3 minute read

RISING THROUGH CHALLENGES WITH AUTOMATION

from JLS Magazine #4

Robotic systems and complete lines by JLS® optimize bakery production

BAKERIES AROUND THE WORLD have faced unprecedented challenges over the past few years. From labor gaps, recalls and supply chain disruptions to an increase in consumer demand for products, the bakery business is an ever-changing landscape.

JLS’ automated robotic packaging systems and complete line solutions are designed to solve these problems while increasing production and ensuring food and worker safety. From sandwich assembly to primary loading and case packing, JLS empowers bakeries to do it all.

I n fact, JLS’ robotic packaging solutions cover a wide variety of both primary and secondary bakery packaging applications that are all backed by the high sanitary design that comes standard on JLS machines. Whether raw pizza dough needs to be handled, cookies or cupcakes loaded into a flow wrapper, tortilla shells stacked to be wrapped or snack cakes placed into cartons or trays, JLS can handle all of it, and more.

Turnkey Sandwich Assembly Systems

With JLS, sandwich assembly is made simple and labor gaps are alleviated. Complete sandwich assembly lines handle everything from primary loading through end-of-line operation. With a complete sandwich line from JLS, your bakery can automatically build sandwiches without having a human hand touch your product.

Accurately stack each component from the bun or bread to protein, cheese and other ingredients. Lines can include slicers, hygienic primary loading systems, flow wrappers or thermoformers, case packers, palletizers and everything in between.

Hygienic Primary Loading with Talon ®

While many primary loading machines utilize the time-consuming method of picking up an item multiple times in order to properly orient, Talon ® sets itself apart by doing it all in one swoop. Talon primary loading systems quickly pick up and properly orient fresh and frozen bakery items such as fresh dough balls, tortillas, muffins and breakfast sandwiches, and then place them into a primary package in a single pick. Made to get wet and never get tired, Talon is ideal for washdown environments.

TALON DOES A LOT MORE THAN JUST THERMOFORMER LOADING. LIKE THE TALONS OF A BIRD OF PREY, TALON IS DESIGNED TO ADAPT EASILY TO ACCOMMODATE A VARIETY OF PRODUCTS AND PACKAGES.

However, Talon does a lot more than just thermoformer loading. Like the talons of a bird of prey, Talon is designed to adapt easily to accommodate a variety of products and packages of various shapes and sizes. To adapt, Talon utilizes multiple end-of-arm tooling options, including vacuum technology, grippers and paddle lifts.

Once a breakfast sandwich is assembled, for instance, Talon can load it into a thermoformer, all in one piece.

For contract packagers that need a versatile system, Talon provides the ultimate flexibility. With a simple endof-arm tooling and recipe change, multiple products can be run on a single machine.

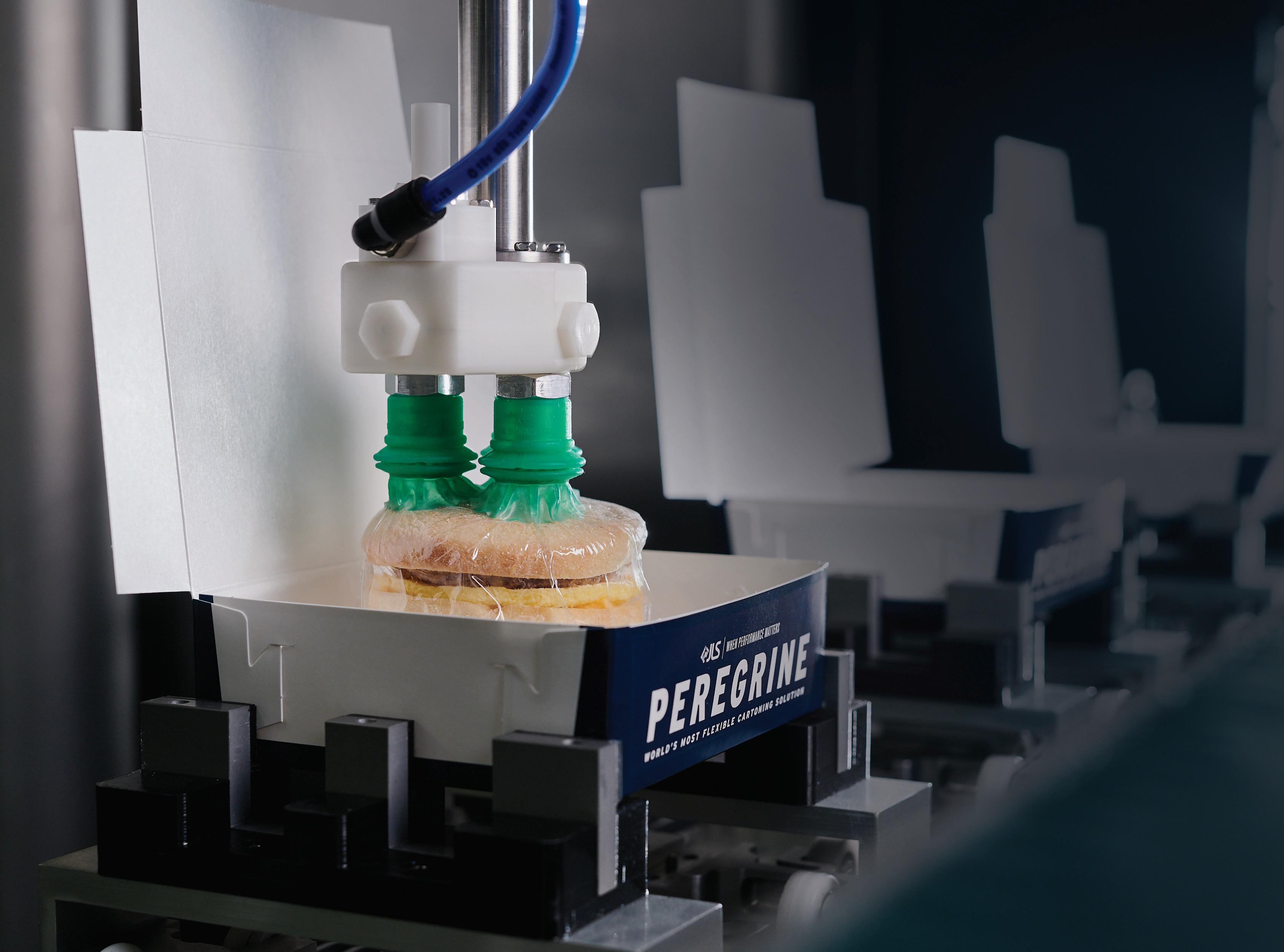

Space-Saving Cartoning with Peregrine ®

The Peregrine ® is a high-speed, vision-guided robotic top-load cartoning system that offers the high sanitary standards that bakeries require. With a small footprint that is one-third the size of traditional top and end-load cartoners, Peregrine places carton forming, loading and closing inline so there’s no wasted real estate, saving valuable floor space.

The Peregrine’s high-speed JLS TRAK ™ and Positive Carton Transport (PCT ™ ) system eliminate problematic handoffs and the need for additional conveyors to move cartons away from the former to accumulate or manage the loading process. Cartons are kept in-line, without turns, from forming to loading, all the way to robotic closing. Peregrine is ideal for cartoning of baked goods such as wrapped donuts, cakes, sandwiches, and more.

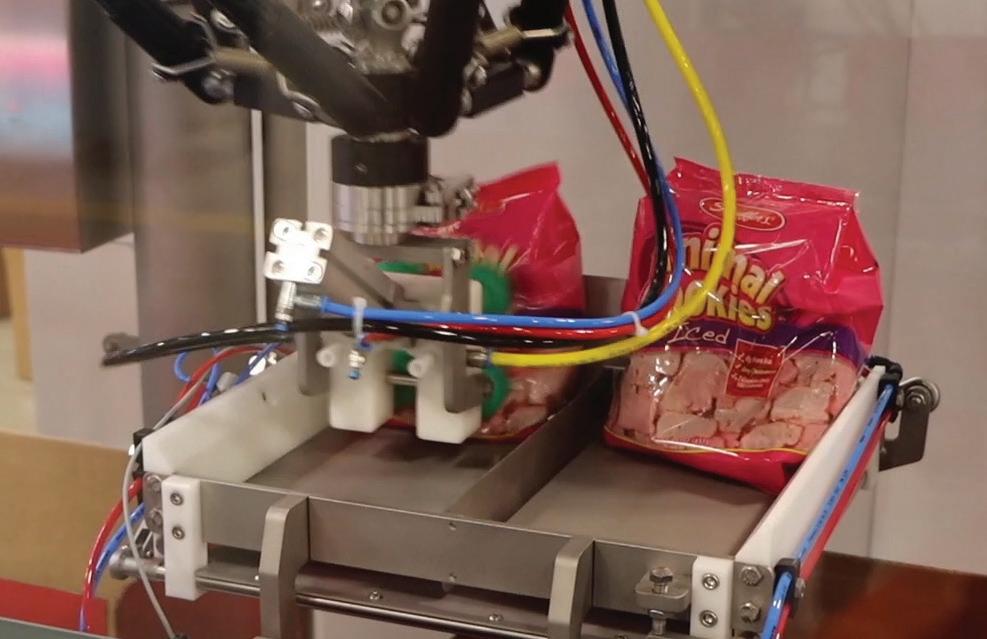

Versatile Case Packing with Osprey ®

As with all of JLS’ packaging systems, high sanitary design is standard with JLS’ Osprey ® robotic case packer, making them ideal for bakeries. Marked by its versatility, Osprey easily integrates into existing lines or helps automate manual processes for baked goods producers. With high-payload delta robots, sloped surfaces and an open design, Osprey never gets tired and excels at working in harsh environments.

Osprey handles various package formats and virtually any baked good, including flat or vertical pack of stand-up pouches of cookies, flat pack of foodservice bags, as well as flow wrapped cookies, thermoformed pouches of bread and more.

Harnessing the power of nature in a hygienic automated solution, JLS’ packaging systems help your production line realize its full potential while maintaining your product’s integrity.

To learn more, scan the QR code or visit jlsautomation.com

Lucas Boucher