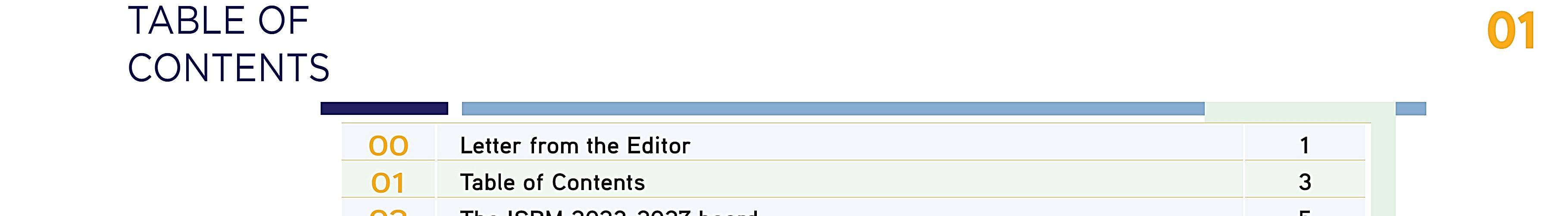

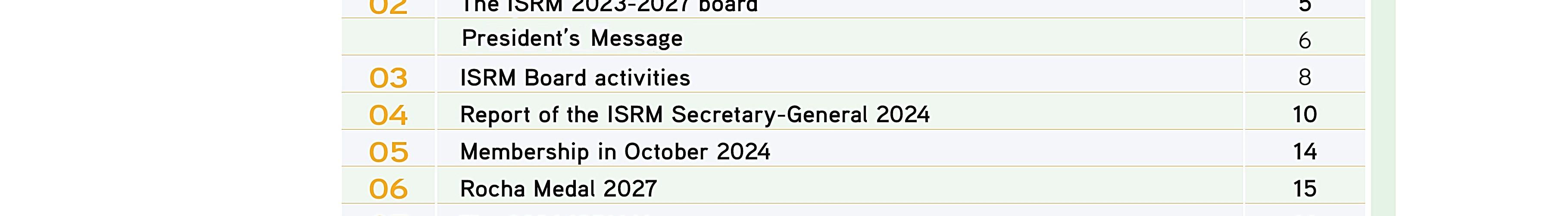

International Society for Rock Mechanics and Rock Engineering

ANNUAL REVIEW 2024

• PRESIDENT'S MESSAGE

• BOARD ACTIVITIES

• AWARDS REPORTS

• SECRETARY-GENERAL

• CONFERENCES

• COMMITEES

• VICE-PRESIDENTS

TECHNICAL PAPERS

• FRANKLIN LECTURE

• ROCHA MEDAL LECTURE

• JOHN HUDSON ROCK ENGINEERING AWARD

• YOUNG ROCK ENGINEER AWARD

• SCIENCE ACHIEVEMENT AWARDS

Volume 27 December 2024

The 2025 ISRM

International Symposium

EUROCK 2025

Expanding the underground space: future development of the subsurface

16-20 June 2025

Trondheim Norway

WELCOME TO TRONDHEIM

MAIN TOPICS

1. New Tools and Techniques

2. Rock Support Design

3. Rock Mass Characterization

4. Prognosis Models in Rock Tunneling

5. Fluid Flow in Rock Mass

6. Ground Investigations

7. Laboratory Testing of Rock

8. Brittle Failure

9. Rock Mass Monitoring

10. Geohazards

11. 3D modelling and Visualization

12. Rock Mass Grouting

13. Sustainability in Rock Engineering

https://eurock2025.com ngb@tekna.no

The Norwegian Group for Rock Mechanics welcomes you to Norway for EUROCK 2025, the international symposium of ISRM.

The event will take place at the Clarion Hotel & Congress in the beautiful city of Trondheim from June 16th to 20th.

The historical city of Trondheim was founded in 997 as a trading post during the Viking Age and served as the capital of Norway until 1217. Today it is the third largest city in Norway and known as the technological hub of Norway, hosting the largest university, the Norwegian University of Science and Tehnology (NTNU), as well as the Foundation for Science and Industrial Research (SINTEF), St. Olavs University Hospital and several other technologyoriented institutions.

KEYNOTE SPEAKERS

Åsa Fransson

Is it watertight? Observations and comments related to grouting of rock mass

Charlie Chunlin Li

A study of the arching effect, bond strength and rock mass failure around rock anchors

Hongwei Huang

Machine learning for safety risk assessment on Rock Tunnel Driving

Jessa Vatcher

Are we in the golden age of numerical modelling?

Marco Barla

The design of energy tunnels for a sustainable future

Mark Diedrichs

Brittle Damage in Rock Mechanics

Thomas Marcher

The challenges of "hard soil and soft rock": an inside into this material's brittle to ductile behaviour

International Society for Rock Mechanics and Rock Engineering

PROF. SEOKWON JEON

ISRM President

sjeon@snu.ac.kr

DR. JOSÉ MURALHA

LNEC, Portugal

jmuralha@lnec.pt

ISRM SECRETARY-GENERAL

DR. LUÍS LAMAS

LNEC, Portugal

secretariat@isrm.net

In Asian cultures, the 60th birthday holds significant meaning. It marks the completion of a full cycle in the Asian Zodiac, symbolizing not only a celebration of health but also the beginning of a new phase and a sense of hope. Similarly, our society, having celebrated its 60th anniversary in 2022, is embracing new changes and developments as it is going through a fresh phase of growth and innovation. These include the expansion of online activities and the construction of a digital archive, increased research and activities related to climate crisis responses, and efforts to promote diversity. We would like to express our heartfelt gratitude to all members, National Groups, Commissions, and other bodies of our society who have contributed to these changes and advancements over the past years.

The News Journal 2024 serves as a yearbook summarizing our society’s activities in the past year. Unlike previous editions, this year’s issue includes several additional features. It features a contribution from Vice President Dr. Muriel Gasc-Barbier, who gave an outstanding presentation on woman’s career development at the ARMS13 Early Career Forum. In addition to the articles that depicted the presentations of the Muller Award, the Rocha Medal and the Franklin Lecture, articles referring to the Science Achievement Award and to the Young Rock Engineer Award are included in this issue. Furthermore, it highlights the objectives of the nine new Commissions established during the current Board term, it provides a summary of the fascinating discussions from the successfully ongoing European Debate series, and it introduces the new National Groups from Morocco that has joined and Iran that has re-joined our society.

The ISRM shares information and facilitates communication among members through various channels, including the News Journal. We look forward to sharing even more valuable and engaging updates and encourage your active participation.

Lastly, the News Journal could not fail to honor the memory of the late Dr. Every Hoek - a giant in rock mechanics whose contributions have a profound and enduring impact in the progress of Rock Mechanics and Rock Engineering. This issue includes an ISRM Tribute prepared by Past-Presidents Prof. Charles Fairhurst and Prof. E.T. Brown, as well as details of the Scientific Farewell Lecture by Prof. Leandro Alejano.

Seokwon Jeon and José Muralha News Journal Editors

ISRM Sponsored Conference

An International Workshop of JTC1 and JTC3

27 April-1 May 2026

Queenstown, New Zealand

The New Zealand Geotechnical Society is delighted to welcome you to the First International Joint Workshop of JTC1 and JTC3 on Landslide Risk Assessment, Communication and Geo-education. We will share the latest research and develop best practice guidelines in the stunning New Zealand city of Queenstown.

Landslides are one of New Zealand’s most significant natural hazards. Since 1760 there have been at least 1,500 deaths from landslides in New Zealand. More fatalities have occurred from landslides than from earthquakes, volcanic activity and tsunami combined over the last 160 years. Queenstown is particularly vulnerable, making it an ideal venue for a conference about landslides. More than 50% of the land around the town is mapped as known landslides, with the underlying quartzofeldspathic schist very susceptible to deep seated failures. The largest failure is the Queenstown Hill Landslide, with an estimated volume of 240 M m³.

Our theme “Landslide Geo-Education and Risk” brings together the full lifecycle of landslide risk management. It encompasses the need to educate the next generation of landslide risk managers, the need to robustly understand landslide risk, and the need to communicate such risk to the public and decisionmakers so that real change is implemented. We believe that bringing together JTC1 and JTC3 to work together on landslide risk assessment, education, communication and outreach is a great opportunity to effect real change.

http://landsliderisk.nz secretary@nzgs.org

ISRM Specialed Conference

6th ICITG

A JTC2 Conference

13-16 October 2026

Graz, Austria

The 6th International Conference on Information Technology in Geo-Engineering (6th ICITG) will be an arena to discuss all topics related to the ongoing digital transformation in Geo-Engineering. Case studies of IT in Geo-Engineering, integration of digital systems (Scan2BIM, BIM2FEM, etc.), benchmark datasets, information modelling, monitoring technology and artificial intelligence are some of the focus topics of the 6th ICITG. It is organized under the auspices of the Joint Technical Committee 2 (JTC2) on “Representation of Geo-Engineering Data” of the Federation of International Geo-Engineering Societies (FedIGS).

Information Technology in Geo-Engineering practice –Case Studies

Integrating digital systems: Scan2BIM, BIM2FEM, etc.

Big open benchmark datasets in Geo-Engineering

Information technology for uncertainty quantification and mitigation

SoA Machine Learning in Geo-Engineering: reinforcement learning, LLMs and more

Real Time Back Analysis

OTHER TOPICS

3D Geological Modeling

AI ethics in geo-engineering

Big Data and Databases

Building Information Modeling (BIM)

Data Collection and Transmission

Data-Driven Investigation and Modeling

Digital twins

General Artificial Intelligence and Machine Learning

Geotechnical instrumentation

Imaging Technology

Information and Communications Technologies

Information technology for sustainability

Intelligent Geomaterials

Remote sensing in geo-engineering

Robotics and autonomous operations

Sensors and Sensing Technologies

Virtual and Augmented Reality

Other Topics Related to Advances in IT in Geo-Engineering

https://www.icitg2026.com contributions.icitg2026@ngi.no

President

Prof. Seokwon Jeon

Dep. Energy Systems Engineering Seoul National University sjeon@snu.ac.kr

Vice-President for Australasia

Dr. Qianbing Zhang

Director of Research Department of Civil Engineering Monash University qianbing.zhang@monash.edu

Vice-President for North America

Prof. Martin Grenon

Département de génie des mines, de la métallurgie et des matériaux

Faculté des sciences et de génie Université Laval magre@ulaval.ca

KIYOSHI KISHIDA

Vice-President at Large

Prof. Kiyoshi Kishida

Department of Urban Management

Kyoto University

kishida.kiyoshi.3r@kyoto-u.ac.jp

JANNIE

Vice-President for Africa

Dr. Jannie Maritz

Faculty of Engineering, Built Environment and Information Technology Department of Mining Engineering jannie.maritz@up.ac.za

Vice-President for Europe

Dr. Muriel Gasc-Barbier

GéoCOD / Cerema Méditerranée muriel.gasc@cerema.fr

Vice-President at Large

Prof. Milorad Jovanovski

University Ss.Cyril and Methodius in Skopje

Faculty of Civil Engiyneering Department for Geotechnics jovanovski@gf.ukim.edu.mk

Secretary-General

Dr. Luís Lamas

LNEC

llamas@isrm.net

KI-BOK MIN KOREA

Vice-President for Asia

Prof. Ki-Bok Min

Dep. of Energy Resources Engineering

Seoul National University kbmin@snu.ac.kr

ESTEBAN HORMAZABAL

Vice-President for Latin America

Dr. Esteban Hormazabal

Managing Director & Corporate Consultant

SRK Consulting Chile ehormazabal@srk.cl

Vice-President at Large

Dr. Fengshou Zhang

Dep. of Geotechnical Engineering

Tongji University fengshou.zhang@tongji.edu.cn

Dear Colleagues,

It is a pleasure to greet you and to share an overview of ISRM activities carried out in 2024. With the commencement of the new Board’s term, various initiatives were planned and implemented. While there are areas that require further progress, I would like to provide a brief summary of the key activities undertaken.

In 2024, Morocco and Iran joined ISRM as new National Groups. The National Group of Morroco, represented by the Moroccan Committee for Soil Mechanics and Geotechnics, is the fourth member from the Africa Region. In October, they hosted the National Geotechnical Symposium in Marrakech, where ISRM Vice President Dr. Muriel Gasc attended as an official representative. Dr. Gasc congratulated them on joining the ISRM and delivered a keynote lecture. We also warmly welcome the rejoining of the Iranian Society for Rock Mechanics (IRSRM) as the ISRM National Group of Iran, which had been an important member of our society but had a brief hiatus due to challenging circumstances. The National Group of Iran has a strong history of hosting ISRM events and active participation of its members in the Board and Commissions. We extend our support and look forward to the future activities of these two new National Groups.

The 2024 ISRM International Symposium was held in conjunction with the 13th Asian Rock Mechanics Symposium in New Delhi, India, in September. During the Council Meeting, revisions to By-law No. 4 and By-law No. 7 were approved. The first amendment eliminated the page quota for proceedings at ISRM Congress and allowed non-members to submit papers. The second clarified the nomination period for the Rocha Medal in relation to the timing of degree completion. Additionally, voting took place to decide the venue for the 2026 ISRM International Symposium, with Fukuoka, Japan, being selected. We hope for your interest and participation in the ISRM International Symposium and ARMS14 in November 2026 in Fukuoka. We thank the National Group representatives for their review and approval of the key agenda items during the Council Meeting.

In the New Delhi Symposium, there were six keynote lectures, the Rocha Medal Award Lecture, and the Franklin Lecture. This was followed by a tribute session for Eda Quadros, during which, in accordance with Indian traditions, rose petals were laid before a portrait. Tributes were shared by several individuals, including Dr. Nick Barton. Programs for students and young scholars, such as the Rock Bowl and Early Career Forum, were also held. The Rock Bowl was a great success, thanks to the efforts of Dr. Resmi Sebastian from the Organizing Committee and the National Group of Brazil. Congratulations to Team ADRI for winning the competition. The 9th Early Career Forum featured eight participants from six countries, i.e. Bangladesh, India, Kazakhstan, Malaysia, Mongolia, and Nepal, who presented their research. Senior members Dr. Muriel Gasc-Barbier and Prof. Krishna Panthi kindly shared insightful lectures on career development, focusing on their journeys as a woman and as a professor from a small local area in Asia. Their insights were both valuable and deeply appreciated. We thank all participants and the National Group of China for supporting the Early Career

Forum through the Education Fund. Special thanks to the Indian National Group, Prof. Mahendra Singh, and the organizing committee for their efforts in making all the ARMS13 programs very successful.

Commission activities were vibrant in 2024, with numerous online and in-person meetings, workshops, and conferences. The Commission on Sorptive Rocks hosted its second workshop in Bukowa, Poland, in September, discussing the roles of sorptive rocks in energy transition, carbon capture, and hydrogen storage. Plans for a third workshop in Inner Mongolia, China, in 2025 are underway. The Commission on Coupled THMC Processes in Fractured Rock Mass held the fourth event of the CouFrac series in Kyoto, Japan, in November, featuring six keynote lectures, six Emerging Scientists presentations, a panel discussion on energy storage, and the Chin-Fu Tsang Coupled Processes Award Lecture. The Commission on Radioactive Waste Disposal also held an in-person meeting during this event, discussing plans for a 2025 workshop. The newly launched Commission on Estimation of Rock Mass Strength and Deformability held its inaugural workshop in Lima, Peru, in December, co-hosted by Sri Lanka and Peru National Groups, with 18 presentations sparking in-depth discussions on methodologies. The Commission on Soft Rocks has confirmed plans for a workshop in Porto, Portugal, in May 2025, coorganized by the National Groups of China and Portugal. Meanwhile, the Commission on Testing Methods is developing new Suggested Methods and plans to publish the “Brown Book” with 15–18 Suggested Methods, by 2025 and to hold a workshop in 2026. The dedicated efforts from the Commission Presidents and members are highly appreciated.

In 2024, four ISRM Online Lectures were held, from the 45th to the 48th, featuring outstanding presentations by Dr. Jonny Rutqivist, Prof. Carlos Carranza-Torres, Prof. Ranjith Pathegama Gamage, and Dr. Sylvie Gentier. We deeply appreciate their kind acceptance to prepare and deliver these wonderful lectures.

The FedIGS Board Meeting was held in May 2024 in Toronto, Canada, followed by an online meeting in October. Key discussions since the May meeting focused on the possibility of jointly hosting a conference among sister Societies, similar to the Geoengineering 2000 Conference held in Melbourne, Australia, in 2000. The four participating sister Societies agreed that 2030 would be an appropriate year for such an event. Discussions are ongoing regarding the venue and program to avoid conflicts with each Society’s events. This may necessitate deviations from our By-laws, potentially requiring discussion and approval at the 2025 Council Meeting. We hope this collaborative effort results in a successful event.

Our sister Society, IAEG, celebrated its 60th anniversary in 2024, hosting the EuroEngeo2024 in Dubrovnik, Croatia, in October. At the IAEG Council Meeting, Prof. Resat Ulusay, the immediate Past-President of ISRM, conveyed our society’s congratulations and was honored with the IAEG Honorary Membership Award. Congratulations to Prof. Ulusay on this achievement.

The ISRM Book Series has published eight volumes to date. I thank the editors, Prof. Xia-Ting Feng and Prof. Resat Ulusay, for their efforts. I am pleased to announce that Prof. Ömer Aydan has completed the ninth book, "Geomechanical Aspects of Abandoned Room and Pillar Mines and Remediation Measures", which is set to be published in April 2025. Additionally, three more volumes are in progress. I deeply appreciate the authors’ contributions.

In July 2025, we lost a great scholar, practitioner, and educator in rock mechanics, Dr. Evert Hoek, the first recipient of the ISRM Müller Award. He leaves behind a remarkable legacy of achievements and teachings. His legacy will continue to influence and inspire future generations. Prof. Charles Fairhurst and Prof. Ted Brown, who shared a close relationship with Dr. Hoek, have written an ISRM Tribute to Dr. Evert Hoek, published in the Winter 2024 issue of the ISRM Newsletter. This is a must-read for everyone in the rock mechanics community. Beyond celebrating Dr. Hoek’s contributions and insights, the tribute outlines a vision for the future direction of ISRM. They emphasize the importance of fostering innovative and environmentally sustainable mining technologies, promoting related research at universities, and highlighting the pivotal role of rock mechanics in addressing climate change, utilizing underground spaces, and exploring the “inner space” of our planet. We are deeply grateful to Prof. Fairhurst and Prof. Brown for their exceptional contributions, providing valuable insights and references that will enrich and inspire the entire community.

I wish you a Happy New Year of 2025 with good health, happiness and prosperity. And I hope to meet you in Eurock 2025 this June and other ISRM activities.

Seokwon Jeon

ISRM President 2023-2027

This first meeting of the 2023-2027 ISRM Board took place on 29 February and 2 March, in San José, Costa Rica. The main objective of the meeting was to define and start the implementation of new initiatives for the on-going 4-year term of office. Following presentations by the Board members several decisions were made, namely the preliminarily approval of the list of technical commissions for the term of 2023-2027, and the creation of the Communication Committee with the objectives of promoting communication among ISRM members via diverse platforms and developing contents that can be more engaging, informative, and enjoyable.

In conjunction with the ISRM Board meeting, the Geotechnical Society of Costa Rica hosted the "International Workshop on Recent Advances in Rock Mechanics", on 1 March. This was the first ISRM activity organised in a Central American country. A rich program with presentations by all Board members and several experts from Costa Rica and a fruitful discussion concerning technical issues on topics of interest took place.

The ISRM held its 2024 Board and Council meetings in New Delhi, India, in conjunction with the 13th Asian Rock Mechanics Symposium - ARMS13, the 2024 ISRM International Symposium.

The ISRM Board held an in-person meeting on September 22. Past activities were reviewed in detail, new initiatives were discussed, and decisions on future actions were made.

The ISRM held its 2024 Council meeting on 23 September in New Delhi, India. 43 National Groups were represented at the Council, which was also attended by the Board members, the Past President Resat Ulusay and observers from the Commissions and the National Groups. Reports of the Board members and Board Committees, as well as the forthcoming conferences were presented. Issues concerning the FedIGS were discussed.

General information regarding the current ISRM statutes and By-laws were presented by the Board. The ISRM has a membership of approximately 9300 individual members and 220 corporate members, belonging to 61 National Groups. After two decades of continuous growth, the number of individual members has stabilized during the last two years. The National Groups of Morocco and Iran joined the Society during 2024.

The National Groups of Macedonia and Japan presented excellent proposals to host the 2026 ISRM International Symposium. The Council, by secret ballot, selected the proposal by Japan, in Fukuoka, from 22 to 26 November, where the 2026 ISRM Board, Council and Commission meetings will take place.

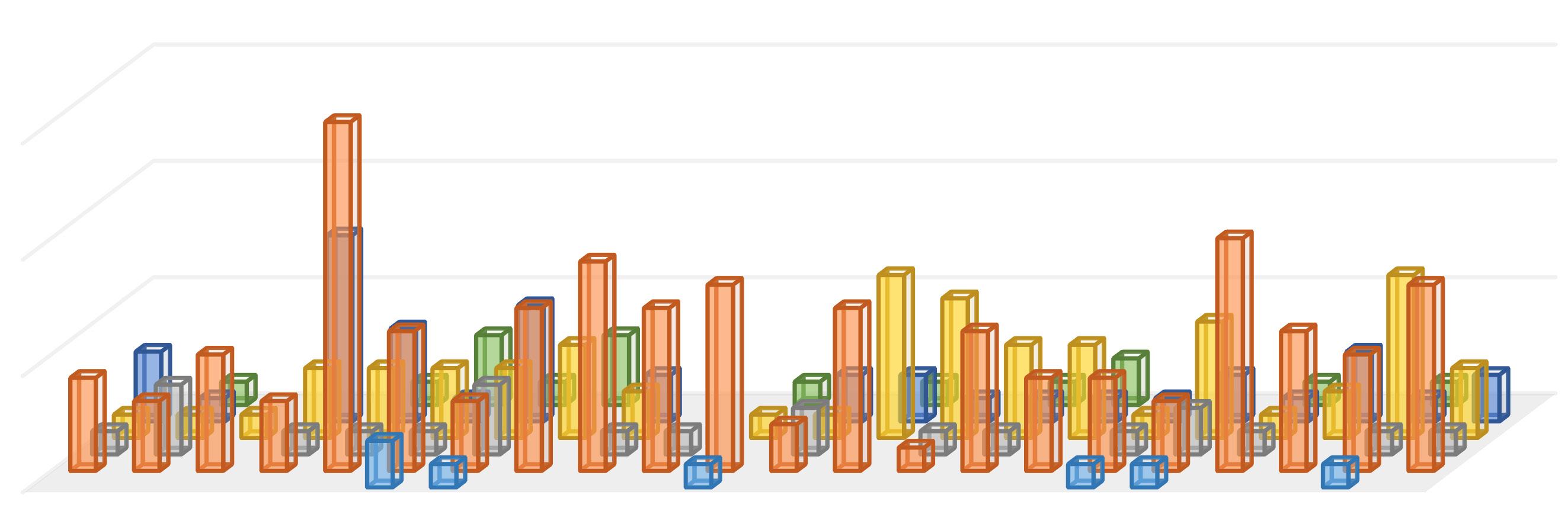

The graph below shows the evolution of the number of individual members across the geographic regions since 1996.

The table below shows the change in individual membership of the ISRM and across the geographic regions in the last 1, 5, 10 and 25 years. Individual Members per Region

Out of the total number of 9225 individual members in 2024, 76 are corresponding members and 9149 are registered through their respective National Groups. Compared with the figures reported at the previous Council meeting in October 2023, this represents a decrease of 81 Individual Members. The number of Corporate Members increased by one, and there are two additional National Groups.

The graphs below show the distribution of individual members, corporate members and National Groups across the geographic regions in 2024.

• 1st ISRM Commission Conference on Estimation of Rock Mass Strength and Deformability – an ISRM Specialized Conference, to be held on 6 December 2024, in Lima, Peru.

The following ISRM sponsored conferences are scheduled:

• Eurock 2025 – an ISRM Regional Symposium, to be held on 16-20 June 2025, in Trondheim, Norway.

Individual Members Corporate Members

2. ADDITIONAL ISRM BOARD MEETING

In 2024, a two-day interim Board meeting and a Seminar took place in Costa Rica from 29 February to 2 March. Additionally, the Board convened two three-hour videoconference meetings on 9 July and 4 September. These meetings were held to complement the annual Board meeting and address important matters for the Society.

3. ISRM SPONSORED MEETINGS

Since the last Council meeting on 10 October 2023 in Salzburg, Austria, the following sponsored conferences have taken place:

• 1st Chilean Congress in Rock Mechanics – an ISRM Specialized Conference, held on 22-24 November 2023 in Santiago, Chile.

• 1st SLRMES Conference on Rock Mechanics for Infrastructure and Geo-Resources Development – an ISRM Specialized Conference, held on 2–7 December 2023 in Colombo, Sri Lanka.

• 14th International Symposium on Landsldes (14th ISL) – a FedIGS JTC1 Conference, held on 8-12 July in Chambéry, France.

• Eurock 2024 – an ISRM Regional Symposium, held on 15–19 July 2024 in Alicante, Spain.

• 5th International Conference on Information Technology in Geo-Engineering (ICITG) – a FedIGS JTC2 conference, held on 5-8 August in Golden, Colorado, USA.

• ARMS13 – an ISRM International Symposium, to be held on 22-27 September 2024 in New Delhi, India.

• VietRock2024 – an ISRM Specialized Conference, to be held on 26 October 2024 in Hanoi, Vietnam.

• CouFrac2024 – an ISRM Specialized Conference, to be held on 13-15 November 2024 in Kyoto, Japan

• Landslides 2026, LAGER - co-hosted by the FedIGS JTC1 and JTC3, to be held on 27 April-1 May 2026, in Queenstown, New Zealand.

• LARMS2026 - X Latin American Congress on Rock Mechanics - an ISRM Regional Symposium to be held on 26 - 28 Aug, 2026, in Brasilia, Brazil.

• Eurock 2026 - Risk Management in Rock Engineering - an ISRM Regional Symposium to be hel on 14-19 September 2026, in Skopje, North Macedonia

• JTC2 6th International Conference on Information Technology in Geo-Engineering - an ISRM Specialized Conference to be held on 13-16 October 2026, in Oslo, Norway

• ARMS14 – an ISRM Regional Symposium, to be held on 22-26 November 2026, in Fukuoka, Japan.

• 16th ISRM International Congress on Rock Mechanics, to be held on 17-23 October 2027, in Seoul, Korea.

4. ROCHA MEDAL

For the Rocha Medal Award 2025, 22 applications were received. The Rocha Medal Committee selected the winner and two Proxime Accessit (runner-up) certificate(s).

Rocha Medal 2025: Dr Lucille Carbillet, from France, with the thesis “From grains to rocks: the evolution of hydraulic and mechanical properties during diagenesis”, presented at the Université de Strasbourg

Proxime Accessit (runner-up) 2025 certificate: Dr Georgios Tzortzopoulos, from Greece, with the thesis “Controlling earthQuakes (CoQuake) in the laboratory using pertinent fault stimulating techniques”, presented at the École Centrale de Nantes

Proxime Accessit (runner-up) 2025 certificate: Dr Quan Zhang, from China, with the thesis “Investigation on the principles and applications of directional rock breaking by instantaneous expansion”, presented at the China University of Mining and Technology

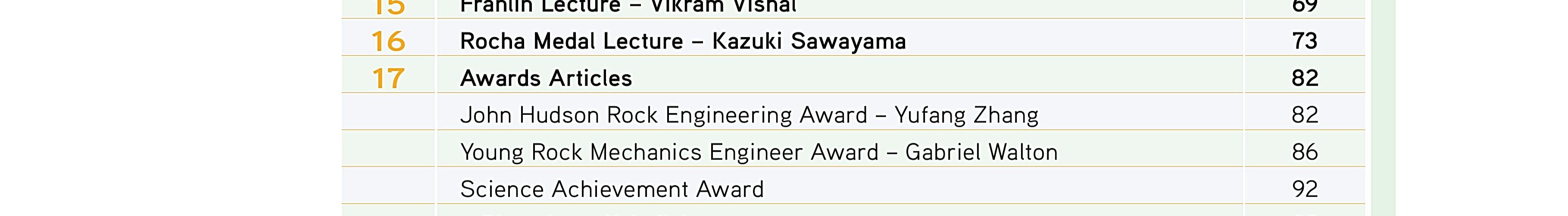

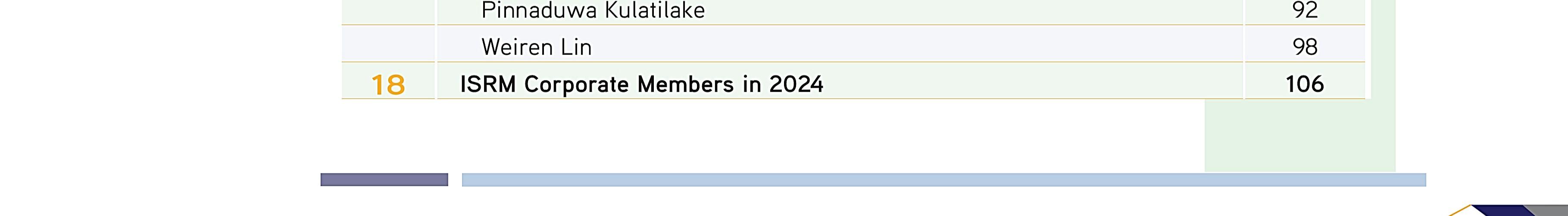

5. ISRM AWARDS

In 2024 the following awards were conferred:

• Rocha Medal awarded to Kazuki Sawayama, from Japan

• Rocha Medal runner-up awarded to Kai Liu, from China

• Rocha Medal runner-up awarded to Mingzheng Wang, from China

• Franklin lecture 2024 awarded to Vishal Vikram, from India

• John Hudson Rock Engineering Award 2024, awarded to Yufang Zhang, from China

• Science Achievement Award 2024 awarded to Weiren Lin, from Japan and Pinnaduwa Kulatilake, from Sri Lanka

• Young Rock Engineer Award awarded to Gabriel Walton, from the USA

6. ISRM MULTILINGUAL GLOSSARY ON ROCK MECHANICS

The multilingual glossary of rock mechanics technical terms is available on the ISRM website since March 2015, under the item “Products and Publications. The translation into 19 different languages has been achieved, Mongolian being the most recent language available.

7. ISRM NEWS JOURNAL

The electronic version of the ISRM News Journal, Vol. 26, December 2023, edited by the ISRM President, Prof. Seokwon Jeon and Dr. José Muralha, was uploaded on the ISRM website, where it can be read and downloaded. The Secretariat sent an info-mail to all members, advertising it. 400 hard copies were printed for distribution during the ISRM sponsored conferences. This 84-page issue of the News Journal contains the annual review of the Society’s activity along 2023, and technical articles related to the ISRM awards.

8. ISRM

Since the 2023 Council meeting, five quarterly Newsletters, prepared by the Secretary General, were published: in December 2023, in March, June, September and December 2024. As usual, all ISRM members received them by email. The Newsletters are also available on the website. ISRM National Groups and individual members are welcome to submit to the Secretariat contributions on rock mechanics topics of interest to our technical community.

9. ISRM WEBSITE

The website of the ISRM (http://www.isrm.net), launched on 1 April 2005, is the main means of information of the ISRM and the main channel for communication with the members. Most benefits being offered to the members are available in the password protected members’ area. The information on the website has been continuously updated during the period corresponding to this report.

10.

The ISRM YouTube channel was launched in October 2021. It allows streaming of live events organised by the ISRM

and the storage of videos, such as the European Rock Mechanics Debates. The ISRM Young Members Channel can be reached at https://www.youtube.com/channel/ UCN8FiYOH6LvUMBd9t5uLOyg.

11. DIGITAL LIBRARY

The ISRM Digital Library started in October 2010 and is part of OnePetro.org, a large online library managed by the Society of Petroleum Engineers. ISRM individual members are allowed to download, at no cost, up to 100 papers per year from the ISRM conferences. ISRM corporate members can download 250 papers.

Papers from the ISRM Congresses and sponsored Symposia have been gradually introduced in the library. Currently, the papers from 79 ISRM sponsored events are available, totalling around 13,000 papers and 105,000 pages.

The first ISRM Online Lecture was broadcast from the ISRM website in February 2013. From those days to the present days, the ISRM broadcast 47 ISRM Online Lectures given by prominent scholars. All lectures are kept in an appropriate page of the ISRM website. Four ISRM Online Lectures were broadcast during the period corresponding to this report, by Prof. Manchao He, Prof. Jonny Rutqvist, Prof. Carlos CarranzaTorres and Prof. Ranjith Pathegama Gamage.

The Secretary General, assisted by the Secretary and the Webmaster, conducted the correspondence and business activities of the Society, as stipulated in the ISRM Statutes.

The correspondence activity continued to be intense, namely regarding official communications and all sort of demands received by the Secretariat.

The business activities include the daily financial management of the Society and the assistance to the ISRM Board in the preparation of the annual budget and accounts.

As usual, the Secretariat made ample use, at no charge, of several facilities available at the Portuguese National Laboratory for Civil Engineering – LNEC. This included use of office rooms and other facilities offered to the Secretariat, telephone and use of LNEC’s computer network, namely for internet access. This support has long been instrumental to the well-being of the Society and is very much appreciated.

The life of the Society and the activity of the Secretariat during the period corresponding to this report were marked by:

• the stabilization of the number of members of the Society;

• the continuation of an intense activity;

• the maintenance of a sound financial situation.

Luís Lamas ISRM Secretary-General

Since 1982 a bronze medal and a cash prize have been awarded annually by the ISRM for an outstanding doctoral thesis in rock mechanics or rock engineering, to honour the memory of Past President Manuel Rocha while stimulating researchers.

In addition to the Rocha Medal award to the winning submission, one or two runner-up certificates may also be awarded.

An invitation is now extended to the rock mechanics community for nominations for the Rocha Medal 2027.

Full details about the Rocha Medal are provided in ISRM By-law No. 7, and all relevant information can be obtained from the ISRM website - isrm.net.

Application

To be considered for the award the candidate must be a member of the ISRM and the official doctorate degree certificate must have been obtained in the two calendar years preceding the year of the selection of the award.

Nominations shall be by the nominee, or by the nominee’s National Group, or by some other person or organization acquainted with the nominee’s work.

Nominations shall be addressed to the Secretary-General and shall contain, in digital format:

• a one page curriculum vitae, including nationality information;

• a written confirmation by the candidate’s National Group that he/she is a member of the ISRM;

Past Recipients

1982 A.P. Cunha PORTUGAL

1983 S. Bandis GREECE

1984 B. Amadei FRANCE

1985 P.M. Dight AUSTRALIA

1986 W. Purrer AUSTRIA

1987 D. Elsworth UK

1988 S. Gentier FRANCE

1989 B. Fröhlich GERMANY

1990 R.K. Brummer SOUTH AFRICA

1991 T.H. Kleine AUSTRALIA

1992 A. Ghosh INDIA

1993 O. Reyes W. PHILIPPINES

1994 S. Akutagawa JAPAN

1995 C. Derek Martin CANADA

1996 M.P. Board USA

1997 M. Brudy GERMANY

1998 F. Mac Gregor AUSTRALIA

1999 A. Daehnke SOUTH AFRICA

2000 P. Cosenza FRANCE

2001 D.F. Malan

SOUTH AFRICA

2002 M.S. Diederichs CANADA

2003 L.M. Andersen SOUTH AFRICA

• a thesis summary, written in English, with between 5,000 and 10,000 words, detailed enough to convey the full impact of the thesis and accompanied by selected tables and figures, and information on word count;

• a copy of the complete thesis and the name of the supervisor(s) if not indicated in the thesis;

• a copy of the doctorate degree certificate;

• a letter of copyright release, allowing the ISRM to copy the thesis for purposes of review and selection only;

• an undertaking by the nominee to submit an article describing the work, for publication in the ISRM News Journal.

Application Deadline

The nomination must reach the ISRM Secretary-General by 31 December 2025.

2004 G. Grasselli ITALY

2005 M. Hildyard UK

2006 D. Ask SWEDEN

2007 H. Yasuhara JAPAN

2008 Z.Z. Liang CHINA

2009 G. Li CHINA

2010 J.C. Andersson SWEDEN

2011 D. Park REP. OF KOREA

2012 M.T. Zandarin ARGENTINA

2013 M. Pierce CANADA

2014 M.S.A. Perera AUSTRALIA

2015 A.L. Bradley ITALY

2016 C.W. Boon MALAYSIA

2017 Bryan Tatone CANADA

2018 M. du Plessis SOUTH AFRICA

2019 Q. Lei CHINA

2020 J. Shang CHINA

2021 Y. Yasuhiro JAPAN

2022 R.S. De Silva SRI LANKA

2023 J. Zhao CHINA

2024 K. Sawayama JAPAN

2025 L. Carbillet FRANCE

February - Interim meeting of the ISRM Board, in San José, Costa Rica

- ISRM Board Seminar "International Workshop on Recent Advances in Rock Mechanics", in San José, Costa Rica

- Publication of the 2023 edition of the ISRM News Journal – Volume 26

March

April

- Publication of the e-Newsletter No. 65

- 45th ISRM Online Lecture by Dr. Jonny Rutqvist: “Coupled Processes Modeling in Energy Geosciences”

- 5th European Rock Mechanics Debate: “Rock Bolting: approaches in Mines and in Tunneling” with the speakers Charlie Li from Norway and Robert Galler from Austria.

- Affiliation of the National Group of Morocco, represented by the Moroccan Committee for Soil Mechanics and Geotechnical Engineering

May - 2024 meeting of the FedIGS Board, in Toronto, Canada

June

July

- 14th International Symposium on Landslides – a JTC1 conference in Chambéry, France

- Publication of the e-Newsletter No. 66

- 46th ISRM Online Lecture by Prof. Carlos Carranza-Torres: “Scaled power law failure criterion for rock”

- ISRM Regional Symposium Eurock 2024, in Alicante, Spain

- Interim meeting of the ISRM Board by videoconference

August - 5th International Conference on Information Technology in Geo-Engineering – a JTC2 conference, in Golden, USA

- Reinstatement of the National Group of Iran, represented by the Iranian Society for Rock Mechanics

- ISRM Board meeting in New Delhi

• Dr. Lucille Carbillet, from France was selected as the recipient of the Rocha Medal 2025

• Dr. Yufang Zhang, from China was selected as the recipient of the John Hudson Rock Engineering Award 2024

• Prof. Pinnaduwa Kulatilake, from Sri Lanka and Prof. Weiren Lin, from Japan were selected and the recipients of the Science Achievement Award 2024

• Dr. Gabriel Walton, from the USA was selected as the recipient of the Young Rock Engineer Award 2024

- ISRM Council meeting in New Delhi

• Approval of the audited accounts of 2023 and Budget for 2025

• Revision of By-laws No. 4 and No. 7

• Fukuoka, Japan was selected as the venue of the ISRM International Symposium in 2026

September

- ISRM International Symposium ARMS13, in New Delhi, India

• Dr. Kazuki Sawayama, from Japan presented the Rocha Medal 2024 Lecture

• Dr. Vikram Vishal, from India presented the Franklin Lecture 2024

• The 9th Early Career Forum was held, under the umbrella of the ISRM Education Fund. 8 young members from the Asian region were invited to make presentations.

• Another edition of the ISRM RockBowl competition took place

• Dr. Yufang Zhang, from China was awarded the John Hudson Rock Engineering Award 2024

• Prof. Pinnaduwa Kulatilake, from Sri Lanka and Dr. Weiren Lin, from Japan were awarded the Science Achievement Award 2024

• Dr. Gabriel Walton, from the USA was awarded the Young Rock Engineer Award 2024

- Publication of the e-Newsletter No. 67

- 47th ISRM Online Lecture by Prof. Ranjith Pathegama Gamage: “Deep Geothermal Energy: A Key Player in the Sustainable Energy Mix”

October - ISRM Specialized Conference VietRock2024, in Hanoi, Vietnam

- 15th edition of the Young Members’ Seminar Series

November - ISRM Specialized Conference CouFrac2024, in Kyoto, Japan

- ISRM Specialized Conference 1st ISRM Commission Conference on Estimation of Rock Mass Strength and Deformability, in Lima, Peru

December

- Publication of the e-Newsletter No. 68

- 48th ISRM Online Lecture by Dr. Sylvie Gentier: “New frontiers for deep geothermal energy: some rock mechanics issues...”

Since February 2013 the ISRM Online Lectures Series has been running offering each year four lectures by renowned experts on cutting-edge topics. In 2024 another four high-level lectures were broadcast from the ISRM website at a preannounced date and time. The complete series of online lectures remain available for all interested to watch in the ISRM.

45th ISRM online lecture, March 2024

Dr. Jonny Rutqvist

Coupled Processes Modeling in Energy Geosciences

46th ISRM online lecture, June 2024

Prof. Carlos Carranza-Torres

Scaled power law failure criterion for rock

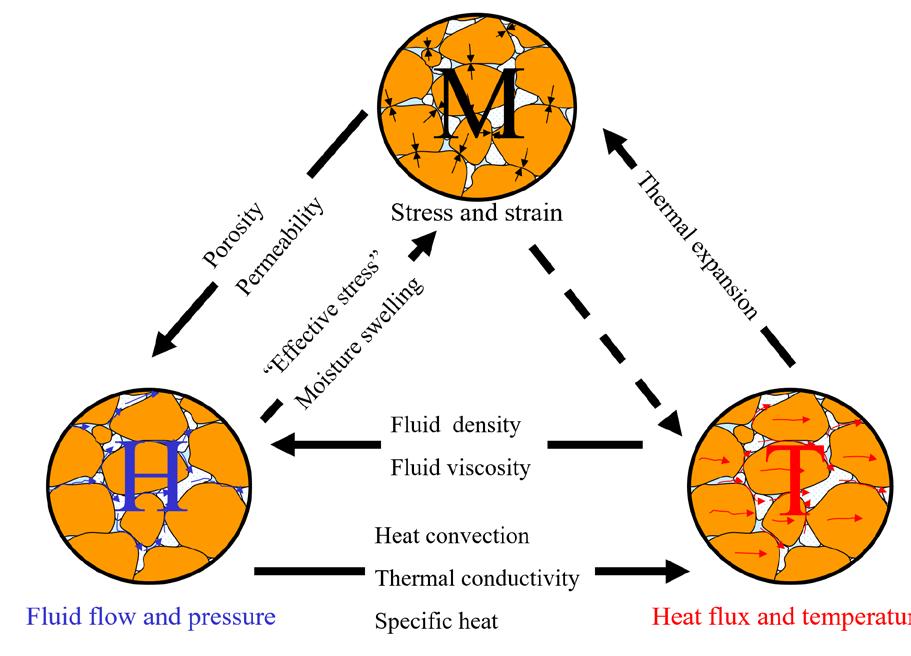

The lecture first introduces coupled thermal-hydro-mechanical (THM) processes and a modeling tool (TOUGH-FLAC) for analyzing such processes in energy geosciences. Thereafter, three examples of large-scale coupled processes model validations are presented. The first is related to a large underground heating experiment conducted at Yucca Mountain, Nevada, U.S.A. It was an 8-year heating of a 50-m-long tunnel at rock temperatures up to 200˚C, and is the world’s largest underground heating experiment to date. The second example involves an Enhanced Geothermal Systems (EGS) demonstration project, at the Geysers geothermal field, California; the largest geothermal energy producer in the world. The project involved THM modelling of hydraulic simulation of a cubic kilometer sized rock volume during a one-year massive cold-water injection into the very hot >250˚C steam-filled fracture rock. The third and final example involves coupled THM processes modeling at the In Salah CO2 storage project in Algeria. Detailed modeling of observed ground surface uplift revealed the creation of a large-scale fracture zone, about 5 km long, in the lower part of the caprock. These three examples, along with numerous other studies, demonstrate the great value of effective coupled THM modeling for design and performance of subsurface energy resources exploration and storage.

The lecture is based on a keynote paper presented in the first the First Chilean Rock Mechanics Congress in Santiago, Chile in November 2023. The lecture presents the formulation of a general power law failure criterion expressed in terms of principal stresses, and normal and shear stresses on the failure plane. The Mohr-Coulomb and Hoek-Brown failure criteria are shown to be particular cases of the general power law failure criterion. The Griffith failure criterion for intact rock, and the generalization of this criterion proposed by Fairhurst in 1964, are also shown to be particular cases of the general power law failure criterion. A scaling rule for the mathematical expressions conforming the power law failure criterion is presented, and its application in the interpretation of triaxial tests results in samples of intact rock that obey the Hoek-Brown and Fairhurst criteria is discussed. The lecture addresses then the problem of determining damage around boreholes in intact rock by estimation of extent of plastic failure and wall convergence of the borehole. Application of the scaled form of the Hoek-Brown and Fairhurst failure criteria is shown to lead to compact dimensionless representations of the extent of plastic failure and borehole wall convergence. Considering that the Fairhurst failure criterion is associated with the Griffith failure criterion, which in turn is based on the assumption that the combination of principal stresses in the criterion leads to the initiation of crack propagation, a conceptual model is introduced in which the Hoek-Brown failure criterion is applied to quantify the extent of failure around the borehole, while the Fairhurst criterion is applied to quantify the extent of fracturing or cracking beyond the failure zone. Additional developments related to shear strength of rockfill materials, included in the paper on which the lecture is based on, are also discussed.

47th ISRM online lecture, September 2024

Prof. Ranjith Pathegama Gamage

Deep Geothermal Energy: A Key Player in the Sustainable Energy Mix

The lecture discusses recent breakthroughs in geothermal energy, with a focus on innovative extraction techniques aimed at establishing geothermal energy as a sustainable energy cornerstone. This lecture reviewed the global and Australian geothermal landscape, underscoring geothermal's vast potential to meet both energy demands and greenhouse gas reduction targets.

Among the cutting-edge methods highlighted were hydraulic stimulation techniques employing advanced fluids, such as supercritical CO2 (ScCO2) and specialized foams. ScCO2 stimulation was shown to create complex fracture networks that optimize fluid flow and facilitate CO2 sequestration, making it a highly effective and eco-friendly alternative to conventional water-based methods. Foam stimulation further enhances geothermal extraction, requiring minimal water, reducing induced seismicity, and enabling carbon storage when CO2-based. These fluid-based techniques offer scalable solutions that significantly lower environmental impact while maximizing energy recovery.

The lecture also introduced the Slow Releasing Energy Material Agent (SREMA), a novel, sustainable approach to rock fracturing. SREMA’s gradual expansion mechanism permits precise control over rock fracturing, improving permeability with minimal environmental disruption compared to traditional techniques. This eco-friendly innovation represents a breakthrough in geothermal and mineral recovery applications.

Thermal stimulation was another key advancement presented, leveraging temperature-induced fracture networks to improve flow paths within geothermal reservoirs. The integration of thermal, ScCO2, and foam-based methods can substantially boost geothermal output, as evidenced by projects like the Habanero field in Australia’s Cooper Basin, where closed-loop systems sustainably harness geothermal heat with a reduced environmental footprint.

These advancements not only provide a viable pathway to net-zero emissions but also offer a scalable solution to global energy needs. By coupling geothermal energy with green hydrogen production, these technologies support a resilient and sustainable fuel future, emphasizing geothermal's critical role in driving the global energy transition and Australia’s leadership in pioneering these efforts.

48th ISRM online lecture, December 2024

Dr. Sylvie Gentier

New frontiers for deep geothermal energy: some rock mechanics issues

The world of deep geothermal energy, traditionally organized around two clearly individualized poles (geothermal power and heat production), must now consider new perspectives, with a convergence between the contribution of 30 years of development of the EGS (Enhanced Geothermal Systems) concept and the contribution of technologies developed over the last twenty years in the O&G field.

The evolution from HDR (Hot Dry Rock) to EGS is illustrated by the development of the Soultz-sous-Forêts site (Alsace, France). This evolution is reviewed in general terms and through rock mechanics issues addressed by the scientific community and more specifically by BRGM (French Geological Survey) and its collaborators over the last 30 years. The first industrial pilot plant connected to the electricity grid was completed in 2008, opening the door to the development of power-generating or cogenerating (electricity/heat) geothermal energy, to be deployed with a more widespread exploitation of deep heat.

The deployment expected and foreseen in the years 2015-2020 has faced difficulties of various kinds: drilling technology and cost, induced seismicity. New fundamental questions about the knowledge of faulted and/or fractured media and their thermo-hydro-mechanical behavior in response to the construction of underground heat exchangers and their operation are discussed.

At the same time, the last twenty years have seen the widespread deployment of shale gas exploitation in the USA, leading to increased technological expertise in drilling (horizontal drilling) and hydraulic fracturing. How the transfer of these technologies to the development of EGS which is likely to give new dynamism to these technologies, with the hope of removing some barriers and minimizing certain risks, is presented.

Finally, this EGS perspective is compared with what we now call AGS (Advanced Geothermal Systems) and the associated research questions.

The objective of ISRM Commissions is to study scientific and technical matters of interest to the Society. In recognition of the critical role of the ISRM Commissions, the ISRM Board created a committee – the Technical Oversight Committee (TOC) to coordinate the commission’s work, report on their performance and to act as oversight for the Commissions. Since ISRM Commissions are appointed by the Board for each 4-year period between ISRM Congresses, establishment of new Commissions or the continuation of pre-existent ones is decided by the new Board following proposal by the TOC.

In the Interim ISRM Board meeting held in San José, Costa Rica, 21 commissions were preliminarily approved for the term 2023-27.

Later in the year, the Board approved the establishment of one additional commissions, bringing the total number of active commissions to 22, as listed below along with the respective chairs and contacts followed by the topics and objectives of the nine new ones.

There are four Joint Technical Committees operating under the umbrella of the Federation of International Geo-Engineering Societies - FedIGS. The current list of JTCs is the following:

JTC 1 - Natural Slopes and Landslides

JTC 2 - Representation of Geo-engineering Data in Electronic Form

JTC 3 - Education and Training

JTC 4 - Environment and Geo-Engineering Sustainability

Artificial Intelligence in Rock Mechanics and Rock Engineering

Beyond Limits: Rocks in the Face of Extreme Conditions

Bio-Rock Mechanics

Coupled Thermal-Hydro-Mechanical-Chemical Processes in Fractured Rock

Crustal Stress and Earthquakes

Deep Mining

Design Methodology

Discontinuous Deformation Analysis - DDA

Earthquake Motions in Rock Engineering

Estimation of Rock Mass Strength and Deformability

Mechanics of Ancient Rock Structures

Planetary Rock Mechanics

Radioactive Waste Disposal

Risks and Reliability in Rock Slope Engineering

Rock Dynamic

Rock Grouting

Rock Weathering and Erosion

Rockburst

Soft Rocks

Sorptive Rocks and Engineering

Testing Methods

Ultradeep Rock Mass Mechanics and Engineering

Dr. Hongkyu Yoon, USA (hyoon@sandia.gov)

Dr. Wasantha Liyanage, Australia (wasantha.pallewelaliyanage@ vu.edu.au)

Prof. Hitoshi Matsubara, Japan (matsbara@tec.uryukyu.ac.jp)

Dr. Jonny Rutqvist, USA (jrutqvist@lbl.gov)

Prof. Furen Xie, China (xxiefr@263.net) and Dr. Jiayong Tian, China (chenlitedtian@263.net)

Dr. Abbas Taheri, Canada (abbas.taheri@queensu.ca)

Prof. Xia-Ting Feng, China (fengxiating@mail.neu.edu.cn)

Prof. Yu-Yong Jiao, China (yyjiao@cug.edu.cn) and Prof. GaoFeng Zhao, China (gaofeng.zhao@tju.edu.cn)

Dr. Naoki Iwata, Japan (n.iwata@cecnet.co.jp)

Prof. Pinnaduwa Kulatilake, Sri Lanka (kulatila@arizona.edu)

Dr. Takafumi Seiki, Japan (tseiki@cc.utsunomiya-u.ac.jp)

Prof. Serkan Saydam, Australia (s.saydam@unsw.edu.au)

Dr. Ju Wang, China (wangju9818v163.com)

Dr. Neil Bar, Hungary (neil@geckogeotech.com)

Prof. Jianchun Li, China (jcli@seu.edu.cn)

Mohamed El Tani, Switzerland (md.eltani@rockgro.com)

Yanli Huang, China (huangyanli@cumt.edu.cn) and Zhongwei Chen, Australia (zhongwei.chen@uq.edu.au)

Prof. Manchao He, China (hemanchao@263.net)

Prof. Xiaoming Sun, China (sxmcumtb@163.com)

Dr. Shimin Liu, USA (szl3@psu.edu) and Dr. Yixin Zhao, China (zhaoyx@cumtb.edu.cn)

Prof. Rešat Ulusay, Turkey (resat@hacettepe.edu.tr)

Prof. Yangsheng Zhao, China (y-s-zhao@263.net) and Prof. Derek Elsworth, USA (elsworth@psu.edu)

The ISRM Commission on Artificial Intelligence in Rock Mechanics and Rock Engineering (CAIRM) focuses on the applications of artificial intelligence (AI) and big data in rock mechanics, geomechanics, and engineering works in rock masses in support of civil, geo-, petroleum, and mining engineering. The main objectives of CAIRM include promoting the development and applications of AI and machine learning for the field of rock mechanics and rock engineering, sharing AI tools and big data among researchers, professionals, and rock mechanics and engineering practitioners, and encouraging international collaboration and exchange of ideas through the commission and ISRM activities.

Rocks exposed to extreme conditions, e.g., extremely high and extremely low temperatures, extremely high pressures, dynamic loading, and creep, are increasingly encountered in rock mechanics and rock engineering applications around the world. This trend is largely attributed to factors like climate change, fire (wildfire, tunnel fire, mine fire, etc.), deep mining, underground storage initiatives, and geothermal energy exploitation. Consequently, there is a growing need to reassess and adapt relevant theories and practices in rock mechanics to tackle these encounters effectively. The primary aim of this Commission is to materialise necessary advancements in understanding rock behaviour under such extreme conditions, pushing beyond conventional boundaries.

Microorganisms have been essential to the weathering and mineralization of the Earth’s crust since their emergence. However, our understanding of how the physicochemical and geochemical properties of rocks, alongside biogeochemical parameters, influence and control the mechanical behavior of rocks remains limited. To clarify the relationship between microbial activity in rocks, the mechanical/material properties of rocks, and geo-hazards, the establishment of a novel field called “bio-rock mechanics” is essential. This commission aims to promote comprehensive research on microbial weathering and mineralization phenomena, while encouraging collaboration and fostering scholarly exchange among scientists in this field.

Earthquakes are known to be one of the natural disasters resulting in the huge losses of human lives as well as of properties as experienced in the recent great earthquakes. It is well known that ground motion characteristics, deformation and surface breaks of earthquakes depend upon the causative faults. Every earthquake causes vibrations and temporary and/ or permanent movement of ground. As it is difficult to measure ground motions at every location, empirical, semi-analytical or numerical procedures are utilized to estimate ground motions.

The main goals of this commission are to provide a review of the available methods (empirical, numerical modelling, back calculation based on field monitored data), to provide guidelines for rock mechanics teaching and practice, and to suggest future research to improve the available techniques in predicting rock mass strength and deformability properties.

Mankind has built rock engineering structures going back to 5000 years at least. Research on learning from ancient rock engineering structures definitely provides essential information and data for assessing the long-term behaviour and performance of some modern rock engineering structures. Therefore, a commission with the goal of learning and obtaining data and information from Ancient Rock Engineering Structures is doubtlessly necessary within the activities of ISRM Commissions. In the pathway of the commission led by Emeritus Prof. Chikasa Tanimoto on “Preservation of Natural Stone Monuments Commission” activities in 1996 and lasted till 2007, the proposed commission intends to further advance research goals on the rock mechanics and rock engineering aspects of Ancient Rock Engineering Structures.

The ISRM Commission for Risks and Reliability in Rock Slope Engineering provides a forum for sharing ideas and challenges relating rock engineering design related to surface excavations in mining and civil engineering. The commission is focusing on addressing uncertainty in ground characterization to produce guidelines for reliability analyses and risk management in rock slope engineering for surface excavations. This will also include guidance on the application of reliability-based analyses for different rock engineering problems, such as rockfalls, stability problems during excavation, as well as for the selection of parameters and design cases from Eurocode 7 related to rock mechanics and rock engineering.

The importance of studying rock weathering and erosion is increasingly evident across various aspects, including rock lithological alteration and deterioration and their engineering implications on mine rehabilitation, the preservation of open pit mines, stability assessments in underground excavations, carbon sequestration through enhanced weathering, and safeguarding heritage sites.

The proposed Commission seeks to reveal the underlying mechanisms of rock weathering and erosion across diverse rock types, establish robust quantitative methods for tracking their time-spatial evolutions, and develop innovative solutions to mitigate weathering and erosion effects in specific applications.

The commission covers the field of ultradeep resource development such as hot dry rock geothermal resources (depth>5000 m and temperature>300°) and coal mining (depth>1500 m), ultradeep geological energy storage such as oil & gas and hydrogen geological storage (depth>3000 m), CO2 ultradeep geological storage (depth>4000 m), ultradeep drilling (depth>8000 m), and earthquake prediction (depth>10000~15000 m) in ultradeep geological mass to address rock mass mechanics and engineering problems and challenges under ultradeep in-situ geological buried conditions. To determine the occurrence, geological and structural characteristics of ultradeep rock mass as well as the rock mass behavior during the long-term migration and storage of the working medium are very important for the engineering design of resource exploitation and geo-hazards prediction in the related fields.

At its Tokyo meeting in September 1981, the ISRM Board decided to institute an annual prize to honour the memory of Prof. Manuel Rocha, ISRM President from 1966-1970. The Rocha Medal is intended to stimulate young researchers in the field of rock mechanics. The prize, a bronze medal and a cash prize, have been annually awarded since 1982 for an outstanding doctoral thesis selected by a committee appointed for the purpose.

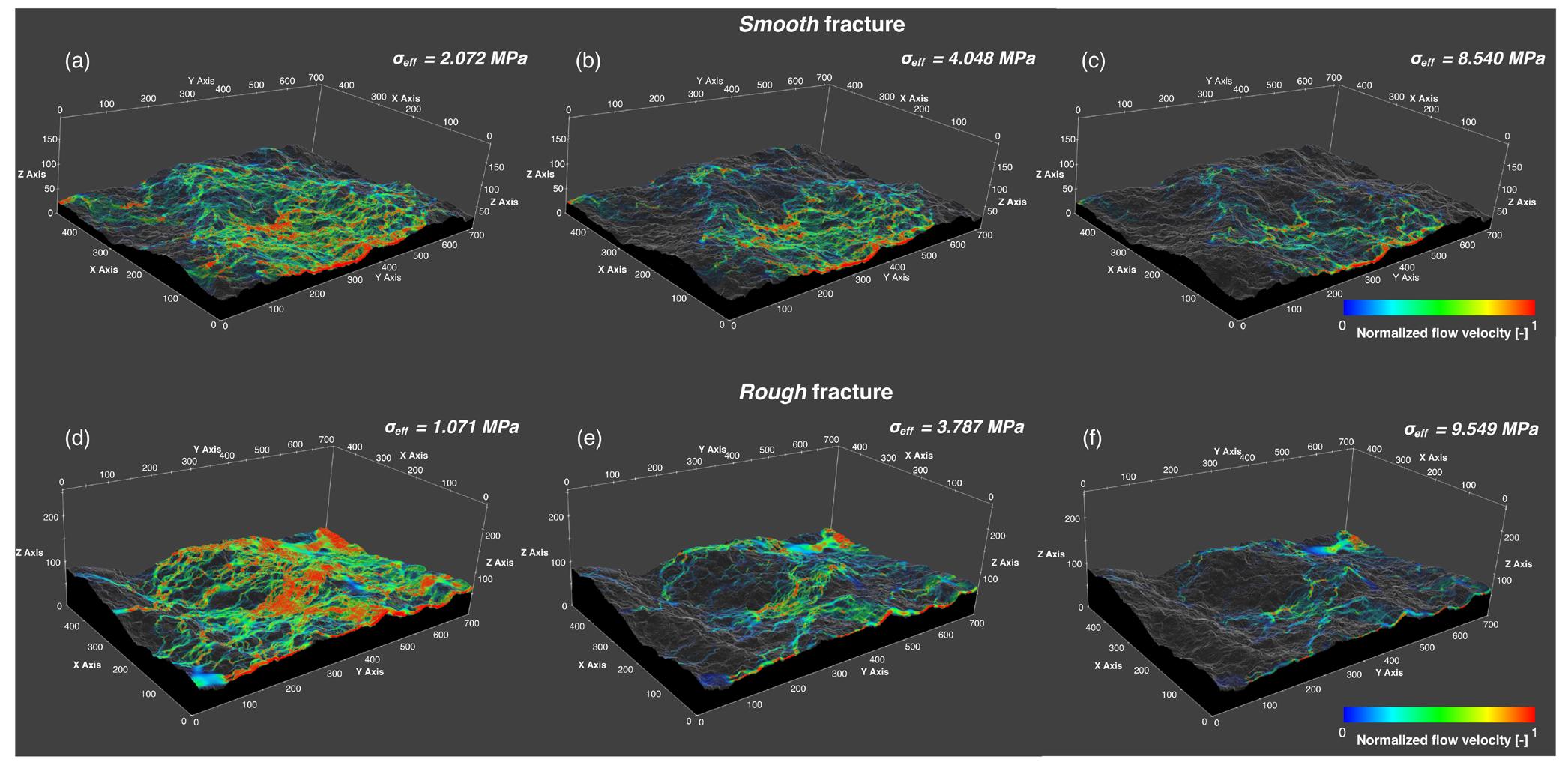

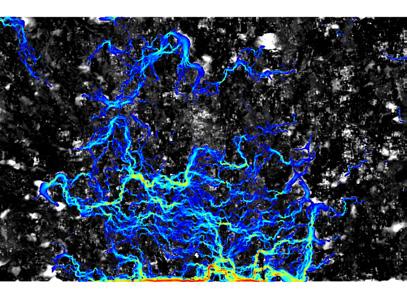

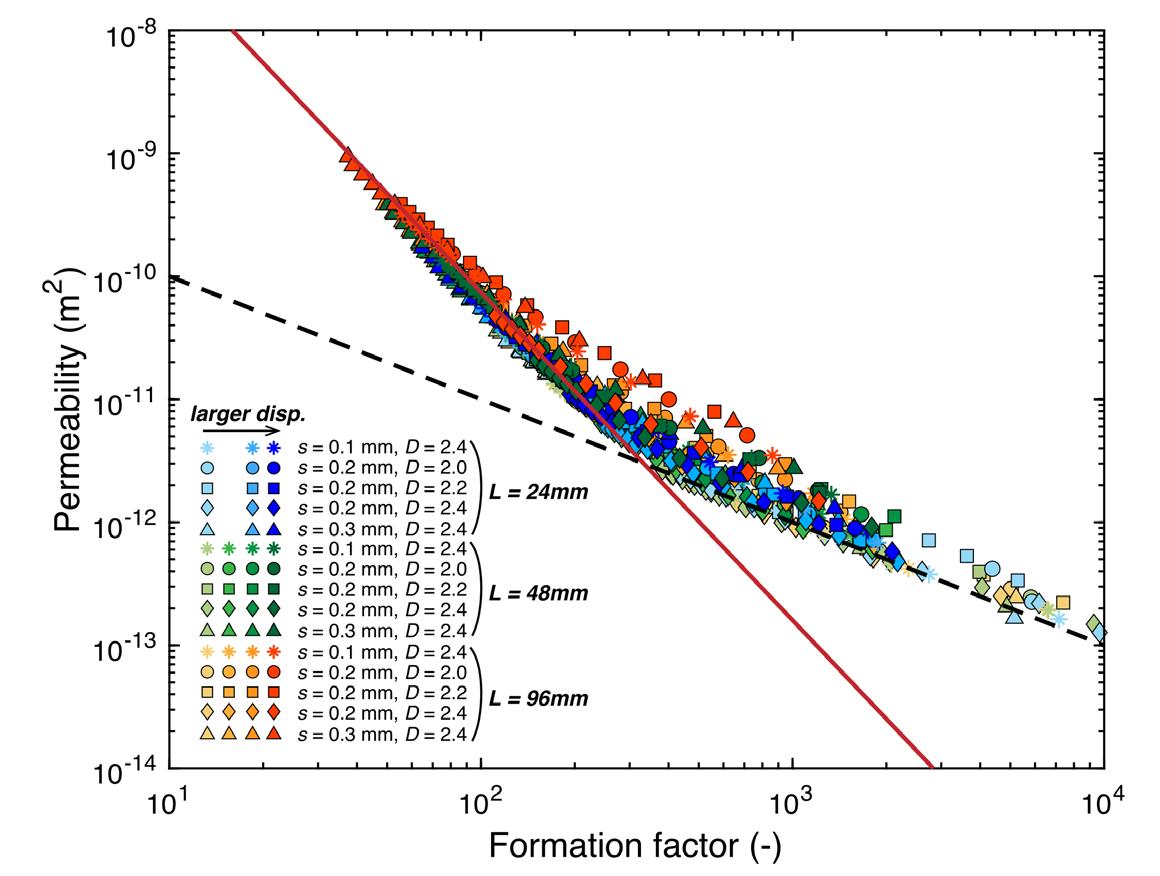

The 2024 Rocha Medal was conferred to Dr. Kazuki Sawayama, from Kyushu University, Japan, with a thesis entitled “Study on the relationships between fracture flow behaviours and geophysical properties for the quantitative monitoring of fractured reservoirs”, and supervised by Prof. Jun Nishijima.

In 2024, two runner up certificates were given to Dr. K. Liu, from Monash University, for the thesis entitled “Dynamic behaviours of rock materials under coupled multiaxial confinement and dynamic loading”, supervised by Prof. Jian Zhao, and to Dr. M. Wang, from Laurentian University, for the thesis entitled “Modeling time-dependent deformation behavior of jointed rock mass”, supervised by Prof. Ming Cai.

The Franklin Lecture was institute in 2011 in order to honour the memory of Prof. John Franklin, ISRM President from 1987 to 1991. The purpose of the ISRM Franklin Lecture is to recognise a mid-career ISRM member who has made a significant contribution to a specific area of rock mechanics and/ or rock engineering. The ISRM Franklin Lecture is given in every year, at the respective ISRM International Symposium, except for those years when the 4-yearly ISRM Congress is held.

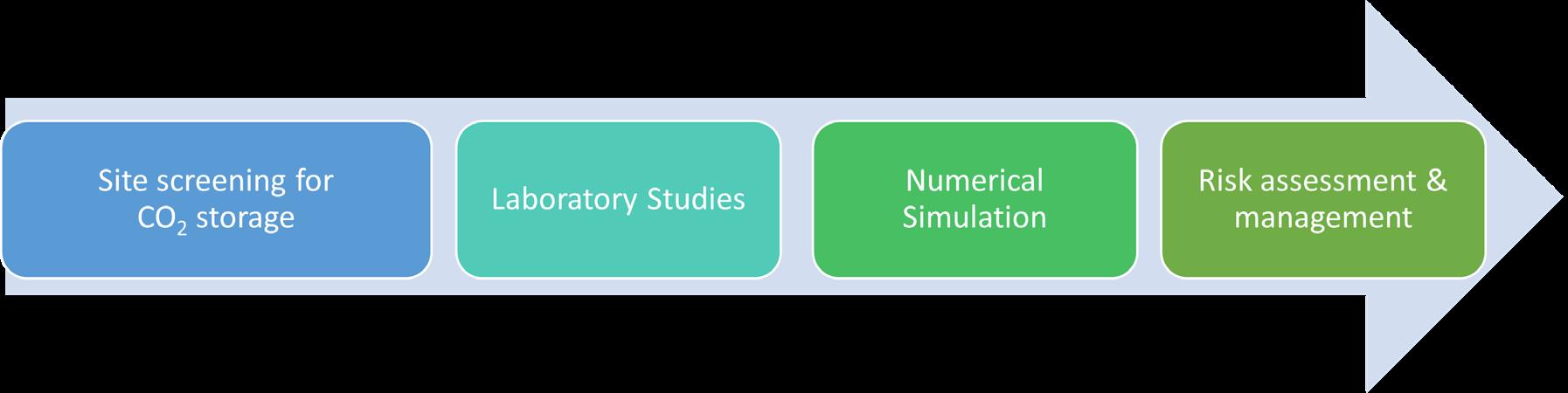

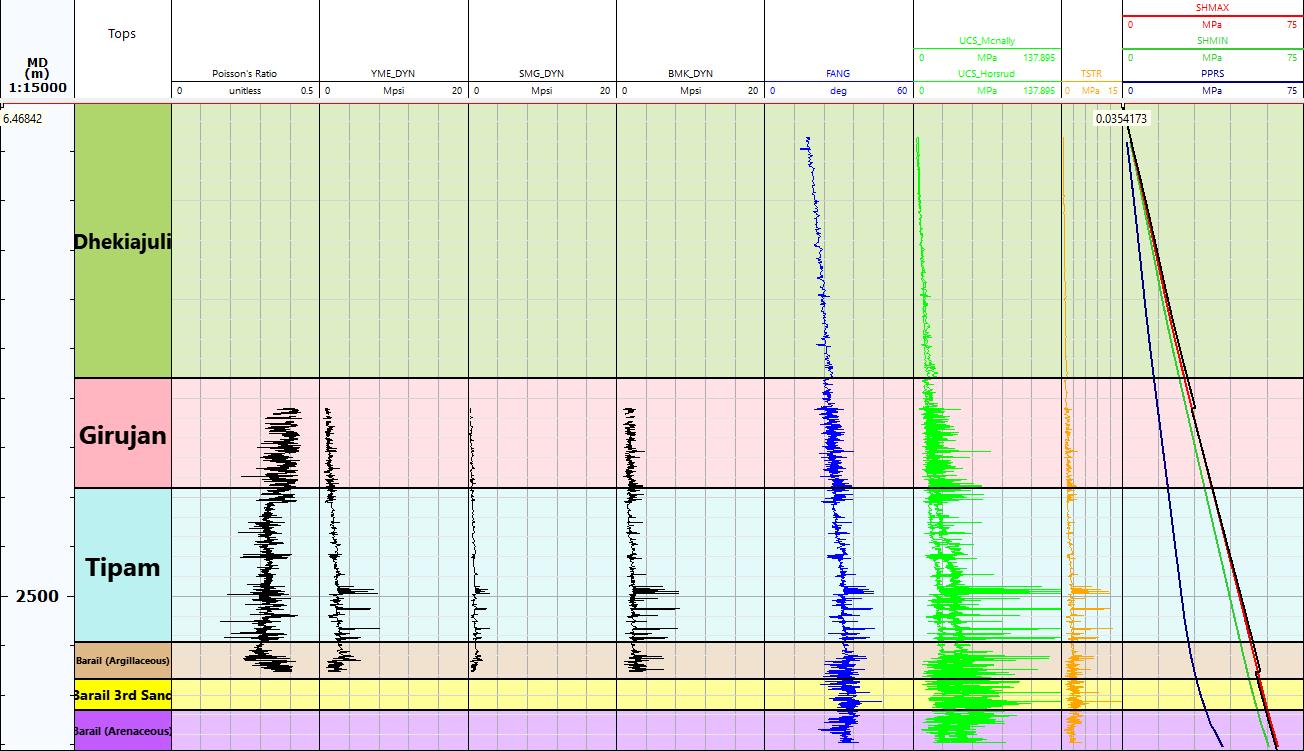

The 2024 Franklin Lecture “Geomechanical constraints in geological carbon dioxide sequestration” was delivered by Dr. Vikram Vishal from India during the ARMS13 Conference held in New Delhi.

The John Hudson Rock Engineering Award honours the memory of Prof. John Hudson, ISRM President from 2007 to 2011, It can be awarded to ISRM individual or corporate members in recognition of their achievements in engineering practice.

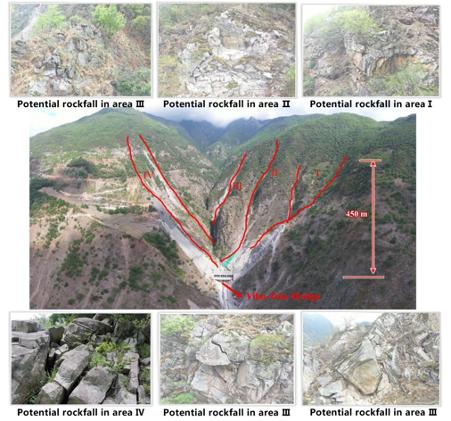

In 2024, this award was attributed to Yufang Zhang, researcher at the China Railway Scientific Research Institute from China, for his research and application of ultra-high and large energygrade flexible protective structure for high position rockfalls on the Chengdu-Kunming Railway, which was recognized as a relevant realization the effectively introduced new and important technologies to current rock engineering practice. This recognition marks Zhang as the first Asian scholar to receive this prestigious award, underscoring his remarkable achievements in rock engineering.

The Young Rock Engineer Award was instituted to acknowledge excellence in the field of rock engineering by ISRM members who are in early stages of their career: under the age of 40 and having worked in rock engineering for a period of about five to ten years.

The Young Rock Engineer Award 2024 was conferred to Dr. Gabriel Walton, from Canada and based in the United States.

Dr. Walton received his B.A.Sc. and Ph.D. in Geological Engineering from Queen’s University (Kingston, Canada) in 2011 and 2014, respectively.

After a brief stint in consulting, he joined the faculty of the Colorado School of Mines in 2015. He has published over 100 peer-reviewed papers, and is an active member of the Rock Engineering community, serving on the Board of Directors of the American Rock Mechanics Association (ARMA) since 2021, as Vice President of ARMA since 2023, and as the Chair of the 2024 ARMA symposium in Golden, Colorado. He was runner-up for the ISRM Rocha Medal in 2017 and received the Faculty Excellence in Research Award from the Colorado School of Mines in 2024.

Dr. Walton’s research group has contributed to the solution of practical engineering problems through collaborations with a variety of industry partners, including addressing deep shaft stability in highly anisotropic ground, application of look-ahead geophysics in tunneling, and application of drone-based monitoring to evaluated potential trends in underground mine convergence. His group has also advanced broadly applicable tools and approaches, including developing modifications to the Voussoir Beam model for flatroofed excavation stability to consider the influence of rock reinforcement, proposing improvements to existing pillar strength estimation methods, and developing best practices for numerical modeling of brittle rock damage and excavation stability. Most recently, Dr. Walton group has focused on the use of point clouds (lidar and photogrammetry) for rock slope monitoring and the application of monitoring results to improve rock slope asset management.

The Science Achievement Award is conferred by the ISRM President, on a bi-annual basis, in the 1st and the 3rd year of each ISRM Presidential tenure period, on up to two ISRM individual members in recognition of one or more of the following contributions to the progress of the science of rock mechanics: making an important advancement of knowledge, or proposing and confirming a new theory to explain certain phenomena.

This year the recipients of this award were Prof. Pinnaduwa Kulatilake, from Sri Lanka, and Prof. Weiren Lin, from Japan.

Prof. Pinnaduwa H.S.W. Kulatilake is a Professor Emeritus at the University of Arizona, USA, and the President of the Sri Lankan Rock Mechanics and Engineering Society. His Ph.D. degree is in Civil Engineering with a Geotechnical Engineering specialty from the Ohio State University, USA. Prof. Kulatilake has over 40 years of experience in rock mechanics and rock engineering and applications of probabilistic, statistical, and numerical methods to civil, mining, and geoengineering.

His teaching has gone beyond the universities he has worked at. He has taught 56 short courses to both practitioners and academicians in 17 countries covering all 6 continents. He has performed research with 95 graduate students, and visiting scholars to earn worldwide recognition for his research. His visiting scholars were supported by various agencies in China, Japan, Turkey, Europe, and India. He has collaborated with industry, research institutes, and universities in many parts of the world for his research, teaching, and service activities. He has published more than 280 papers, which resulted in more than 7850 citations. He has co-authored a book on “Rock mass stability around underground excavations in a mine”, he has edited four conference proceedings and served as the Guest Editor for two special issues in an international journal. All those activities led him to deliver more than 40 invited keynote lectures and 50 other invited lectures throughout the world.

Recently, he formed the Sri Lankan Rock Mechanics and Engineering Society (SLRMES) as a member country under the International Society of Rock Mechanics and has been serving as the President of the SLRMES since October 2022. He has organized and chaired three successful international conferences, the most recent one, which was an ISRM Specialized Conference, was held in Sri Lanka in December 2023.

Prof. Kulatilake has performed research in two specific fields. In the rock mechanics area, his research has been on the topics of discontinuity geometry, roughness, and aperture; discontinuity strength, deformability, and fluid flow modeling; rock mass deformability; rock mass strength; rock mass hydraulic behavior; civil-geotechnical rock slope stability; open pit and underground mine stability; geohazards; and rock blasting. In his second area of research, he developed and/ or applied probabilistic, statistical, and numerical methods to solve geo-engineering problems.

Based on more than 15 highly innovative journal papers his research group published on rock joint geometry parameters, his group developed a highly sophisticated computer package incorporating 26 calculation programs and 24 graphical programs to perform discontinuity network modeling including validations in rock masses in 3D.

Prof. Weiren Lin has dedicated approximately 30 years to the study of rock mechanics in the fields of geoengineering and geoscience. His primary research interest lies in the in-situ stress state of rock mass in deep subsurface rock formations. This includes stress measurement techniques, interpreting the geomechanical and scientific implications of stress states, and developing stress measurement methodologies. His secondary research interest lies in the evaluation of the physical properties of rock, such as thermal conductivity, compressive/tensile strength, elastic wave velocity, resistivity, and permeability under high-pressure and high-temperature conditions. Prof. Lin has published 110 peer-reviewed papers in international journals, including three papers published in top journals (Nature or Science), 52 papers published in peerreviewed domestic (Japanese) journals, 51 papers published in international conference proceedings (for example, ISRM Congress), six invention patents, and six book chapters.

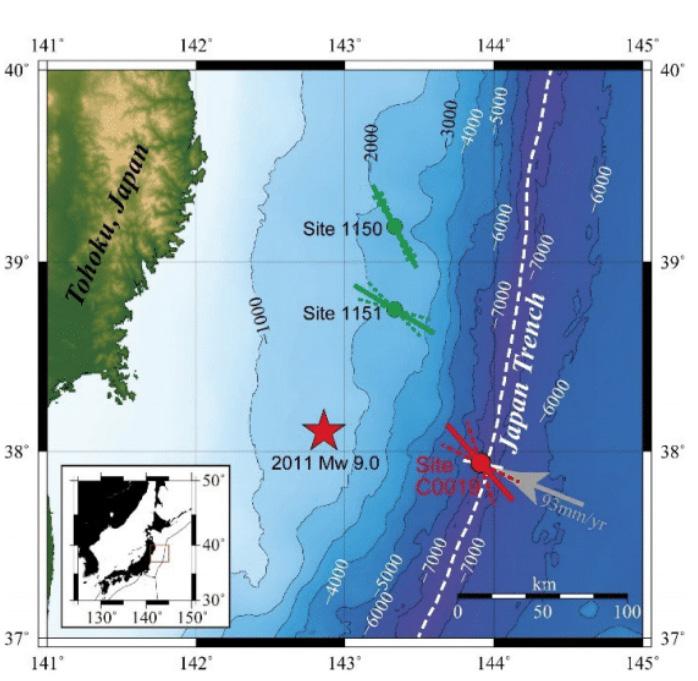

Notably, Weiren Lin has successfully measured the postearthquake stress state around the Pacific and North American plate boundary fault, which caused the 2011 Mw 9.0 Tohoku earthquake. With his colleagues, he concluded that a complete stress drop occurred, which increased the faultslip displacement and eventually resulted in a devastating tsunami. This research, which was based on rock mechanics measurements, was published in ‘Science’ with Weiren Lin as the first author, and made an important advancement of knowledge to the fields of geoscience and geoengineering.

Weiren Lin’s major scientific achievements are:

• determining stress state in vicinity of earthquake-source faults and stress drop accompanied by the 2011 Mw 9.0 Tohoku earthquake;

• development of stress measurement methods and their application

• measurement of physical properties under high-pressure and high-temperature conditions.

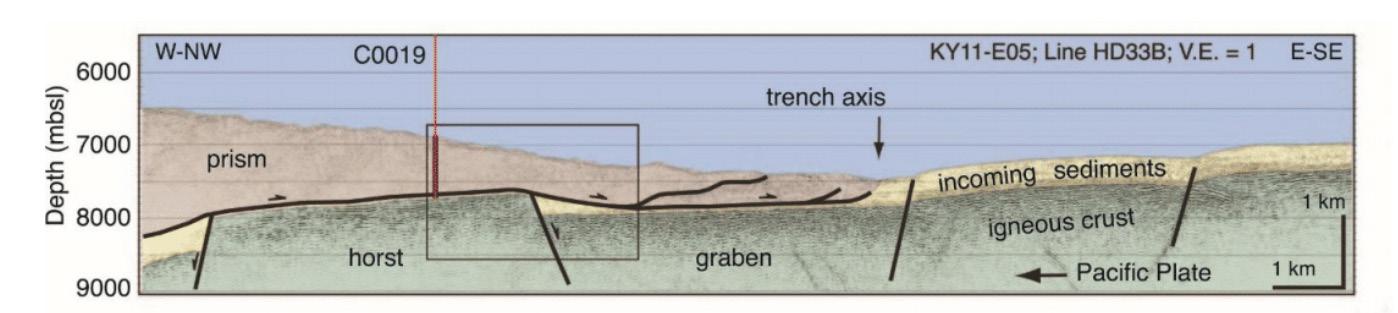

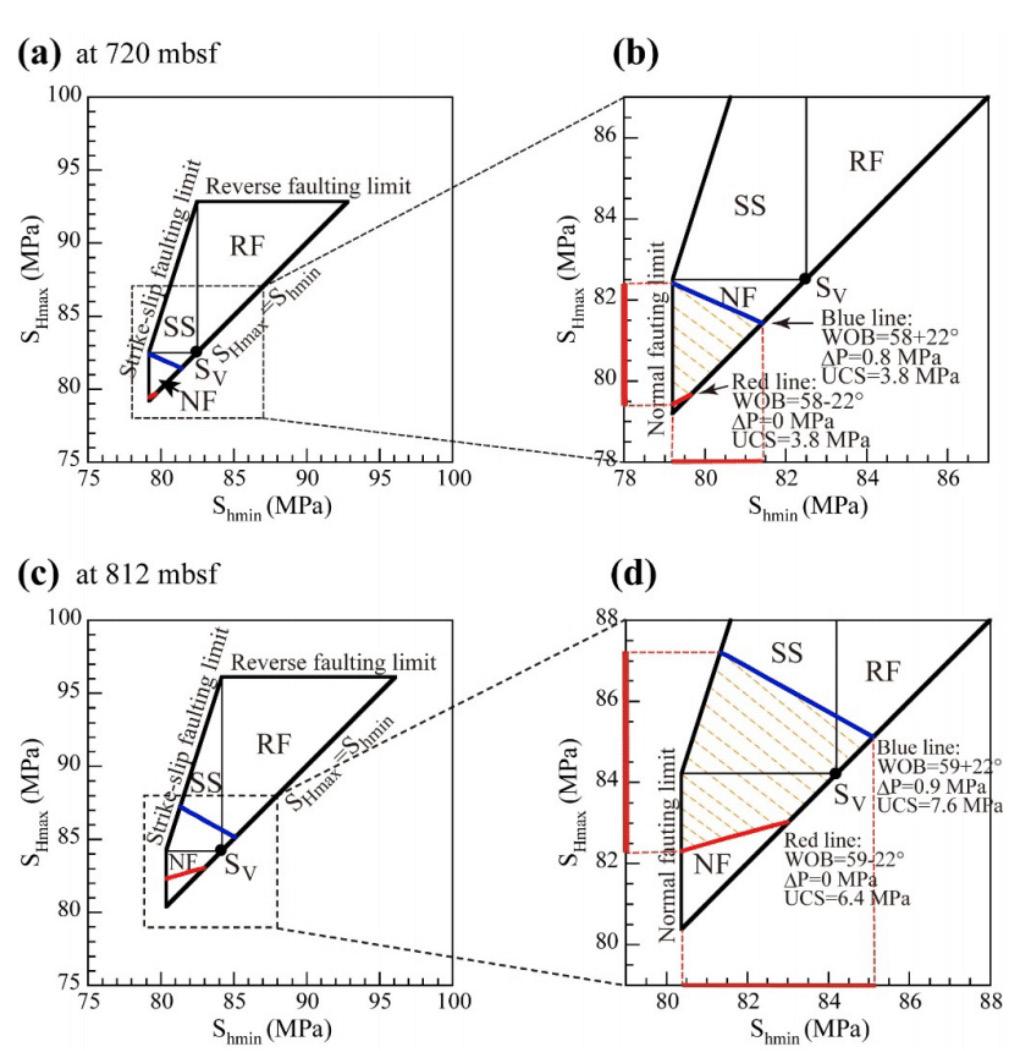

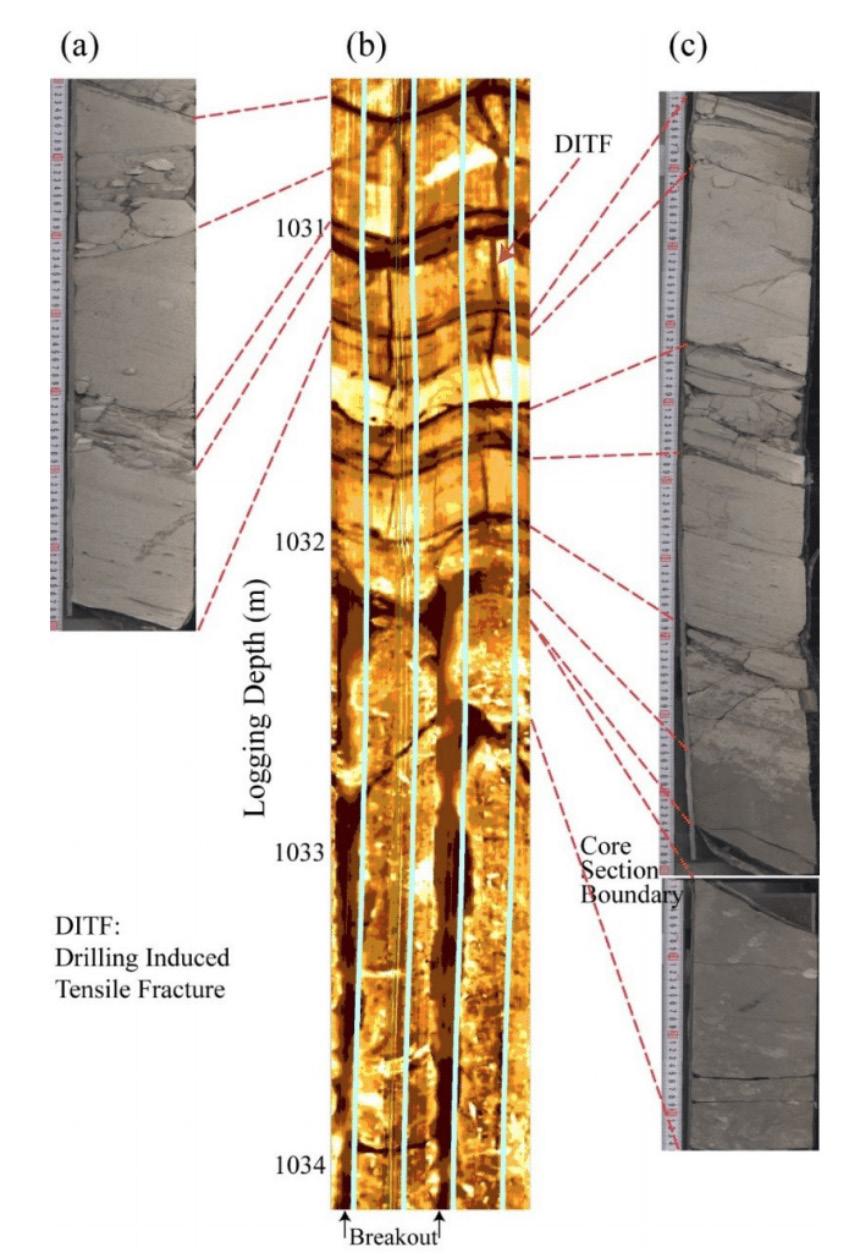

The Mw 9.0 earthquake produced a maximum coseismic slip of >50 m on the plate boundary fault close to the Japan trench, triggering a devastating tsunami. Before the earthquake, it was widely accepted that an earthquake releases only part of the stress driving the earthquake fault. To elucidate the recordbreaking displacement of the coseismic fault-slip, Prof. Lin and colleagues conducted stress measurements using conventional rock mechanics methods in deep ocean drilling that penetrated the earthquake-source fault at a depth of approximately 820 m below the seafloor, at a water depth of approximately 7000 m. The stress measurement results based on borehole breakout

analyses and the anelastic strain recovery (ASR) method indicated a complete stress drop and large energy release during the earthquake. This complete stress drop increased the coseismic fault slip and resulted in a devastating tsunami. By using actual stress measurement data obtained by rock mechanics approaches, this research led to the discovery of unexpected stress drop during the enormous earthquake. This initial discovery marked a significant leap forward in understanding the correlation between earthquake occurrence and stress changes, highlighting the pivotal role of stress measurements in seismic research.

The determination of in-situ stress states is one of the most important issues in rock mechanics and rock engineering. However, significant challenges persist in refining measurement techniques for this purpose. In the past two decades, Prof. Lin and colleagues have established a practical test protocol and data processing procedure for determining three-dimensional in-situ stresses from anelastic strain recovery (ASR) measurements. They have conducted over ten case studies with in-situ stress measurements using the core-based ASR technique, including deep drilling projects both on land and in marine environments, spanning diverse geoengineering and geoscience applications). These case studies covered a wide range of rock types, core sample retrieval depths, and research backgrounds. The success of these applications confirmed that the ASR technique is useful and applicable to most deep-drilling, particularly to deepdrilling that penetrates sedimentary rocks. Additionally, Prof. Lin has used borehole breakouts analysis to determine the insitu stress in various drilling projects. The stress measurement methods developed by Prof. Lin have provided the rock mechanics community with valuable resources for planning, conducting, and evaluating stress measurements.

The physical properties of rocks depend on pressure and temperature, which increase with depth in the deep subsurface, particularly in large depths of several kilometers. For the correct evaluation of the physical properties of rock, such as the thermal conductivity, Prof. Lin and colleagues have carried out physical property measurements under high-pressure and high-temperature conditions to simulate the actual in-situ conditions. To elucidate the mechanisms behind the impact of high temperature on the physical properties of rock, Weiren Lin investigated the thermal microcracking of granitic rocks subjected to high-temperature. His experimental studies on the physical properties of rock have contributed a wealth of valuable data to the field of experimental rock mechanics.

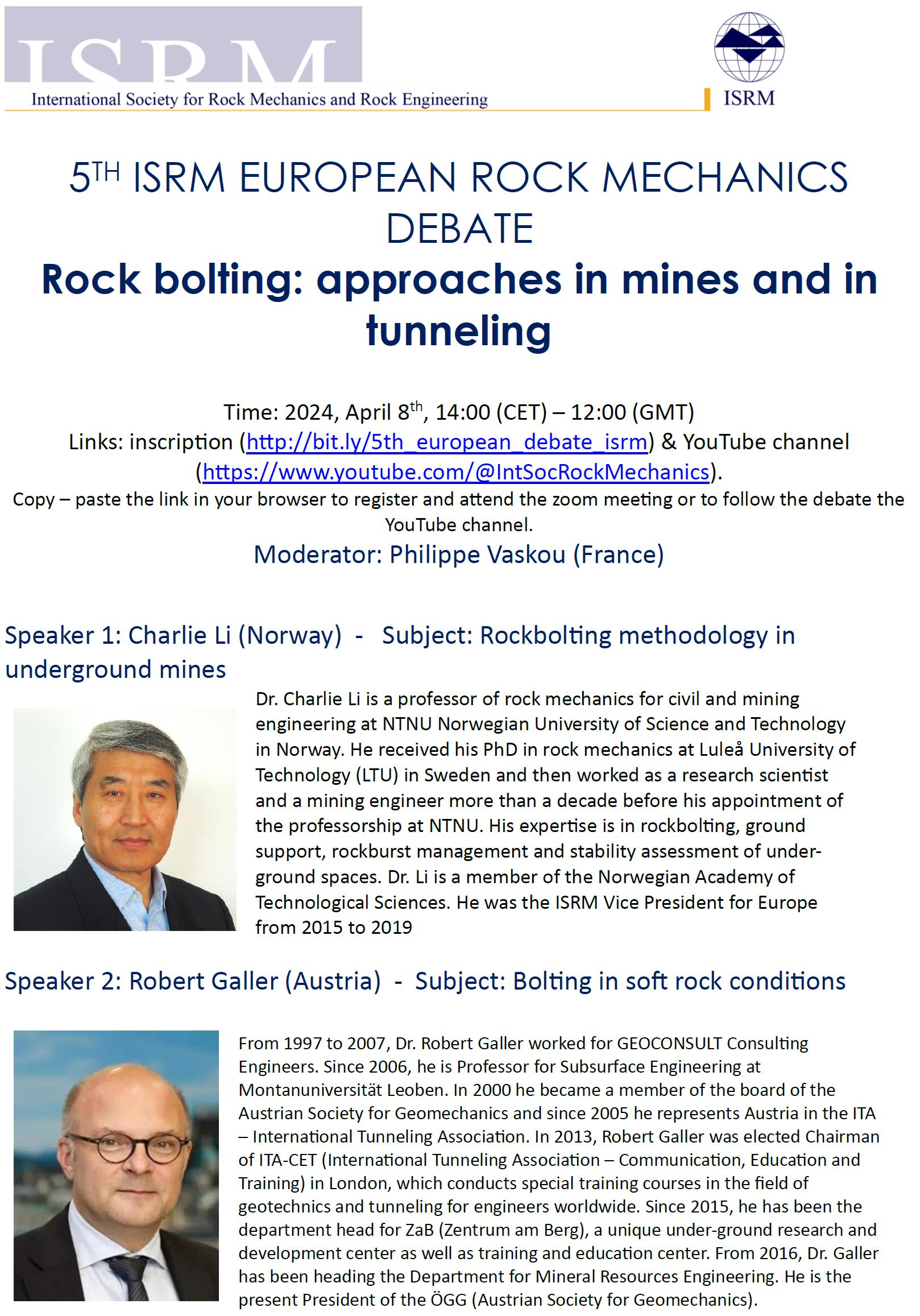

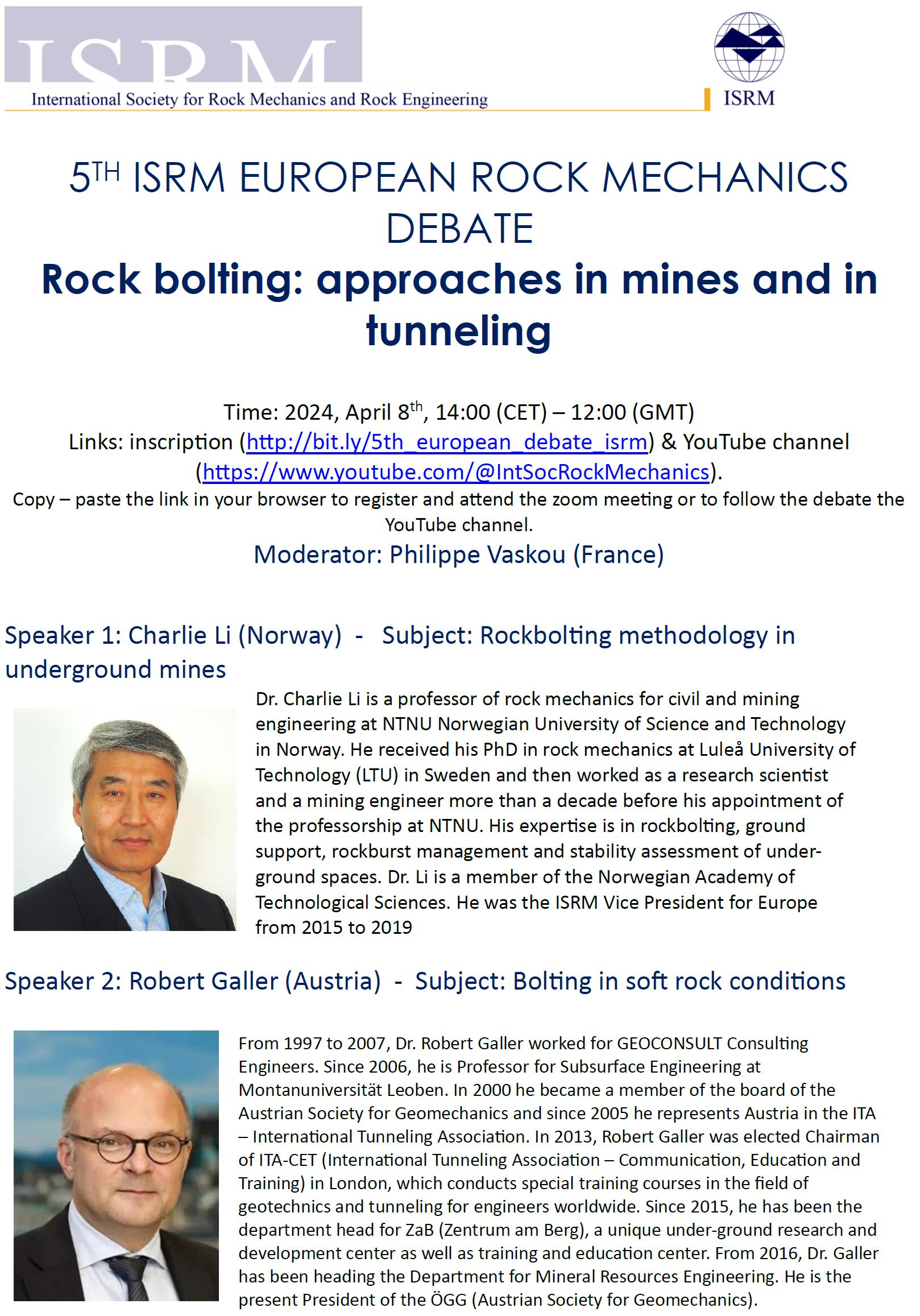

European Rock Mechanics Debates started in 2021 and aim at stimulating communication among academics and practitioners of rock mechanics and rock engineering in Europe, organized initially by the Vice-President for Europe Leandro Alejano supported by Charlie Li and Philippe Vaskou. The debates are held virtually and each one will have two speakers, with different perspectives on a hot rock engineering topic or on a specific technical aspect of rock mechanics. 2024 saw two more editions of these events again moderated by Philippe Vaskou, from France.

Rock bolting: approaches in mines and tunneling

safety, reduces ground movement, and increases the bearing capacity of the ground, making it a valuable solution in construction and mining projects. The process requires careful site analysis, accurate design, and precise execution to be effective.

Why Rock Bolting is Done in Soft Ground Conditions:

: Soft ground, such as clay, silt, or loose sand, often lacks the strength to support excavations or structures without additional reinforcement. Rock bolting helps stabilize the ground, providing support to prevent collapses or failures.

load reaches the ultimate load of the bolt stem. The distribution of the axial load in a frictional bolt is similar as in a fully grouted bolt before slip occurs. The distribution of the axial load in a dynamic energy-absorbing frictional bolt is similar as in an end-anchored conventional static bolt, but its ultimate load and displacement capacity are significantly higher than the latter. Some issues related to rockbolting design are also outlined in the end of the presentation.

Preventing Ground Deformation: In soft ground, soil and rock layers can deform or shift when loads are applied, particularly during construction or excavation activities. Rock bolts help prevent unwanted movements, reducing the risk of subsidence, landslides, or cracking in structures.

• Cost-Effective Reinforcement: In some cases, rock bolting can be a more economical solution than complex mechanical stabilizing techniques, especially in projects requiring only moderate reinforcement.

• Increase Bearing Capacity: By anchoring the soil and weak rock layers to stable strata deeper underground, rock bolts improve the bearing capacity of the ground, allowing for the safe construction of buildings, roads, or tunnels.

Types of Rock Bolts Used in Soft Ground Conditions:

• Solid Rock Bolts: Steel bars with end plates or resin anchors, useful in semi-consolidated soft rock or fractured ground.

• Resin-anchored Bolts: Used in more fractured soft rock or when the ground conditions are not stable enough to anchor directly into the rock.

• Cable Bolts: Steel cables that provide greater flexibility and can be tensioned more easily, often used for larger-scale stabilization of soft ground or tunnel linings.

• Fiberglass or Composite Bolts: These are lighter and resistant to corrosion, used where durability and performance are key in wet or acidic ground conditions.

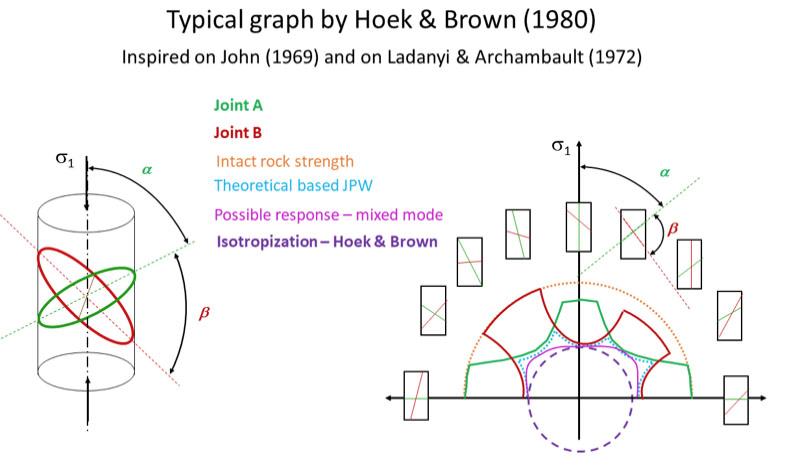

Failure criteria: Mohr-Coulomb vs Hoek&Brown

MOHR-COULOMB FAILURE/ YIELD CRITERION AND REMARKS ON A GENERALIZED LINEAR THEORY

Joseph F. Labuz | University of Minnesota, USA

The popular Mohr-Coulomb (MC) failure criterion is a reasonable approximation to strength data for isotropic rock, featuring a linear relation between major σI and minor σIII principal stresses with fitting parameters on a Mohr diagram known as friction angle and cohesion (σs intercept). Criticisms of MC are the absence of the intermediate principal stress and the inability to represent a curved failure surface. A general linear theory called Paul-Mohr-Coulomb (PMC) removes these limitations by (a) including all three principal stresses and (b) approximating a nonlinear failure surface with piecewise linear segments. The fitting parameters for PMC are the friction angle for axisymmetric compression φc, friction angle for axisymmetric extension φe, and isotropic tensile strength Vo (σn intercept). Note that PMC reduces to MC if φc = φe. Further, the nonlinear shape of the MC failure surface can be approximated in a piecewise linear manner with planes P1 and P2, each with friction angle φ (i) and strength Vo(i)

MC planes P1 and P2 fitted to approximate the nonlinear failure surface in the Mohr diagram; tension cutoff criterion −σIII = T = uniaxial tensile strength is included.

Ming Cai | Laurentian University, Canada

Rock and rock mass strengths are required in rock engineering design. The Hoek–Brown failure criterion, now integrated into most geotechnical modeling tools, is one of the most widely used criteria in rock mechanics and rock engineering. This presentation traces the development of the Hoek–Brown failure criterion from its initial formulation for intact rock to its later generalization for jointed rock masses. The criterion for intact rock is an empirical failure criterion based on data fitting of laboratory test data, and it describes rock strength better than the Mohr–Coulomb failure criteria over a wide range of confinement, including in the tension zone. The generalized Hoek–Brown criterion provides a practical tool for engineers to estimate rock mass strengths in engineering designs. The creation of the Geological Strength Index (GSI) addressed the challenge of linking geological conditions to rock mass strength. GSI is determined by rock mass structure and joint surface conditions, which can be assessed using field mapping data. A method for quantifying the GSI is presented, along with examples demonstrating the application of the Hoek–Brown failure criterion in rock engineering design analyses. The importance of implementing a field monitoring program to verify design analysis employing the Hoek–Brown failure criterion is emphasized. Finally, the assumptions and limitations of the Hoek–Brown failure criterion are discussed in comparison to the Mohr–Coulomb failure criterion.

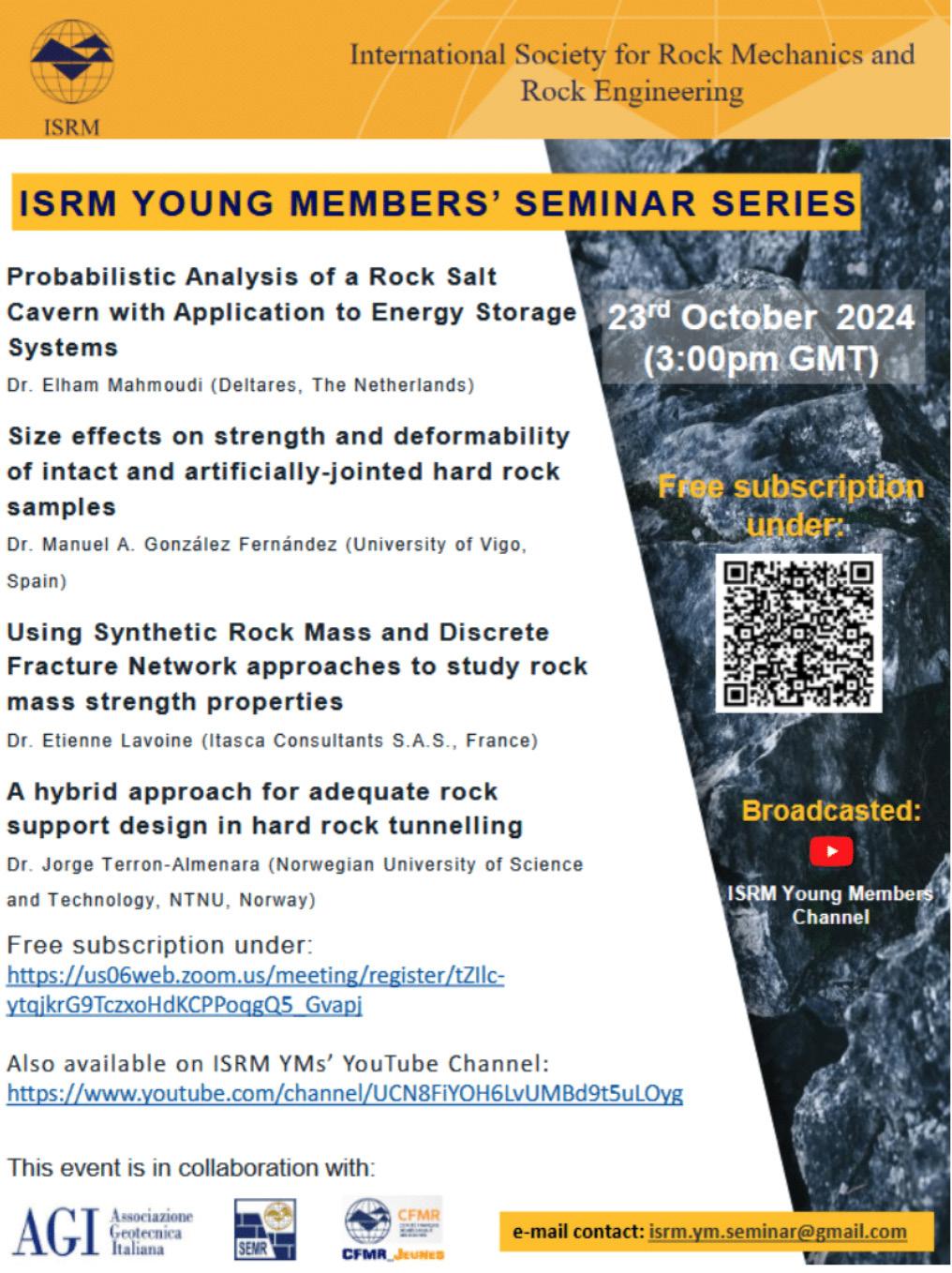

The ISRM Young Members’ Seminar (YMS) Series consists of virtual events aimed at providing a global platform for ISRM young members to share knowledge, experiences, and ideas. The events foster knowledge and friendship among young professionals and students of rock mechanics and rock engineering on an international scale. The ISRM Young Members Committee and the YMS organising committee invite young members with careers in research or industry, working in the public or private sectors, to participate and share their work with the broader rock mechanics and rock engineering community.

Since its establishment in November 2021, the ISRM Young Members’ Seminar Series provided a platform for young members to collaborate and showcase their achievements to their peers. In 2024, the organizing committee delivered three live seminars with 11 speakers from all over the world. The recordings of these presentations are available on ISRM Young Members YouTube channel https://bit.ly/ youtubeisrmymchannel.

13th seminar - 21st February 2024

Numerical modeling of rock fracture processes: Investigating mechanisms of rock fracture under dynamic loading in laboratory and small-scale tests. Gyeongjo Min, Jeonbuk National Univ., South Korea

Forecasting potential rock slope failure in open pit mines using the state of the art of technology. Rachmat Musa, Ground Probe, Indonesia

Numerical simulations of hydraulic fracturing using water or CO2 for volcanic rock under geothermal conditions. Yutaro Maeda, Osaka University, Japan

Laboratory earthquakes decipher control and stability of rupture speeds. Peng Dong, China University of Geoscience, China

14th seminar - 17th June 2024

Partially depleted oil and gas reservoir rock as a possible CO2 storage: experimental study. Cecília Belén Laskowski. Universidad Nacional de la Patagonia San Juan Bosco, Argentina, and Universidad Politécnica de Madrid, Spain

Characterization of the variability and uncertainty in in situ stress using Bayesian statistics. M. Amir Javaid, University of Toronto, Canada

Geomechanics of injection-induced seismicity in Illinois Basin. Nikita Bondarenko, University of Illinois, Urbana-Champaign, USA

15th seminar - 23rd October 2024

Probabilistic Analysis of a Rock Salt Cavern with Application to Energy Storage Systems. Elham Mahmoudi, Deltares, The Netherlands

Size effects on strength and deformability of intact and artificially-jointed hard rock samples. Manuel A. González Fernández, University of Vigo, Spain

Using Synthetic Rock Mass and Discrete Fracture Network approaches to study rock mass strength properties. Étienne Lavoine, Itasca Consultants S.A.S., France

A hybrid approach for adequate rock support design in hard rock tunnelling. Jorge Terron Almenara, Norwegian University of Science and Technology, NTNU, Norway

In March 2024, the Moroccan Committee for Soil Mechanics and Geotechnical Engineering (MCSMGE) was approved by the Board as the ISRM NG of Morocco.

MCSMGE is a non-profit professional society, whose members work in the construction sector for various organizations, as project owners, design offices engineers, university professors and researchers. The goal of the society is to promote studies directly or indirectly linked to soil and rock mechanics, for foundation and excavation practice, special construction techniques related to soils and rocks with the purpose of sharing up to date results and lessons learned from special projects with the scientific community.

President: Mustapha Fares

Based on the cooperation between several universities, rock mechanics laboratories and the ISRM Commissions on Testing Methods, video films depicting the execution of several ISRM Suggested Methods prepared mainly for educational purposes are embedded on the webpage of the Commission on Testing Methods.