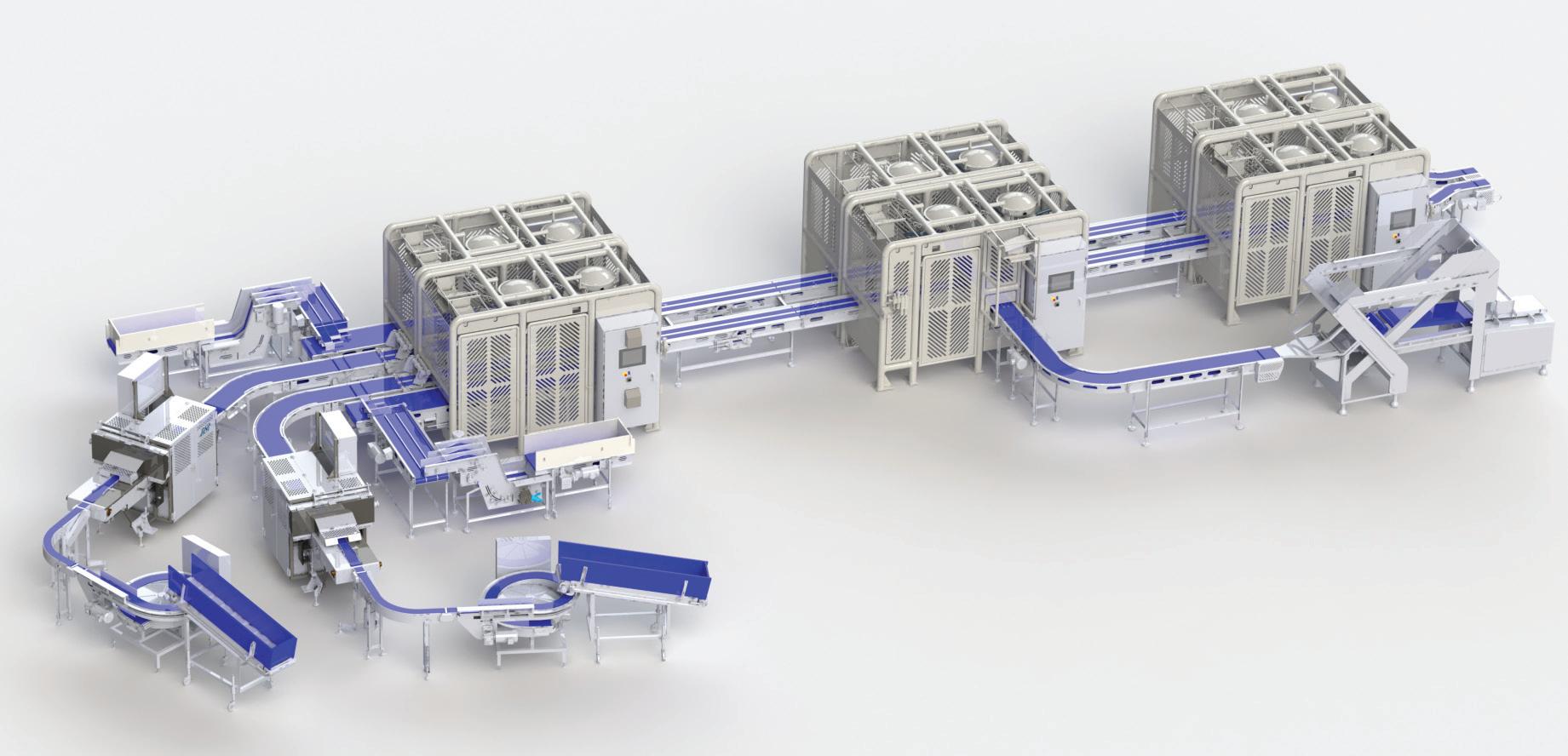

Creativity and innovation at core of JLS® system integration

from JLS Magazine #4

Attention to detail and strong company culture drive success opportunities to design and build the internal systems and processes that are used to build the packaging systems we produce. Anybody can build a custom automation system. Very few organizations have the tools, people and skill sets to marry software, hardware and process together to produce such a variety of custom machines, concurrently, under tight timelines.

Q: How has JLS met and solved these challenges?

Boucher has over 20 years of engineering experience, including eight years at JLS. For the past several years, he and his team have been working on larger systems, which have ramped up in demand over the past four years, spurring the need to expand their facility.

Boucher discusses how their team solves the challenges of system integration. JLS provides fully customized systems for everything from sandwich assembly and confectionery, all the way to raw and packaged meat and cheese, and even wet wipes.

Q: What challenges have you encountered with getting into systems design and integration?

BOUCHER: The most interesting and impactful opportunities aren’t actually system design and integration. They are the

BOUCHER: Stepping up to those challenges and meeting them has three main focuses. One is that we are continually hiring high-caliber candidates. Our headcount continues to grow. As a second point of focus, the continual improvement of processes between and within departments, from high-level management and down, is important. The third is innovation with a focus on minimization. The JLS-type of solution tends to use software or creative solutions to solve problems without resorting to a lot of hardware. Solving problems in that way is inherent in good sanitary and hygienic design since the more hardware you have, the less sanitary the solution is. At JLS, you never hear, “That’s how we’ve always done it.” We’re always looking for new ways to solve problems.

Q: How are other OEM components selected for your systems?

BOUCHER: Sometimes the customers dictate specific equipment that they want us to use. We have an excellent application engineering department that will engage with one or multiple sub-vendors to do preliminary testing to validate solutions during the vetting process. The team knows the go-to partners for certain applications.

Q: How important is your ability to do full system FATs to your customer?

BOUCHER: It’s incredibly important. JLS goes above and beyond in that every time we can get all the equipment in-house to test it, we do. We are specifically expanding our building to handle in-house FATs for this growing segment. Having us handle this at our York facility has helped customers save a month’s worth of production time in many cases.

Q:

What sets JLS apart from other systems integrators?

BOUCHER: We will do whatever it takes to make our software better and more tightly integrated into other systems. A lot of other integrators don’t have that software focus. To us, this means no more software pains for our customers.

Q: What role does creativity play in systems integration at JLS?

BOUCHER: Creativity and innovation are at the core of JLS culture. They are central to being able to look at a problem.

Whether it be end-of-arm tooling or total line integration, our team likes to ask questions, seek advice, get hands-on experience, do reviews, and question all the assumptions that went into the initial planning of a particular project. Our engineering team just doesn’t sit at their desks and march forward with ideas that are presented to them, they are constantly doing reviews and having brainstorming sessions.

Q: In what ways do you feel that developing a good culture contributes to the success of larger projects?

BOUCHER: While good overall company culture is key to general business success, it is essential for the system engineer to set the tone and bring everyone in the company together to make large projects successful. Systems engineers need to be able to multitask and appreciate all the different viewpoints for what is needed. Good systems engineers keep everyone around them engaged and wanting to go above and beyond to solve the problems and get the job done.

At JLS, time and time again, what makes a large project successful is being incredibly meticulous, detailed, and organized to bring together, document, and execute on the integration between equipment. It takes a lot of drive, passion and commitment to the details to make it work. And our team has that drive and passion.

To learn more, scan the QR code or visit jlsautomation.com/integrated-systems

Dennis Gunnell