The evolution of the breads sector in FTG is fascinating, thanks to fresh, global avours taking the lead – and consumers wanting so much more from this essential staple. We also focus on the latest packaging innovators, alongside an exclusive Q&A with UKHospitality CEO, Kate Nicholls. With part two of our lunch! show preview and pro les galore, it’s certainly a bumper 80-page edition. Cheers!

Editor Alex Bell,

Tel: 01291 636349, email: alex@jandmgroup.co.uk

Advertising Paul Steer, Tel: 01291 636342, email: paul@jandmgroup.co.uk

Production Gareth Symonds, Tel: 01291 636339, email: gareth@jandmgroup.co.uk

Subscriptions and Customer Service Tel: 01291 636338, email: subscriptions@sandwichandfoodtogonews.co.uk

Editorial Address Sandwich & Food To Go News, Engine Rooms, Station Road, Chepstow NP16 5PB www.sandwichandfoodtogonews.co.uk

In association with The British Sandwich & Food To Go Association.

PHONE +44 (0) 1291 636338

FAX +44 (0) 1291 630402

WEB www.sandwich.org.uk

EMAIL info@sandwich.org.uk

Paper used in the production of this publication is sourced from sustainable managed forests.

NEWS

Pages 04-14. Round-up of the latest stories

PROFILE

Pages 16-18. In pursuit of excellence – H-Pack

Pages 30-32. Creativity without compromise – Paci c West

Pages 38-40. Day in the life – Simply Lunch

Q&A

Pages 20-21. Time to get busy – Kate Nicholls, UKHospitality CEO

THE BRITISH SANDWICH & FOOD TO GO ASSOCIATION

Pages 22-28. The Sammies 2025

PREVIEW

Page 34-36. lunch! show (part two)

BREADS & WRAPS SPECIAL

Pages 43-58. Fosters Bakery / Mission Foods / Roberts Bakery / Baked Earth / Dina Foods

PACKAGING INSIGHT

Pages 59-71. Colpac / Conglom / Coveris / Xampla

REGULARS

Page 72. Classi eds

Page 74. New products

Page 75. BSA listing index

We focus on key data announcements, sustainability milestones, inspirational product launches and technological innovation in foodservice.

The revised date for the inaugural Food to Go Conference has been confirmed as Wednesday, 22 January 2025 at London venue One Birdcage Walk.

Organised with the support of the British Sandwich & Food to Go Association, the event features presentations and discussions with industry heavyweights covering crucial topics affecting the sector. These include:

The ever-changing FTG market:

● Simon Stenning, strategy advisor and futurist.

● Rhian Thomas, Institute of Grocery Distribution.

● Gavin Rothwell, Food Futures Insights.

Sustainability and the move to net-zero:

● Andy Cato/George Lamb, Wildfarmed.

● Fran Haydock, Greencore.

● Joanne Elsdon/Paul IrwinRhodes, Greggs.

Transforming work through technology:

● Warwick Wakefield, Flexeserve.

● Mostafizur Rahman, chief engineer, AI Tech, MTC.

● Joe Heather, Deliverect

How to make delivery work for you with industry expert, Peter Backman.

Why switching from barcodes is better for you and your customers with GS1’s Camilla Young.

SPONSORED BY

DISCUSSION

Each themed session will conclude with a discussion forum.

SPONSORSHIP

To support the Food to Go Conference 2025 as a sponsor, get in touch with Sandra Bennett on 01291 636348 or by email to sandra@jandmgroup. co.uk.

Find out more at www.thefoodtogoconference.co.uk.

The latest Foodservice Price Index (FPI) report from Prestige Purchasing and CGA by NIQ reveals more progress in the fight against inflation in the hospitality sector, with rates dropping to 3.1% in July.

It means inflation has now fallen for 13 consecutive months, bringing respite to businesses and consumers who have faced historically high prices. However, the report also indicates an uptick in month-on-month prices, with the whole basket of items increasing by 0.2% from June. This was largely driven by the beverage categories of the Foodservice Price Index, which have consistently risen since March this year, contributing to YoY inflation of 7.3% in the mineral waters, soft drinks & juices segment, and 4.7% in the tea, coffee & cocoa category.

On the food side, two of the Index’s eight categories recorded a year-

on-year decrease in July, with dairy and oils & fats down by -0.1% and -1.7% respectively. In contrast, the vegetables and sugar, jam, syrups & chocolate categories saw sharp rises of 9.6% and 8.4% respectively.

High inflation in the vegetables category is predominantly driven by potato pricing.

Reports suggest that English white potatoes are up around 90% YoY as a result of 2023’s challenging harvest. However, if the 2024 harvest progresses without climatic interruptions, spikes are unlikely to repeat.

Shaun Allen,

Prestige Purchasing CEO, said: “The sustained YoY decline in foodservice inflation is encouraging but the slight month-on-month increase and significant inflation in certain categories, particularly beverages and vegetables, remind us that the journey towards price stability is ongoing.”

Fresh Kitchen – which hand-prepares pickles, sauces and condiments – is launching a range of 18 new products into Brakes.

It’s designed to help alleviate the pressure on kitchens facing challenges around recruiting and retaining skilled chefs. The products are all hand-prepared by highly skilled operators using the same process as

a professional kitchen, just on a bigger scale. It means that chefs can enjoy all the quality benefits, without having to spend the time preparing them.

The list includes Great Taste award-winning Fresh Kitchen Pickled Watermelon. This vibrant red offering is perfectly balanced in a vinegar pickle that creates both sweet and sharp flavours; Comeback Sauce is a spicy dipping option, inspired by Mississippi, perfect for seafood cocktails, burgers, chicken and BBQ accompaniments; and Golden Beetroot Piccalilli, an award-winning blend of golden beetroot, sultanas and a medley of diced vegetables, enrobed in a sharp dressing infused with mustard seeds.

Other options include Pickled Chilli Pineapple, Pickled Pear, Makhani Curry Sauce and Hot Honey Sauce.

Fresh Kitchen products do not use artificial colours, flavours, or preservatives and are created using produce from Fresh Direct, which is also sited at the Bicester Food Village.

Paul Nieduszynski, CEO of Sysco GB, said: “We felt there was a gap in the market for of high-quality sauces and pickles that chefs can serve without needing to spend time creating them. We follow the same process as any chef would. The expertise and experience of our operatives means chefs are guaranteed a great product every time.”

Crimestoppers figures show that reports of energy theft have increased by nearly half (48%) since the start of the cost of living crisis. Motivations include businesses hoping to cut the price of energy bills or not even paying for what they have used.

However, there is a safe way to address this issue, as suspicions can be reported anonymously through the Stay Energy Safe service.

Energy theft, which includes bypassing gas or electricity meters, poses an unjust threat to law-abiding businesses. It creates an environment that transfers the costs of revenue losses to other energy consumers. Tampering with meters, cables, wires or pipes also puts staff and unsuspecting customers in danger, leading to explosions and fatal fires.

In a tragic example, meter tampering went unnoticed and led to the death of a business owner’s employee. The owner tampered with the electricity meter to avoid paying bills, creating dangerous conditions that resulted in a fatal electrocution. The owner was found guilty of manslaughter and fined £40,000.

Energy theft is serious and extremely dangerous. Those found guilty can be jailed for up to five years. Fines start at around £2000 but penalties can be much higher.

If you suspect meter tampering, you can report it while staying 100% anonymous.

Stay Energy Safe won’t ask who you are; they’ll just pass on what you

know. Stay Energy Safe is a service run by the independent charity Crimestoppers. They are independent of the police and ensure that suspicions can be reported anonymously.

Visit stayenergysafe.co.uk or call 0800 023 2777.

Following the launch of its first ever CSR report in March 2024, which revealed significant progress on several key sustainability commitments, Délifrance’s efforts to reduce its Greenhouse Gas (GHG) emissions have been certified by the Science Based Targets Initiative (SBTi).

Objectives include a 42% reduction in GHG emissions for scopes 1 and 2, as well as 29% reduction in GHG emissions for scope 3, all by 2030. Délifrance has also set itself an ambitious goal of non-deforestation on their main potentially affected raw materials by the end of 2025.

These emissions reduction targets, aligned with its parent company –French cooperative group VIVESVIA – are consistent with the goals of the Paris Agreement, aimed at limiting the temperature increase to 1.5°C above pre-industrial levels.

The SBTi certification process is

a significant milestone for Délifrance, providing its stakeholders with verified assurance of a long-term commitment to reducing its environmental footprint.

This includes focusing on the biggest impact areas of GHG emissions such as raw materials purchasing, energy and refrigerant gases used in its factories, and freight.

Nathalie Genebes, global CSR director at Délifrance said: “Achieving SBTi certification reflects our deep commitment to sustainability and the validation of our efforts to integrate environmental responsibility into our core business strategy.

“As a leading manufacturer of baked goods, we are dedicated to continuing our work in reducing our carbon footprint, to reaching our 2030 targets and supporting

the ambitious climate goals of VIVESCIA Group.”

Find Délifrance’s CSR report at www.delifrance.com/uk/our-csrapproach-baking-good-better

Frozen food distributor Central Foods has introduced a vegan and gluten-free sausage to its free-from range for the foodservice sector.

The KaterVeg! vegan and glutenfree VG sausage is made to the same recipe as the KaterVeg! vegan meatballs, one of the most popular products supplied by Central Foods.

Made from soya, the KaterVeg! VG sausage is a high-in-fibre source of protein and low in sugar, suitable for vegan and gluten-free diners, making it versatile for any menu.

Gordon Lauder, MD of Central Foods, said: “Our KaterVeg! vegan meatballs are very popular, so we decided to use the same recipe to create the VG sausage.

“It’s moist, juicy and really tasty – a super addition to our plantbased sausage and burger range. This new product will provide our

foodservice customers with a delicious option that is suitable for both vegans and gluten-free diners.”

Each sausage weighs 50g and the KaterVeg! VG sausages are supplied frozen in packs of 40.

The KaterVeg! range is Central Foods’ own brand range, offering a wide variety of meat-free and vegetable-based products to the catering sector. All are suitable for vegetarians, many are also suitable for vegans, and a growing number are suitable for both vegans and coeliacs who require gluten-free options.

Central Foods currently sells to over 180 independent wholesalers, as well as larger national and regional wholesalers. The company is a catering partner across the whole foodservice sector.

For more info, visit centralfoods.co.uk.

With over 50 years experience in mobile retail Jiffy are the name you can trust, our success relies upon your success. Call us now to arrange a demo Tel 01274 596000 sales@jiffytrucks.co.uk Looking for new revenue streams? Supply your products with the original Jiffy truck.

Our temperature controlled food delivery vehicles are designed to display and vend your pre-made Hot and Cold food. Delivering direct creates you a captive audience, offering customers the ultimate in convenience and service. Call us today and take the first step towards increasing your sales.

· Established 1974 www.jiffytrucks.co.uk

· Our mobile “shops” have no rent or rates to pay and operate with one staff member.

· Our trucks are chosen by all the major names in mobile catering for their build quality and reliability.

· Flexible finance packages available.

· Fully accredited by the BSA

· Whole vehicle type approved

· A very profitable addition to any food business.

Potato product supplier, Aviko, has launched a new guide to brunch. Complete with insights and a host of inspiring recipes, it aims to help operators unlock the potential of hash browns and maximise profit.

With nearly half of UK consumers (47%) eating brunch at least once a week*, operators have even more of a reason to focus on this daypart and elevate their offerings. To support foodservice in this mission, Aviko has produced a comprehensive guide called Let’s Brunch, that focuses on four major brunch concepts – ‘Loaded Brunch’, ‘It’s a Wrap’, ‘Plant-Based’ and ‘Sweet Treats’ –providing inventive ways to serve the nation’s favourite brunch items, including Aviko Hash Browns.

The guide contains a deep dive into consumer attitudes towards brunch, with experimental ways to curate flavourful dishes inspired by world food trends. Plus, words of wisdom from Pablo Eggsgobao, who shares how Aviko Hash Browns are making an impact on menus and helping meet consumer demand.

Mohammed Essa, commercial director UK & Ireland, Aviko, said: “This guide is packed to the brim with recipe inspiration that will help chefs take classic menu items and elevate them to a whole new level – think savoury and sweet as you’ve never seen before, and global fusions to keep diners coming back for more! Through independent research, we can see a huge opportunity for operators to incorporate our tasty potato products into dishes, as a massive 74% of people are likely to order hash browns for brunch*. Plus, with ‘crunch’ and ‘golden colour’ being top features to what makes a tasty hash brown*, Aviko has you covered.”

Recipes include Eggs Benedict Loaded Fries which comprise Aviko SuperCrunch Fries, streaky bacon, and Hollandaise sauce; Maple and Bacon Ice Cream Fries; and Breakfast Bao Bites for something on the go. As well as elevated plant-based suggestions such as Meat Free ‘Totchos’, plus many more.

For the full guide, go to aviko.co.uk to download free. *Aviko Independent Research, July 2024

Fresh Food For Now Company have announced the return of a duo of savoury bars, available now in travel, forecourt and impulse channels.

Grabbing the attention of busy commuters and people on the road, the Buffet Bar and Scotch Egg Bar are designed to address between-meal cravings, available in shelf-ready packaging to improve visibility on fixture.

Protein-packed to meet demand from the 53% of consumers looking to stay fuller for longer1, the bars also combine several of the UK’s most-reached-for snack formats. The Buffet Bar is 100% British sausage meat filled with crunchy coleslaw, soft cheese and creamy mayo and wrapped in crispy golden breadcrumbs.

Tapping into the well-loved snacking staple of a savoury egg – brought by over a third of the population and particularly popular with younger consumers2 – the Scotch Egg Bar sees sausage meat filled with perfectly seasoned egg mayonnaise, encased in a breadcrumb coating.

As lifestyles get more hectic and we move away from traditional mealtimes, snacking has seen significant growth. In the UK, one in three replace main meals with snacks3, accounting for 29% of total consumption occasions4

Out-of-home snacking is particularly buoyant, worth a staggering £3.8 billion across a variety of channels5. With the likes of forecourts and travel over-indexing on all-day grazing in particular, the new bars are an on-the-go option or lunch ‘add on’ for operators in this space.

Wayne Greensmith, head of customer marketing at Fresh Food For Now Company, said: “If you’re thinking our tasty new snack bars look familiar... you’d be right! We’ve brought back the iconic format, previously Ginsters, that was beloved by the nation over for many years. There’s nothing quite like it on the market, so this tasty twosome will be flying off your fixture.”

Email hello@foodfornow.co.uk.

1&3 Guardian, Yougov, Waitrose – Food and Drink Report 2023, Mintel

2 Kantar WPO Savoury Pastry 52 we 24.01.24

4 Kantar Usage, IH/CO occasions 52 w/e May 2023 (vs. May 2019); 5 ibid

Flexeserve is the global leader in hot-holding displays, with revolutionary products Flexeserve Zone, Flexeserve Hub and cloud-based service, Connect. So much more than a manufacturer, Flexeserve also offer unrivalled expertise through the unique service - Flexeserve Solution. Meet the team today and solve your hot food pain points.

Control and automate your entire hot-holding estate efficiently, with our award-winning cloud-based service.

EG On The Move, master franchisee of Cinnabon in the UK, is continuing its rollout. Recent openings at the Bullring in Birmingham and in Livingston, Scotland, launched to waiting crowds, with Cinnafans travelling from afar to get their Bons!

The team is planning at least another six stores for the rest of 2024, including Brent Cross Shopping Centre in London and more outlets in Scotland. The team has also been busy with Cinnabon menu launches, teaming up with Oreo to introduce three new products in April.

Harjinder Dasanjh, brand manager, Cinnabon® UK, is co-ordinating the rollout: “The response to our outlets is amazing, we always open to crowds and the feedback is great. Whether a kiosk, store or even our Cinnabus, the products are in demand! We have bold plans, including another London opening and a strong presence in

Scotland – our first kiosk opened in July in Livingston to great success.”

This further cements Cinnabon’s position as a leading foodservice and retail convenience operator.

For Cinnabon fans unable to visit

an outlet, Cinnabon treats are also available to order through Deliveroo, Uber Eats and Just Eat, or can be ordered online for next day delivery nationwide via the Cinnabon website, cinnabon.co.uk.

Hoshizaki, a leading supplier of commercial refrigeration and icemaking equipment, has announced the relaunch of its new virtual showroom. This innovative platform allows customers to explore an extensive range of products in a fully immersive and interactive environment, direct from their mobile

or tablet, thanks to quicker loading times and an improved user interface.

It's a unique way for customers to browse Hoshizaki’s extensive range of refrigeration and ice-making equipment, accessible from anywhere in the world.

A key feature is the ability to interact with the products in

a way that is not possible in a physical showroom. Customers can explore different features, zoom in on specific detail and even view them in operation. Additional resources include detailed product specifications, 3D models and videos.

Roberto Lazo, digital marketing specialist from Hoshizaki, said: “We are delighted to be launching our new virtual showroom, which we believe will be a game-changer in the commercial refrigeration and icemaking industry. It offers a convenient way for customers to explore our extensive range of products, and we believe it will be a valuable resource for businesses and distributors looking to make informed decisions about their purchase. The user-friendly platform assists you in articulating product details and benefits, key features and space considerations, with supplementary information material.”

Stagione® Light is a new line of paperboard food packaging from Colpac – part of its Stagione® range. Stagione® Light showcases the iconic shape and roll-top design of Colpac’s original range, offering customers lighter products that are manufactured from one piece of paperboard. The new packs are made from FSC® certified*, recyclable paperboard in accordance with UK and European recycling guidelines.

Stagione® Light has three size variants: 500ml and 750ml rectangular, with 1000ml square.

Colpac commissioned new machinery to develop the products and has extended its Stagione® range to provide a wider choice and lower cost entry points.

This new line can be used to serve hot or chilled dishes in foodservice environments. The grease-resistant barrier and webbed design makes the packs leakproof when filled with wet, instant eat foods. Stagione® Light can also be utilised to package chilled food-to-go such as salads or baked goods in foodservice or retail environments.

To reduce complexity and align with the current range, the new bases fit the current wide selection of lid options that Colpac offers. They include rPET and PP clear lids, and PP and PE coated paperboard lids. Tight fitting lids provide a leakproof seal for transport and display and maintain food freshness. To further extend shelf-life, Stagione® Light can be film sealed thanks to roll-top construction.

To maximise brand opportunities, the packs offer allover printing as they are formed from a single piece of paperboard. This includes printing on the base, which is ideal for ingredient information.

“We have listened to customer feedback and utilised our materials and manufacturing expertise to extend our wellestablished Stagione® concept,” said Colpac commercial director, Andrew Grimbaldeston.

Visit colpacpackaging.com/products/chilled-food-to-go/ salad-pots/stagione-light *Colpac’s FSC® license code is CO41147.

Antunes has introduced the Wrap and Snack Toaster, featuring an innovative toasting system. The GST-1V model is now exclusively available in the UK through Jestic Foodservice Solutions.

As a leading provider of countertop cooking equipment, from egg stations to steamers, Antunes looks to help foodservice operators expand menus, improve service and grow more profitably. The latest development in their portfolio is the new Wrap and Snack Toaster, providing sites with the highest quality, reliability and consistency in a compact footprint.

Ideal for wraps or bread, it utilises dual-belt technology that grips the product as it moves along the heat source, eliminating transition defects. With fully programmable temperature and motor speed settings, as well as adjustable compression, the toaster

has the flexibility to easily customise production and deliver every time.

The model features a wide toasting lane for consistent dual-sided toasting of up to three filled wraps side-byside, offering the ultimate ease of use during service with continuously moving belts, allowing operators to immediately load product as needed without delay.

Energy efficient, it provides up to 30% energy savings compared to other toasters. The unique design keeps heat locked in the toasting chamber, while the outside surface remains cool to the touch. Easy to operate, there is a versatile control panel for quick adjustments to toast quality when needed.

Michael Eyre, Jestic product director, said: “The perfect toaster can simplify and streamline the toasting

process and selecting the right platform that can handle a kitchen’s needs is critical. The Antunes innovation team has ensured versatility, flexibility and high performance in equal measure.”

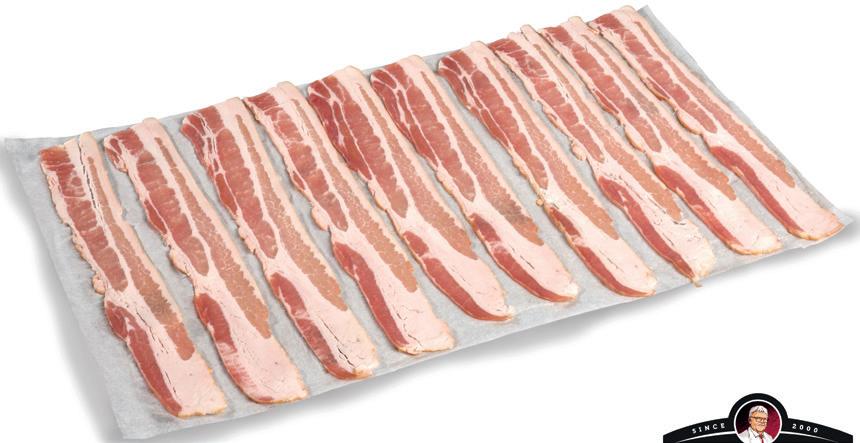

Crispy Bacon

Ready to eat

Convenient to use

Natural beechwood smoked bacon rashers

•Succulent and ready to eat

•No additives

•EU-27 origin

•Diced / strips / slice / whole fillet

•Versatile

•Great tasting

•Crunchy

•The ideal ingredient

Coated breast fillet products

•Crunchy coatings with tender chicken

•Cookin 5 range

•Be-spoke product design service

•EU-27 origin

•Limited handling

•Natural beechwood smoke

•Convenient, cook it your way

•Great tasting

•Ready to eat

•Convenient

•Thinly sliced

•The perfect breakfast rasher

H-Pack is a market leader in sustainable food packaging with exciting NPD in the pipeline, so we got the lowdown from head of merchant sales, David Martin.

What are the latest H-Pack developments around sandwich and food to go?

We’re working with pioneering materials and have invested a lot in product development, setting us apart from many competitors.

In a world that demands ecofriendly options, there’s a hunger for more alternative choice. H-Pack is on the brink of launching new and game-changing recyclable lines. There’s huge internal anticipation from senior management and the business is currently being reassessed to maximise every opportunity.

In recent months, we’ve launched kraft alternatives to our white, paper souffle pots and octagonal design,

standalone, premium, kraft paper food containers, with accompanying PET lids. Neither product is available from any other UK supplier. The aim is to continue to set ourselves apart by offering unique, quality options.

"In a world that demands eco-friendly options, there’s a hunger for more alternative choice."

Talk to us about the global presence of Hotpack and how that relationship contributes to UK operations?

Hotpack was established in Dubai almost 30 years ago and, in that time, has grown to become the largest manufacturer and distributor of food packaging materials in the Middle East. With 2.2 million sq ft of factory space, located at 14 Gulf locations, Hotpack’s manufacturing encompasses over 3500 products. It has branches all over the world and an international supply chain that is rigorously monitored, confidently supplying to some of the largest global consumers on a grand scale.

With this heavyweight operation behind us, H-Pack delivers a vast

selection of international premium lines. We work with customers to develop bespoke products, taking full advantage of the latest technology and operating to internationally recognised standards. We can also guarantee a tightly competitive price structure.

The name Hotpack certainly carries weight and enables us to provide efficiency of scale, giving us access to an exhaustive range of suppliers, while benefitting from having an in-depth knowledge of the UK market.

You’ve been in the role approaching a year and have extensive experience. Tell us about the last 12 months in terms of priorities and progress. I brought my own team with me, which helps when you’re moving to a big corporate. You need people you can trust, who know how you work. It also meant that I was able to hit the ground running.

My remit was to build on what H-Pack has managed to achieve in the past seven years since its inception, and put strategies in place across the warehouses and in the offices, that

"We work with customers to develop bespoke products, taking full advantage of the latest technology.”

will enable the business to enjoy the strongest position for future growth.

I’m currently implementing a targeted marketing plan to drive our positioning as a one-stop shop for the catering and food to go sectors, who we mainly reach via the wholesale and cash-and-carry markets. We want to expand on our share by positioning H-Pack as the ultimate ‘go to’ brand.

Talk about your partnerships with retailers/suppliers/brands/ in the FTG sector – both short and long term?

Long term, we want to build solid relationships with customers and

hold on to our most valued suppliers, increasing the business in specific channels that give us the best return. Short term, we will continue to trial new suppliers as it keeps us fresh. Also, we can’t claim to be offering the best unless we have properly explored all alternatives.

What are the key elements to keeping customers and clients happy?

Listening and giving them what they want. Also, it’s important to pass on any cost-saving. Customers really value being rewarded for their loyalty with specific price cuts and deals. They’ll bring their business back if you can demonstrate fair pricing, efficiency and the ability to handle all sizes of orders.

There have been many challenges in terms of sky-high costs, Brexit, conflict, political uncertainty, etc. How have you navigated these?

The main impact of Brexit for the UK packaging industry has been the repercussions on the Irish market. The paperwork involved with shipping

to Ireland is prohibitive, so we deal with that by asking those customers to collect from us and giving them special collection prices. It’s not ideal and our share of the Southern Irish market has shrunk as a result but it’s better than no share at all.

We’ll continue to offer this solution, to maintain a presence and prevent the business from disappearing into Europe, while waiting to see what the new government does to potentially improve the situation.

Container rates since January have steadily risen and are as high now as they were during Covid, thanks to certain shipping areas being no-go zones. We’re buying all over the world to try and counter this and get the

best that we can. Some of the bigger brands, like the supermarket giants, won’t be paying the same price for these containers as they inevitably ship more. The cold hard reality is

that UK industry will always struggle to prosper if we’re expected to pay higher prices.

Labour is in power. What are you hoping for?

I’d like the government to look at the situation in Ireland and make it easier for the UK to do business there. I also think there must be a way for us to take control of our shipment rates in the UK. We’re hopeful there will be an intervention on this at some point. And, hopefully, the market picks up – which will happen when people have money in their pockets and can treat themselves to takeaways and spend more on FTG.

What can we look forward to from H-Pack in the future?

We’ll continue to try and get costs as far down as we can, so people get value. In an ideal world, every business should be turning a profit and earning – however, those surviving and managing to push forward are leaning into existing resources to keep customers onside. As part of the Hotpack family we have invested in our future growth, with extra warehouse and office space in the UK.

The next 12 months will be about driving a return on this investment, keeping an eye on customer service and speedy delivery, while making sure that the FTG sector sees us as a reliable and cost-effective supplier, always putting its customers first.

For further information, see page 74.

Introducing H-Pack’s exclusive, kraft paper pot range, including a UK first – kraft souffle pots.

This latest offering provides the catering and ‘food to go’ market with a more sophisticated choice of portion and souffle pots, for hot and cold foods, from sauces, curry and mushy peas to coleslaw and salads.

The quality pots are available in a range of sizes, including 2oz, 4oz, 6oz and 7oz. With complementary lids available in paper and PP (polypropylene), H-Pack is, once again, providing a fully sustainable option to ensure its customers have a packaging solution that is most pleasing to the end-user.

Stand out choices for stand out food.

Labour is now in power, so what should happen next?

During the election campaign, it was pleasing to see hospitality recognised as a crucial sector that serves Britain and creates places where people want to live, work and invest. We have now been working closely with the new government to ensure that Labour’s manifesto promises are delivered, including encouraging urgent action to replace the broken business rates system and reduce the burden that currently sits on the high street.

Reform of the Apprenticeship Levy would also be transformational for hospitality’s investment in skills, helping us attract more people into the fulfilling roles we have to offer. It would crucially free-up funds to

As we hope for an innovative approach to foodservice challenges with a new Prime Minister, CEO of UKHospitality, Kate Nicholls, examines his key priorities.

enable the rollout of our successful skills pilot in partnership with the Department for Work and Pensions, which supports people out of work to develop new skills and pursue a career in hospitality.

Green investment is becoming an increasingly key priority, so further government support to help drive efforts to net zero is essential. For example, through the introduction of investment credits.

We also need to see reduced employer National Insurance contributions to help with staffing costs, while cuts to VAT can help relieve pressure to better facilitate lower prices and higher footfall, which is key to making our sector competitive again with the rest of Europe.

It’s been a tough time for business. What have you seen in terms of resilience and innovation?

Hospitality of all shapes and sizes has faced considerable challenges in recent years, including high energy costs, inflation and food and drink price rises, not to mention the lasting impact of the pandemic. However, despite continued economic difficulties, the sector has shown immense creativity to adapt operations and services. And it’s been fantastic to see how businesses have come together to overcome obstacles and provide excellent experiences.

As a sector that provides jobs and opportunities for everyone across the country, hospitality is a central pillar to local communities and the

wider UK economy. It’s essential that the government provides the right resources to support future growth.

Ingredient costs are volatile, as are supply chains. Are you optimistic?

The latest Foodservice Price Index from CGA reveals a steady decline in food inflation with the YoY rate dropping to 4.6%, the lowest figure in 28 months1, while the Bank of England’s decision to cut interest rates to 5% paints a promising picture. Despite these signs of stability, it’s clear that hospitality venues are not yet out of the woods when it comes to cost pressures, given that food inflation remains significantly higher than the economy’s wider level of inflation, which is currently at 2%. We urge the government to take much-needed action to support the hospitality sector by delivering its manifesto commitment to fix the broken business rate system.

Food security is a hugely important topic. Can there be more assistance from Westminster?

This is undeniably a priority, with global supply chains facing considerable strain against the backdrop of increased geopolitical instability and climate change. It’s important to ensure that those in the food & drink supply chain remain productive and profitable to help guarantee security and contribute to wider growth.

With the National Farmers’ Union (NFU), British Retail Consortium (BRC) and Food & Drink Federation (FDF), we signed a joint letter to all political parties ahead of the election, highlighting the importance of giving consumers access to a wide range of fresh produce and healthy food via more sustainable supply chains.

As well as working closely with businesses from farm to fork, we have also been involved in high level political discussions on the topic of increasing UK fresh produce to improve food security within the hospitality industry, including Number 10’s recent Farm to Fork Summit.

The UK delivers superb innovation around foodservice packaging and labelling. Would you agree?

We have been pioneers in packaging and labelling innovation in recent years, with businesses continually looking for ways to make it more reusable and sustainable. We welcomed the government’s ban on

single-use plastic items that came into force in October last year, which included plates, bowls and cutlery, and we support further legislation to help accelerate sustainable practices.

How can the sector continue to improve its sustainability model, both short and long term?

Despite the excellent work already being carried out, there is clearly more that can be done. Hospitality is uniquely positioned in that it’s a truly collaborative industry, evidenced by UKHospitality’s Environmental Sustainability Seminar coming up in October – where industry peers and leaders will provide advice and guidance on their own journeys, for the betterment of the wider sector.

We have already seen significant progress when it comes to the likes of cutting food waste, moving to renewable energy and working with suppliers to reduce their scope 3 emissions – all with their overarching objective of reaching net zero by 2040. Longer term, certain things need to be addressed, such as a reform of investment policy, including credits, to ensure it supports the transition to net zero and incentivises investment in green energy and decarbonisation. This, in addition to working to improve the capacity of the grid to allow businesses to move to fully electric outlets, will be fundamental.

1CGA Prestige Foodservice Price Index Snapshot Rep - May 24

The search to find the best in the business is on and here’s everything you need to know about the Sammies 2025

Once again we find ourselves turning our thoughts to that heady night in May when the movers, shakers and food to go makers of the industry gather to celebrate all that has been accomplished in the previous twelve months.

Each year, the awards provide a moment for reflection and this was especially true in 2024, which marked the 30th edition of this special event.

Equally though, with so many of the awards emphasising the importance of innovation, alongside the incredible creativity on display during the Sandwich & Food to Go Designer competition, the Sammies are a herald of great things to come.

For this reason, we’ve tweaked a couple of the award categories for

2025 to better reflect the areas where boundaries are being challenged and inventiveness thrives.

With distinct awards for both New Ingredients and New Packaging, as well as the freshly minted Business & Product Innovation Award, we hope to further reward the pioneering spirit which sits at the heart of our industry.

MEET US FOR LUNCH!?

The Sammies team will be on stand L1361 at the lunch! show on 18-19 September 2024 with details on how you can enter the awards, how the judging works and to answer any questions you may have.

JOIN US FOR DINNER?

The winners will be announced at the Sandwich & Food to Go Industry Awards Dinner on 8 May 2025 at the Royal Lancaster London.

AND IN THE MEANTIME?

Over the coming pages you’ll find an outline of each of the award categories. Full details of each award and how to enter will be on the awards website –www.thesammies.co.uk

This award shines a spotlight on the independent retailers which so often lead the way in new trends and tastes.

This award recognises development and innovation by suppliers and focuses on new ingredients.

This award recognises development and innovation by suppliers and focuses on new packaging.

Open to any sandwich (not a range) this award rewards innovation within the sandwich market, in both the hot and cold sectors.

This award recognises the work being done to provide consumers with new, interesting and innovative healthy eating products.

This award recognises development and innovation in the food to go market by manufacturers and foodservice businesses.

From forecourts and motorway services to airports, railway platforms and bus stations, this award recognises the work businesses are doing to develop and drive this sector.

This award will recognise the work being done by the convenience retailers to develop the sandwich and food to go market in the high street. En Route Retailer

This award is a broad category aimed at new equipment, ordering systems, software or similar innovative product ideas or business initiatives.

This award recognises those retailers who have done the most to develop their business over the last year.

This award will recognise the work being done by the café retailers to develop either the high street or in-store market.

This award recognises the work being done by the chain retailers in developing the market in the high street.

This award is presented to a sandwich or food to go retailer, manufacturer or supplier who has initiated a successful and innovative marketing campaign to achieve strategic goals.

This award is designed to recognise the work being done at all levels of the industry to reduce the sectorʼs impact on the environment and improve sustainability.

This award recognises the overall contribution made by manufacturers to elevate and grow the industry.

This lifetime achievement award is in the gift of the British Sandwich & Food to Go Association management committee and is special recognition of the recipientsʼ contribution to the industry.

SPONSORED BY

Thereʼs still time to enjoy the benefits of sponsoring.

All sponsorship packages include a table at the awards dinner.

If youʼd like to sponsor email Sandra Bennett sandra@jandmgroup.co.uk

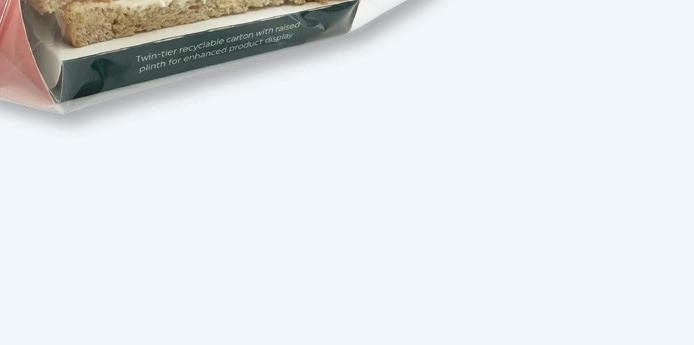

ProAmpac’s recyclable carton board sandwich wedges’ design and construction offer strength and protection. Providing the optimum balance between product visibility and branding opportunities, sustainability, cost-effectiveness, and ease of use while retaining ultimate product freshness.

The Sandwich & Food to Go Designer Competition is back and here is where the journey starts.

All you need to do right now is register to take part at www.thesammies.co.uk

Closing Date 15 NOVEMBER 2024

How it works

Once the registration windows close, all the entrants will receive the sponsor’s ingredients to help them create their recipes. These will then be judged by the sponsors with the best progressing to one of the regional heats.

Heat winners in each of the categories will progress to the live final which takes place on 8 May 2025 at the Royal Lancaster London ahead of the Sammies Awards Dinner, where the winners will be revealed.

The Heats

NORTHERN HEAT 4 March 2025 at Roberts Bakery, Northwich

MIDLANDS HEAT 5 March 2025 at Flexeserve, Hinckley

SOUTHERN HEAT 6 March 2025 at Brakes, Reading

Labneh is the cream cheese spread that is the Mediterraneanʼs best kept secret. Our Labneh is produced in Greece by our longstanding partner dairy, made with pasteurised cowʼs milk.

Labneh has a similar flavour profile to Authentic Greek yogurt, with a thicker, creamier consistency, with a slight salty note. It is highly versatile and great for adding injections of flavour into all sorts of dishes.

Our gammon follows the traditional Wiltshire process which during the curing stage is soaked in a live brine for a minimum of 3 days.

The finished product is very succulent with a soft slightly fibrous yet tender texture.

This excellent source of protein is allergen free and can be served hot or cold, as well as plain or glazed.

H. Smith Food Group plc is one of the UKʼs leading independent frozen food service companies specialising in the oriental, fusion/ crossover and food-to-go markets.

Chicken is an extremely popular and versatile ingredient for both sandwiches and food-to-go dishes. Weʼre excited to see what competitors can do with ours.

A new sponsor for the competition this year, the Roberts family knows a thing or two about baking. Ever since Robert Roberts baked his fatherʼs first loaf 130 years ago, four generations of baking skills and passion have followed.

Which of their products will be the star of this category is still to be decided.

New for 2025, Flexeserve and ProAmpac are joining forces for our exciting Hot-hold Food to Go Competition.

The chefs must produce a hot-hold, food to go using a ProAmpac packaging product from the ʻSome like It Hotʼ range. It will then be placed into a Flexeserve Zone unit.

Judging takes place 2.5 hours later so this category is not for the faint-hearted!

THE FUTURE OF THE FOod to Go MARket >>>

including Simon Stenning

Strategy Advisor & Futurist

Rhian Thomas

Institute of Grocery & Distribution

Gavin Rothwell

Food Futures Insights

Sustainability and the Move to Net Zero >>>

including George Lamb / Andy Cato

Wildfarmed

Fran Haycock

The Greencore Approach

Joanne Elsdon / Paul Irwin-Rhodes

Heading for Net Zero at Greggs

Transforming work through technology >>>

including Warwick Wakefield

Director Customer Experience, Flexeserve

Mostafizur Rahman

Chief Engineer AI Technology, MTC

Joe Heather

Deliverect

PLUS >>>

Peter Backman

Market Analyst Camilla Young GS1

It’s an exciting time at Pacific West, with a fully cooked seafood range focused firmly on the food to go sector.

Pacific West has been at the forefront of responsibly sourced, innovative seafood products for over 25 years. And creativity around value-added fish, scampi, salmon and prawns is nothing new, but an innovative first for foodservice is sure to have an impact.

“We are delighted to be showcasing our range of fully cooked seafood,” said Martin Finegan, managing director, Pacific West Foods.

“This will enable operators with even the most limited cooking facilities to deliver a seafood solution on their menus. It’s all ready to eat in under two minutes in a ‘High Speed Oven’, such as a Merrychef. For manufacturers, the product is fully cooked so can be utilised to create paninis, wraps, tacos, salads and more – it’s a whole new angle.

“Included is a new air crisp coating, enabling products to stay crisper for longer. For flexitarians, now is the time for food to go operators to take full advantage of this protein opportunity.”

And while the posh fish finger-style sandwich has been a hero product for some time, it has evaded the food to

go sector to a degree. “Now, with the Pacific West fully cooked fish goujons, bites and portions, this can be a menu option,” continued Finegan. “The beauty of seafood is that it takes on flavours well, allowing manufacturers and operators to add on-trend sauces – we have seen growth in world flavours, including Korean, Japanese and Americana profiles across the sector.

“But the traditional fish finger style sandwich, with a chunky tartare sauce, is timeless and missing in FTG… until now!”

Seafood has such a positive consumer profile in terms of its health and protein benefits, and while grocery inflation increased to 1.8% in July (up from 1.6% in June), global seafood costs are falling – and Pacific West is looking to take advantage.

“Our innovation is chef and trend driven, while being at the core of what we do. We are constantly researching and eating out, with our development team challenging the manufacturing aspect of the business continuously.

“One example is the growth of sourdough on the bakery shelves in retail, inspiring our latest sourdough crumb that is on our fish portions and goujons – available in plain and lemon, it has been really exciting to bring this type of crumb to the FTG sector.

“We are known in the industry for creativity and working to challenge food trends in our range. Pacific West has won many awards over the years for our innovation, including in 2024 at the BFFF (British Federation of Frozen Foods) Awards Dinner – bronze awards for Sweet Chilli Squid Bites and Katsu Fish Goujons.

“The secret is to never stand still, while looking to lead the market and add value for customers. Whether that is new style coatings, flavour profiles or ranges like the fully cooked, we are always exploring new ideas.

“Being a manufacturer, we are perfectly placed to work with customers on exclusive products and see it as a joint partnership. Customers know that buying Pacific West is a mark of quality and consistency.”

While Pacific West has relationships with major pub and restaurant brands, with the new fully cooked range, it is seeking connections with QSR, travel and FTG sectors.

“In addition, we are in discussion with manufacturers that supply this sector. Our expertise in manufacturing and managing the complex supply chain means we are already geared up to work at scale and a fast pace.”

And with green shoots of optimism in hospitality having been boosted by the first quarter-on-quarter growth in outlets in two years, by 0.5% (Hospitality Market Monitor from CGA by NIQ & AlixPartners), with easing of inflation and household bills, these numbers are a welcome sign.

“It’s important to clarify that we have our own manufacturing plants, meaning that we are the producer and therefore not layering margins on costs. This helps us to maintain competitive pricing to enable our customers to make their margin too.

“We invest in NPD and, due to our scale, look at global sourcing – i.e. prawns, fish, squid at the best market price, without compromising on quality and processing standards. This raw material is then sent to our manufacturing plant to create the end-product. Our UK team is dedicated to understanding the complex market on the ground here.

"For manufacturers, the product can be utilised to create paninis, wraps, tacos, salads and more."

“To launch the fully cooked range, we have invested in an exclusive, dedicated factory. Furthermore, we have a continuous review and investment plan across our different manufacturing sites.”

One of the best things about seafood is that it switches easily from summer into winter and is often determined by the serving suggestion. So, maybe salads and lighter dishes in the summer; pastas, breads and something more substantial in the colder months.

“The difference is around the serving ideas, so we work with customers on their NPD process. We always want to be inspiring with innovation, that’s what excites us! We are currently working on phase two of the fully cooked range and look forward to sharing what’s coming in spring 2025.”

Various launches later this year include sweet & sour breaded king prawns, sweetcorn fritters, red Thai calamari and veg nests, plus sweet & sour calamari spring rolls.

To get up close and personal with all the products and

"The di erence is around the serving ideas, so we work with customers on their NPD process."

developments, you can talk with Pacific West at lunch! –stand L128 (full preview from p34).

“We will be showcasing the fully cooked range, but the real attraction is the menu that chef Steve Walpole has created, aimed at the FTG sector. We’ll be serving samples on the stand, so come and try them,” concluded Finegan.

The countdown is on for lunch! - the definitive café, coffee shop and foodto-go event, which opens its doors on 18-19 September at ExCeL London. Renowned for being the ‘event of the year’ for operators, retailers, cafés and coffee-shops across the country, visitors can explore the best food, drink and tech innovations from 300+ suppliers.

Co-located with the 10th anniversary of Casual Dining (the

definitive event for the restaurant, pub & bar industry), a visit is essential to staying ahead of the curve, with all the latest new products on show. Operators can also benefit from meeting exciting suppliers and accessing insightful seminars from industry leaders, all while networking.

The 2024 lunch! exhibitor list ranges from latest startups to established household brands.

These include Scrocchiarella (part of SpeediBake), Simply Lunch, Raynor

Foods, Fresh Food For Now, Deli Lites, New Yorker Bagels, Hestia Flatbreads, Danora AS, Around Noon, Pacific West Foods, Emmi, Whole Creations, Norseland, Magrini, TMI Foods – and many more.

The line-up of legends and leaders across three theatres (sponsored by Lipton Ice Tea) has been confirmed. They include: Julian Metcalfe OBE, founder & group CEO, itsu; Emma Woods, chair, Tortilla; Will StrattonMorris, CEO UK, Caffè Nero; Roland Horne, founder & CEO, WatchHouse; Shereen Ritchie, CEO, buns from home; Keith Bird, former CEO, Marugame Udon Europe; Neil Sebba, managing director, Tossed; and Christian Binney, food innovation director, Burger King.

“I love lunch! as the exhibition is so diverse. The halls are well-organised and new food trends can be seen throughout the stands,” said Binney.

James Norris, food & beverage director, SSP Group, UK & Ireland; Josh Kleiner, head of operations & marketing, Sandwich Sandwich; and Elton Gray, operations & delivery excellence director, Creams Cafe are the latest names to be added to the seminar line-up.

TeaJoy will bring its selection of signature drinks, including Passionfruit Jasmine Tea with Strawberry Boba and Lychee Jasmine Tea (stand L1134).

Not Guilty Food Co Ltd/The Skinny Food Co showcase new low-calorie coffee in cans, highprotein chocolate-filled wafers and zero-sugar cookies (stand L165).

Neat Sweets feature their new Fruity Berry Bears & Sour Citrus Bears (50g bags) – with less than 2g of sugar per 50g bag – that’s 95% less than other high-street sweets! (stand L990).

Pastorfrigor GB proudly presents the latest in refrigeration technology – the Filip GR rear feed multideck, Energy Class B, designed for high-traffic areas (stand L365).

OLALA! are thrilled to introduce their latest range of innovative, plant-based seafood alternatives (stand SU-15).

Nourish will introduce The Nutty One, a chocolatey coconut brownie with a satisfying crunch of almond nut butter and luxurious covering of dark chocolate (stand L1333).

Conglom International’s range of hot and cold cups and lids, Kraft boxes and bowls will be on show –plus PFAS free moulded fibre food containers that can be composted (stand L375).

As well as exciting interviews and keynotes, lunch!’s panels are a huge draw for operators. They include:

● OPERATIONS FOR FOOD-TO-GO Featuring: Emily Bagshaw, head of central operations, Tortilla; Shoaib Muhammed, director of operations, Wendy’s; Emily Hawkley, director of operations, Burgerism; and Elton Gray, commercial and operations director, Creams Cafe. Chaired by Shereen Ritchie.

● COFFEE SHOP LEADERS PANEL Roland Horne; David Ferguson, co-owner, Bob & Berts; Will Kenney, commercial director, 200 Degrees Coffee; and Kallie Kocourek, vice president UK, Roasting Plant Coffee UK. Chaired by Will Kenney.

● MARKETING FOR FOOD-TO-GO Mariam French, marketing director, LEON; Malachy O’Keeffe, head of marketing, Wingstop; and Rob Burns, marketing director, Chopstix.

● OPERATIONS FOR COFFEE SHOPS Edyta Stec, director of operations, GAIL’s; Russell Simpson, director of operations, The Coffee House; and Luke Shaughnessy, regional operations director, Costa Coffee. Chaired by Shereen Ritchie.

● THE FOUNDERS PANEL Dimeji Sadiq, founder & owner, Vegan Shack; Stephen Grocutt, founder, Cornish Bakery; and Dawn O’Sullivan, founder, Boost Juice Bars. Chaired by Simon Stenning, founder, Future Foodservice.

● THE BSA PANEL: Customer Satisfaction - Critical Factors That Keep Customers Coming Back Kirk Brazier, growth director, Esa Retail; Sam Brotchie, founder, Sexy Buns; Rusty Warren, senior NPD

& innovation manager, Subway – EMEA; and Flora Zwolinski, senior insight manager, Lumina Intelligence. Chaired by Alex Bell, Editor, Sandwich & FTG News.

Also, join experts for eye-opening research, data and analysis, including:

● Making Delivery Profitable – The Move To First Party Delivery: Peter Backman, founder & CEO, Thedelivery.World

● Paris, New York And Beyond: FTG Concepts To Learn From Across Europe And North America: Gavin Rothwell, director, Food Futures Insights

● Coffee: A Global Inspiration Tour: Shannon Goldsmith, senior insight analyst, IGD

● The Future of Formats: Rhian Thomas, head of insight, IGD

● Consumer Trends and Opportunities in the UK’s Retail Food-to-Go landscape: Seton Leung, head of UK foodservice, Circana

For the full programme and timings, visit lunchshow.co.uk/programme.

REGISTER FOR A FREE TRADE TICKET TO LUNCH!

lunch! (co-located with Casual Dining) will take place on 1819 September 2024 at ExCeL London. For more information and to register for a free trade ticket, visit lunchshow.co.uk and quote priority code VLU45 on the registration page.

Savoury PRETZEL BURGER BUNS for creative variations

Fully baked, 80 g

Pre-cut (web-cut), meaning less work for your team

Perfect results every time: just defrost and top individually

www.ditsch.com

What does your role entail?

I collaborate closely with my team to ensure we remain up to date with latest legislation, enabling them to perform their duties effectively. My responsibilities encompass managing all aspects of food hygiene, quality, safety and authenticity, with welldefined control measures in place.

Customer satisfaction is a critical component – and maintaining that focus is one of my primary objectives.

What’s your career background and how did you end up at Simply Lunch?

I have experience across various sectors, including the dairy industry (UHT and pasteurised milk processing/ packing, yoghurt manufacturing), juice manufacturing, ready-to-eat food, RTE salads and pies. I chose to apply my expertise in a company where most of the ingredients

We go behind the scenes of key jobs in the foodservice sector. First up, technical & procurement director at Simply Lunch, Nadeem Shahzad.

I’ve worked with are used, making sandwich manufacturing a natural choice. I see significant potential at Simply Lunch and believe I can both contribute my expertise and expand my knowledge in this sector.

Has your job changed over the years?

I began my career in production and warehouse management but realised that my passion lay in the technical sector. This led me to shift towards technical systems management. Over time, I moved into technical management, where I have worked in hygiene, systems, accreditation & certification, auditing, and the legal aspects of food manufacturing.

I have also focused on improving raw material and packaging sourcing, ensuring that supply quality assurance meets customer requirements and exceeds their expectations.

What’s exciting at Simply Lunch?

Our commitment to improvement. We strive to avoid complacency by constantly challenging ourselves to exceed our measurable objectives.

Are there technical developments we can look forward to in 2025?

Digitisation is a key focus, and we are excited about advancements in this area. We are introducing in-line verification to enhance quality control and efficiency across production. Additionally, we are adding two product lines to support growth and meet increasing demand. These developments, along with our continued innovation, will help us deliver high-quality products.

Tell us about your colleagues.

We have a dedicated team led by our technical manager, who ensures that

all departmental objectives are met. It includes multiple hygiene managers overseeing safe manufacturing, quality controllers on each line ensuring customer specifications are followed, a quality systems manager handling management and assurance teams verifying overall standards.

What is it like at Simply Lunch?

I’ve been with the company for around seven years. It is a familyowned business with a culture that emphasises teamwork, customer focus & satisfaction, and continuous improvement. I am proud to be part of this organisation.

Competition is fierce in the sandwich industry – what gives you the edge? We stay competitive by closely monitoring trends and ensuring that we stay ahead in key areas such as demand, innovation, NPD and sustainability. Adapting quickly to changing consumer preferences allows us to introduce products that resonate with customers. We invest in continuous research and development, which drives innovation across our product lines, ensuring that we offer cutting-edge solutions that meet and exceed expectations.

Sustainability is also at the core of our strategy. We are committed to

reducing our environmental impact through responsible sourcing, waste reduction initiatives and packaging solutions. This not only aligns with consumer values but strengthens our brand reputation in the marketplace.

Our strong relationships with suppliers and partners enable us to maintain standards while being agile in response to market shifts. The focus on digitisation and technology adoption enhances our operational efficiency, allowing us to deliver consistent quality and value at scale.

By combining these efforts, we ensure that Simply Lunch remains a leader in the competitive FTG sector.

Simply Lunch has opened an innovation lounge and office in Croydon, London, marking a significant milestone in the company’s growth and commitment to driving innovation and change in the FTG market.

The Innovation Lounge is designed as a dynamic hub for creativity and collaboration, providing Simply Lunch with a state-of-the-art space to work closely with customers and partners. With a dedicated team of development chefs, it features a fully equipped kitchen for product tastings and development sessions, allowing Simply Lunch to craft innovative and exciting offerings. The space enables experimentation and tasting, where ideas and flavours can be explored and perfected.

The Lounge also includes a uniquely designed retail environment that simulates store conditions. This allows Simply Lunch and its partners to visualise products on the shelf and delve into the science of retail

merchandising optimisation. By analysing consumer behaviour and shelf placement, Simply Lunch aims to help clients enhance product visibility and drive sales.

“We are committed to working closely with customers to develop products that not only meet consumer expectations but exceed them. This state-of-the-art facility allows us to do just that,” said Sam Page, managing director at Simply Lunch.

In addition to its focus on product development and customer collaboration, it offers modern and ergonomic workspaces for Simply Lunch’s team. This facilitates staff events, fostering a culture of collaboration, creativity, teamwork and growth among employees.

Reflecting Simply Lunch’s commitment to sustainability, the facility incorporates eco-friendly design elements and practices, aligning with the values of social and environmental responsibility.

Simply Lunch has been creating and delivering sandwiches and other culinary options for over 40 years. Recent investment has increased manufacturing capacity by 30%, enabling the business to keep up with demand. With these improved capabilities, additional production lines and further investment in electric vehicles to expand its delivery fleet, the company anticipates 100% growth over the next four to five years.

Simply Lunch was recognised by the FEBE Growth 100 and honoured with the Manufacturer of the Year award at The Sammies 2024.

“We are excited about the future possibilities that our Innovation lounge brings,” added Page. “It positions us to better serve and innovate for our customers.”

Simply Lunch invites existing and potential customers to discuss how they can elevate their food-to-go o erings in 2024 at hello@simplylunch.co.uk.

Food to go future

High-street & independents, insights, NPD

INSIGHT

Shopfitting Counter display, equipment, tech, case studies

FOCUS

Seasonal and festive fare

PREVIEW

Veganuary 2025

With innovative environmental practices and valuable sector insights, Fosters Bakery remains an impressive international player.

Fosters Bakery specialises in creating bespoke breads for sandwich and FTG operators. Baking since 1952, the business supplies throughout the UK and globally – including France, Spain, UAE, Kuwait and Hong Kong. Offering frozen products by the pallet and truckload through wholesalers, it’s always aware of the latest trends and what’s hot in terms of consumer requirements.

“We’ve seen an increase in requests for squidgy baps and buns – but also bread rolls for hot-hold cabinets,” said Fosters Bakery (Staincross) Ltd managing director and president of the Craft Bakers Association, John Foster.

“Sourdough is gaining popularity but it’s not always ideal for sandwich makers. To enhance flavour and compensate for reduced salt, customers opt for bread that contains sourdough without necessarily featuring it. There’s been a rise in demand for square or rectangular sandwich baps.

“And operators have moved to vegan brioche buns to reduce costs, considering the high price of butter and eggs.”

Fosters is also offering products made from regeneratively farmed wheat.

“While soil depletion seems a long way away from serving our customers, we’ll all suffer even higher prices and shortages unless we tackle it. The higher price of bread made from regenerative flour is currently deterring many buyers,” continued Foster.

When it comes to sustainability and environmental credentials, Fosters Bakery sees this as a priority.

“Our Yorkshire heritage values efficiency and minimal waste, which aligns with the principles of sustainability we’ve practiced for decades. The main difference now is the added responsibility of monitoring and reporting.

“Our recycling initiatives, which won awards over 30 years ago, continue. Efficient bulk packaging, lighter weight wrapping film and print on box (no label) optimises distribution, saves customers money and reduces on-site waste for customers too.

“We generate electricity onsite using a combined heat and power (CHP) plant; the ‘waste’ heat is free. About onethird of our daytime electricity comes from solar panels on our roof, with plans for further expansion.

“We’ve installed automatic lighting and increasingly energy-efficient equipment. Our multiskilled engineering team repairs equipment in our well-equipped workshop, extending its life.

“This year, we also added underground water interceptors to clean surface water leaving our site. Additionally, we are reducing the weight of baking tins to save energy and reinsulating ovens to reduce skin heat loss.

“Most of our business is conducted online rather than face-to-face visits, reducing the need to travel. This irks us somewhat because some of our customers serve travel hubs and we feel we are letting them down, but our

customers dictate the meeting format. Additionally, a local retiree makes bird and bat boxes from any broken wooden pallets, 12 of which are installed around the bakery site.”

Mainly serving customers across the UK, with 9% of sales exported to Europe, the Middle and Far East, the Fosters sales team is in regular contact with customers and distributors. Some deal directly with the product development team for unfiltered collaborations on new ideas, while visits to the bakery often fuel ideas and enthusiasm.

“Business is seasonal. Summer brings a surge in demand for burger buns and hot dog rolls of various sizes for barbecues and festivals. In winter, we see an increased requirement for English breakfast muffins and bread for hot toasted sandwiches. We also make mince pies and gingerbread figures; we’ve been full-on with mince pie production since July.

“Operating costs have been the significant challenge for us and customers. Baking inherently requires a lot of heat, so rising energy prices have been distressingly high. Additionally, the increase in the minimum wage has impacted costs across the board, even though we pay above the minimum wage. We are investing in robotics and automation and have remodelled our loading bays, all to reduce staffing costs.

“Recruitment was challenging for a while – but capitalising on our village location, we developed strategies that are working. Recruiting ultra-local through village

social media forums has been successful. A five-minute walk to work instead of a commute is as good as a pay rise, with more leisure time too. We’ve adjusted some shifts to align with school times.

“Steering clear of agency working also provides greater stability for us and employees. A cycle-to-work scheme allows staff to get a bike or electric bike with tax-free repayments, while secure onsite bike storage and car parking is valued by colleagues.”

As for 2024 so far, sales are up but profits are down. “The economic squeeze affects our customers too, tempering passing on all increased costs. We believe in sharing the burden fairly. Our family ownership takes a long-term view, focusing on sustainable growth rather than short-term profits, a strategy that has served us well for 72 years.

“The future is uncertain and there are always challenges. Weather conditions have impacted crops, domestically and globally, leading to potential shortages of commodities, quality issues with others and inevitable price volatility.

“The new government tax rises could further squeeze consumer discretionary spending. Potential changes to VAT, whether an increase or extension, add to the uncertainty.

The government has a budget deficit; you and I must pay to fix it, so things could get harder.

“Changes to employment laws, such as guaranteed hours, if not carefully crafted and implemented, could severely affect areas of FTG. Many outlets, especially those near arenas, travel hubs or attractions, depend on flexible staffing to cope with irregular and weatherdependent events.

“With vehicle charging stations springing up everywhere, I notice drivers sitting in the car while they wait (Café Tesla). That’s a growing opportunity for handheld food that doesn’t dribble down your front as you eat it. With our onsite product development team, we are well placed to be at the forefront of innovation,” concluded Foster.

James Brown, out of home channel controller at Mission Foods, fills us in on what consumers are looking for in this increasingly vibrant sector.

You’re a major player in the sandwich & FTG bread market. What trends have you seen in 2024… and what can we look forward to?

When considering consumer trends to replicate out of home (OOH), Mission Foods recommends the following:

Fusion flavours: According to research1, we should expect more of an emergence of British fusion foods – combining new global tastes with the familiarity of traditional dishes. While consumers continue to seek out authentic Mexican, Caribbean and Eastern European dishes with playful interactive elements, this relationship with British classics lends itself perfectly to our range or wraps and flatbreads.

Plant-forward eating: Demand for meat-free dishes is still strong. Mission Foods can help when catering for flexitarian, vegetarian and vegan diets, as all our wraps and flatbreads are vegetarian – and most are now suitable for vegans too, with each complementing a variety of dishes and fillings. Furthermore, chefs can be sure they are substantial enough to satisfy any appetite.

Breakfast: According to Lumina Intelligence, greater footfall and numbers of consumers returning to work are driving visits to OOH venues for breakfast, with a desire beyond traditional bread, such as wraps and flatbreads. These versatile carriers lend themselves to a range of global cuisines and dishes, helping to expand usage occasions for bread and bakery products, including breakfast and brunch.

Cost of living: Mission Foods’ range of wraps, naans, pittas and flatbreads offer quick, easy-to-prepare solutions for chefs to keep costs down and maximise profits. Consumers are seeking value for money. The low-ticket nature of menu items like wraps means this category is well positioned. Additionally, all our Mission Wraps are now HFSS compliant, following a reformulation programme in Summer 2022.

Versatility is a watchword for your bread business. What key products deliver that? Within wraps and flatbreads, we see the most popular flavour variant being plain (or original) – accounting for 50% of Mission Wraps and 52% of Mission Flatbread sales.

"The low-ticket nature of menu items like wraps means this category is well-positioned."

We know that sandwiches are staple menu items in all OOH outlets, but trends show that consumer tastes are evolving. As appetites for traditional bread become smaller, our wraps, naans, pittas and flatbreads are ideally placed. The range can also incorporate familiar sandwich filling favourites and dishes from global cuisines, including Asian, Mediterranean, Middle Eastern, Mexican and American –offering consumers the sense of discovery they crave.

There’s a confluence of traditional and global demand for flavours and dishes – how do you offer crossover? Traditional fillings should be a staple for sandwiches and wraps on every OOH menu or service counter, as they continue to offer broad appeal. However, the last few years have seen a shift in UK consumer tastes.

In addition to our iconic soft Plain Flour and Wheat Flour Tortillas, we offer unique Flavoured Wraps, including Chargrilled, Tomato and Red Chilli. We also launched Seeded Tortillas earlier this year, offering a nutritious twist on a classic! Packed with a blend of seeds, these wraps are ideal for healthy lunches, quick snacks or gourmet dinners.

Easily accessible are our quick and easy recipes – ranging from Cauliflower Wrap with Avocado Mayo and Slaw to a Bacon & Sausage Bean Melt, Bacon and Butternut Squash Wraps, English Breakfast Wrap and Leftover Roast Wraps with Beef & Horseradish. While providing operators with the inspiration to offer something new and differentiated, these recipes appeal to consumers seeking something different!

Hot or cold, sweet or savoury, our wraps also provide an exciting twist to menus. For example, switching up a traditional cheeseburger with a Cheeseburger Quesadilla recipe; or offering surprise and delight on the pudding menu with Sweet Tacos or Dessert Cups made with wraps, combining signature seasonal fruity flavours of orange and strawberry, with chocolate. Our flatbreads and naans are a perfect canvas for flavoursome toppings.

Here are some key examples:

● Breakfast: Toasties and Breakfast Wraps, and Huevos Rancheros

● Lunch: Garlic Bread Quesadillas, Cauliflower Wrap with Avocado and Slaw, Peri Peri Chicken Pittas

● Dinner: Cheeseburger Quesadillas, Beef and Guacamole Burritos, Tandoori Squash Naan Pizza

● Dessert: Sweet Tacos or Dessert Bowls made from Wraps, combining signature seasonal flavours, and Flatbread S’mores.

Is it difficult to compete in such a busy marketplace and how do you maintain your USP?

At Mission Foods, we are renowned for providing a range of authentic, great tasting, quality wraps, flatbreads, naans and pittas. It is also essential to stock well-known brands which consumers can trust, to ensure consistent quality and drive satisfaction and loyalty.

Furthermore, chefs can be sure they are substantial enough to satisfy any appetite – ensuring a tasty experience for the consumer, whatever the meal occasion.

With Mintel research showing ‘ease of eating’ as the sixthbiggest consideration for bread and baked goods, carriers like wraps and pittas offer the benefit of convenience.

Consumer testing shows that Mission Foods’ wraps and pittas score highly on this, as well as versatility – along with the ability to hold a variety of fillings well.

What is the focus for 2025?

Keeping our full range of products highly visible, with impactful marketing campaigns, and responding to trends. Our NPD, driven by consumer insight with regards to favourite dishes and flavours, continues to be a focus for us this year and beyond.

Fusion food trends 2024 - Bidfood

A premium product from the Just Egg Chilled Foods collection - free-range, ready-peeled, hard boiled eggs.

A long-life product, with 17 days shelf-life, the eggs are individually packed to ensure optimum freshness; preserving flavour and providing maximum convenience.

Perfect for the health conscious, with just 65 calories per egg, Just Egg’s hard-boiled eggs are great for sandwiches and snacking on the go.

The Just Egg team is passionate about its high protein, healthy option products, from point of origin and packaging to appearance and taste. It is meticulous about the quality of its eggs, priding itself on offering customers the very best.

Hard boiled eggs are a staple of the British diet and Just Egg guarantees the highest quality offering. If you want to give your customers the freshest, tastiest version of their favourite snack, Just Egg is the only brand to choose.

Combining traditional family values with a keen eye on the latest trends, Roberts Bakery is as resilient and productive as ever.

From bread to biscuits, Roberts Bakery offers something for everyone. Family focused, with a remarkable 130-year heritage, a community ethos has always been prevalent.

“Roberts is fortunate enough to supply most of the sandwich industry in some capacity – whether it’s via our catering loaves, paninis or historically our speciality breads,” said Megan Stubbs, national account manager.

“Our customers recognise us for manufacturing quality products paired with exceptional customer service, helping us strengthen our valuable relationships. Roberts has been lucky enough to have extremely supportive and loyal customers, especially in the face of adversity when the fire happened in June last year.”

Indeed, the fire at the Northwich site impacted two manufacturing plants, which produced branded and non-branded lines. The business decided to move the Roberts Biscuit Division to Winsford, just four miles away, to create a new ‘Centre of Excellence’. Existing plant equipment was moved to the new site, with a fast-tracked installation of a robotic capability. Meanwhile, the Speciality division at Ilkeston in Derbyshire

continued to focus on artisan products and speciality breads.

The bakery sector is thriving, with supermarkets particularly prevalent. Tesco has just revealed its Christmas range, which includes a somewhat lavish Chicken & Pork Pate en Croute and Brie, Bacon & Cranberry Galette.

“This year, we have seen numerous trends,” stated Verity Turner, category & insight manager at Roberts. “From new and unusual flavours to nextgeneration hybrids, innovative formats from overseas and better holistic health offerings. Quoting The Food People (TFP), there are three key themes which have been paramount in influencing the bakery category:

● Elevated treats

● Familiar favourites

● Cost & convenience.